Calculation method for performance interval of production device

A technology of production equipment and calculation methods, applied in the direction of calculation, manufacturing computing systems, computer parts, etc., can solve the problems of low accuracy of interval clustering and ignore the correlation between indicators, so as to achieve clear accuracy, avoid influence, The effect of accurate clustering results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

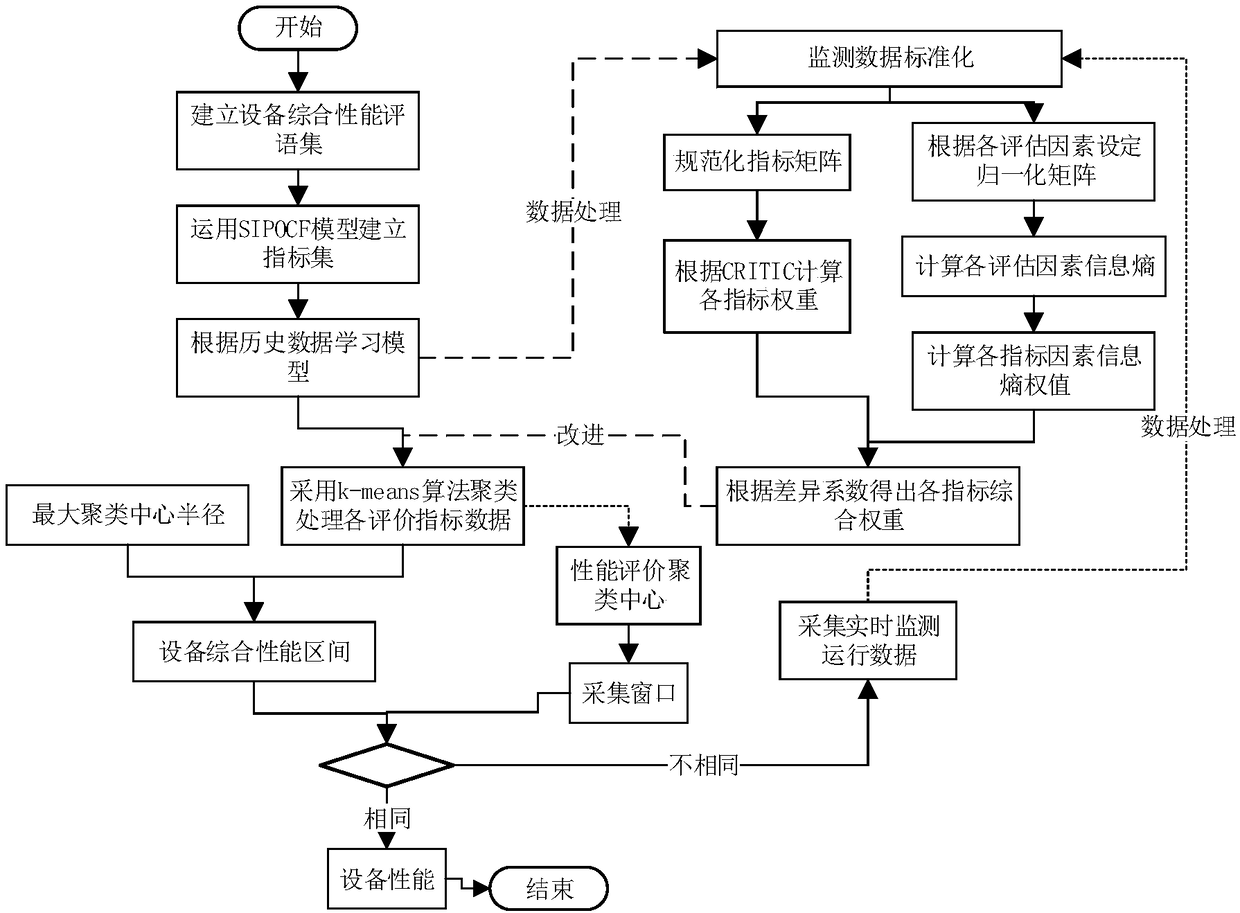

[0048] The following describes in detail the routines of the embodiments of the present invention (such as figure 1), this example routine is implemented on the premise of the technical solution of the present invention, and provides a detailed implementation manner and a specific operation process, but the protection scope of the present invention is not limited to the following example routines.

[0049] The implementation routine can be mainly divided into the following steps:

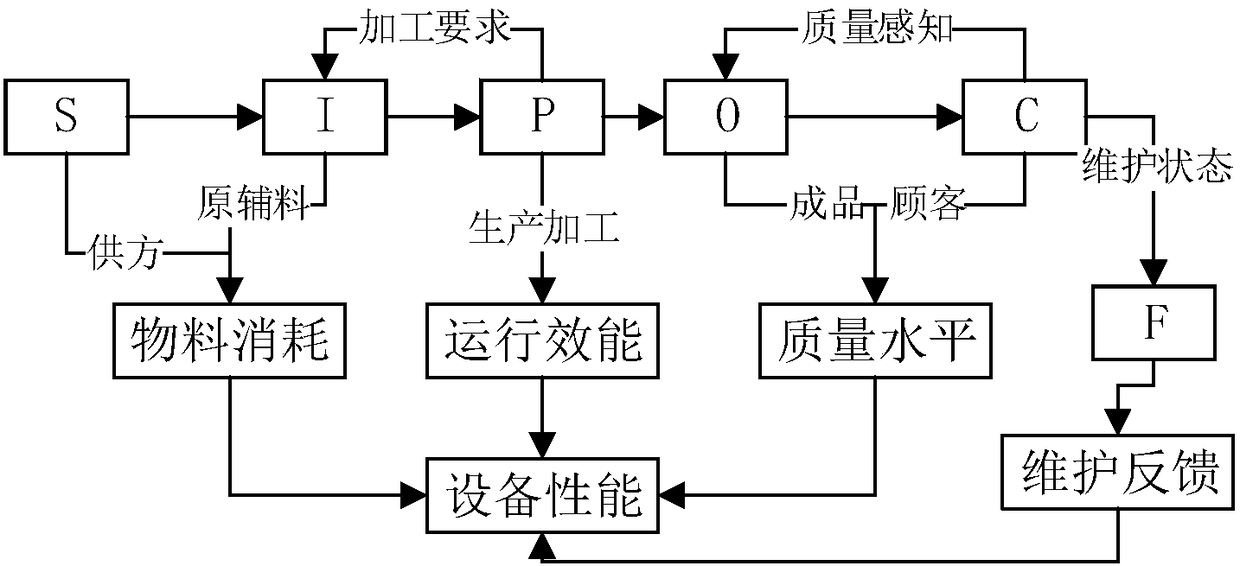

[0050] Step 1: Apply the S-I-P-O-C-F model (eg figure 2 ) to formulate key performance indicators of equipment production activities and build an analysis model for key indicators of performance evaluation.

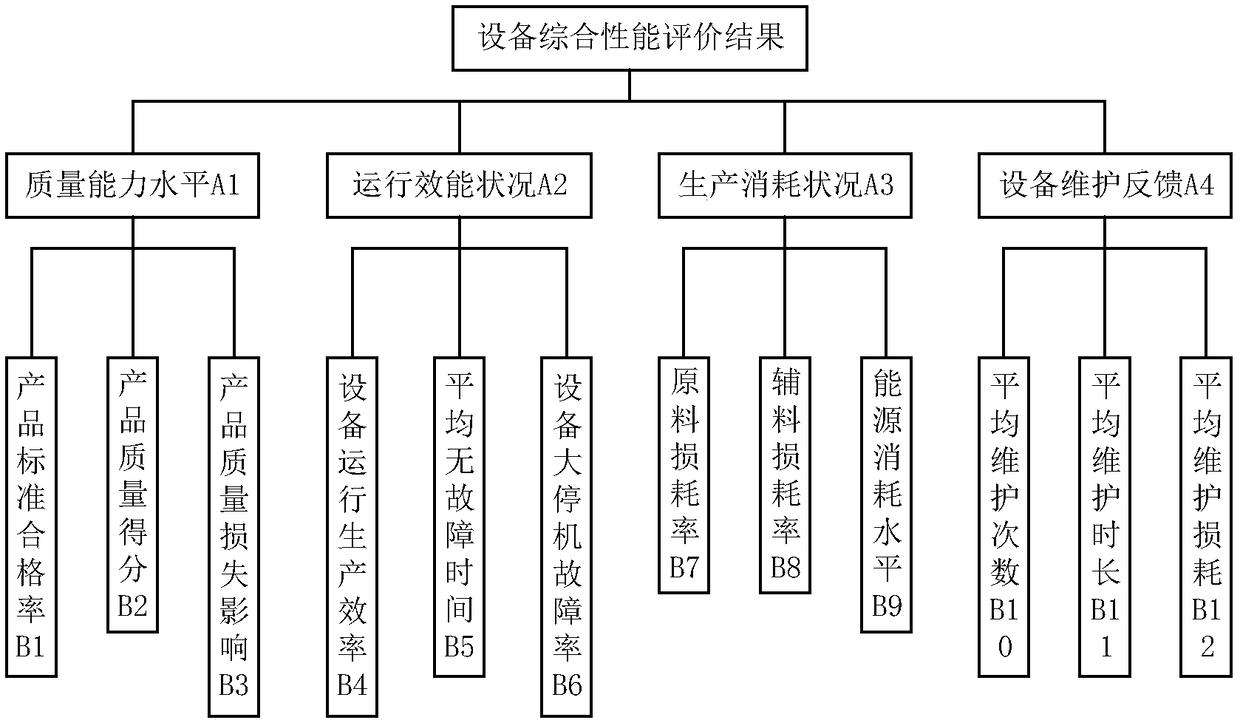

[0051] There are four key dimensions of equipment comprehensive performance:

[0052] 1. Quality level. The core of equipment performance evaluation is the product quality produced by the equipment. For key quality parameters, quantitatively evaluate the internal and external quality of pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com