Metal bent tube production device

A production equipment and metal technology, applied in the field of metal elbow production equipment, can solve problems such as troublesome operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Further detailed explanation through specific implementation mode below:

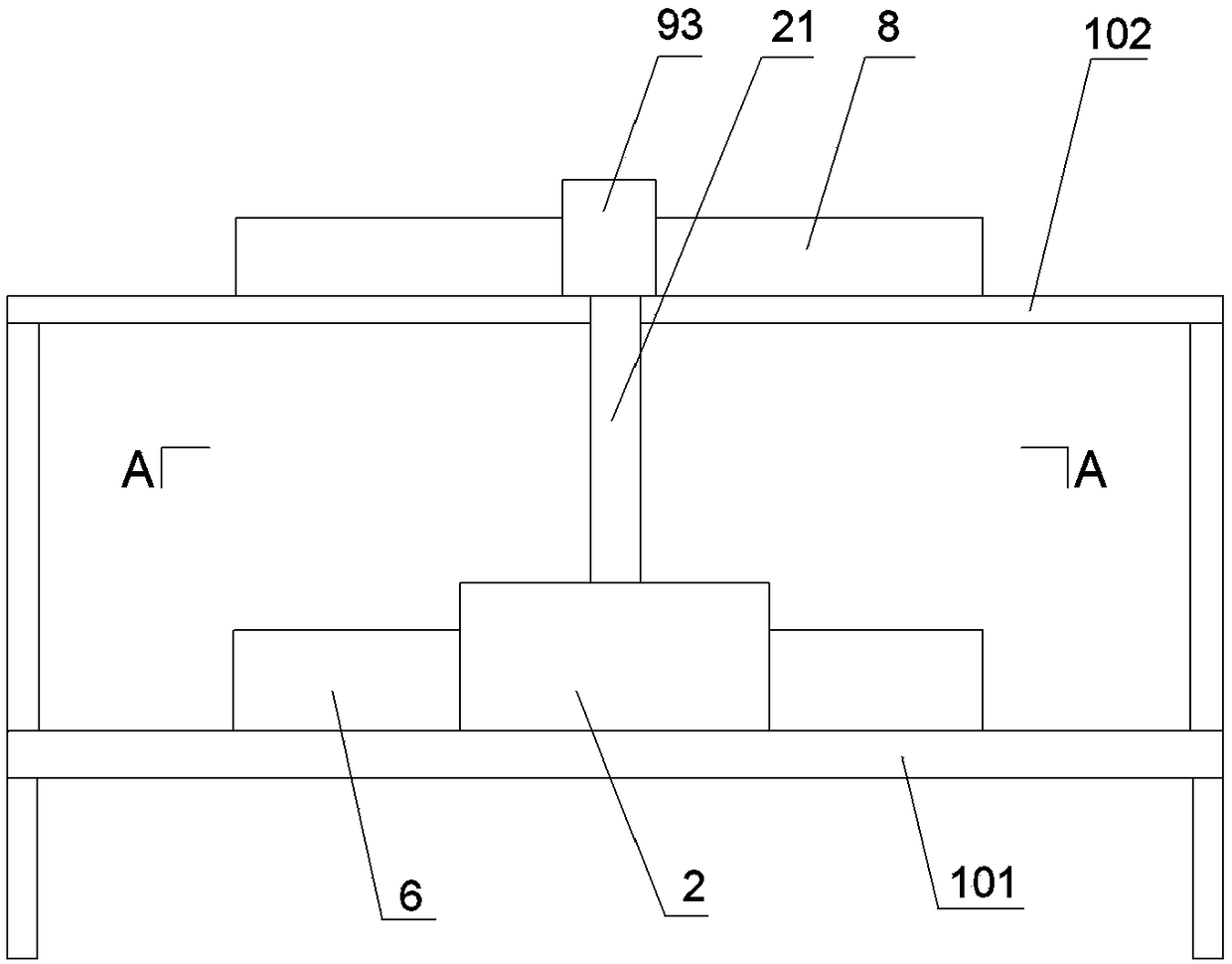

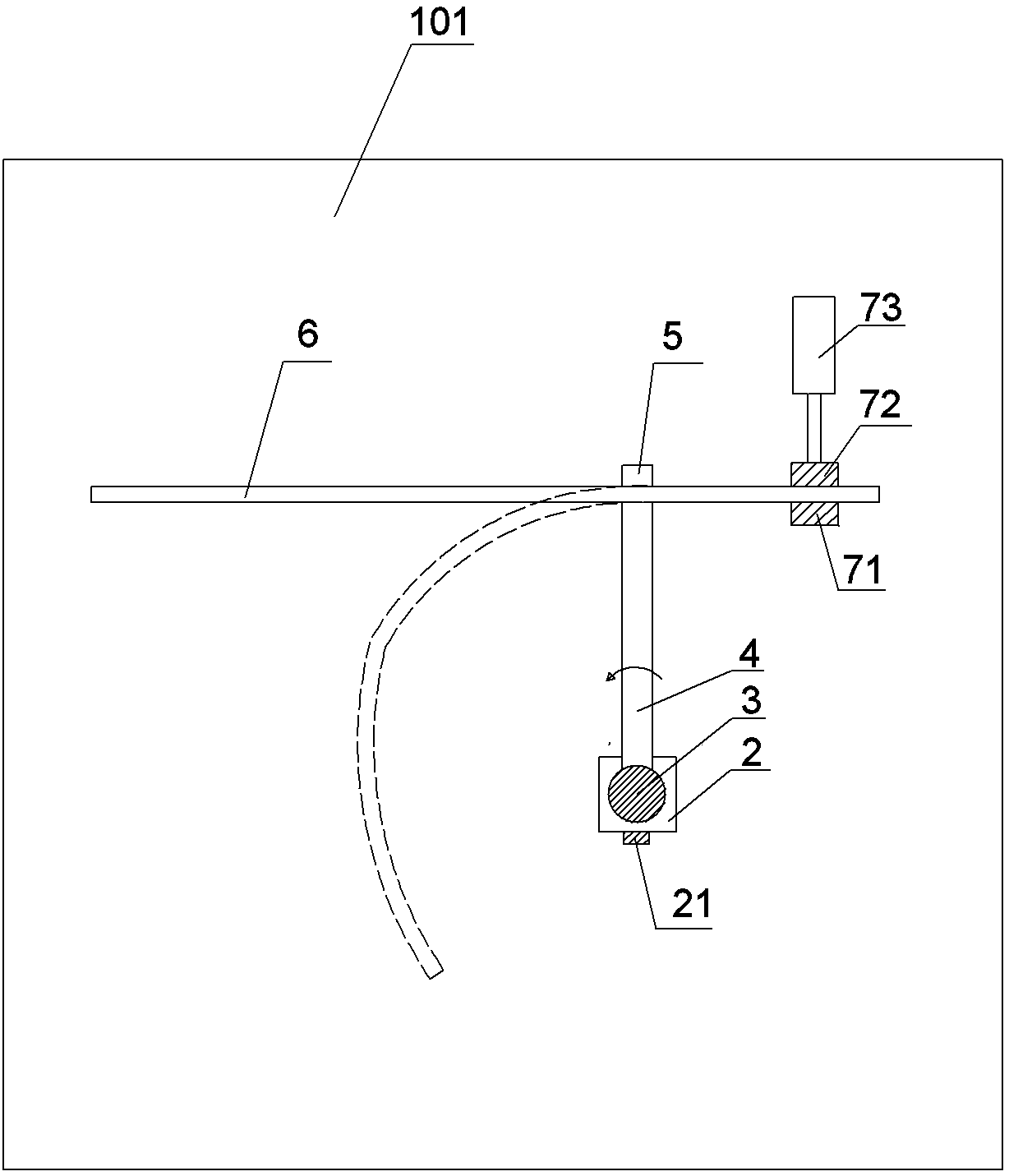

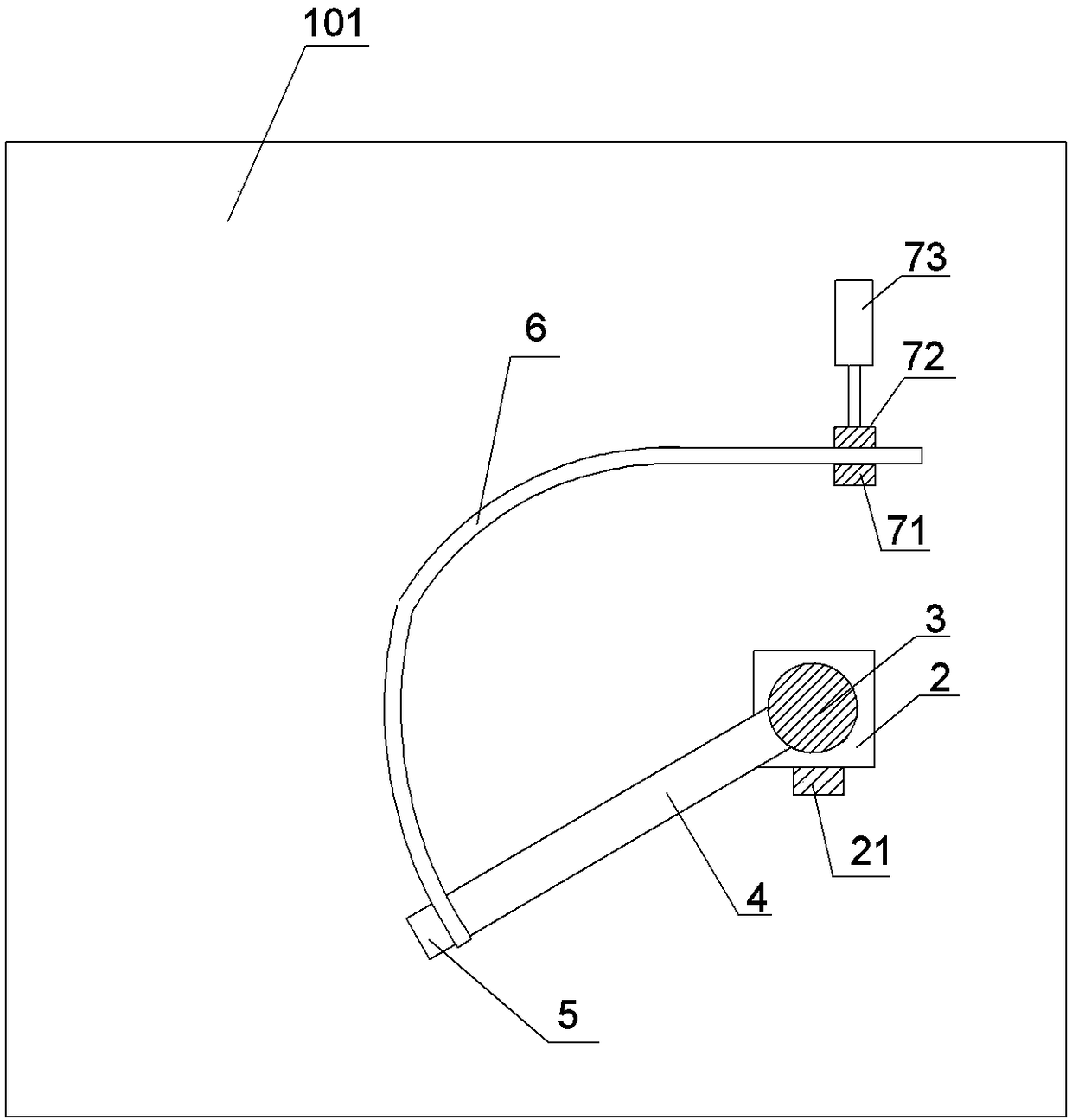

[0026] The reference signs in the drawings of the description include: lower platform 101, upper platform 102, mounting base 2, first transmission rod 21, rotating shaft 3, rotating rod 4, first fixing rod 41, first groove 42, first sliding Rod 43, first spring 44, fixture 5, metal pipe 6, first clamping block 71, second clamping block 72, hydraulic cylinder 73, standard test piece 8, sliding sleeve 9, first connecting rod 91, middle Vertical rod 92, collar 93, first conductive sheet 94, second conductive sheet 95, second transmission rod 10, second connecting rod 11, second fixed rod 111, second groove 112, second sliding rod 113, the second spring 114 .

[0027] Such as figure 1 As shown, a metal pipe bending production equipment in this embodiment includes a frame, and the frame includes an upper platform 102 and a lower platform 101. The lower platform 101 is made of iron, and the lower pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com