Honeycomb seal and method and system for making the same

A honeycomb sealing and honeycomb technology, which is applied in the field of product manufacturing to reduce production costs, ensure molding quality, and simplify the processing process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the purpose, technical solution and advantages of the present invention clearer, the following examples are given to further describe the present invention in detail.

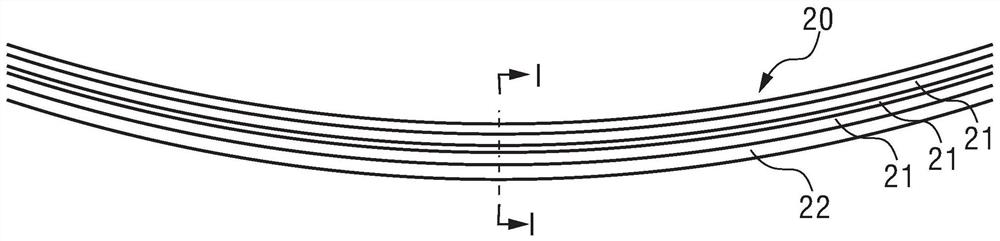

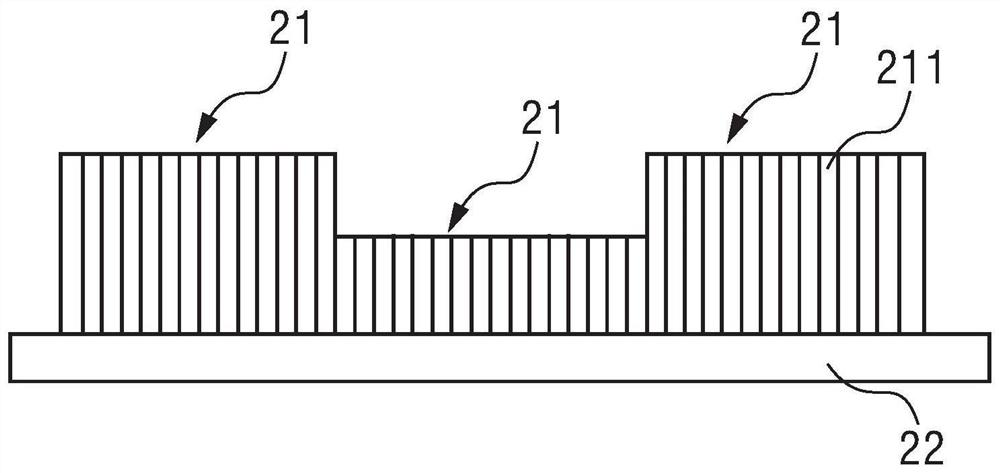

[0035] Figure 2A to Figure 2C It is a structural schematic diagram of the honeycomb seal in the embodiment of the present invention. in, Figure 2A main view, Figure 2B for Figure 2A The enlarged view of the cross-sectional view of I-I in the middle, Figure 2C It is a partial enlarged view of the honeycomb belt. Such as Figure 2A to Figure 2C As shown, the honeycomb seal 20 includes: at least one honeycomb belt portion 21 ( Figure 2A and Figure 2B Take the case of three honeycomb belt parts 21 as an example) and a base part 22.

[0036] Wherein, each honeycomb belt portion 21 has a plurality of integrally formed small honeycomb holes 211 . Integral molding in this embodiment means that the small honeycomb holes 211 are no longer welded by two parts, but formed at one time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com