Car Flanging Plastic Mold

A technology of flanging shaping and automobiles, which is applied in the direction of forming tools, manufacturing tools, vehicle parts, etc., and can solve the problem that the two sides of the die cannot be exactly guaranteed to be symmetrical

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below by means of specific embodiments:

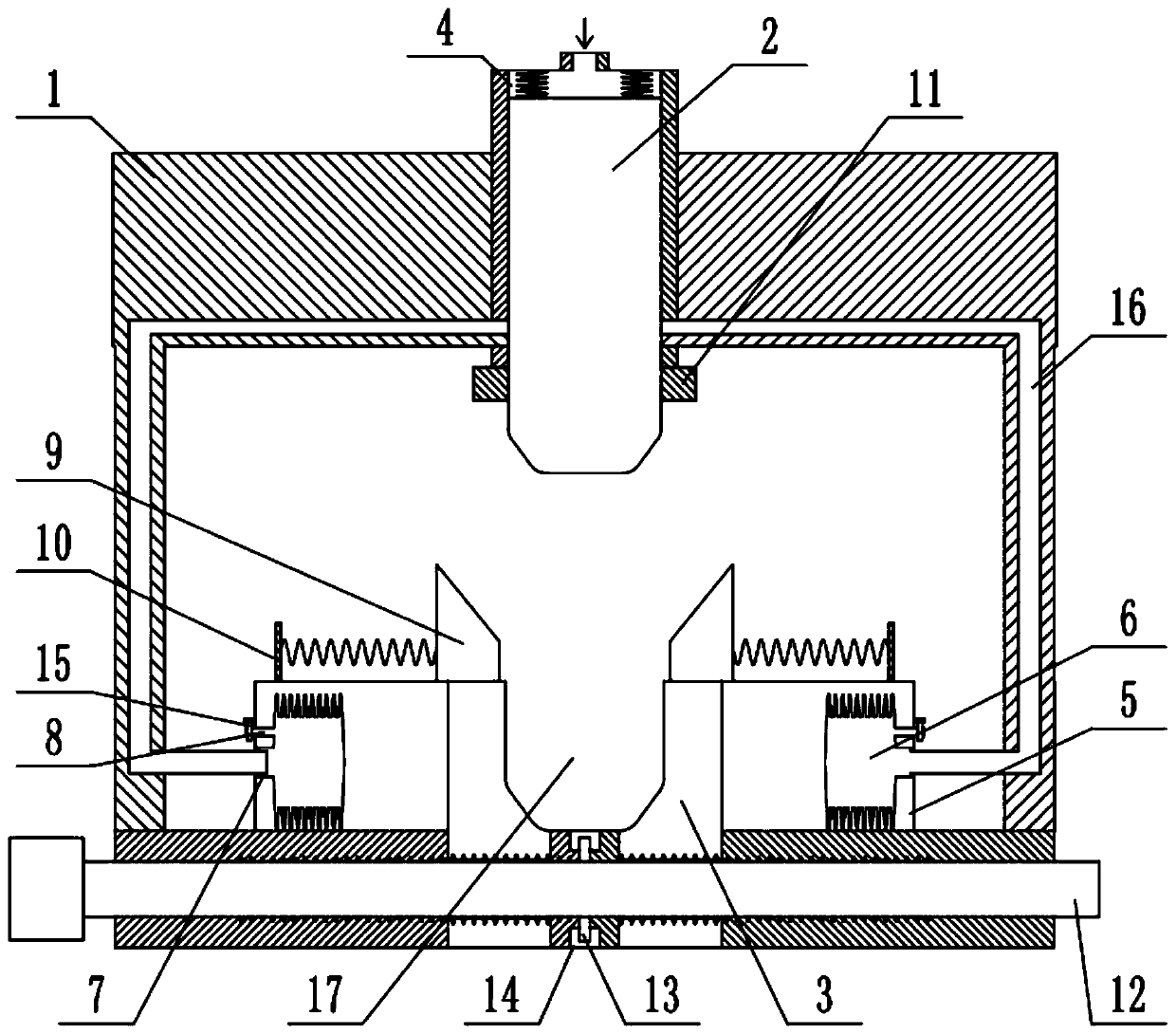

[0021] The reference signs in the drawings of the description include: support seat 1, punch 2, recess seat 3, chute 4, limit seat 5, compressed air bag 6, air inlet 7, air outlet 8, positioning block 9, support plate 10. Rubber ferrule 11, adjusting screw rod 12, clamping block 13, clamping groove 14, valve 15, air pipe 16, die 17.

[0022] Such as figure 1 As shown, the car flanging plastic mold includes a support seat 1 and an adjustment mechanism. The top of the support seat 1 is provided with a punch 2, and the bottom of the support seat 1 is slidably connected with two symmetrical recesses along the center line of the support seat 1. 3. The adjustment mechanism can control the moving distances of the two recesses 3 to the center line of the support seat 1 to be equal, that is, the distance from the center line of the left recess 3 to the support seat 1 is the same ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com