Push-type plastic accessory delivery mechanism used for car

A conveying mechanism, push-type technology, applied in the direction of conveyor, conveyor objects, transportation and packaging, etc., can solve the problems of easy bumping, low efficiency, trouble, etc., to improve installation efficiency and effect, reduce installation requirements, and flexibly move Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

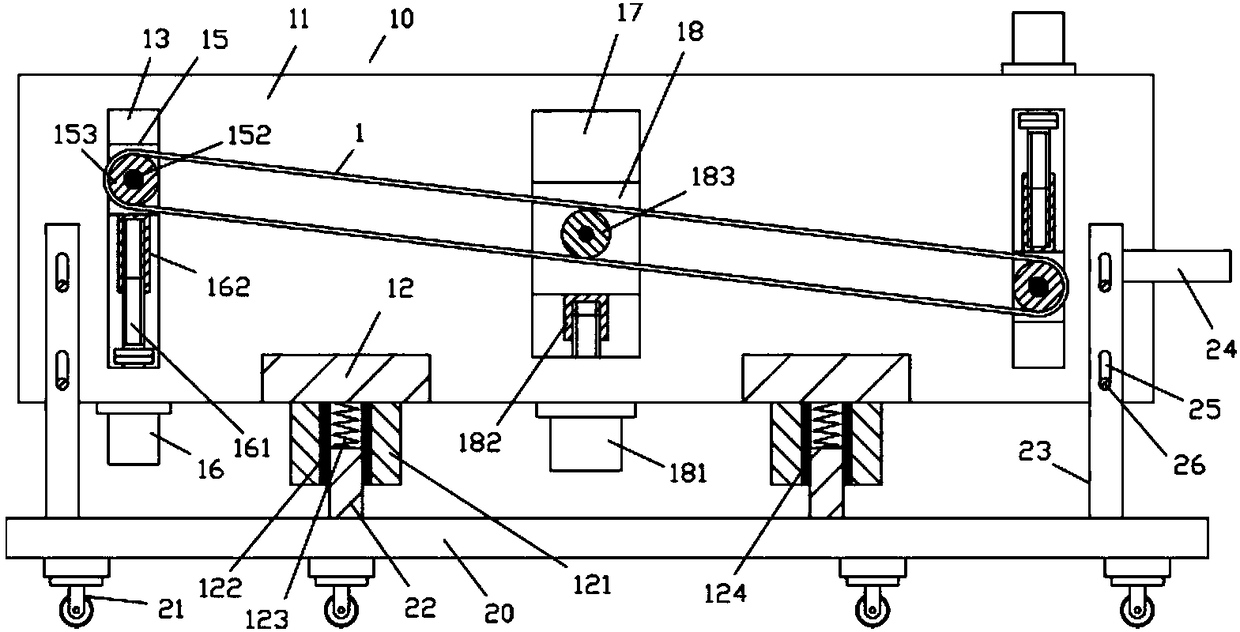

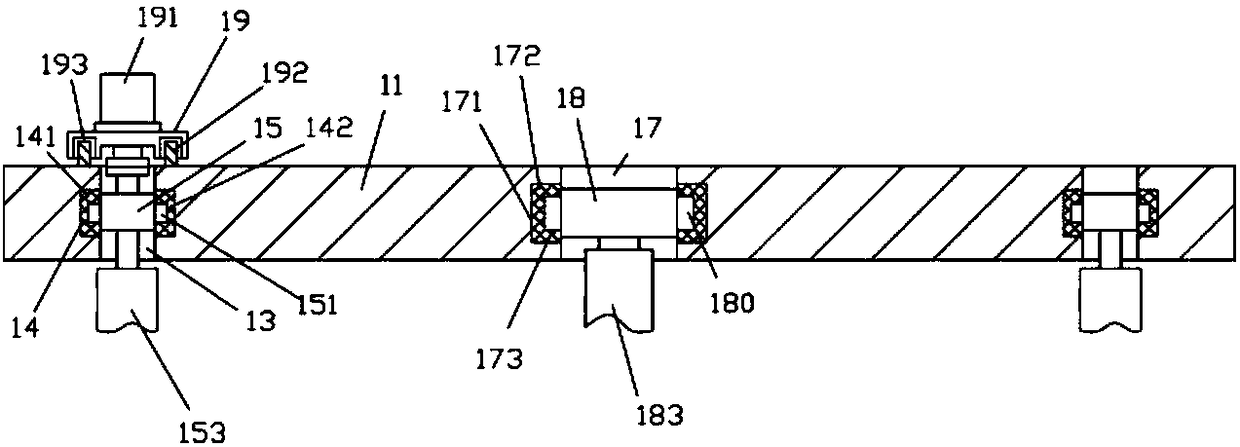

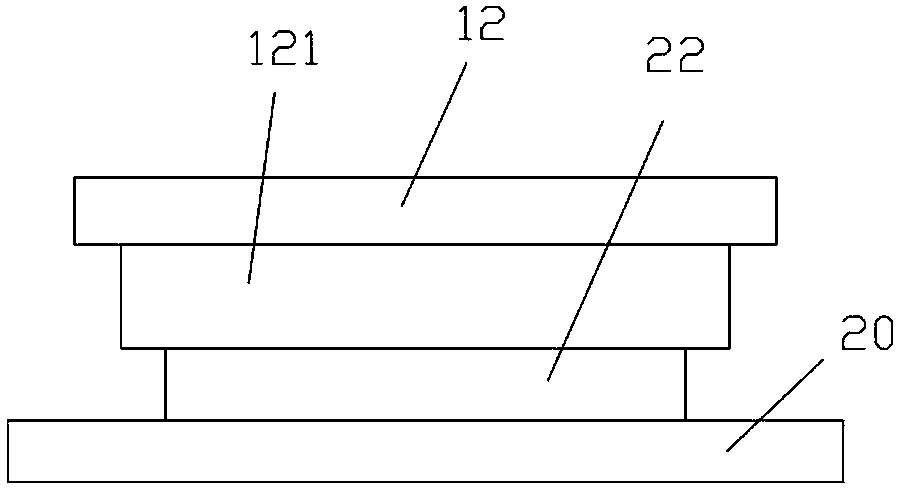

[0019] Examples, see e.g. Figure 1 to Figure 3 As shown, a push-type automotive plastic parts delivery mechanism includes a frame 10, the frame 10 includes two side support plates 11, the bottom surface between the two side support plates 11 is fixed with a lower connecting plate 12, the main The base plate 20 is located directly below the frame 10, the bottom surface of the main base plate 20 is fixed with a plurality of push casters 21, the top surface of the main base plate 20 is fixed with two insertion buffer blocks 22, and the bottom surface of the lower connecting plate 12 is fixed with elongated blocks. 121, the middle part of the bottom surface of the elongated block 121 has an elongated groove 122, and the plug buffer block 22 is inserted in the elongated groove 122, and the top surface of the elongated groove 122 is fixed with a plurality of buffer springs 123, and the buffer springs 123 The bottom end of the main base plate 20 focuses on the top surface of the plu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com