Battery pack structure

A technology of battery packs and battery modules, applied in secondary batteries, circuits, electrical components, etc., can solve the problems of high cost, poor heat dissipation effect, heavy weight, etc., and achieve less space occupation, good heat dissipation effect, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the object, technical solution and beneficial technical effects of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific implementations described in this specification are only for explaining the present invention, not for limiting the present invention.

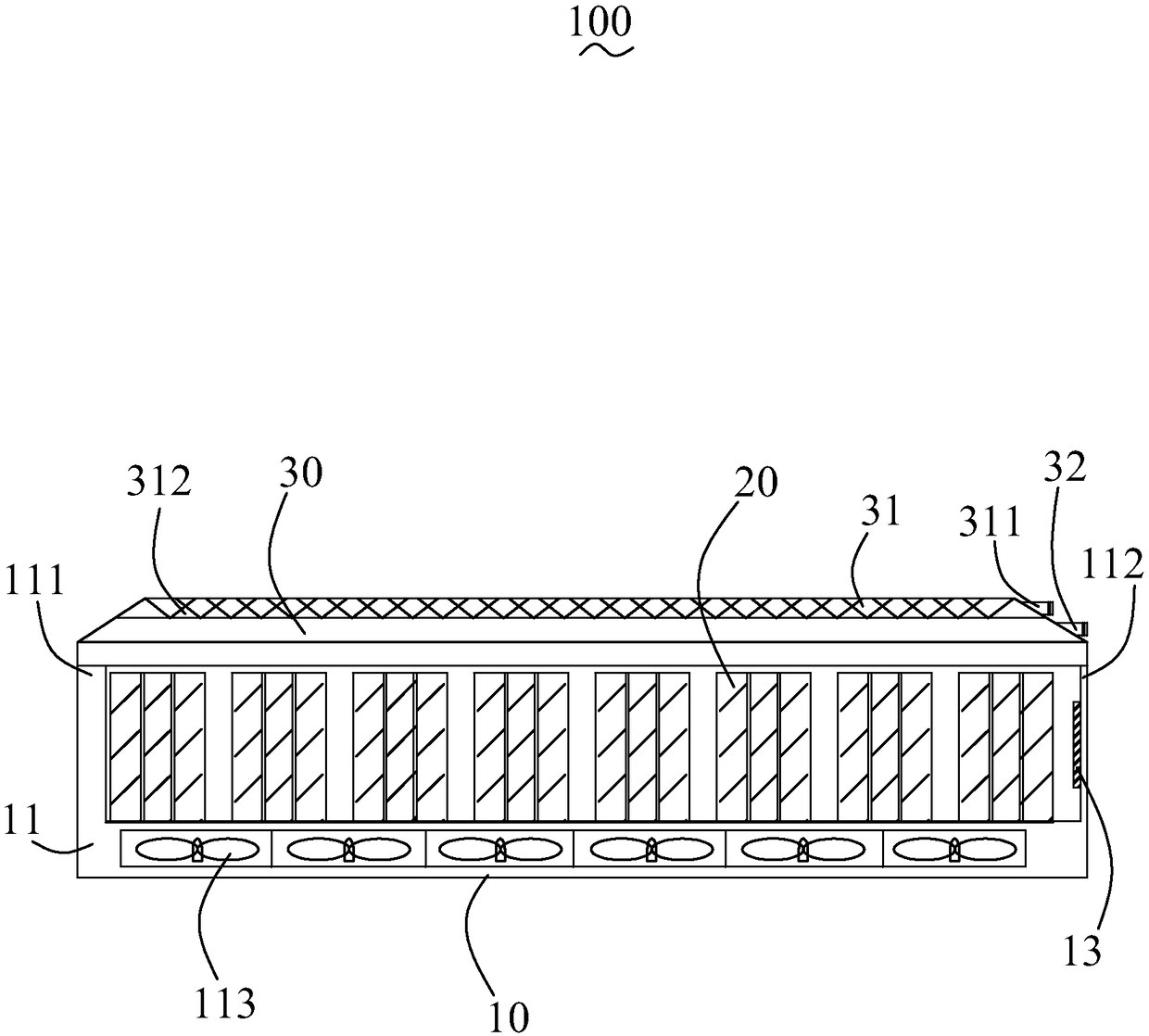

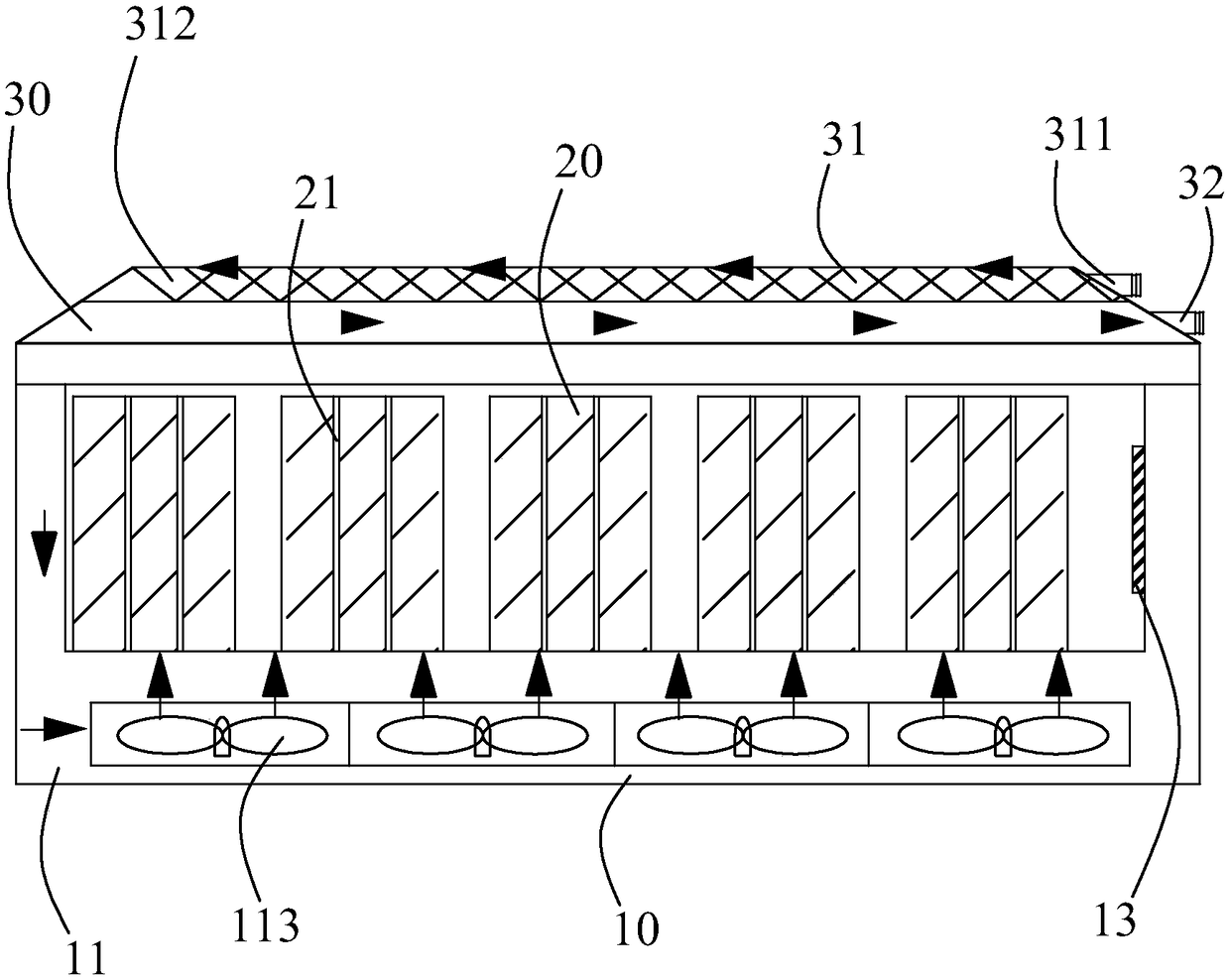

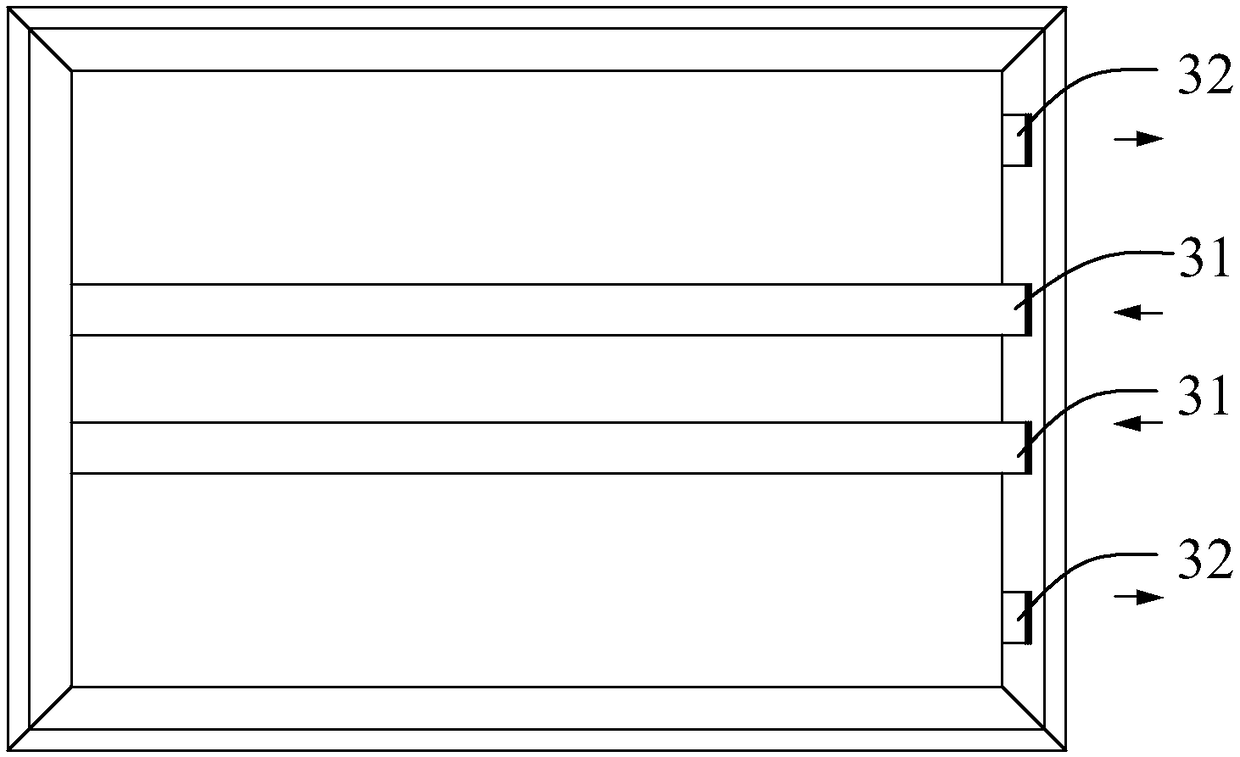

[0015] see Figure 1 to Figure 4 , the present invention provides a battery pack structure 100 , comprising a box body 10 having an open end and a hollow cuboid shape, a plurality of battery modules 20 and a box cover 30 corresponding to the box body 10 . The box body 10 is integrally formed and has a flow channel 11 on its inner wall. The flow channel 11 includes an open end 111 and a closed end 112 away from the open end 111 . Each battery module 20 is provided with a plurality of cooling passages 21 that run through both ends of the battery mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com