Release paper suction feeding and cutting applying device

A technology of applying device and release paper, which is applied in the direction of pile separation, sending objects, thin material processing, etc., can solve the problems of cutting width adjustment, inability to adjust the position of release paper, and cutter width, etc., and achieves stable and reliable cutting effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings, but it is not intended to limit the protection scope of the present invention.

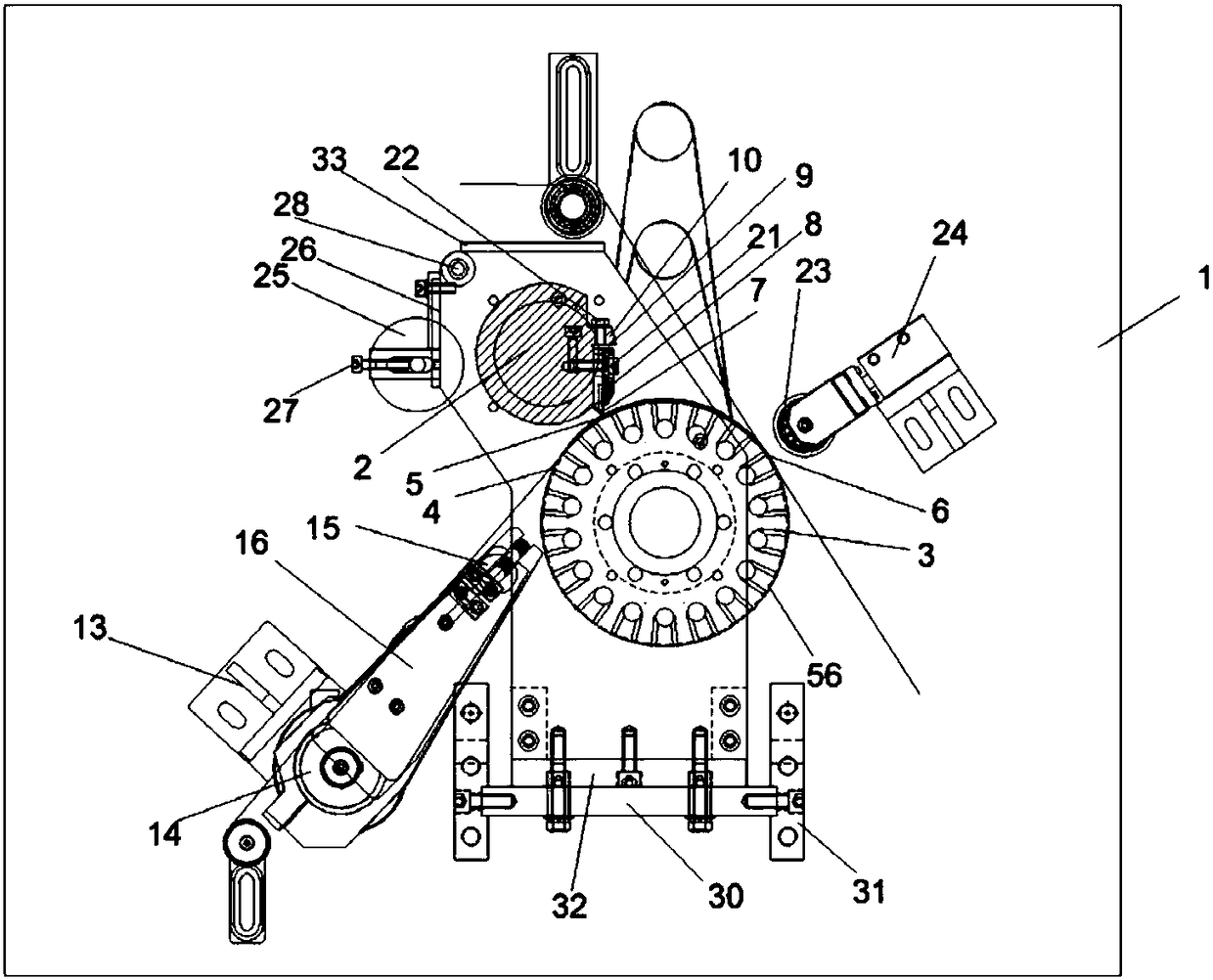

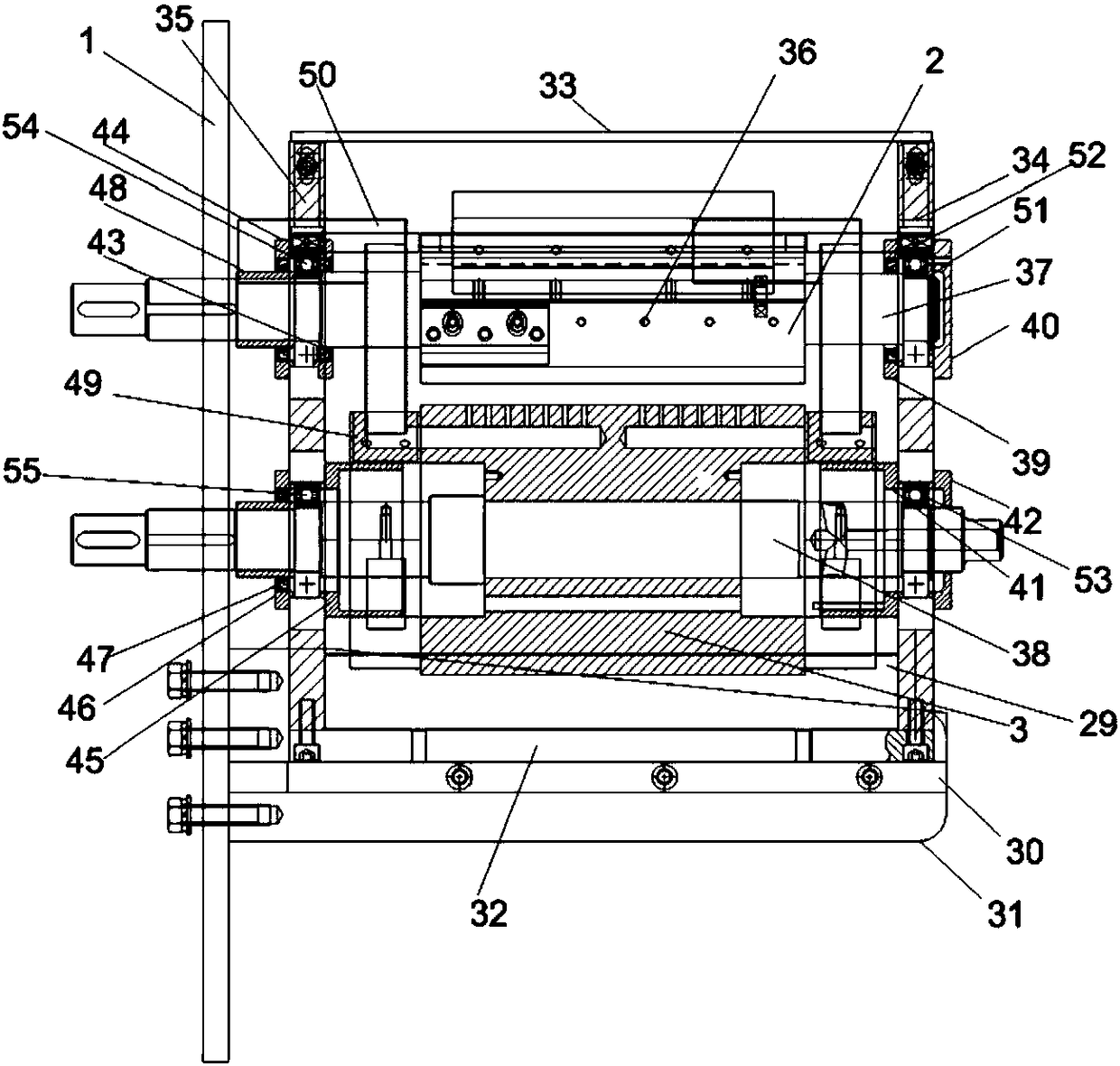

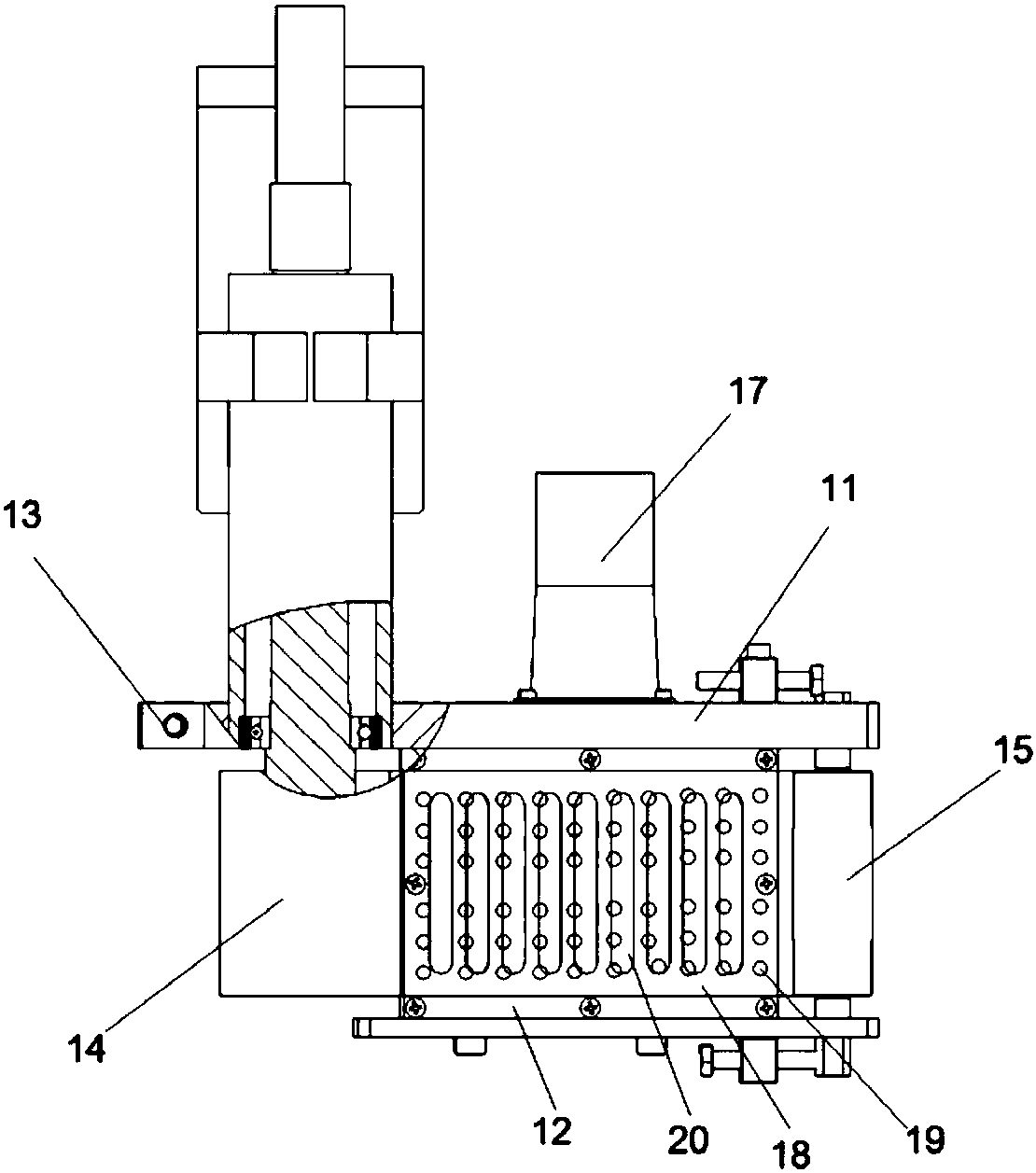

[0030] like Figure 1-3As shown, a release paper suction feeding and slitting application device includes a support backboard 1, a suction feeding mechanism and a slitting application mechanism installed on the support backboard 1 and matched with each other. Suction feeding mechanism comprises base 13, driving roller 14 installed on the base 13, tension roller 15, anti-adhesive conveying belt 18 tensioned on driving roller 14 and tension roller 15, anti-adhesive conveying belt 18 below. Suction box 16, anti-stick conveying belt 18 is provided with some first air suction holes 19, and slitting application mechanism comprises support, bottom roller 3 and cutter roller 2 installed on the support and the cutter roller 2 installed on the cutter roller. Knife 7 and the pressure roller ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com