Tea leaf storage box

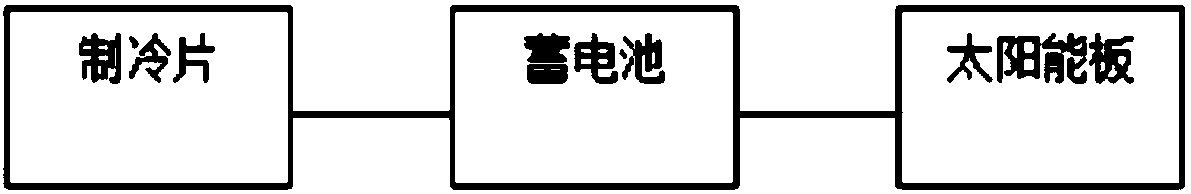

A technology for storing boxes and tea leaves, which is applied to the types of packaging items, special packaging items, electrical components, etc., to achieve the effect of convenient storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The following are the preparation steps of the photoanode in the dye-sensitized solar cell of the present invention:

[0046] Step 1. Clean the Zn chip

[0047] Cut and clean the Zn sheet, and the cleaning work can be done by the usual methods in this field;

[0048] Step 2: Using hydrothermal method to grow ZnO nanowire film on the surface of Zn sheet

[0049] a). First, prepare a mixed solution, where the mixed solution contains 0.04 mol zinc acetate, 0.06 mol glycol amine and 100 ml absolute ethanol. The mixed solution is magnetically stirred at room temperature for 30 minutes, and then the mixed solution is placed at 70°C In the oil bath, magnetically stirred for 12 hours to obtain the ZnO seed layer solution; then slowly immerse the Zn piece in the ZnO seed layer solution, let it stand for 20 seconds, and slowly pull it out, keeping the pulling speed at 0.05 cm / s, and then pull it out The Zn flakes are placed in an oven at 60℃ for drying, and then the Zn flakes are placed...

Embodiment 2

[0071] The following are the preparation steps of the photoanode in the dye-sensitized solar cell of the present invention:

[0072] Step 1. Clean the Zn chip

[0073] Cut and clean the Zn sheet, and the cleaning work can be done by the usual methods in this field;

[0074] Step 2: Using hydrothermal method to grow ZnO nanowire film on the surface of Zn sheet

[0075] a). First, prepare a mixed solution, where the mixed solution contains 0.04 mol zinc acetate, 0.06 mol glycol amine and 100 ml absolute ethanol. The mixed solution is magnetically stirred at room temperature for 30 minutes, and then the mixed solution is placed at 70°C In the oil bath, magnetically stirred for 12 hours to obtain the ZnO seed layer solution; then slowly immerse the Zn piece in the ZnO seed layer solution, let it stand for 20 seconds, and slowly pull it out, keeping the pulling speed at 0.05 cm / s, and then pull it out The Zn flakes are placed in an oven at 60℃ for drying, and then the Zn flakes are placed...

Embodiment 3

[0094] The following are the preparation steps of the photoanode in the dye-sensitized solar cell of the present invention:

[0095] Step 1. Clean the Zn chip

[0096] Cut and clean the Zn sheet, and the cleaning work can be done by the usual methods in this field;

[0097] Step 2: Using hydrothermal method to grow ZnO nanowire film on the surface of Zn sheet

[0098] a). First, prepare a mixed solution, where the mixed solution contains 0.04 mol zinc acetate, 0.06 mol glycol amine and 100 ml absolute ethanol. The mixed solution is magnetically stirred at room temperature for 30 minutes, and then the mixed solution is placed at 70°C In the oil bath, magnetically stirred for 12 hours to obtain the ZnO seed layer solution; then slowly immerse the Zn piece in the ZnO seed layer solution, let it stand for 20 seconds, and slowly pull it out, keeping the pulling speed at 0.05 cm / s, and then pull it out The Zn flakes are placed in an oven at 60℃ for drying, and then the Zn flakes are placed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com