A color steel tile laying device

A color steel tile, tile shop technology, applied in the direction of roofing, construction, building structure, etc., can solve the problems of workers' hand cuts, falling accidents, etc., to reduce potential safety hazards, improve construction safety, reduce falls and injuries. Effects of electric shock risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

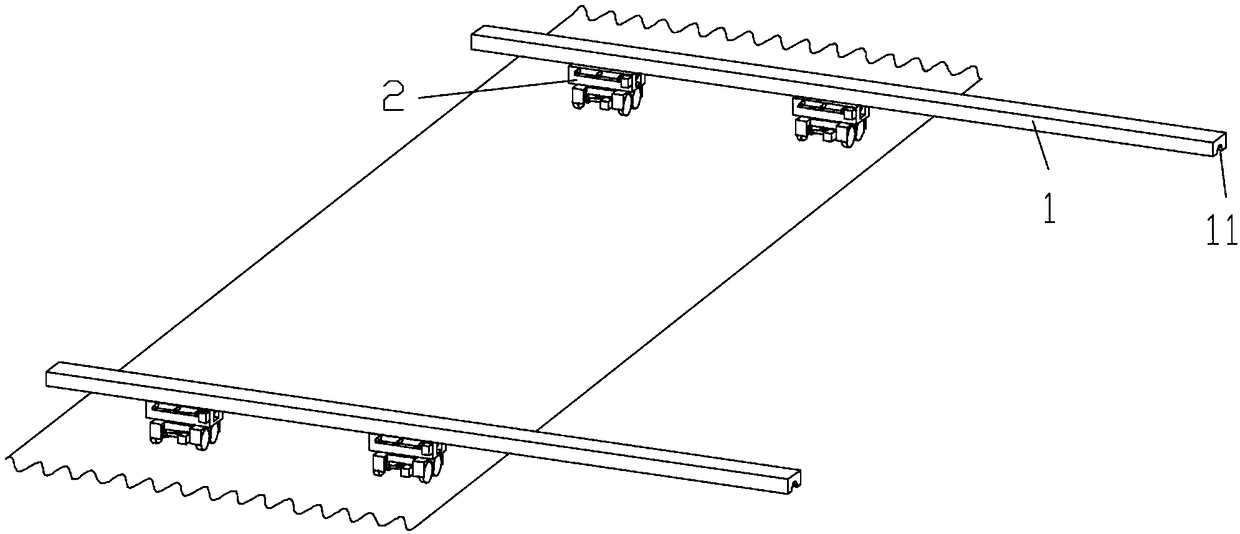

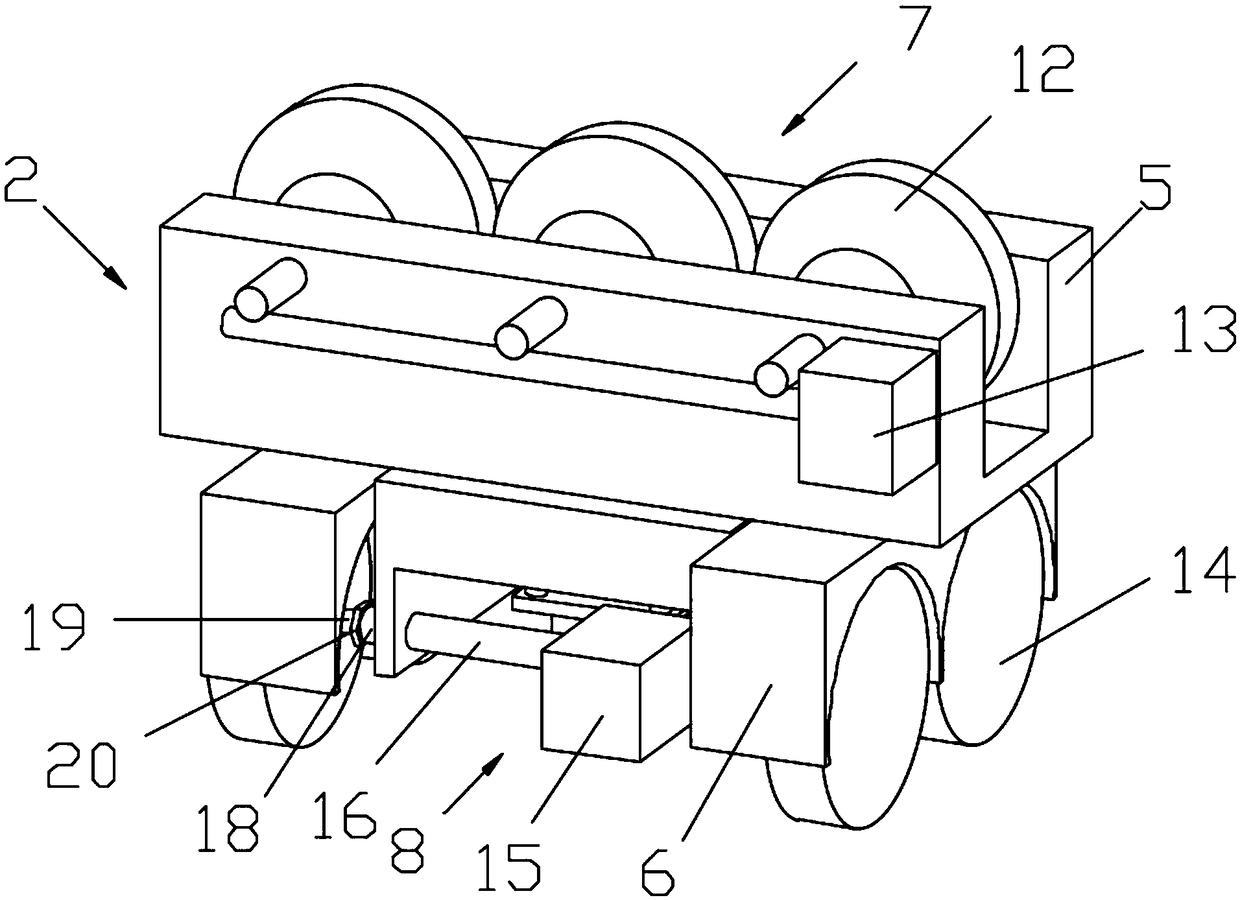

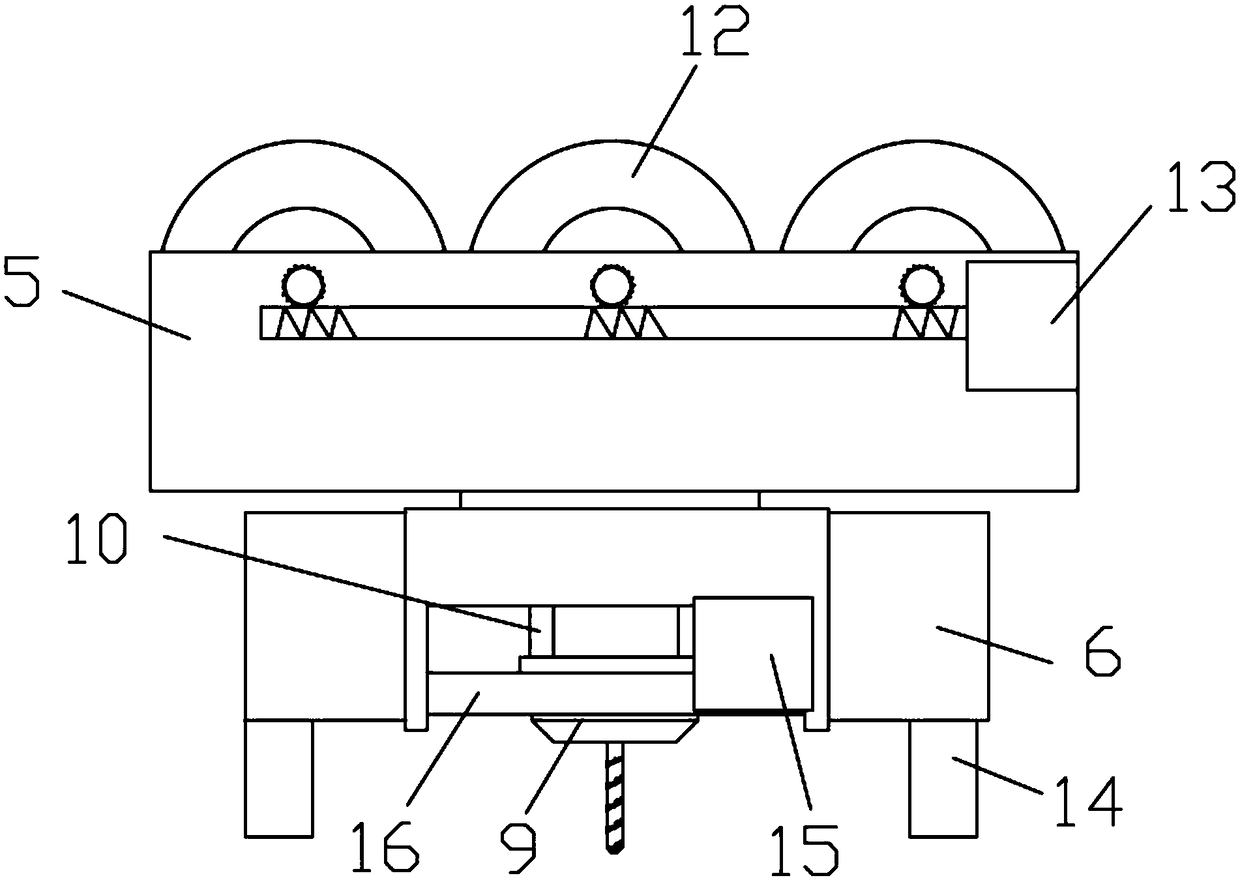

[0022] see Figures 1 to 5 , a color steel tile laying device, including a guide rail 1, a carrier 2, an electric drill 9, a controller 3 and a remote control terminal 4, the number of the guide rails 1 is at least two and they are arranged parallel to each other on the roof. The device 2 includes a first electromagnet 5, a second electromagnet 6, a first drive mechanism 7 and a second drive mechanism 8, and the carrier 2 is adsorbed on the bottom of the guide rail 1 by the first electromagnet 5, and the carrier 2 2 The color steel tile is adsorbed by the second electromagnet 6, the first driving mechanism 7 drives the carrier 2 to move along the guide rail 1, and the second driving mechanism 8 drives the carrier 2 to move along the color steel tile concave The slot moves, the electric drill 9 is installed on the bottom of the carrier 2 through the electric telescopic rod 10, the first electromagnet 5, the second electromagnet 6, the first drive mechanism 7, the second drive m...

Embodiment 2

[0029] see Figures 1 to 5 The difference between this embodiment and Embodiment 1 is that the number of the second rollers 14 is at least two, and the second rollers 14 are connected to each other through a connecting shaft 16, and the connecting shaft 16 is connected to the second roller through a transmission mechanism. The motor 15 is connected. Improve the firmness of the adsorption between the carrier 2 and the color steel tile, avoid the deviation of the carrier 2 during the punching process of the device, and improve the quality of the punching, thereby improving the installation firmness of the color steel tile and improving the color steel tile. The firmness of the connection between them can avoid damage to the roof caused by typhoon weather and improve the service life of the color steel tile.

[0030] Specifically, the transmission mechanism is a worm gear 17 transmission. The roof of the color steel tile is an inclined roof, and the carrier 2 will slide down du...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com