Coarse screening device for sand screening machine

A technology of sand screening machine and coarse screening, which is applied in the directions of screening, loading/unloading, transportation and packaging, etc. It can solve the problems of easy adhesion and clumping of sand, low efficiency of sand screening, etc., and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

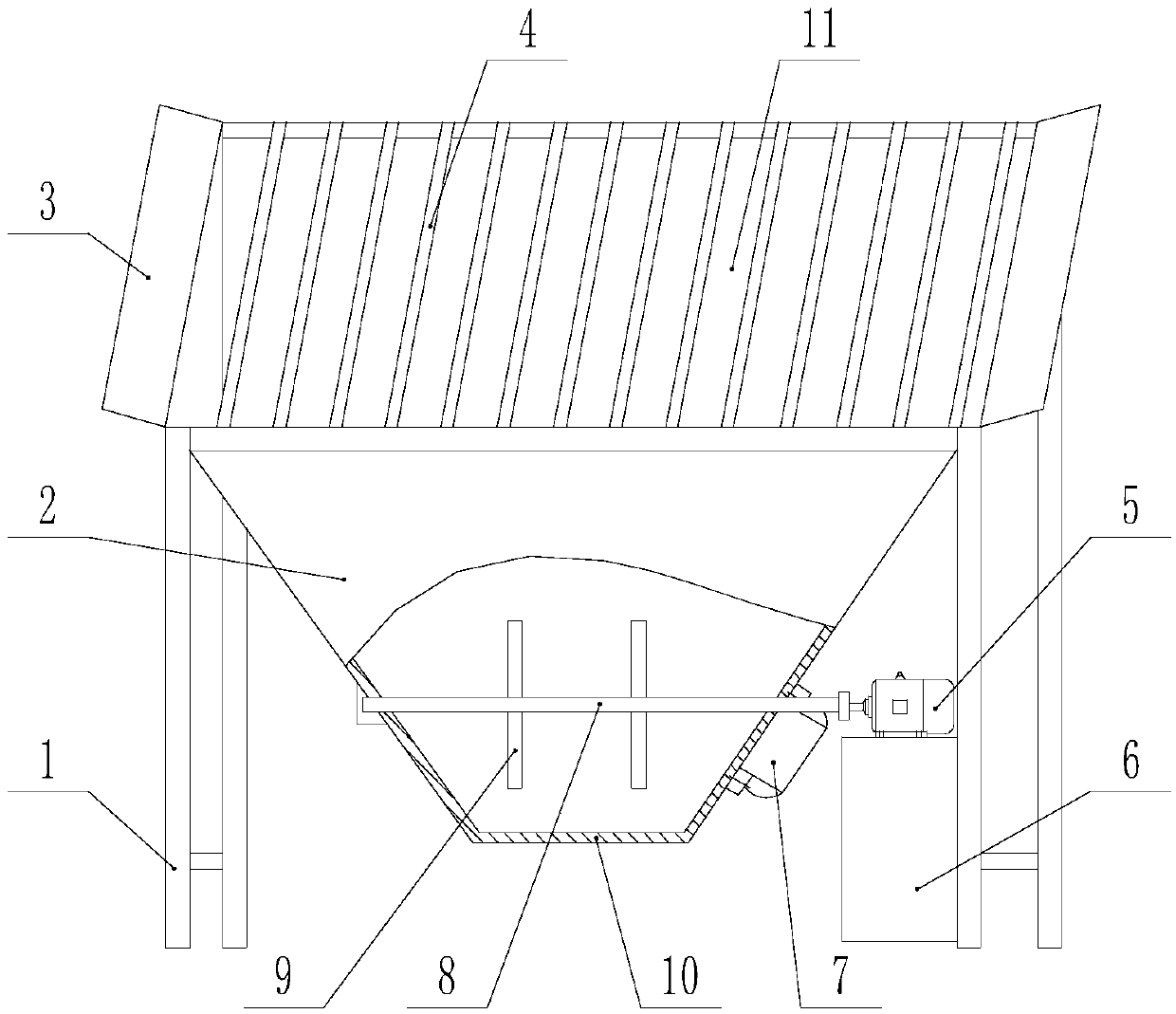

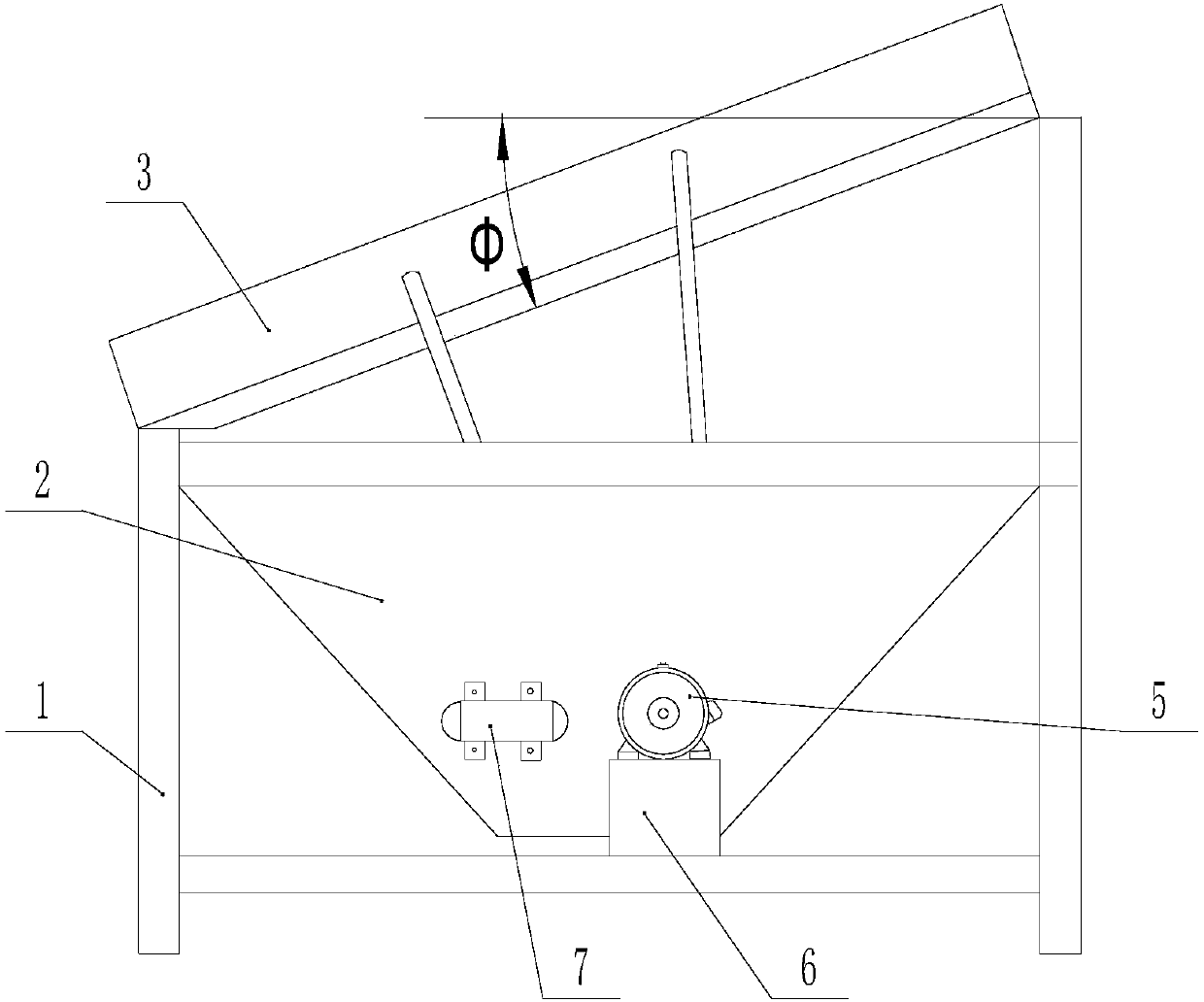

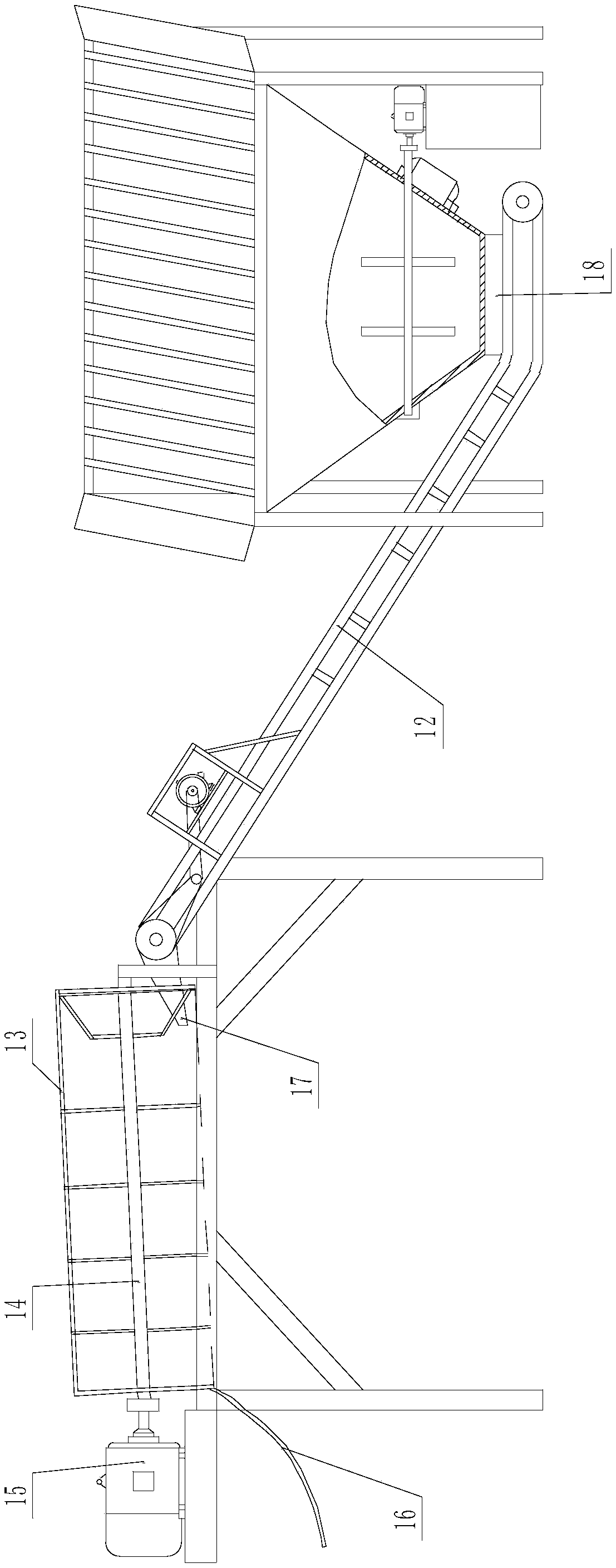

[0025] Such as Figure 1-3 As shown, a coarse screening device for a sand screening machine includes a frame 1 and a feed hopper 2, the feed hopper 2 is installed on the frame 1, and the bottom of the feed hopper 2 is provided with a material leakage port 10. The feed inlet 11 of the hopper 2 is arranged obliquely, and the filter roll 4 installed in parallel is arranged at the feed inlet 11, and the filter roll 4 is welded on the feed hopper 2; one side of the feed hopper 2 is provided with A vibration motor 7, the vibration motor 7 is installed on the lower right shell of the feed hopper 2 through bolt connection; a stirring shaft 8 is arranged in the feed hopper 2, and a stirring blade 9 is welded on the stirring shaft 8; One end of the stirring shaft 8 protruding from the feed hopper 2 is connected with the first reduction motor 5 through a coupling, and the other end is rotatably installed on the left end housing of the feed hopper 2 through a bearing; the first reduction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com