A construction method for a circular silo

A construction method and circular technology, applied in the field of silos, can solve the problems of high cost, heavy workload, and high safety risks of scaffolding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

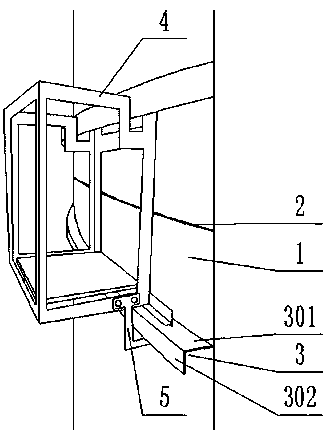

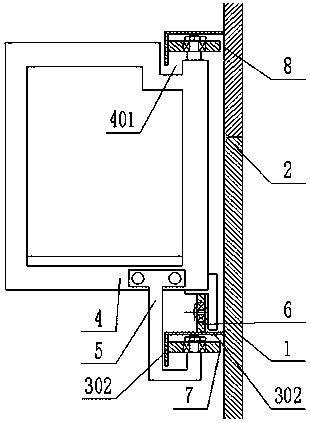

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0026] A construction method for a circular silo, comprising the steps of making a cylindrical silo enclosure part and the steps of making a top cover part above the silo enclosure part. When making the silo enclosure part, a plurality of cylindrical silos with equal diameters are prefabricated first. The two axial ends of the warehouse body are made of iron material, and then each warehouse body is hoisted and stacked together from bottom to top, and then the welding and fixing between each adjacent two warehouse bodies is completed sequentially from bottom to top, and then Installing the top cover to the top of the enclosure also includes the following steps:

[0027] A Before the enclosure of the circular trough is made, an annular guide rail is fixed on the outer circumference of each enclosure 1 that constitutes the enclosure, and the guide rail ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com