A magnetic fluid double suspension bearing system

A support bearing and double support technology, which is applied to bearings, shafts and bearings, mechanical equipment, etc., can solve the problems of low load capacity, small torque, wide temperature range, etc., to increase load capacity and stiffness, relieve design restrictions, improve Effects of Adjustability and Accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

[0025] The present invention is described in detail below in conjunction with accompanying drawing: As a kind of preferred scheme,

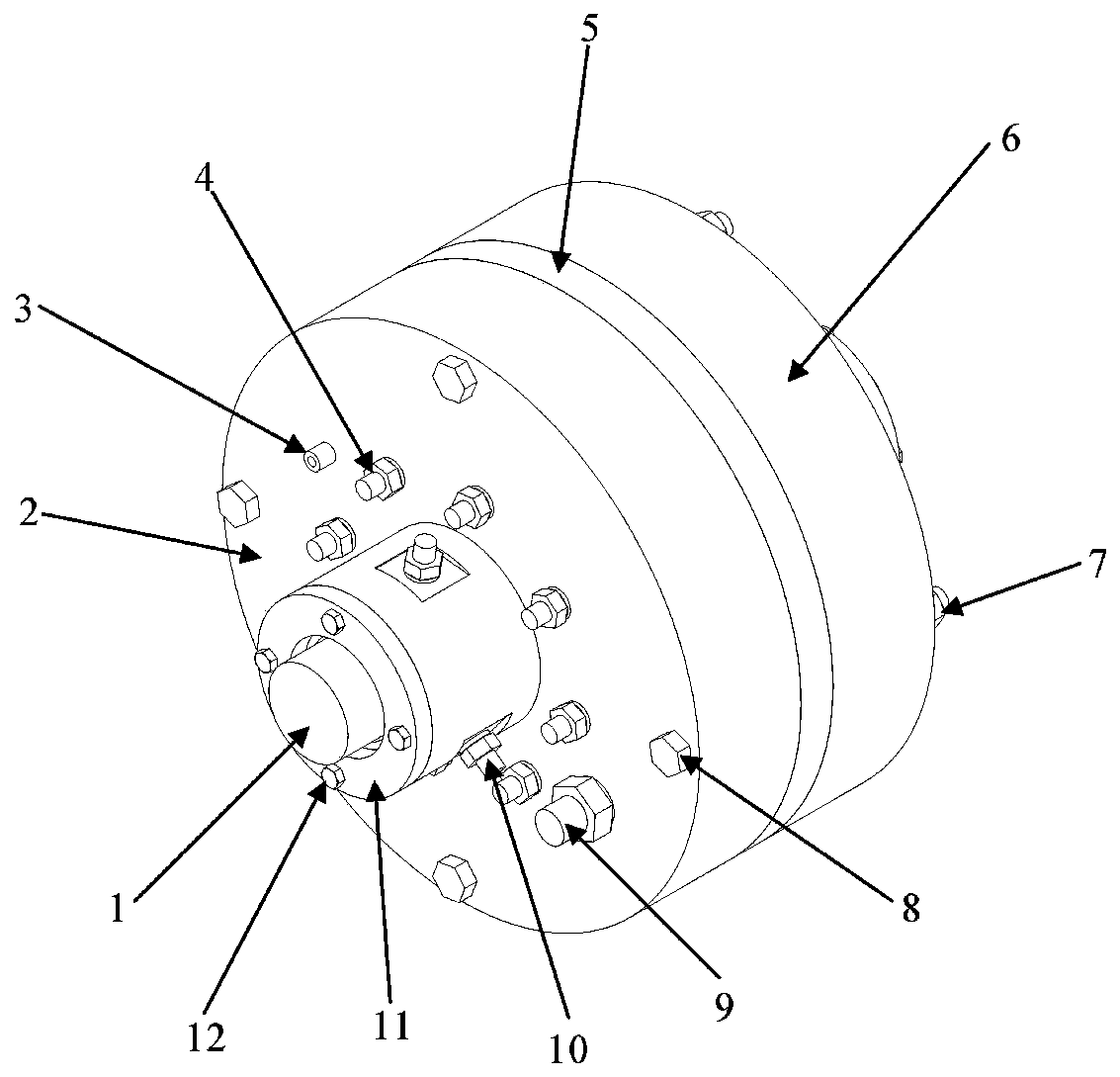

[0026] A magnetic fluid double suspension bearing system of the present invention, such as figure 1 As shown, a new type of magnetic fluid double support bearing system combining hydrostatic bearing and magnetic suspension bearing is adopted, which mainly includes hydrostatic bearing system and electromagnetic suspension bearing system.

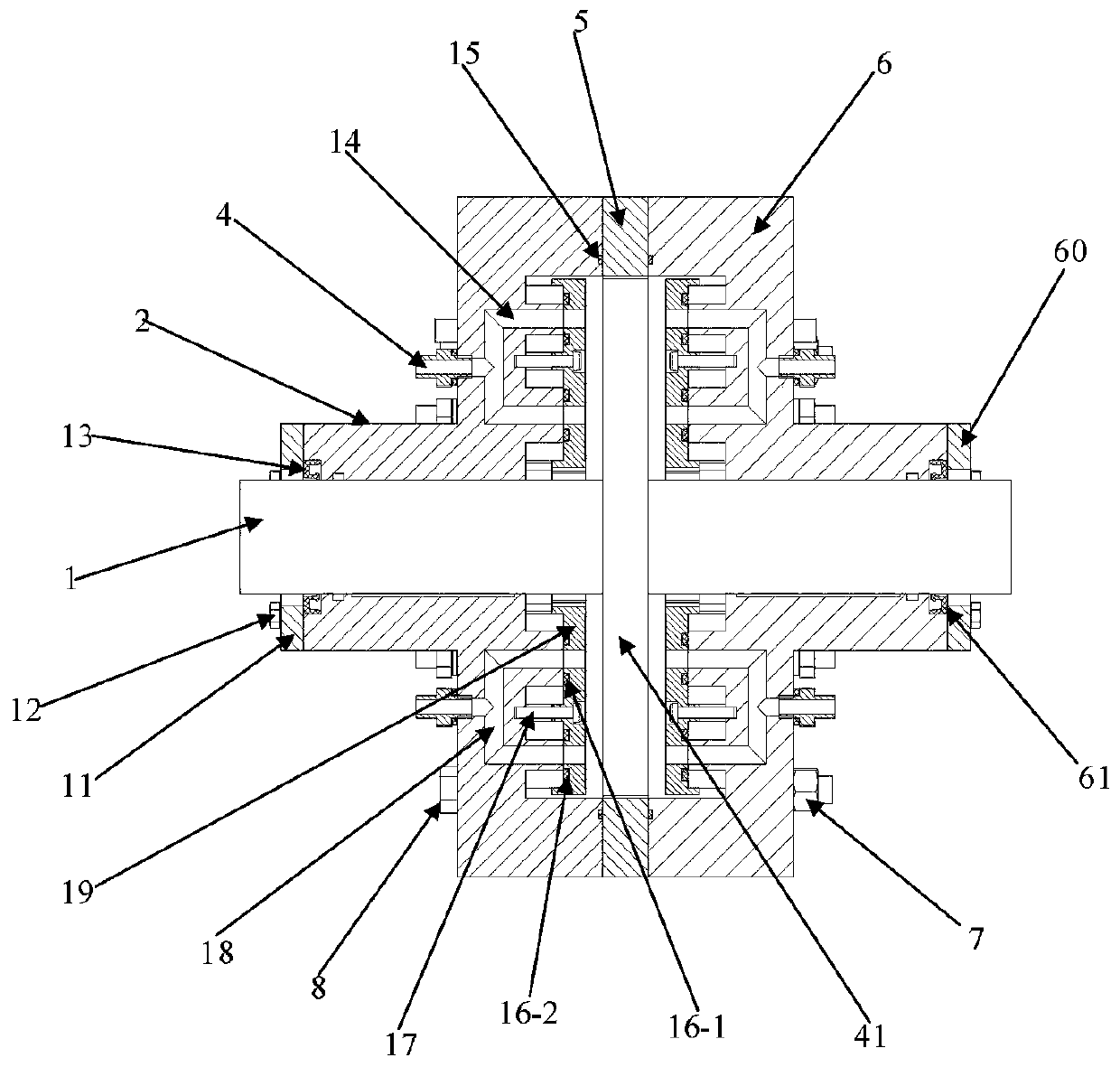

[0027] Such as figure 1 and 2 As shown, the magnetic fluid double suspension bearing system includes a first end cover 11, a first sealing frame 13, a first bushing 2, a shaft 1, a thrust plate 41, a gasket 5, a second end cover 60, a second Sealing frame 61 and second shaft sleeve 6;

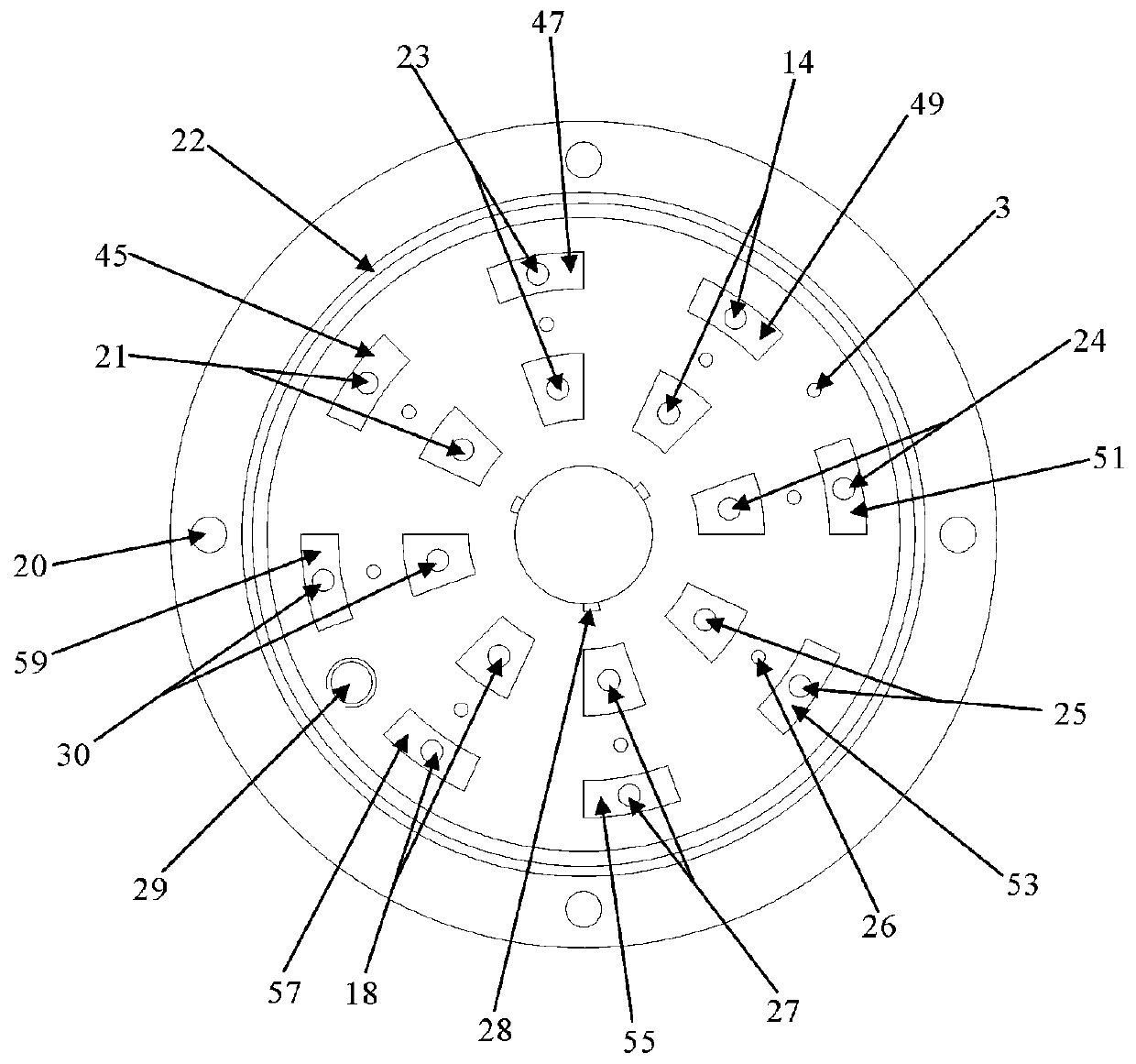

[0028] The first bushing 2, such as Figure 2-5 As shown, eight pairs of evenly distributed magnetic poles are arranged along the circumference at its inner end, each pair of magnetic poles is arranged radially, and the thick...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com