Method for producing patterned flexible conductive graphene cloth

A flexible conductive and graphene technology, which is applied in the direction of improved hand-feeling fibers, textiles and papermaking, fiber processing, etc., can solve the problems of high cost and long time consumption, and achieve the effect of low cost, high conductivity and low process requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The preparation of the flexible conductive graphene cloth of embodiment 1 stripe pattern

[0022] (1) Soak the commercialized gauze fabric in the trichlorovinylsilane compound solution for 1h, and the contact angle of the treated cloth fabric is 153°;

[0023] (2) Fix the stripe pattern template on the surface of the cloth fabric and perform plasma treatment for 1s, remove the template, soak the cloth fabric in graphene oxide aqueous solution for 5s, take it out and dry it in vacuum at 50°C for 5h to obtain patterned graphite vinyl cloth;

[0024] (3) Put the prepared cloth fabric containing the graphene oxide pattern into a hydrazine hydrate solution, and heat it in an oil bath at 90° C. for 3 hours to obtain a patterned flexible conductive graphene cloth;

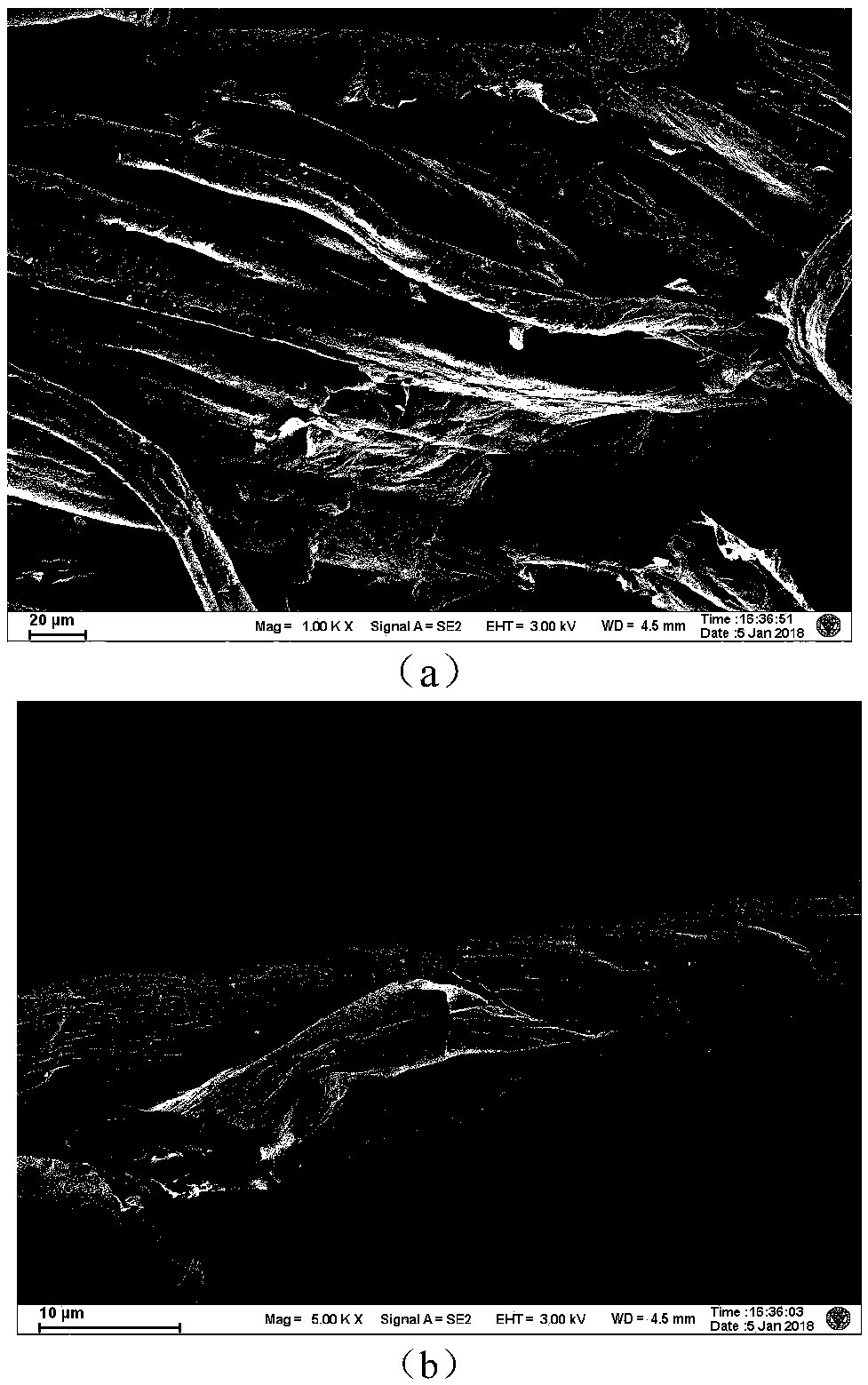

[0025] (4) Transfer the prepared flexible conductive graphene cloth to pure water for soaking, rinse, and dry at room temperature to obtain the striped patterned flexible conductive graphene cloth, such as figure...

Embodiment 2

[0026] The preparation of the flexible conductive graphene cloth of embodiment 2 flower patterns

[0027] (1) Soak the commercialized cotton fabric in the trichlorovinylsilane compound solution for 2.5h, and the contact angle of the treated fabric is 156°;

[0028] (2) Fix the pattern template on the surface of the cloth fabric and perform plasma treatment for 3 seconds, remove the template, soak the cloth fabric in graphene oxide aqueous solution for 50 seconds, take it out and dry it in vacuum at 65 °C for 3 hours to obtain a patterned pattern graphene cloth;

[0029] (3) Put the prepared cloth fabric containing the graphene oxide pattern into a hydrazine hydrate solution, and heat it in an oil bath at 50° C. for 5 hours to obtain a patterned flexible conductive graphene cloth;

[0030] (4) Transfer the prepared flexible conductive graphene cloth to pure water for soaking, rinse, and dry at room temperature to obtain the patterned flexible conductive graphene cloth, such as...

Embodiment 3

[0031] The preparation of the flexible conductive graphene cloth of embodiment 3 circuit patterns

[0032] (1) soak the commercialized silk cloth fabric in the trichlorovinylsilane compound solution for 5h, and the contact angle of the treated cloth fabric is 159°;

[0033] (2) After fixing the circuit pattern template on the surface of the cloth fabric, perform plasma treatment for 5s, remove the template, soak the cloth fabric in graphene oxide aqueous solution for 100s, take it out and vacuum dry it at 100°C for 1h to obtain patterned graphite vinyl cloth;

[0034] (3) Put the prepared cloth fabric containing the graphene oxide pattern into an ascorbic acid solution, and heat it in an oil bath at 150° C. for 1 hour to obtain a circuit-patterned flexible conductive graphene cloth;

[0035] (4) The prepared flexible conductive graphene cloth is transferred to pure water for soaking, rinsed, and dried at room temperature to obtain the flexible conductive graphene cloth of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com