Agitator device for smelting optical glass

A technology of optical glass and stirrer, applied in glass furnace equipment, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of inconvenient detection operation, unreliable detection method, and dependence on experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

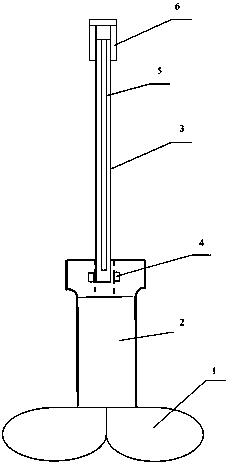

[0016] Such as figure 1 As shown, a stirrer device for optical glass smelting of the present invention is characterized in that the stirrer device includes a helical paddle 1, a paddle main rod 2, a straight rotating shaft 3, a cross fixed head 4, Cooling water pipe 5, torque sensor 6; screw type blade 1 is provided at the bottom of blade main rod 2, and cross fixed head 4 is arranged on the top of blade main rod 2, and one end of the straight rotating shaft 3 is fixed by a cross The head 4 is cross-connected with the blade main rod 2, the top of the straight rotating shaft 3 is equipped with a torque sensor 6, the straight rotating shaft 3 is a hollow tube structur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap