Placing frame of large stone plate

A technology for placing racks and slabs, which is applied in the direction of external frames, transportation and packaging, packaging, etc. It can solve the problems that the storage cart cannot be stored and carried, the product quality cannot be guaranteed, and the use limitations are large. It achieves a compact structure, Wide range of application, anti-bruise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the specific embodiments in the accompanying drawings.

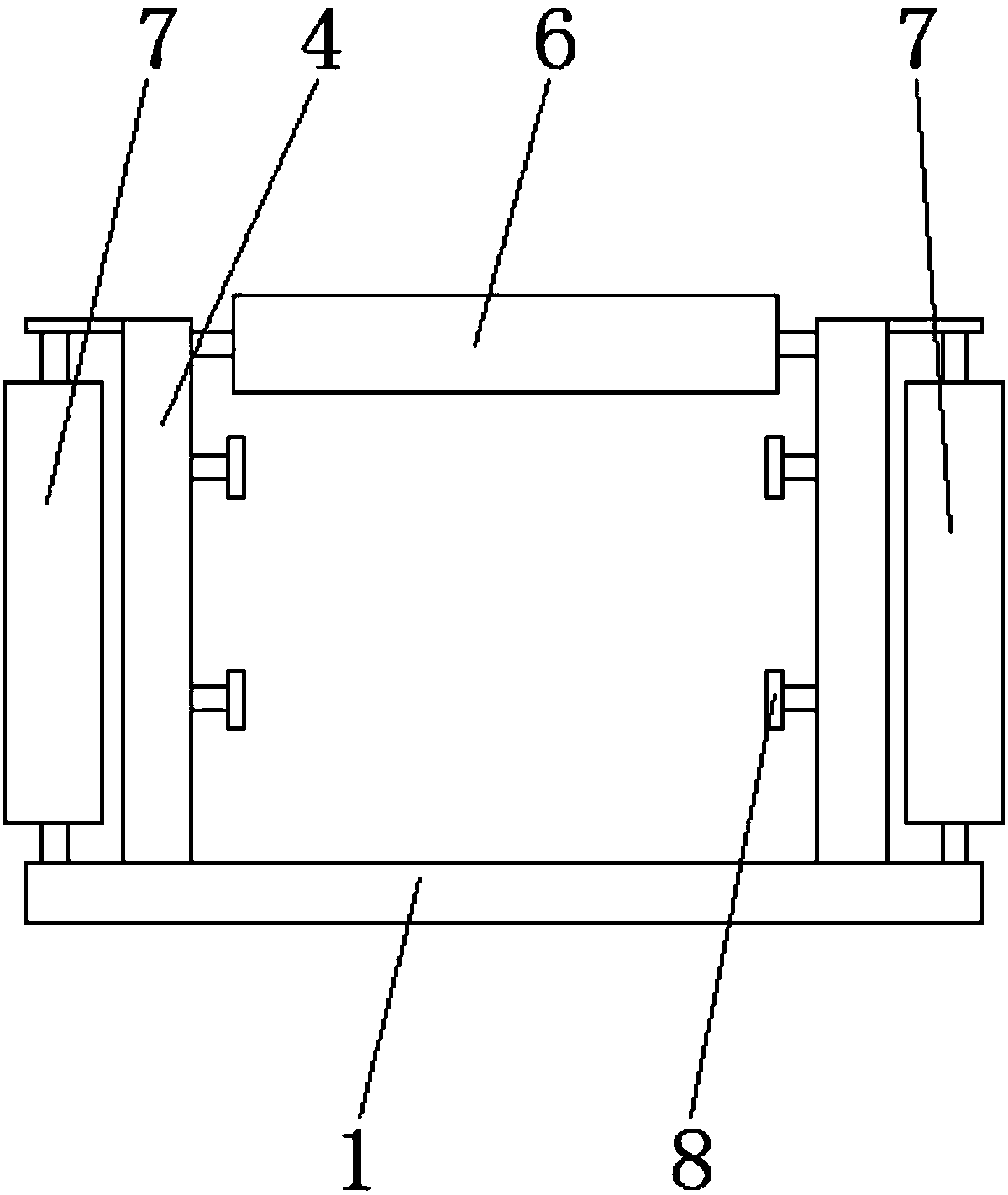

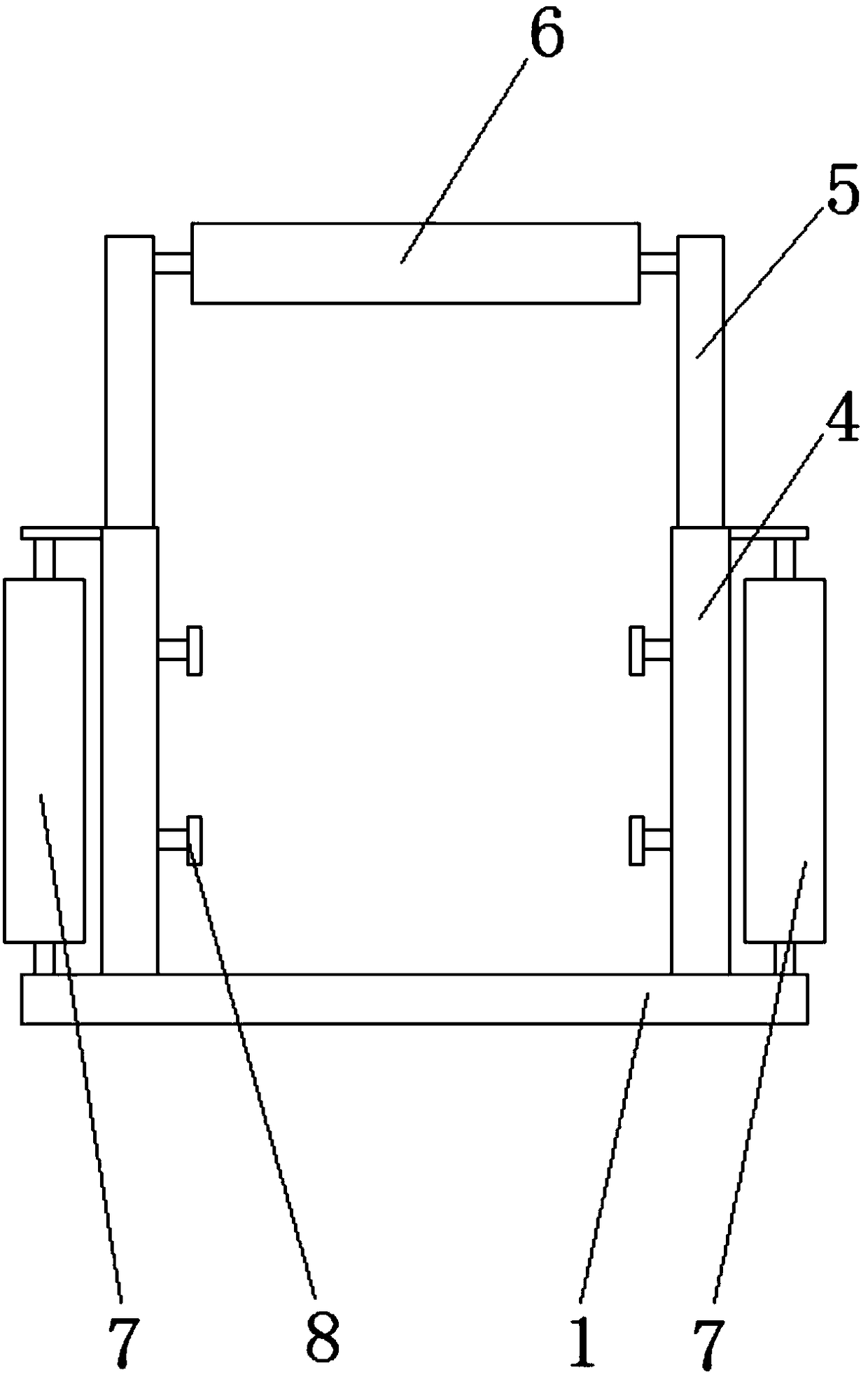

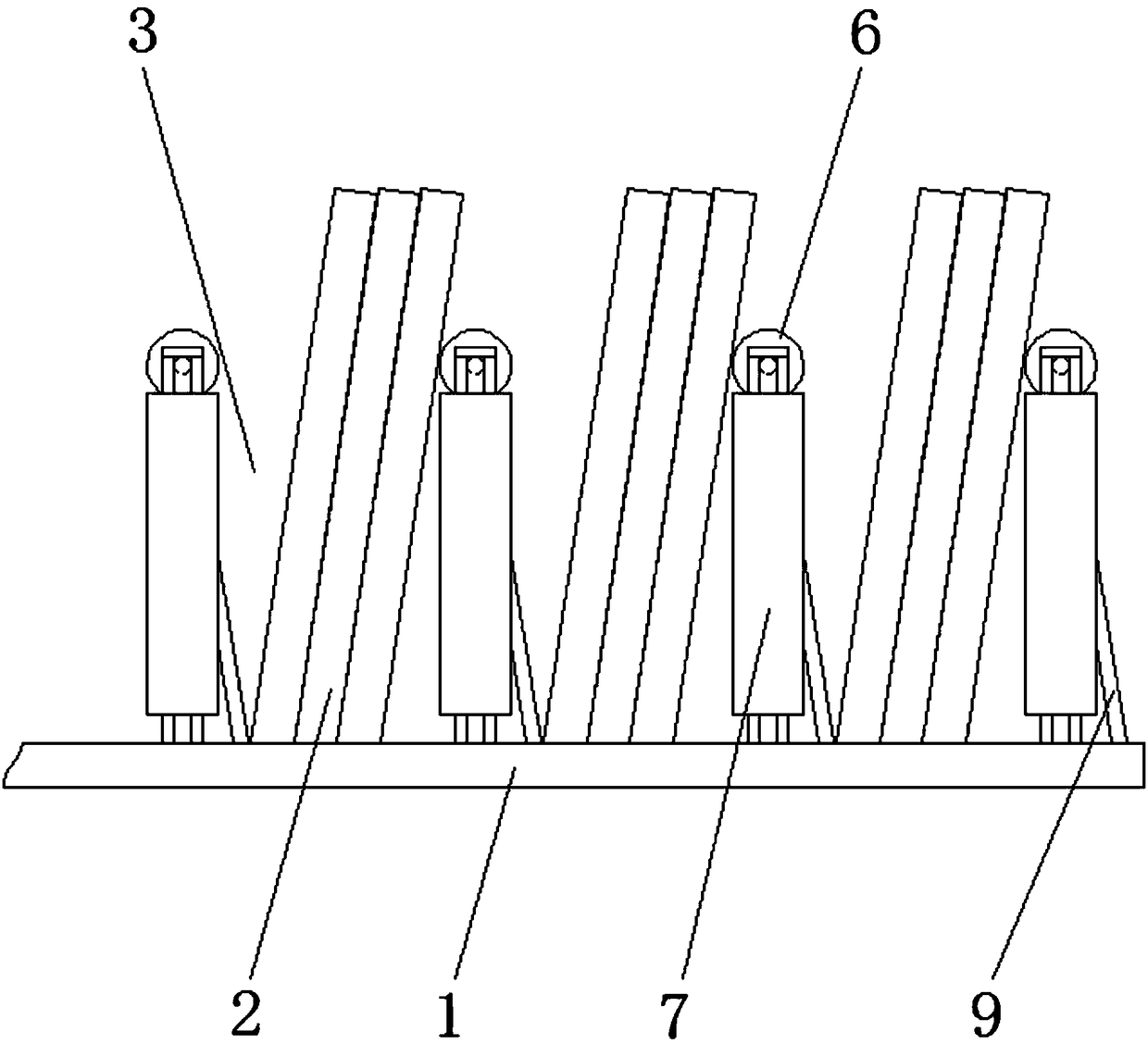

[0018] refer to Figure 1-3 , a large stone slab placement frame according to the present invention includes a base 1 and a plurality of sets of supporting components arranged side by side above the base 1, wherein the base 1 is composed of beams and longitudinal beams, and is a square frame, and the supporting components are perpendicular to the Base 1, the space formed between two adjacent sets of supporting components is used as accommodating chamber 3 for accommodating slate 2, and slate 2 is placed obliquely in this accommodating cavity 3, and each set of supporting components is supported by symmetrically distributed on both sides of base 1 Each support rod 4 is provided with a telescopic rod 5 movably inserted in the support rod 4, the support rod 4 is a hollow structure, and the telescopic rod 5 is plugged into the inner cavity of th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap