Implementation method for increasing ink stirring efficiency of printing plant

A realization method and technology of a printing factory, which are applied in mixers with rotary stirring devices, accessories of mixers, chemical instruments and methods, etc., can solve the problems of waste of resources, low efficiency, ineffective blades, etc., reduce shaking, improve Stirring efficiency, avoid splash effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

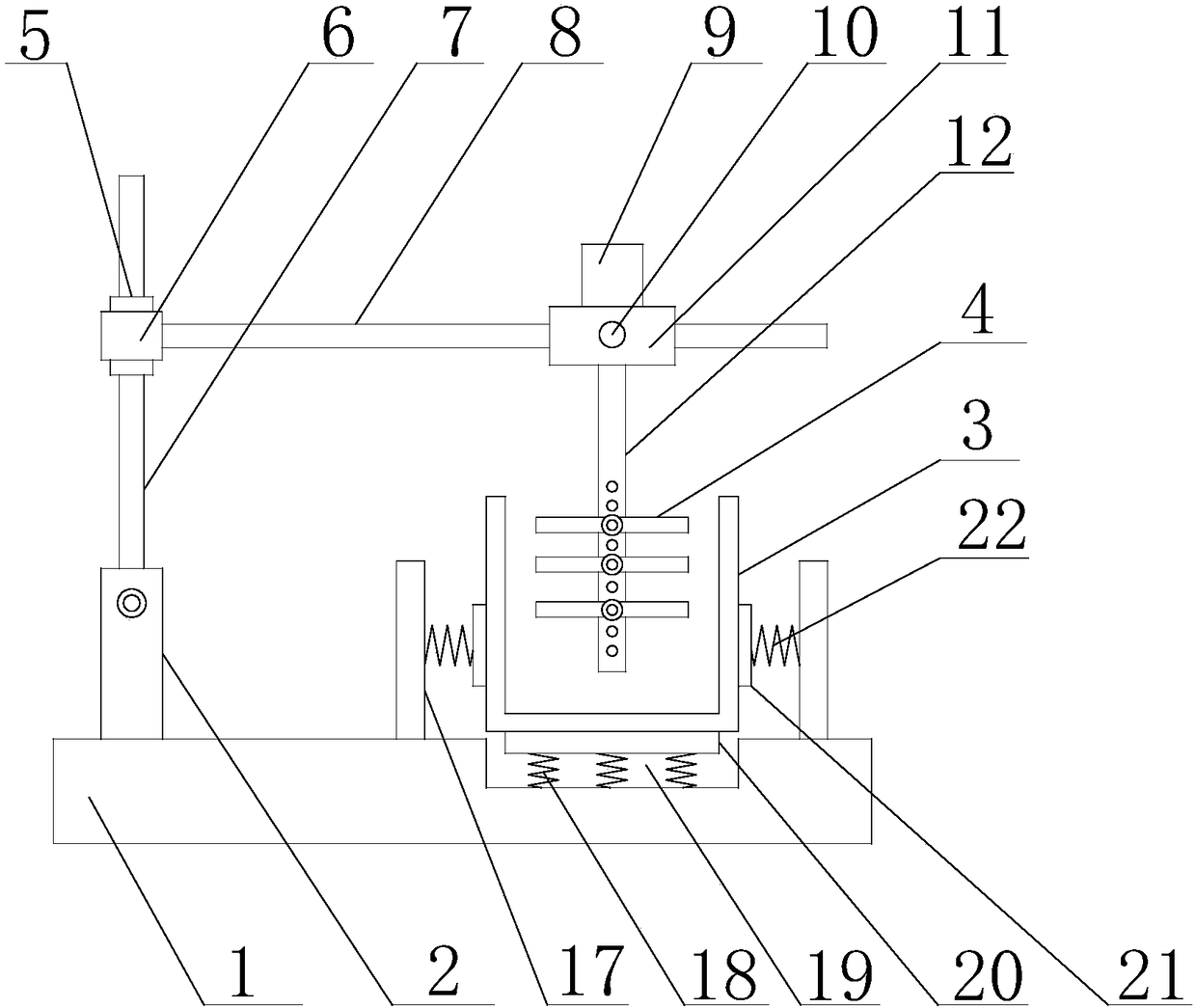

[0035] Such as Figure 1 to Figure 4 Shown, the realization method that the present invention improves printing ink stirring efficiency, comprises the following steps:

[0036] 1) Pour the ink to be stirred into the mixing tank 3;

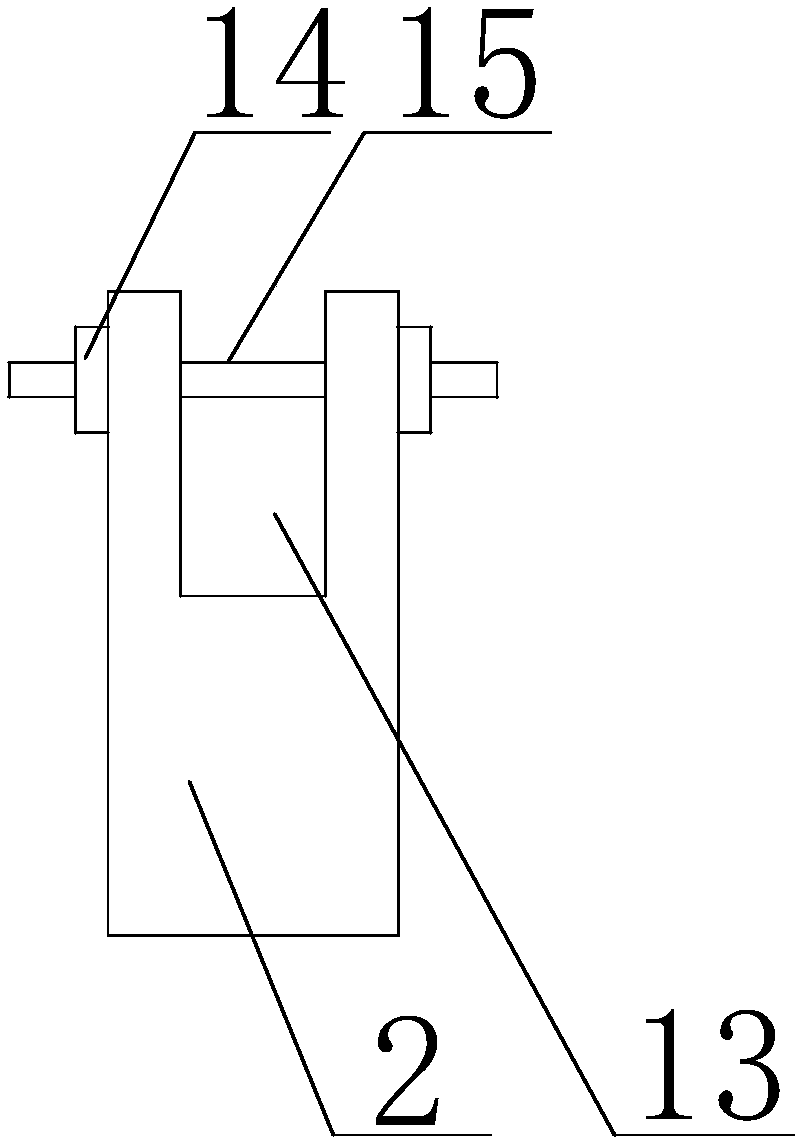

[0037] 2) Place the mixing bucket 3 on the shock absorbing element, and fix the mixing bucket with the pressing plate 21;

[0038] 3) adjust the position of the stirring plate 4 according to the capacity of the ink poured into the mixing tank 3;

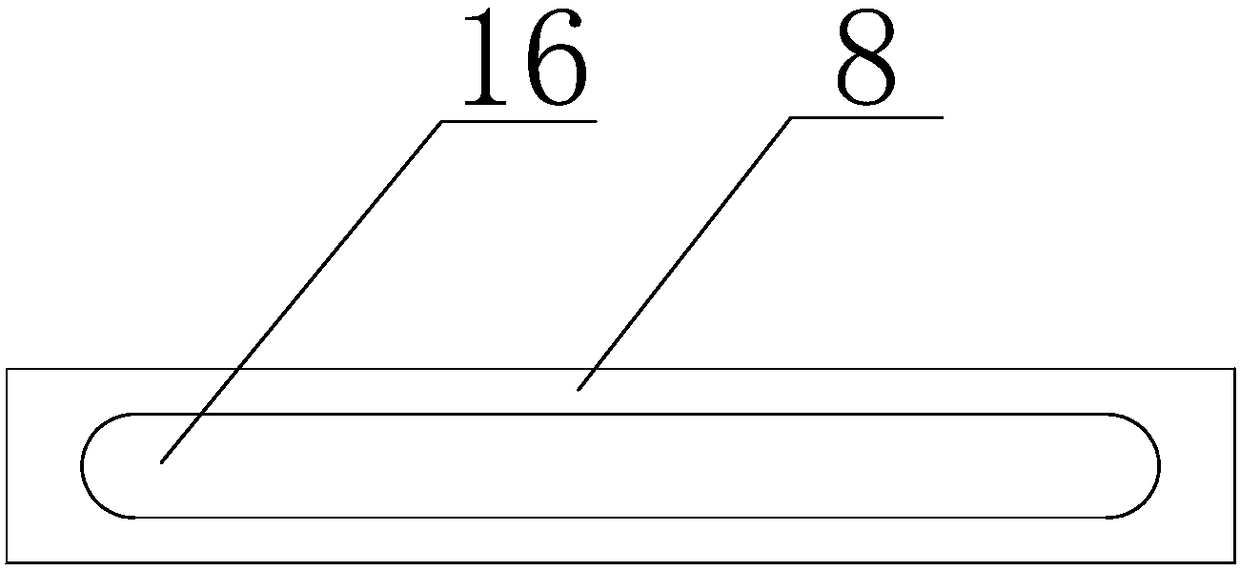

[0039] 4) Unscrew the limit ring 5, adjust the height of the horizontal plate 8, so that the output shaft 12 extends into the mixing tank 3, and the stirring plates 4 are all located in the ink;

[0040] 5) Open the driving mechanism 9, and the driving mechanism 9 drives the output shaft 12 to rotate, forcing the stirring blade 4 to stir the ink;

[0041] 6) Stir for 5-8min, close the driving mechanism 9, and adjust the inclination angle of the support rod 7;

[0042] 7) Turn on the driving mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com