Adjustable scrubbing device

An adjustable, mounting plate technology, applied in the direction of cleaning methods and utensils, cleaning hollow objects, chemical instruments and methods, etc., can solve the problems of cleaning chemical paint buckets with different specifications, and achieve simple structure, wide application range, and ensure The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

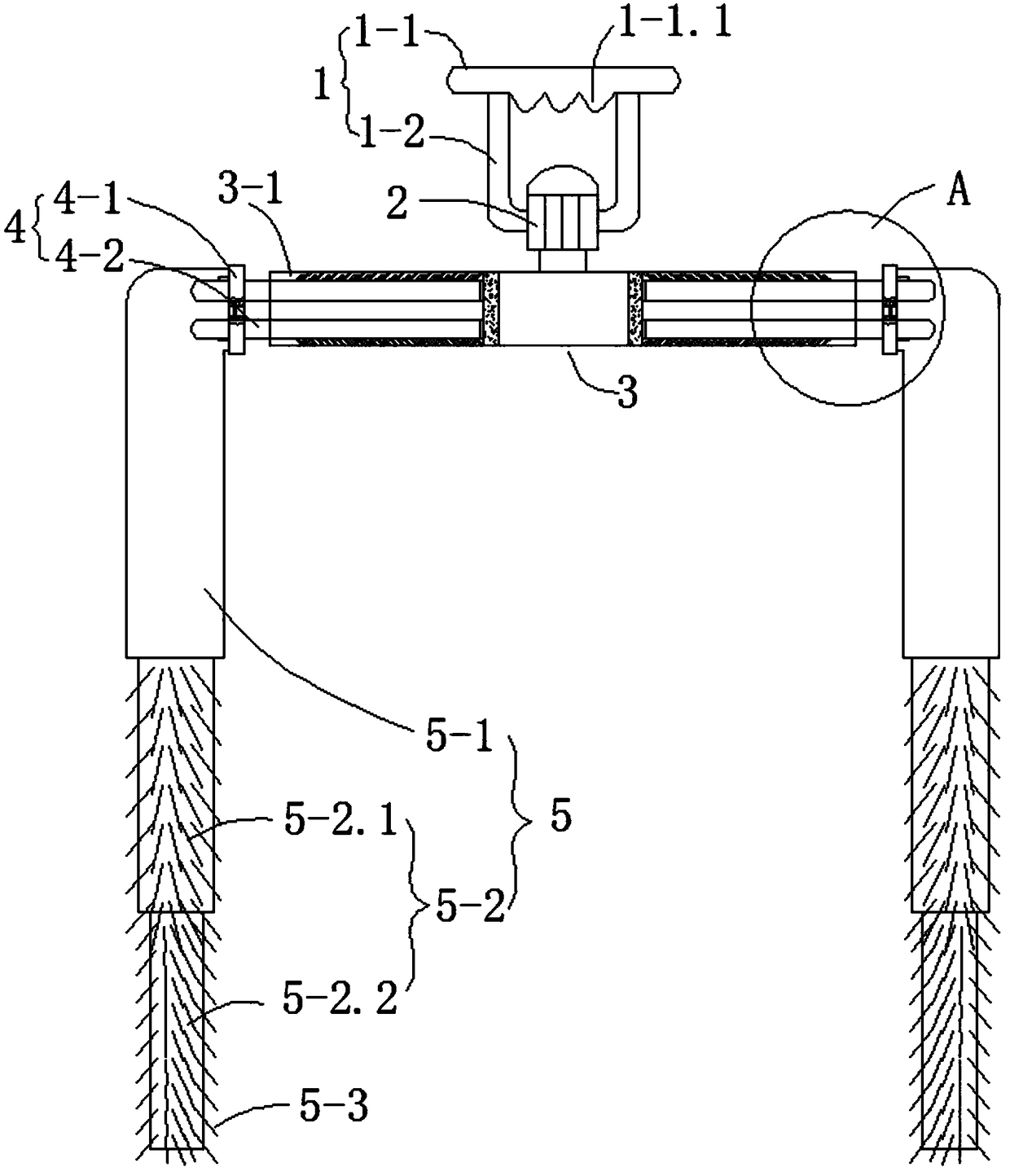

[0022] like figure 1 As shown, the present embodiment provides an adjustable scrubbing device, including a horizontal mounting plate 3 and two telescopic scrubbing assemblies 5 vertically arranged on both sides of the horizontal mounting plate 3, the two telescopic scrubbing assemblies 5 are symmetrical about the horizontal mounting plate 3, The middle part of the horizontal mounting plate 3 is fixedly connected with a driving mechanism 2 that drives the horizontal mounting plate 3 to rotate, the driving mechanism 2 is provided with a handheld assembly 1, and horizontal mounting grooves 3-1 are respectively dug inside the two ends of the horizontal mounting plate 3. , the two horizontal installation grooves 3-1 are respectively provided with adjustment assemblies 4 that can reciprocate along the horizontal installation grooves 3-1, and the two telescopic scrubbing assemblies 5 are respectively arranged on both sides of the horizontal installation plate 3 through the adjustment ...

Embodiment 2

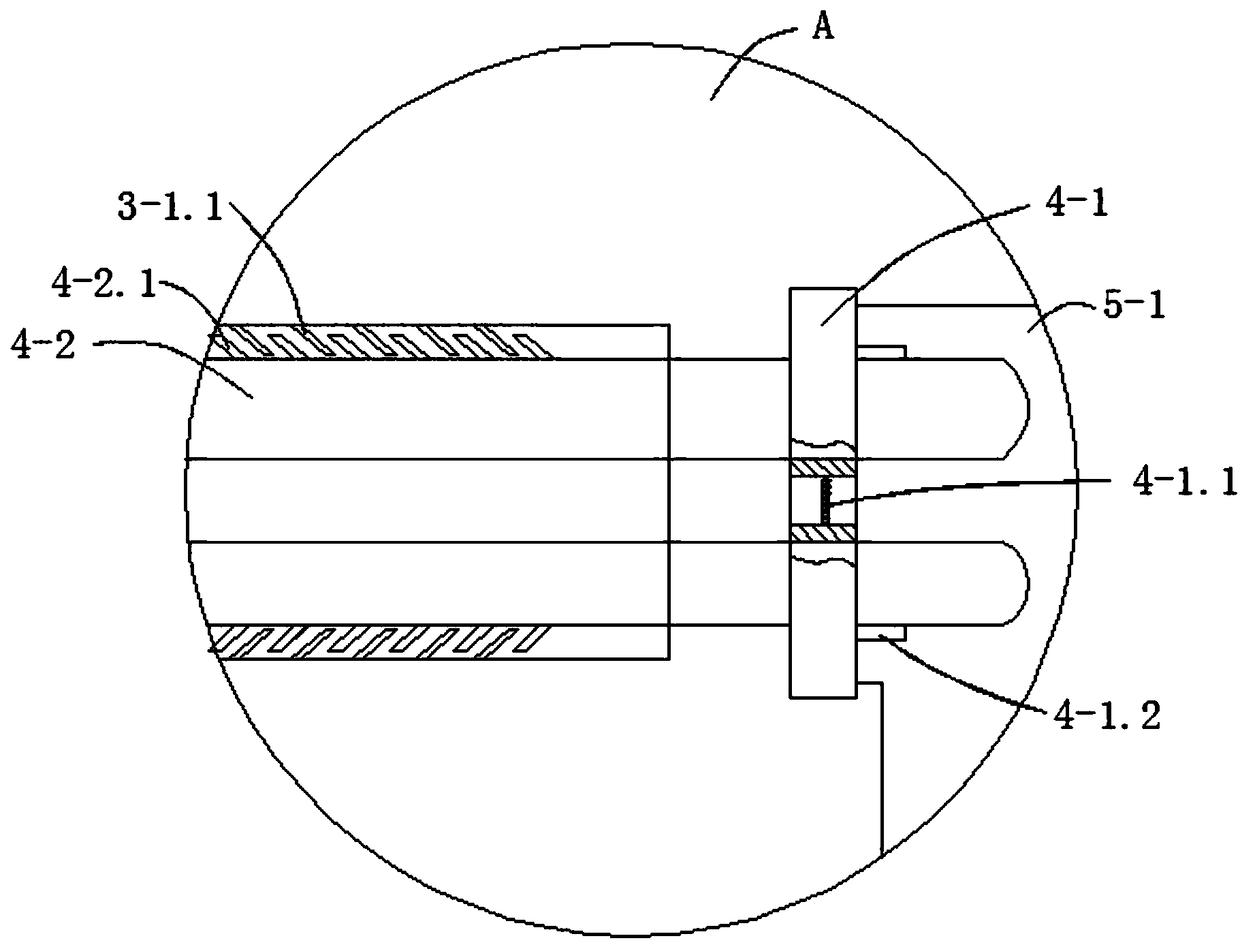

[0024] like figure 2 As shown, the present embodiment is further optimized on the basis of embodiment 1, specifically:

[0025] The adjustment assembly 4 includes two adjustment rods 4-2 and a connecting sleeve 4-1 sleeved on the two adjustment rods 4-2. One end of the two adjustment rods 4-2 is arranged in the horizontal installation groove 3-1, and the other end extends To the outside of the horizontal installation groove 3-1, it is fixedly connected with the telescopic scrubbing assembly 5 through the connecting sleeve 4-1. There are a number of inclined teeth 4-2.1 evenly distributed on the outer side walls of the two adjustment rods 4-2, and the groove wall of the horizontal installation groove 3-1 There are a number of anti-backward inclined teeth 3-1.1 adapted to the inclined teeth 4-2.1 to prevent the adjustment rod 4-2 from retreating. The connecting sleeve 4-1 is provided with elastic parts 4-1.1, elastic parts 4- The two ends of 1.1 are respectively fixedly connec...

Embodiment 3

[0028] This embodiment is further optimized on the basis of Embodiment 2, specifically:

[0029] The telescopic scrubbing assembly 5 includes a multi-section telescopic cylinder 5-2 and a housing 5-1 for accommodating the multi-section telescopic cylinder 5-2, the housing 5-1 is fixedly connected to the connecting sleeve 4-1, and the A plurality of bristles 5-3 are evenly distributed on the circumferential outer wall of the multi-section telescopic cylinder 5-2;

[0030] The multi-section telescopic tube 5-2 is a two-section telescopic tube, and the two-section telescopic tube includes a large-diameter tube 5-2.1 and a small-diameter tube 5-2.2, and the diameter of the large-diameter tube 5-2.1 is the same as that of the shell The ratio of the diameter of the 5-1 is 1:1.2, and the ratio of the diameter of the large-diameter tube 5-2.1 to the diameter of the small-diameter tube 5-2.2 is 1:0.8; The tube 5-2 is accommodated therein, which reduces the storage space of the device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com