Intelligent robot for storing dangerous chemicals

A technology of intelligent robots and dangerous chemicals, applied in the field of intelligent robots, can solve the problems of strong mobility, various types and high risks, and achieve the effect of preventing private carrying and use, realizing intelligent management, and convenient operation and use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

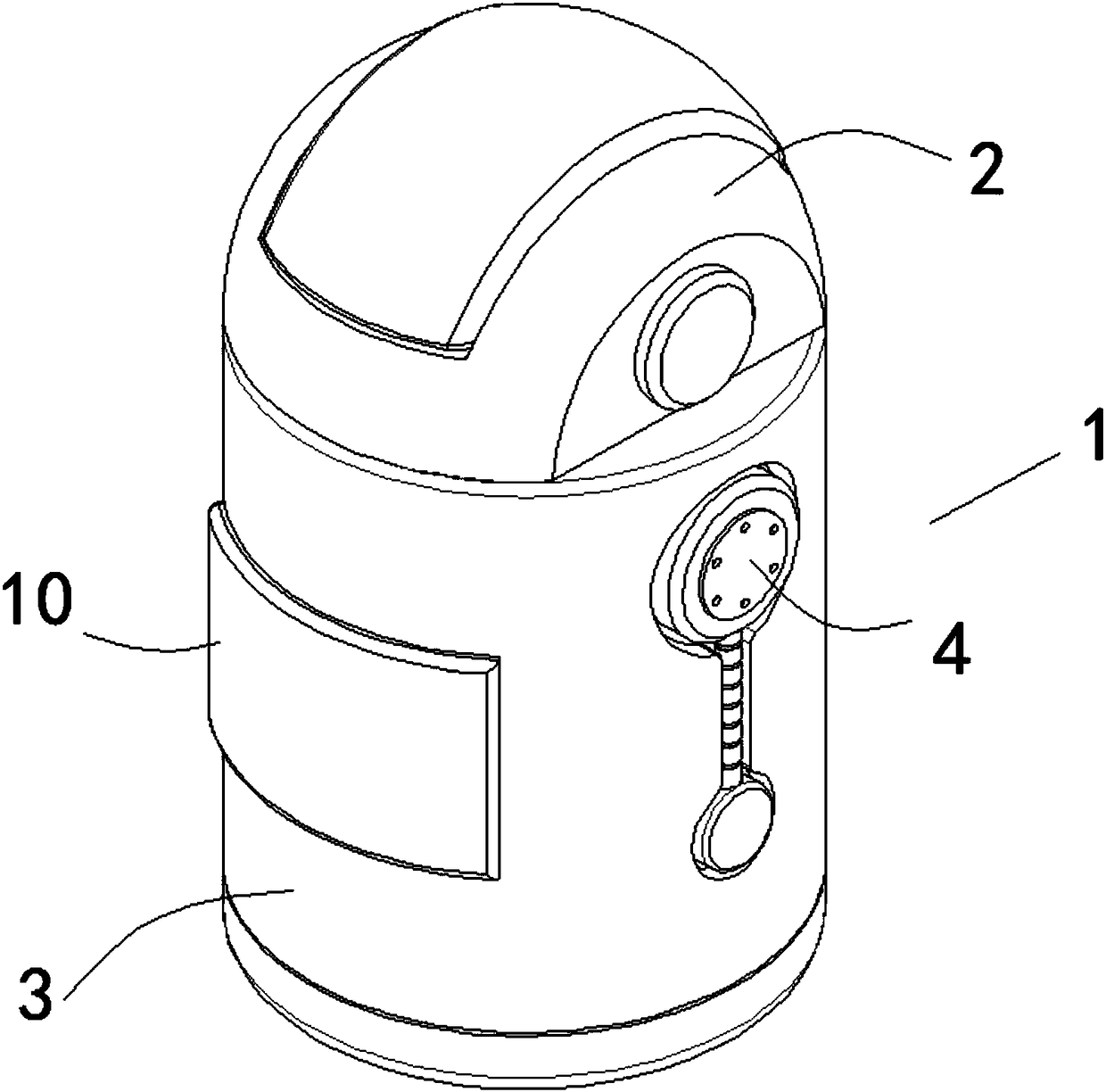

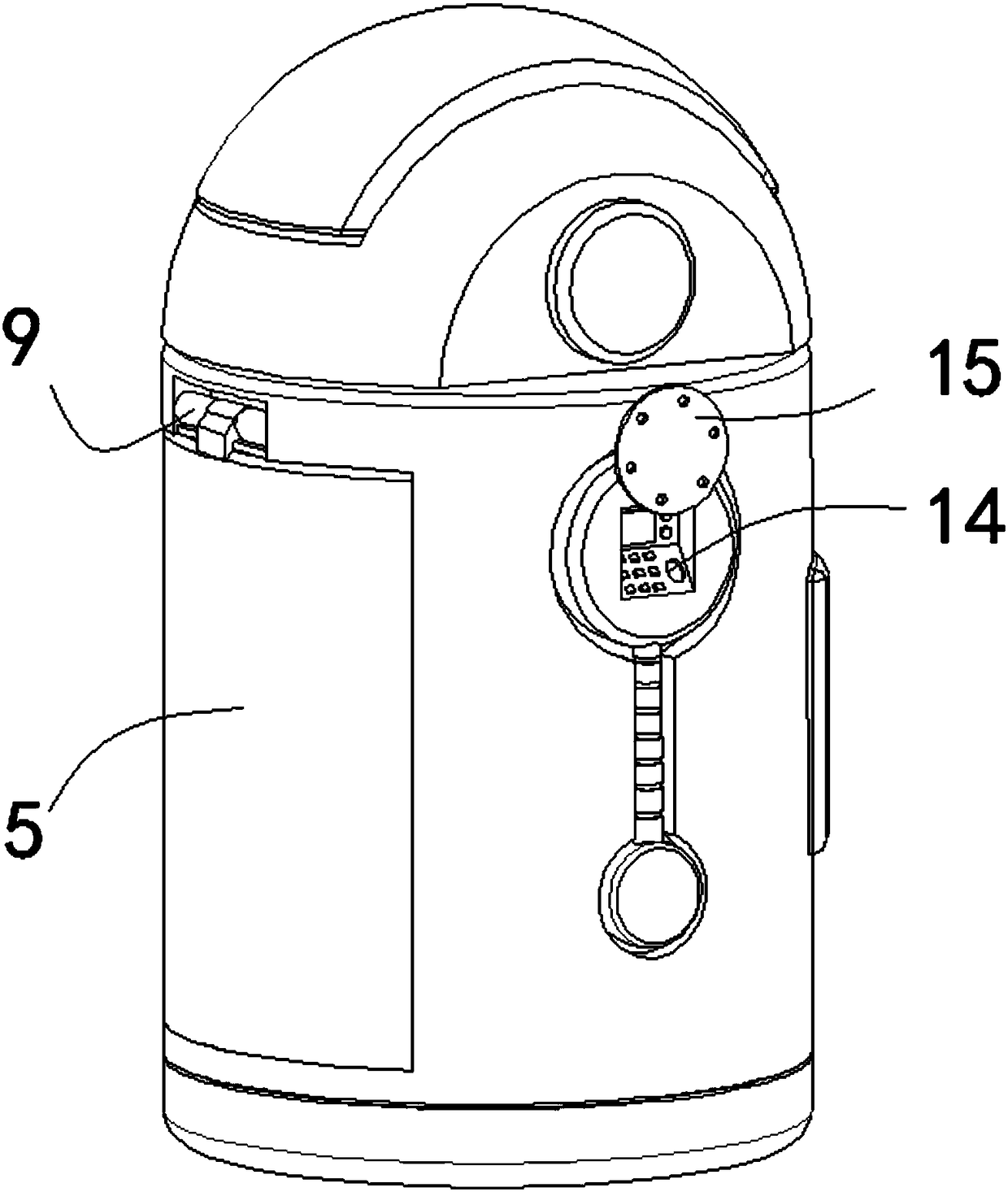

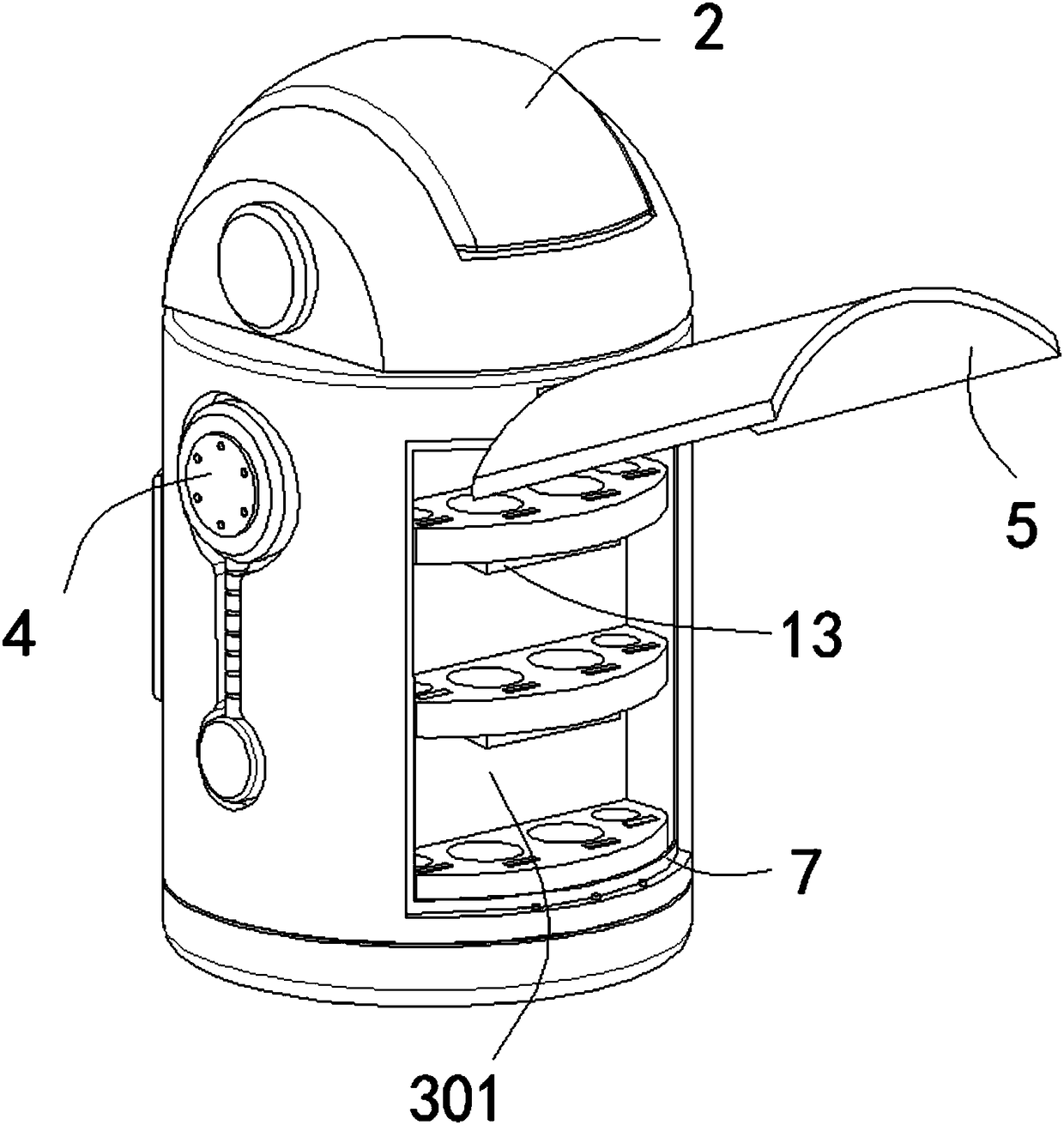

[0032] A kind of intelligent robot for storing hazardous chemicals in this embodiment, refer to Figure 1-6 : Including a robot body 1, the robot body 1 includes a head 2, a body 3 and an arm 4; it also includes a storage structure and an intelligent control system, the storage structure includes a cover 5 and a placement plate 6, and the rear side of the body 3 is provided with Storage cavity 301, the inner wall of the storage cavity 301 is vertically evenly arranged and fixed with a placement plate 6, the top of the placement plate 6 is provided with a placement groove 601, and the front side of the storage cavity 301 is annularly fixed with a sealing edge 7, and the sealing edge 7 is installed on the front side There is an electromagnetic lock 8, the upper end of the cover 5 is connected with the driving shaft 9029, the cover 5 is matched with the inside of the placement groove 601, and pressed against the outside of the sealing edge 7, the lower end of the cover 5 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com