Counterweight guide rail connecting device for elevator

A technology of counterweight guide rails and connecting devices, applied in transportation, packaging, elevators, etc., can solve the problems of complex structure, high manufacturing cost, high production cost, etc., and achieve easy installation and use, reduce manufacturing cost, and simple overall structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The counterweight guide rail connection device for elevators of the present invention will be further described in detail in conjunction with the accompanying drawings and embodiments of the present invention.

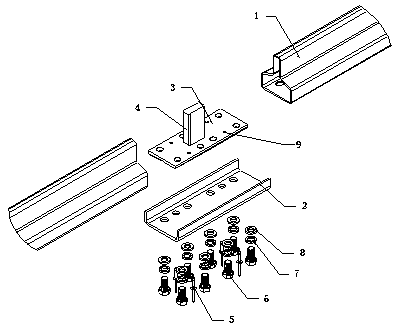

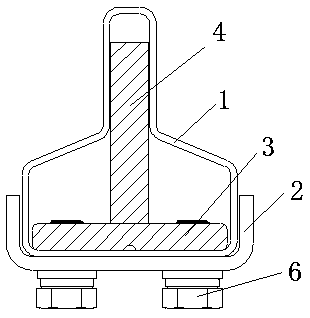

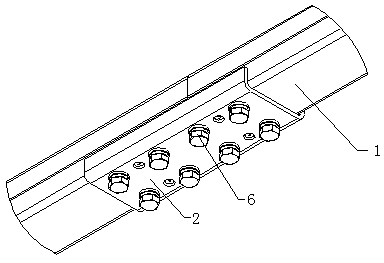

[0025] Such as figure 1 , figure 2 with image 3 As shown, the elevator counterweight guide rail connection device includes: guide rail backing plate 3, the two ends of the guide rail backing plate 3 are respectively inserted into the inside of the counterweight guide rail 1 to be connected, and are fixedly connected or detachably connected with the counterweight guide rail 1. Therefore, the connection between the counterweight guide rails 1 is convenient, and it is convenient for workers to operate, install and use. Due to its simple structure, the manufacturing cost of the connecting structure of the counterweight guide rail 1 is reduced, and the cost of the elevator is further reduced. In terms of material selection, the material selection of the guide ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com