3D printer leveling device

A technology of 3D printers and leveling devices, which is applied in 3D object support structures, processing platforms/substrates, additive manufacturing, etc., can solve problems such as single function, inconvenient operation of leveling devices, and affect printing effects, so as to reduce vibration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

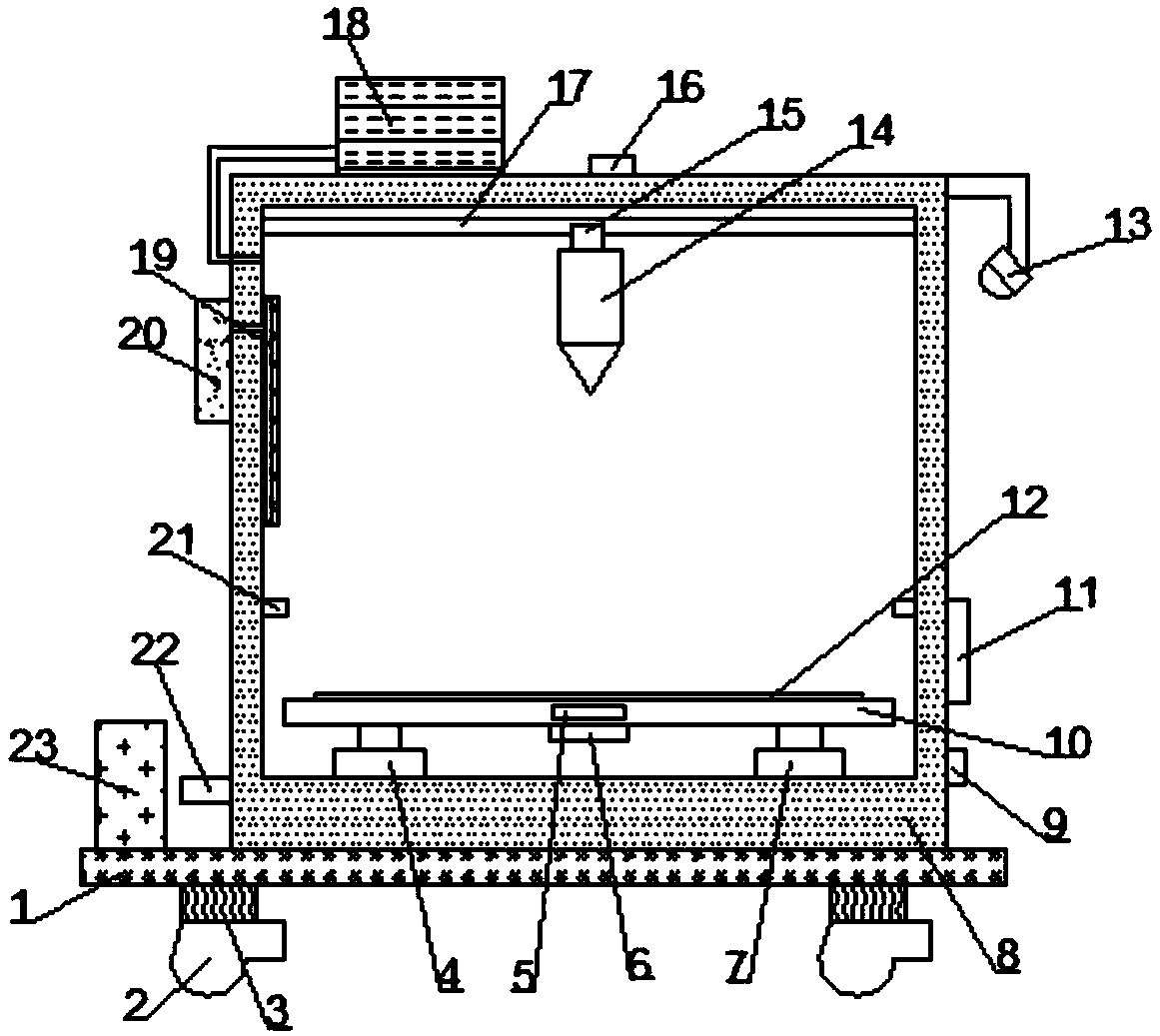

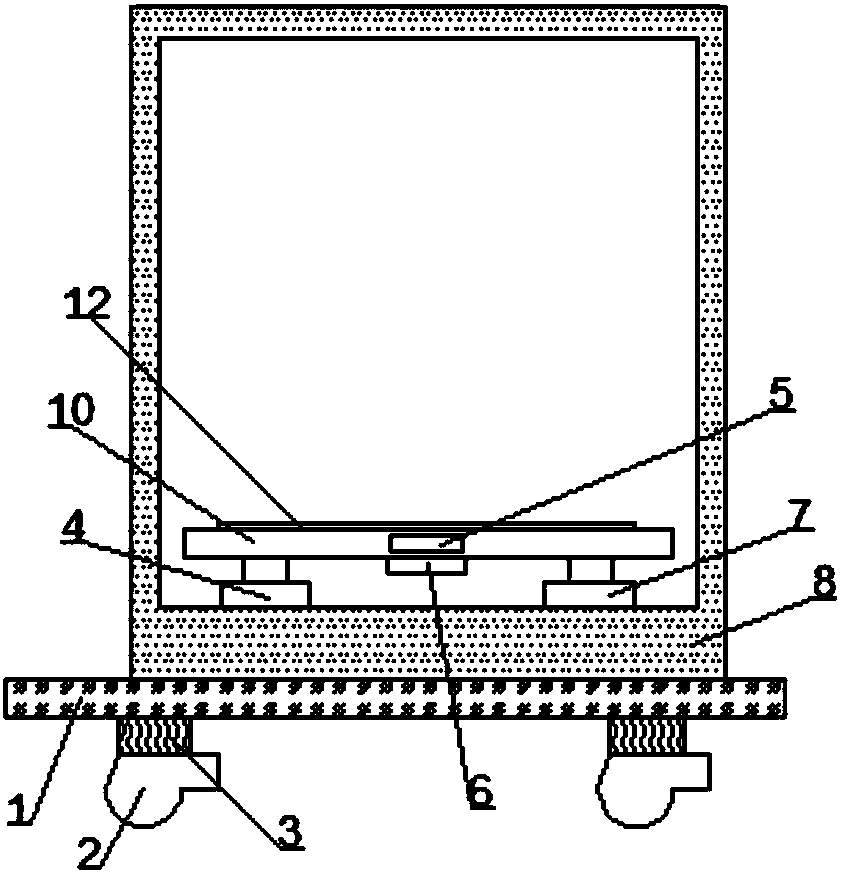

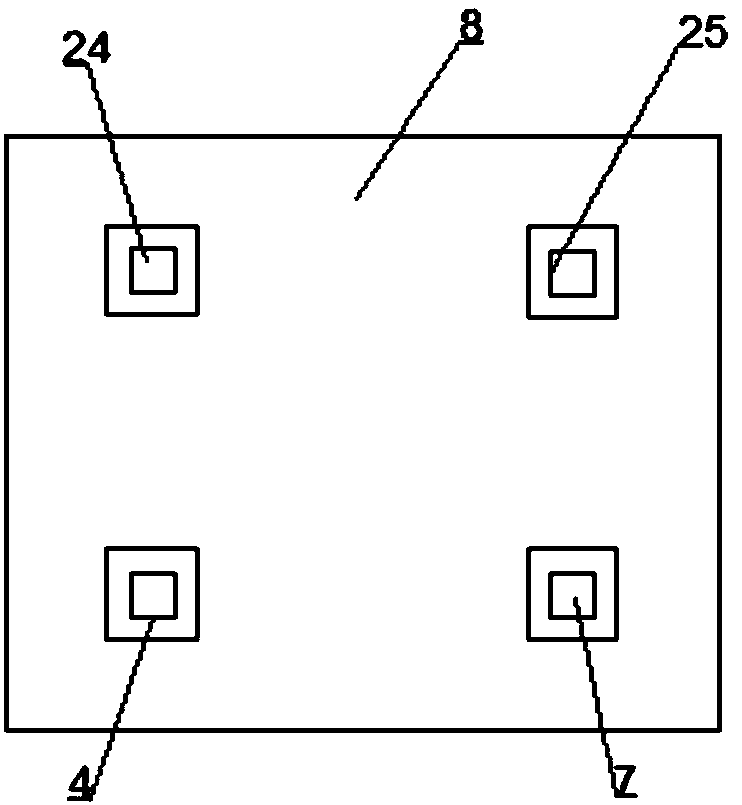

[0025] like Figure 1-5 As shown, a 3D printer leveling device includes a base 1, a 3D printer body 8 and a printing platform 10, the top of the base 1 is fixedly connected to the 3D printer body 8 by bolts, and the inner bottom of the 3D printer body 8 is installed through a mounting seat There are No. 1 electro-hydraulic cylinder 4, No. 2 electro-hydraulic cylinder 7, No. 3 electro-hydraulic cylinder 24 and No. 4 electro-hydraulic cylinder 25, and No. 1 electro-hydraulic cylinder 4, No. 2 electro-hydraulic cylinder 7, and No. 3 electro-hydraulic cylinder 24 The output end of No. 4 electric hydraulic cylinder 25 is connected to the printing platform 10, the bottom of the printing platform 10 is equipped with a level sensor 6 through a mounting piece, the inside of the 3D printer body 8 is provided with a suction pipe 19 and one side of the suction pipe 19 Through the suction hole, the top of the 3D printer body 8 is provided with a guide rail 17, and the lower end of the guid...

Embodiment 2

[0033] like Figure 1-5 As shown, a 3D printer leveling device includes a base 1, a 3D printer body 8 and a printing platform 10, the top of the base 1 is fixedly connected to the 3D printer body 8 by bolts, and the inner bottom of the 3D printer body 8 is installed through a mounting seat There are No. 1 electro-hydraulic cylinder 4, No. 2 electro-hydraulic cylinder 7, No. 3 electro-hydraulic cylinder 24 and No. 4 electro-hydraulic cylinder 25, and No. 1 electro-hydraulic cylinder 4, No. 2 electro-hydraulic cylinder 7, and No. 3 electro-hydraulic cylinder 24 The output end of No. 4 electric hydraulic cylinder 25 is connected to the printing platform 10, the bottom of the printing platform 10 is equipped with a level sensor 6 through a mounting piece, the inside of the 3D printer body 8 is provided with a suction pipe 19 and one side of the suction pipe 19 Through the suction hole, the top of the 3D printer body 8 is provided with a guide rail 17, and the lower end of the guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com