A method of compensating the residual magnetic field inside the magnetic shield of laser atomic magnetometer

A technology of residual magnetic field and atomic magnetic force, applied in the size/direction of the magnetic field, using magneto-optical equipment for magnetic field measurement, magnetic field offset compensation, etc., can solve problems affecting the effect of magnetic field compensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

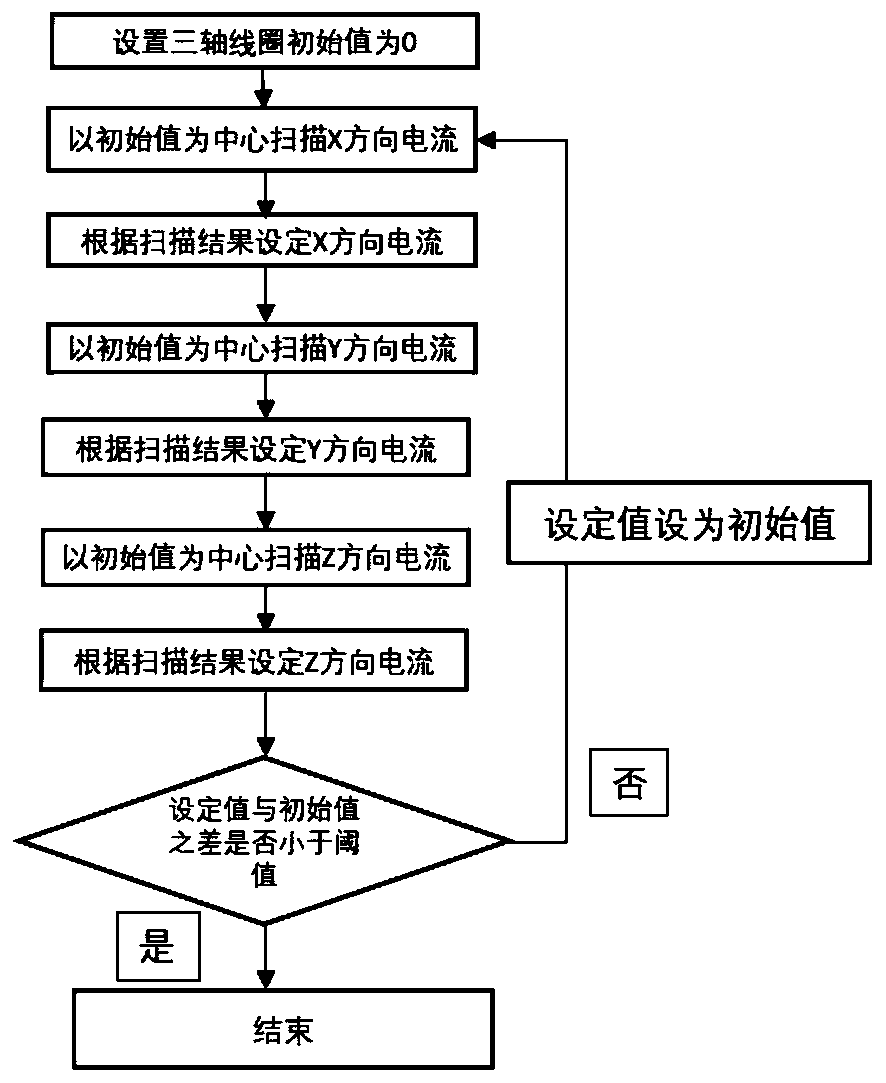

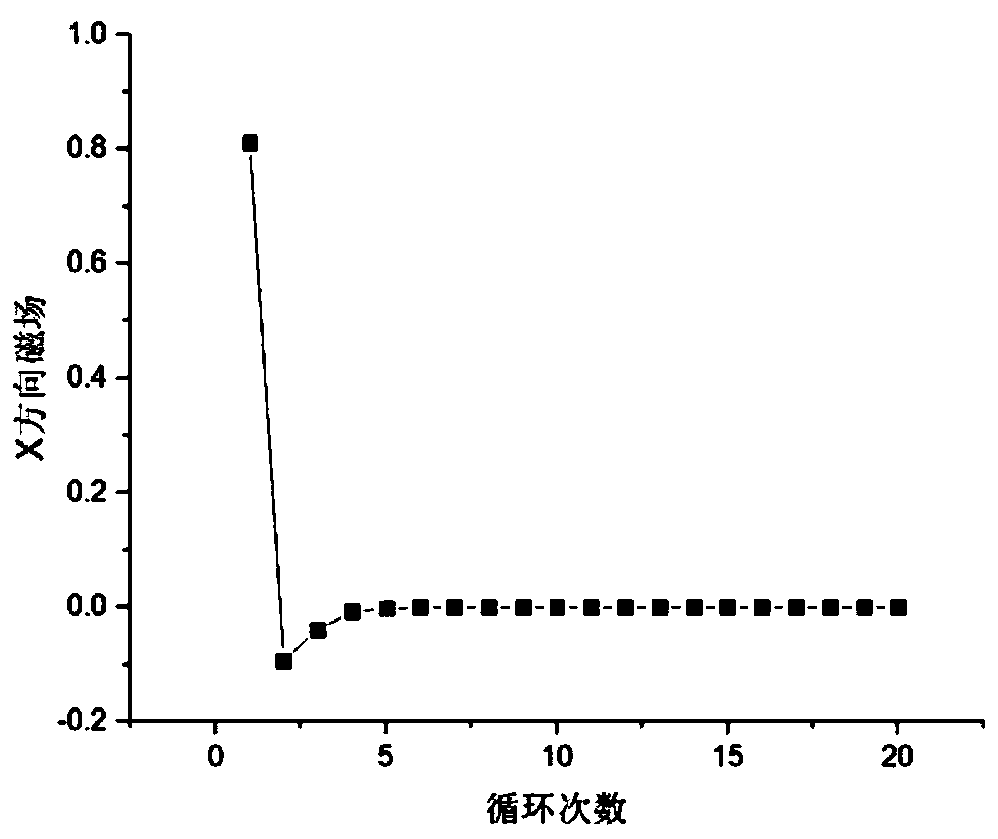

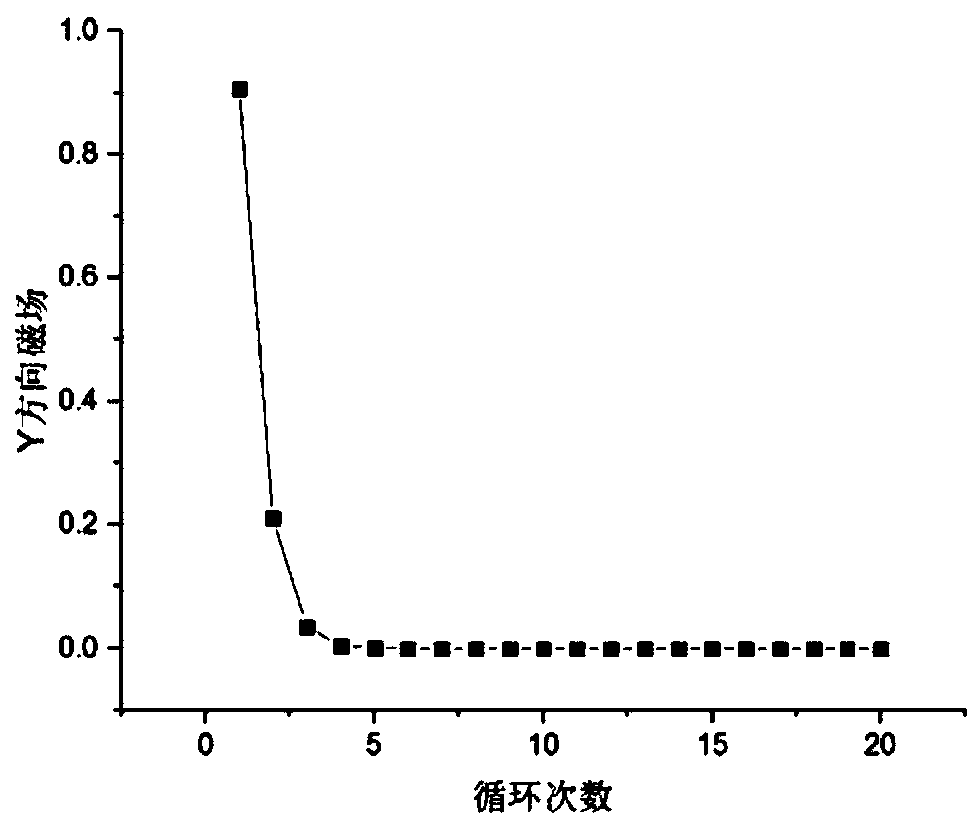

[0029] Below in conjunction with specific embodiment, and figure 1 — Figure 5 , to further illustrate the present invention.

[0030] In this embodiment, the alkali metal atom vapor bubble 7 is used as the cesium atom vapor bubble, Figure 5It is a structural schematic diagram of a single-beam laser atomic magnetometer, and the cesium atom vapor bubble is located at the inner center of the magnetic shield 4 . The 894nm laser beam emitted by the laser 1 propagates along the X axis, and is amplitude modulated by the acousto-optic modulator 2 , the modulation frequency is given by the lock-in amplifier 10 , and the modulated 894nm laser beam passes through the polarizer 3 into linearly polarized light. After the 894nm laser passes through the cesium atom vapor bubble placed in the center of the magnetic shield, the laser is decomposed into two beams orthogonally by the polarization beam splitter prism 8, and the laser polarization plane is obtained by detecting the change of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com