Chain joint dismounting machine

A technology of chain and joint dismantling, which is applied in the direction of belts/chains/gears, chain elements, mechanical equipment, etc. It can solve the problems of manual sorting, time-consuming and laborious, etc., and achieve the goal of avoiding sorting, improving production efficiency, and high degree of automation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

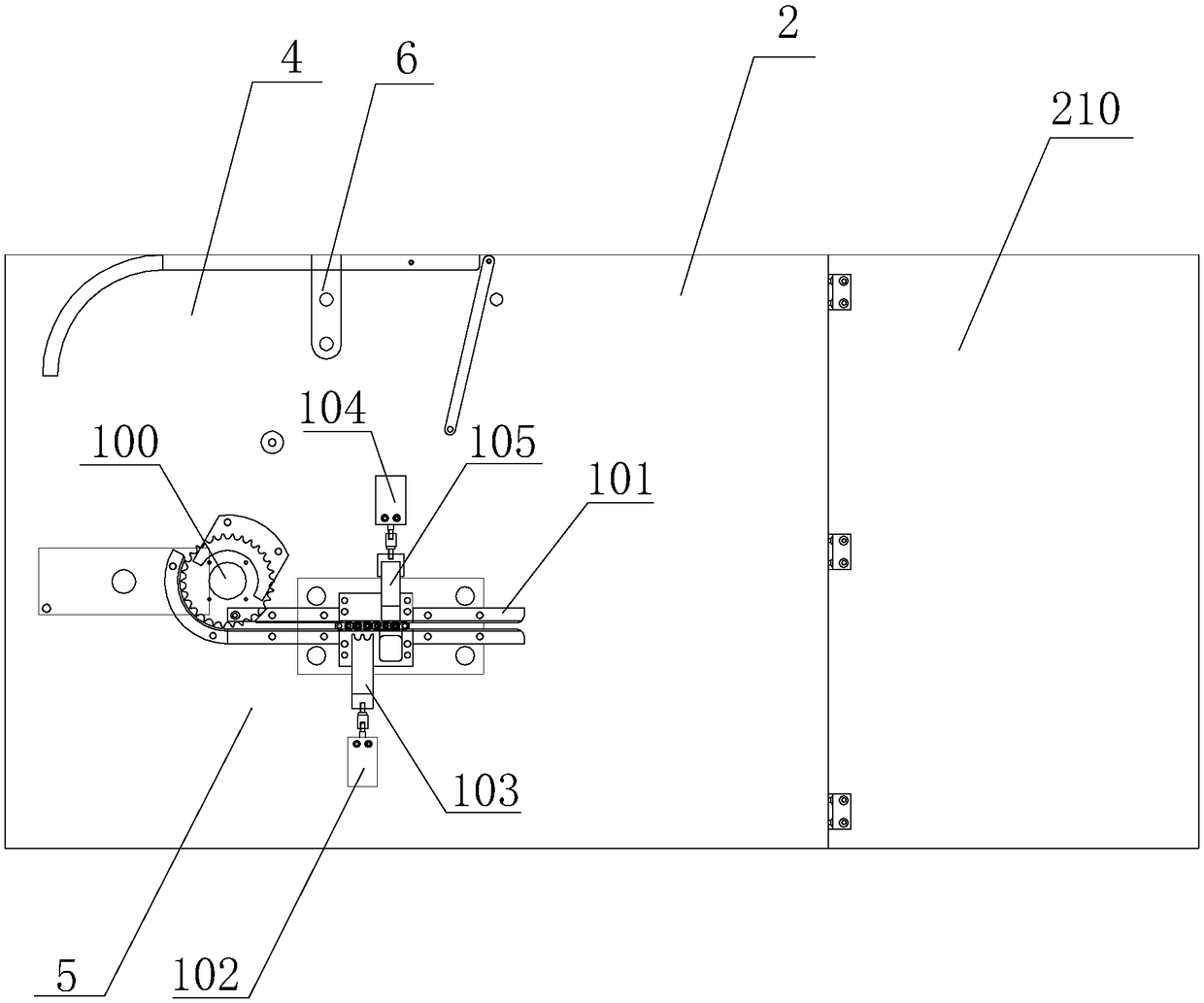

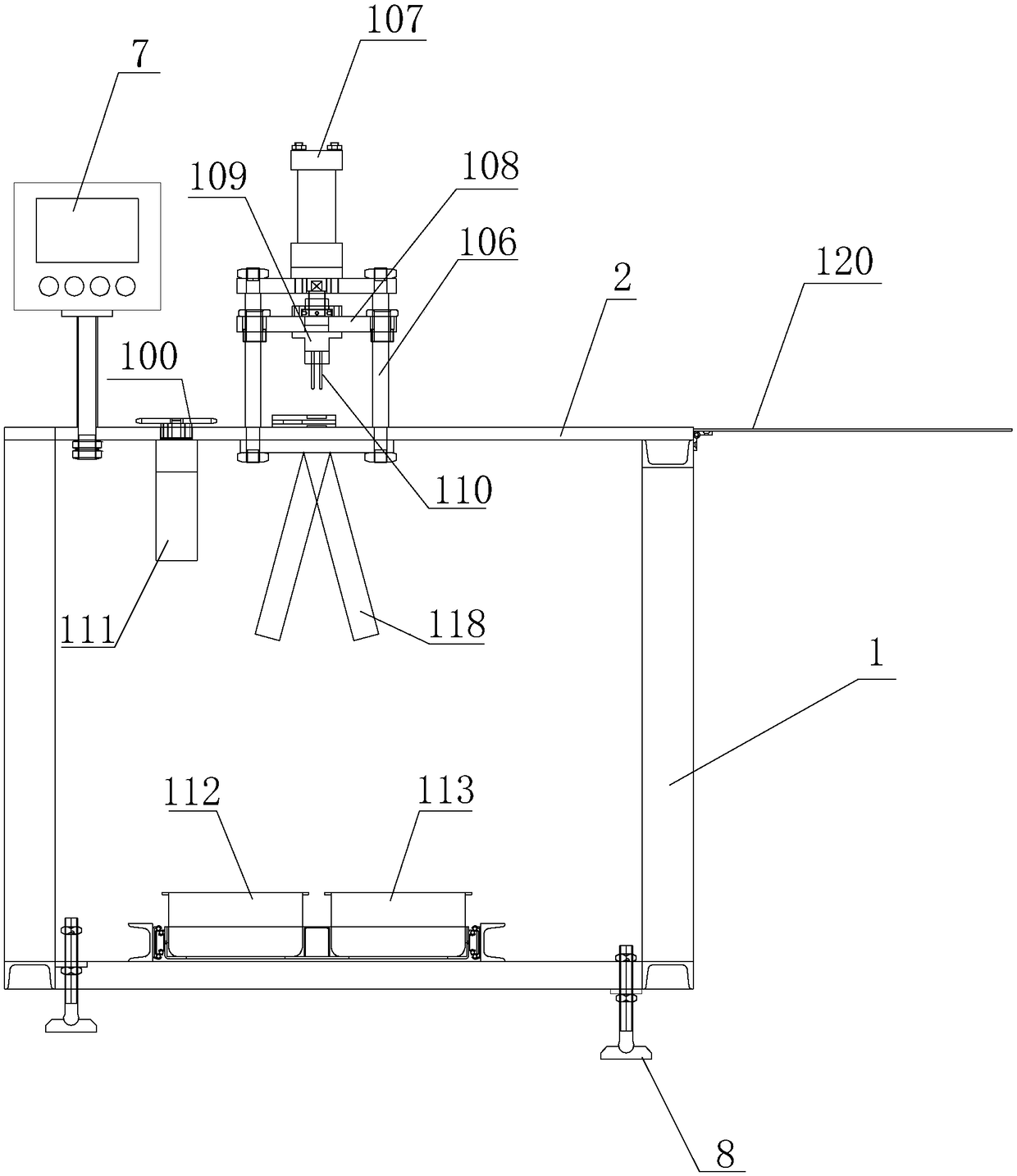

[0029] Such as figure 1 , figure 2 As shown, a chain splitting machine includes a frame 1, a table 2 and a splitting mechanism. The bottom of the frame is provided with a height-adjustable machine foot 8, and the table top is arranged on the frame; the table top is divided into a stacking chain area 4 and a disassembly area 5 according to the process steps; the table top is located after the chain is dismantled. One side of the output is a foldable discharge flap 120 . The PLC controller 7 that controls the circuit of the whole device is provided on the table.

[0030] Such as figure 1 As shown, the chain stacking area is provided with a position sensor 6 and a rotatable chain retaining plate 116, and a detachable positioning post 117 is provided on the outside of the chain retaining plate on the table.

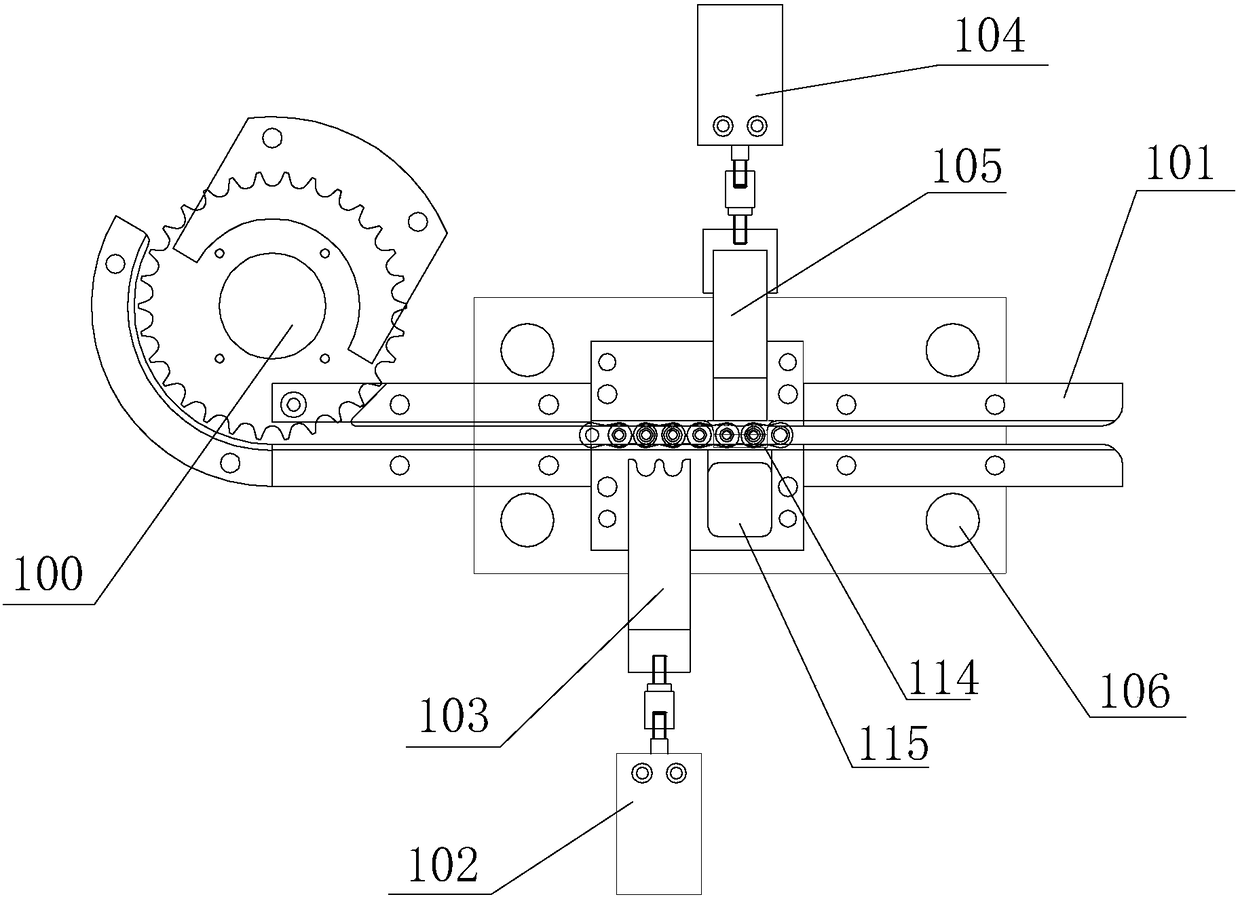

[0031] Such as image 3 , Figure 4 As shown, the joint removal mechanism includes several sprockets 100 located in the joint removal area, a chain guide channel 101, ...

Embodiment 2

[0034] The difference between this embodiment and embodiment 1 is that Figure 5 As shown, in this embodiment, the steel needle is provided with a vertical buffer spring 119 in the slot on the joint seat.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com