Clipping machine for sisal fiber

A technology of sisal fiber and wool shearing machine, which is applied in the direction of continuous winding spinning machine, spinning machine, textile and papermaking, etc. It can solve the problems of lower production efficiency, easy shutdown of shearing machine for maintenance, and large loss of shearing machine. To achieve tight and smooth collection, ensure the effect of sisal, and improve the efficiency of shearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

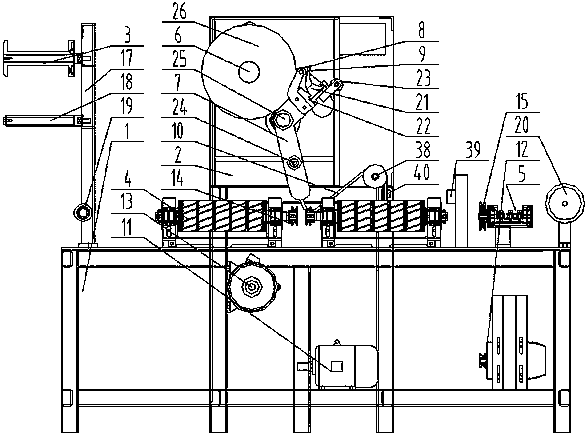

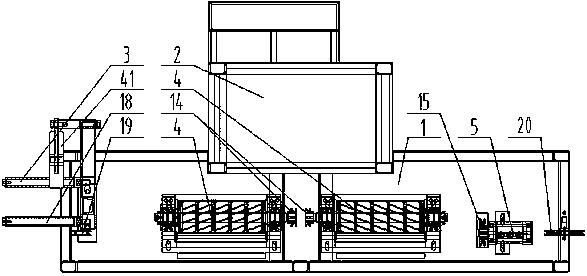

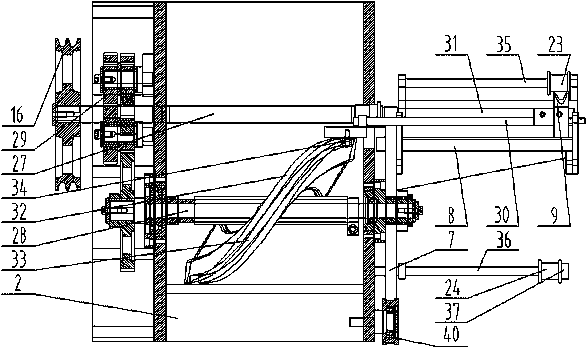

[0033] combine Figure 1~Figure 4 As can be seen, a kind of shearing machine of sisal fiber of the present invention comprises base frame 1, and the top of described base frame 1 rear side is fixed with receiving box 2, and the top surface of described base frame 1 is provided with discharging device, Shearing device and twisting device, the front end face of described material receiving box 2 is provided with material receiving device, and described material receiving device comprises the material receiving rod 6 that is rotatably connected to material receiving box 2, and the front end of described material receiving box 2 On the surface, the side of the receiving rod 6 facing the twisting device is provided with a receiving reciprocating wire device, and the receiving reciprocating wire device includes a receiving wire frame 9 fixed on a slider 21, and the slider 21 is along the The receiving rod 6 reciprocates in the axial direction, and the receiving rod 6 provides a driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com