Screw bolt type continuous lifting system and screw bolt type continuous lifting method for offshore platform

A technology of offshore platforms and lifting systems, applied in the direction of lifting devices, etc., can solve the problems of difficult processing of pile legs, inability to realize lifting of pile legs, and high difficulty of lifting control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

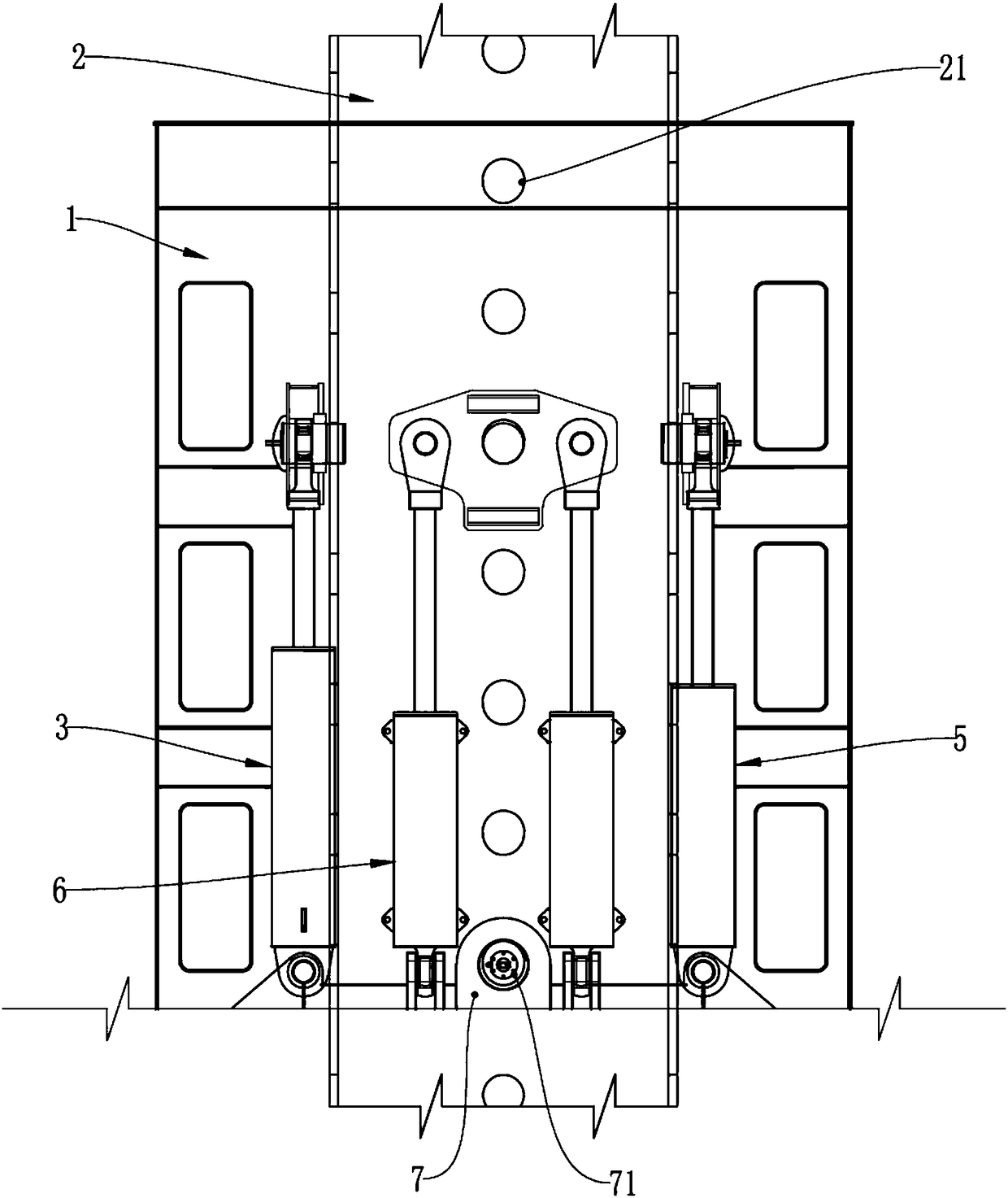

[0067] The screw bolt type continuous lifting system for the offshore platform of the present embodiment, such as figure 1 As shown, it includes a pile-fixing room 1, a pile leg 2 and a lifting unit. The pile-fixing room 1 is fixed on the platform deck, the pile leg 2 runs through the pile-fixing room 1, and the lifting unit is installed on the Pile fixing chamber 1, the lifting unit drives the pile leg 2 up and down;

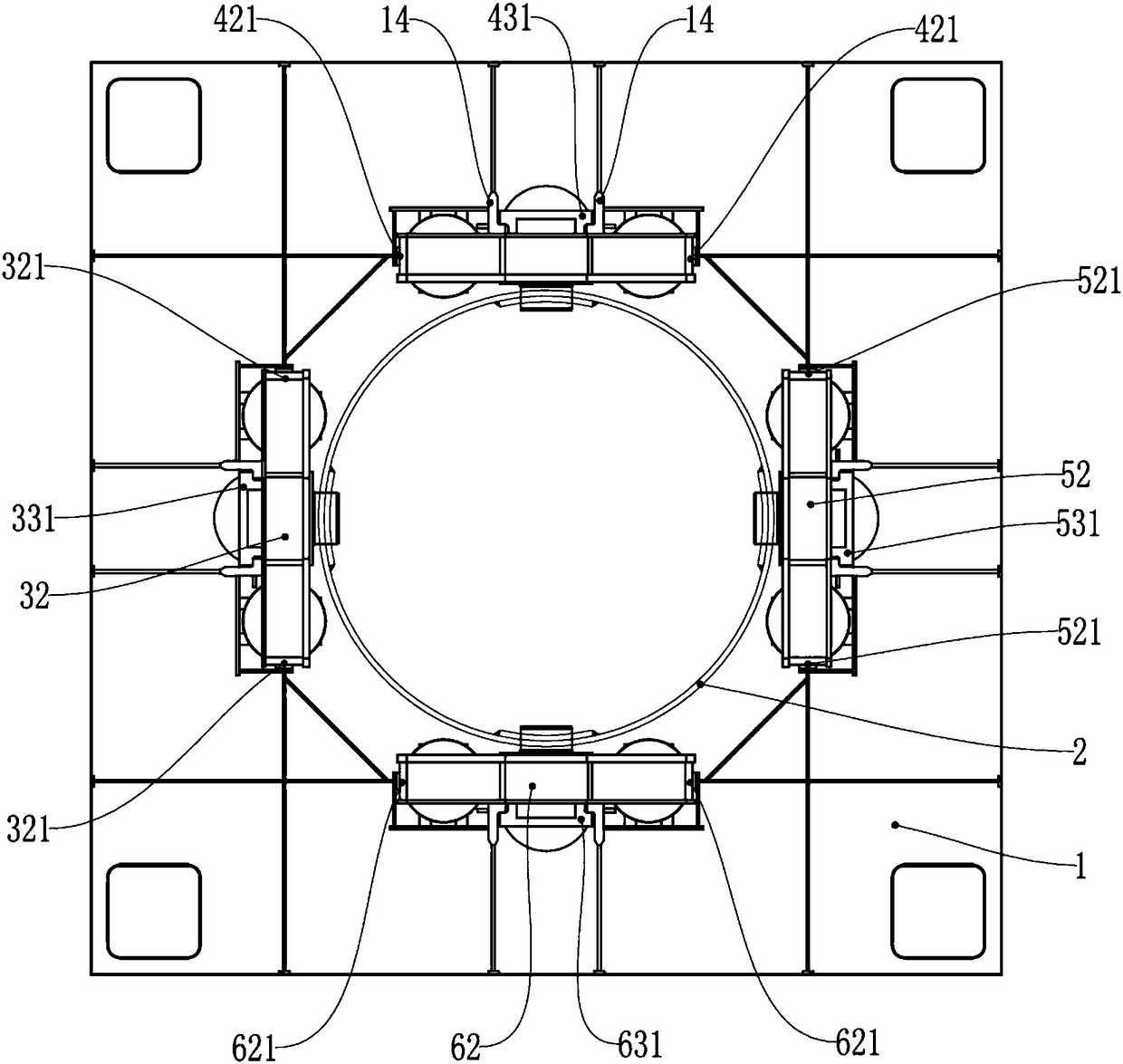

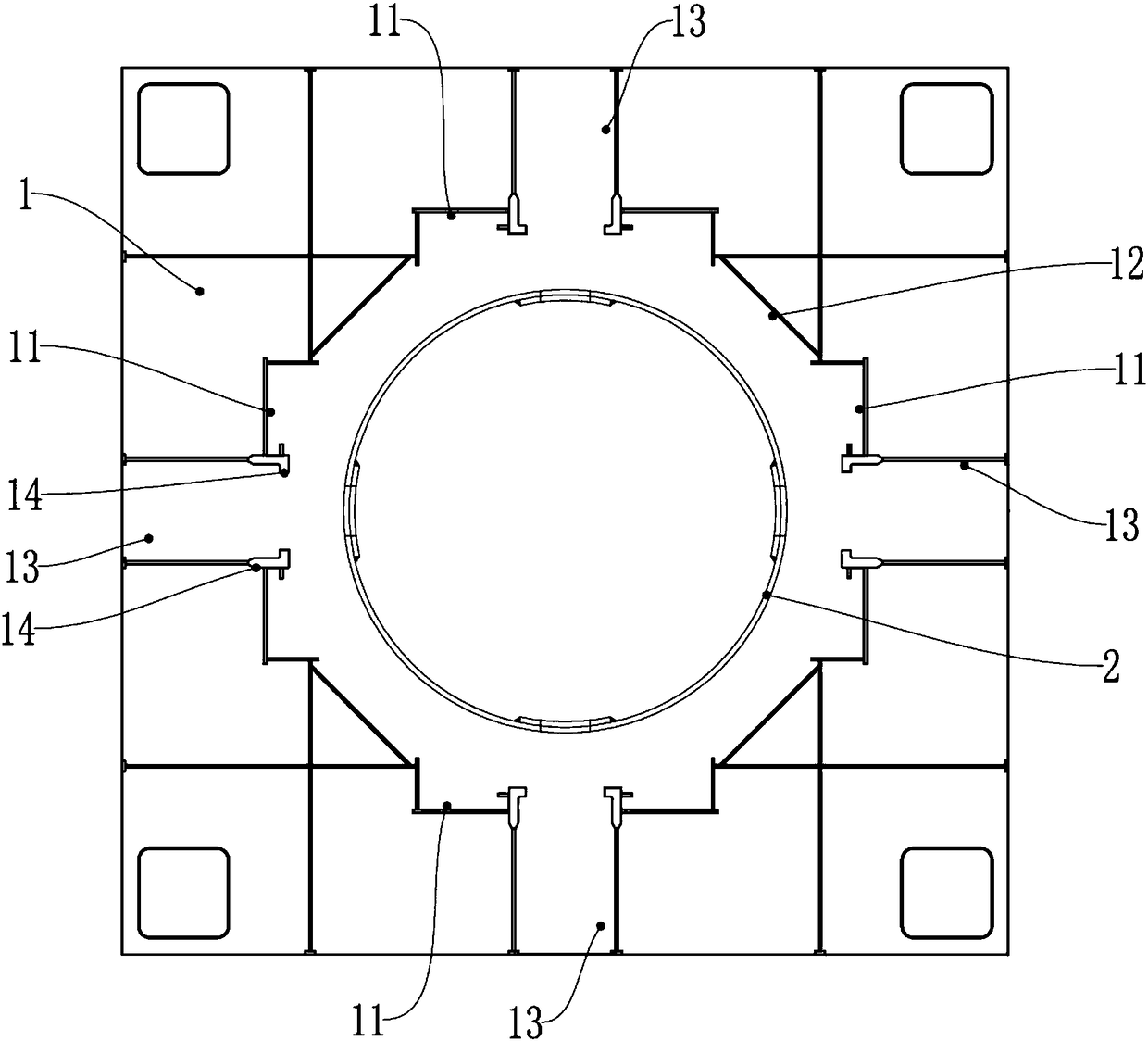

[0068] Such as Figure 4 As shown, four rows of pin hole groups are longitudinally arranged in pairs of the pile legs 2 relative to each other, and each pin hole 21 of the four rows of pin hole groups is aligned on the same plane; Relatively, four first guide grooves 11 are longitudinally arranged, such as image 3 As shown, the four rows of pin hole groups of the legs 2 correspon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com