Cutter head of nasal hair trimmer

A technology of trimmer and cutter head, which is applied in the direction of metal processing, etc., to achieve the effect of improving comfort, improving shearing efficiency, and good use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

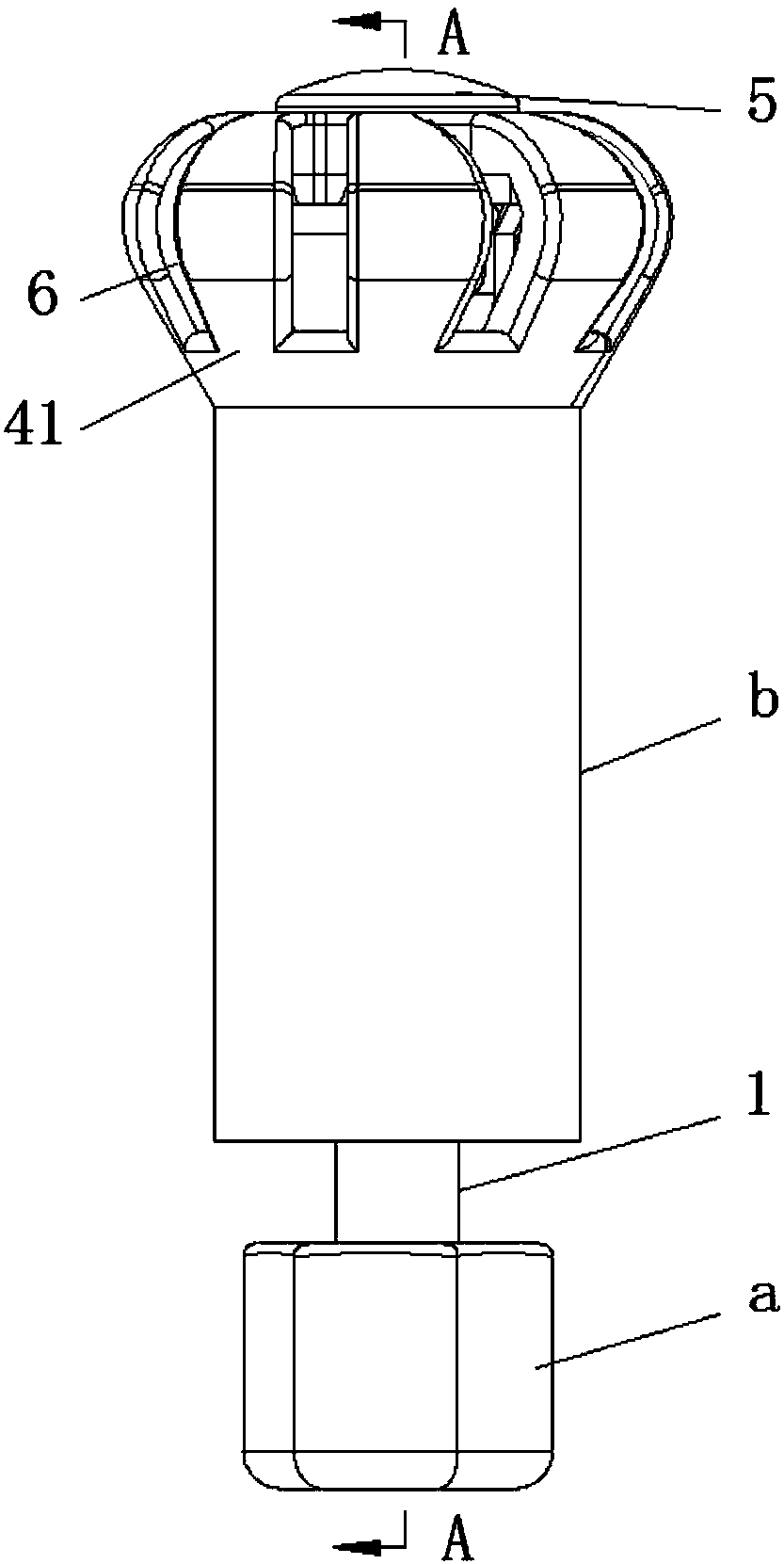

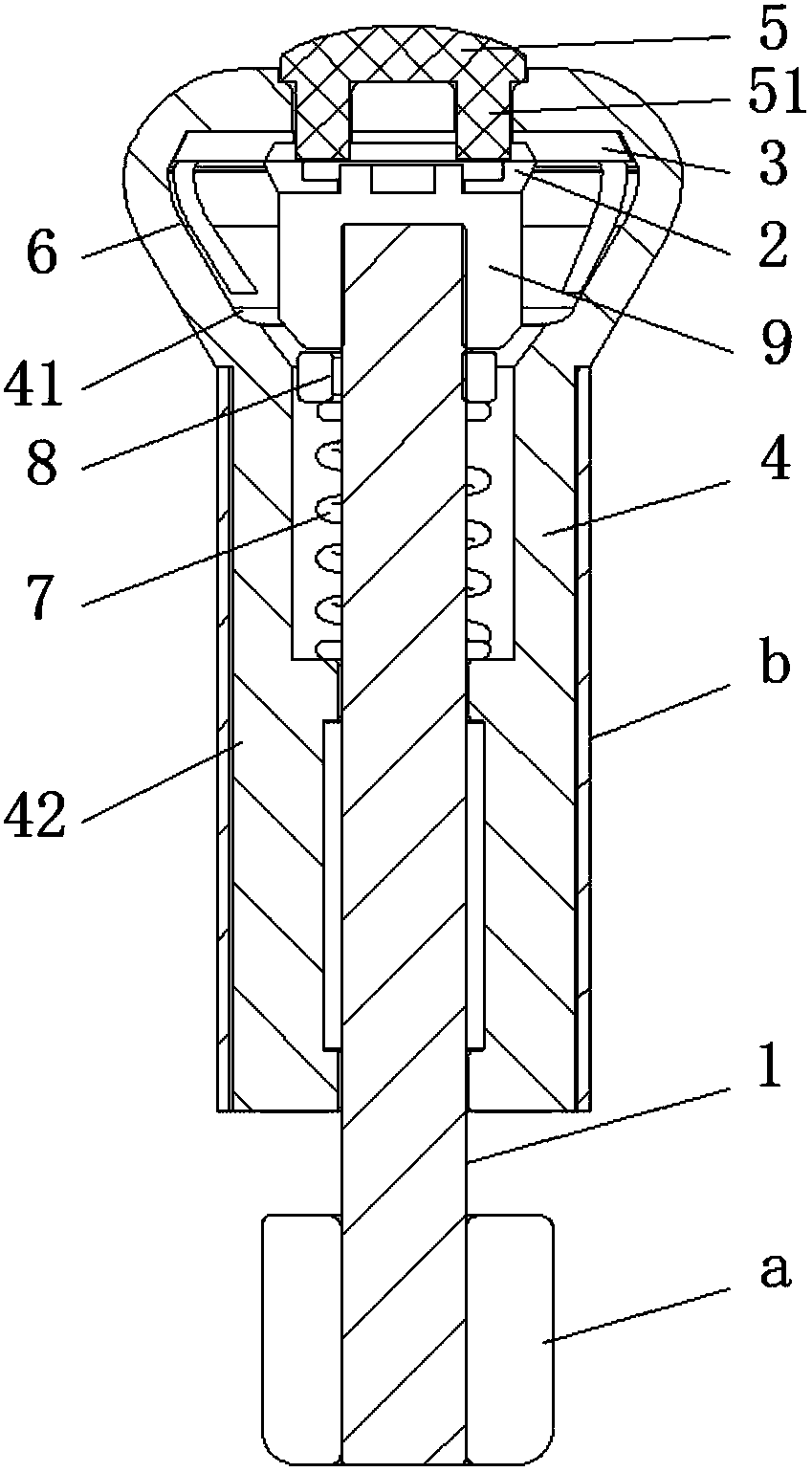

[0024] Please refer to the attached Figure 1-4 , a nose hair trimmer cutter head of the present embodiment is used to be connected to a handle with a transmission element, including a connecting rod 1, a moving knife 2, a fixed knife 3, a cutter head cover 4 and a face cover 5, the connection One end of the rod 1 is connected to the moving knife 2, and the other end is connected to the transmission element. The cutter head cover 4 includes a cutter covering part 41 and a connecting rod covering part 42. The cutter covering part 41 connects the moving knife The knife 2 and the fixed knife 3 are covered therein, the connecting rod covering part 42 covers the connecting rod 1, the fixed knife 3 is attached to the moving knife 2, and the moving knife 2 is in the transmission Under the driving of the element, the bottom surface of the fixed knife 3 rotates and cuts the nose hair in a sliding contact manner, and the pillar 51 on the face cover 5 penetrates from the top of the cutte...

Embodiment 2

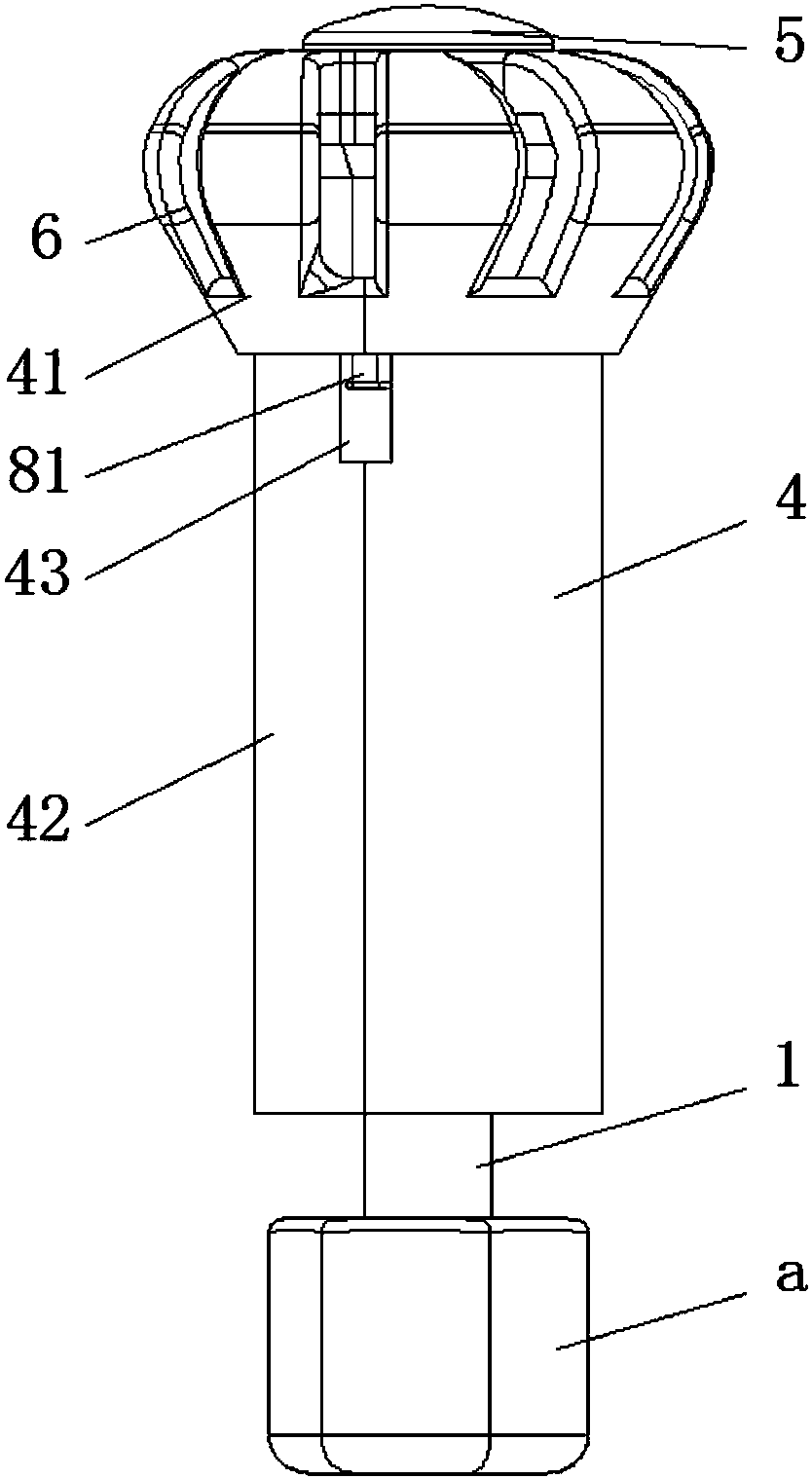

[0036] Please refer to the attached Figure 5 , The difference between this embodiment and Embodiment 1 is that the cutter head cover 4 is not composed of two split half-covers 44 , but the cutter covering part 41 is composed of an upper cover 411 and a lower cover 412 .

[0037] In this embodiment, the tool covering part 41 is composed of an upper cover 411 and a lower cover 412 . The cutter covering part 41 is arranged to be composed of the upper cover 411 and the lower cover 412 to facilitate the installation of the movable knife 2 and the fixed knife 3. After the movable knife 2 and the fixed knife 3 are installed, the The tool covering part 41 is synthesized. The combination of the upper cover 411 and the lower cover 412 may be fixed by spot glue or ultrasonic welding.

[0038] Other structures and corresponding effects of this embodiment are the same as those of Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com