Thumb-tag needle structure of hosiery knitting machine

A technology for pressing needles and sock machines, which is used in weft knitting, knitting, textiles and paper making, etc., can solve the problems of increasing the difficulty of maintenance of sock machines, uneven return force, and low positioning accuracy of rotating shafts, and achieves improved product quality. Qualification rate, flexible swing of pressing needles, and avoiding missing needles and injections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

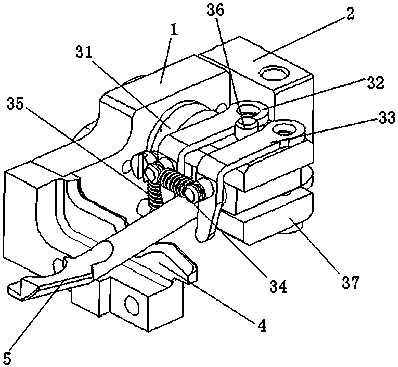

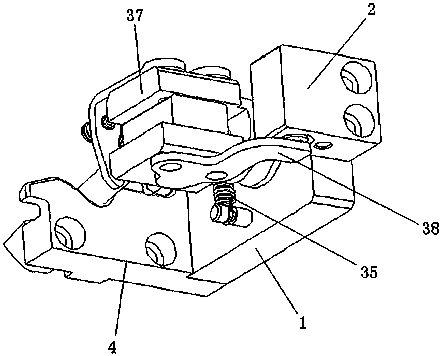

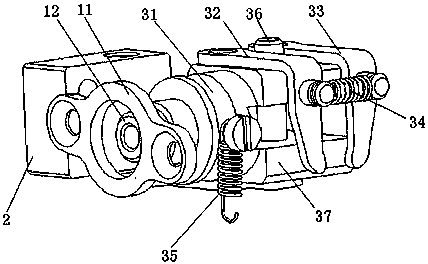

[0024] Combine below Figure 1-3 for further clarification. A needle-pressing structure of a hosiery machine of the present invention includes a base 1, a cylinder 2 is installed on one side of the base 1 (the figure shows that the cylinder 2 and the base 1 are installed by screws), and one side of the base 1 is installed on a track piece 4 , the track piece 4 is detachably installed on the side of the base 1 (the figure shows that the track piece 4 is installed on the base 1 by screws), the track piece 4 is used to adjust the track of the pressing pin 5, and the pressing pin 4 is used to It is connected in a detachable way, which can facilitate the replacement of models; the base 1 is installed with the shaft 131 through the bearing 11, and the bearing pressure plate 12 is installed on one side of the bearing 11, which can further prevent dust from entering and affecting the accuracy; the shaft, 31 is installed on one side There is a pressing pin mounting frame 38, and the p...

Embodiment 2

[0027] Others are the same as in Embodiment 1, and the cylinder 2 and the base 1 are integrally formed, which can improve the precision.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com