Automatic measurement device for hexasectioned orifice cage retainer

A technology of automatic measurement and measurement device, which is applied in the direction of mechanical diameter measurement, etc., can solve the problems affecting the accuracy and measurement efficiency of the cage cage with six equal holes, measurement data deviation, and low degree of automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

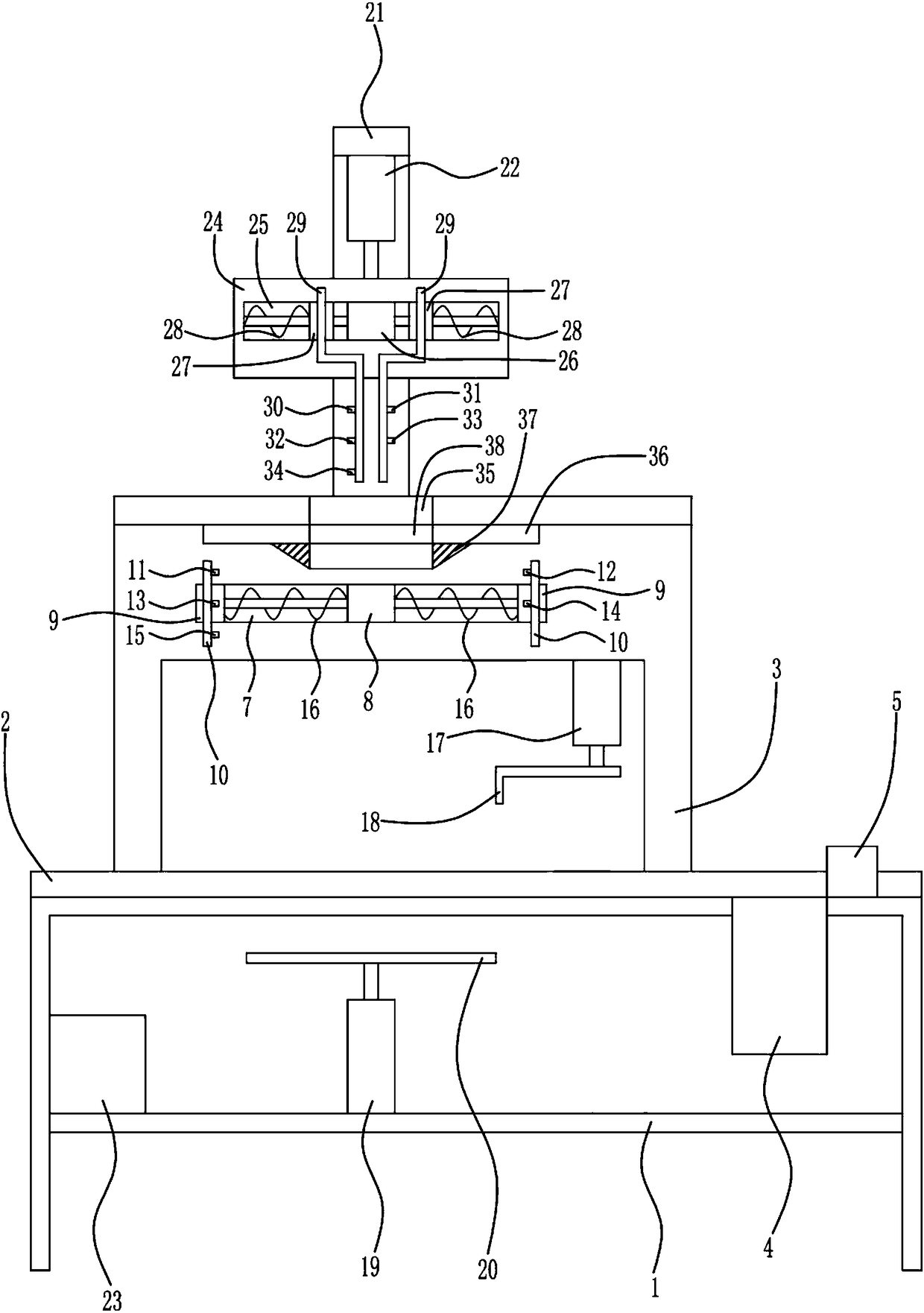

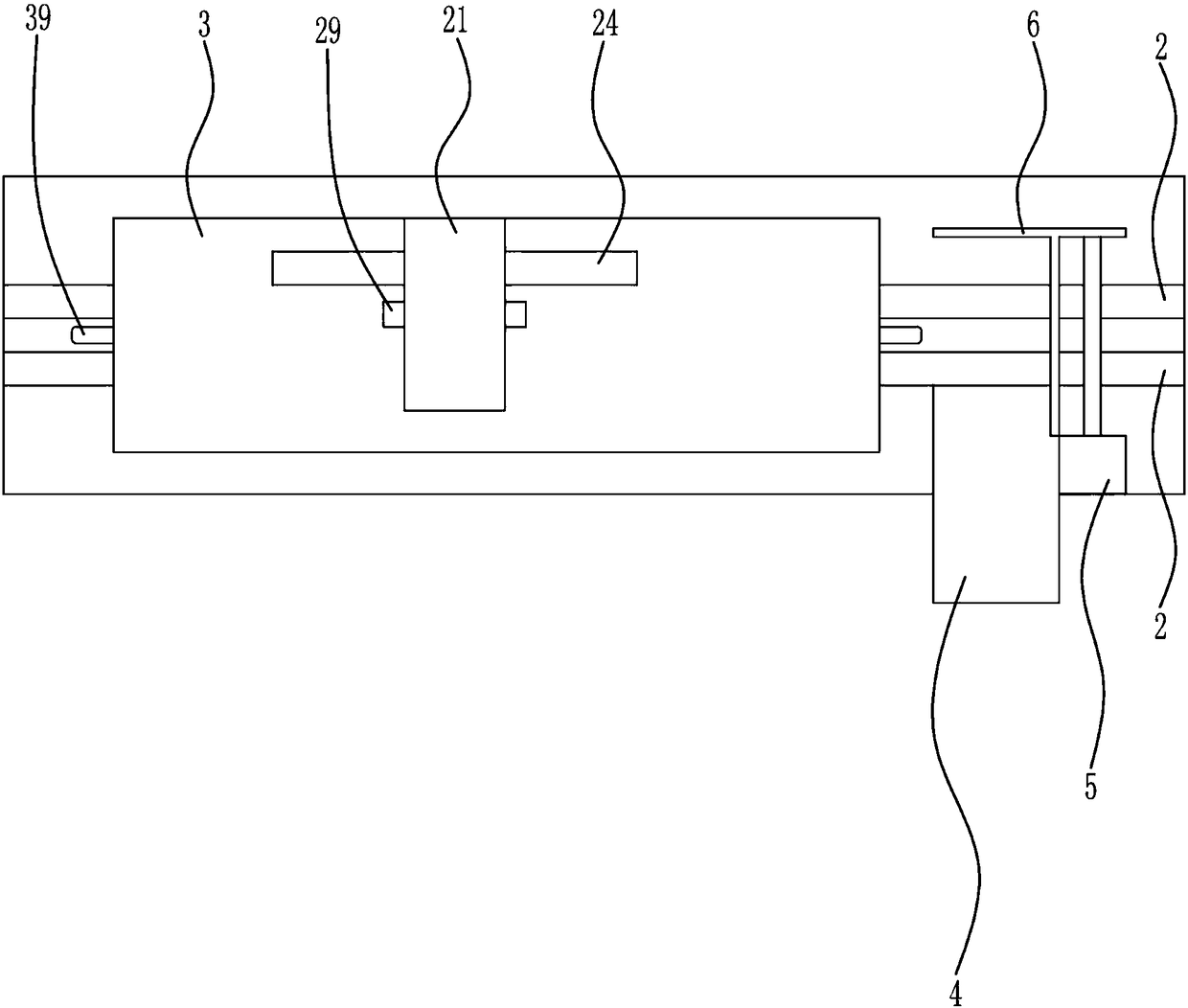

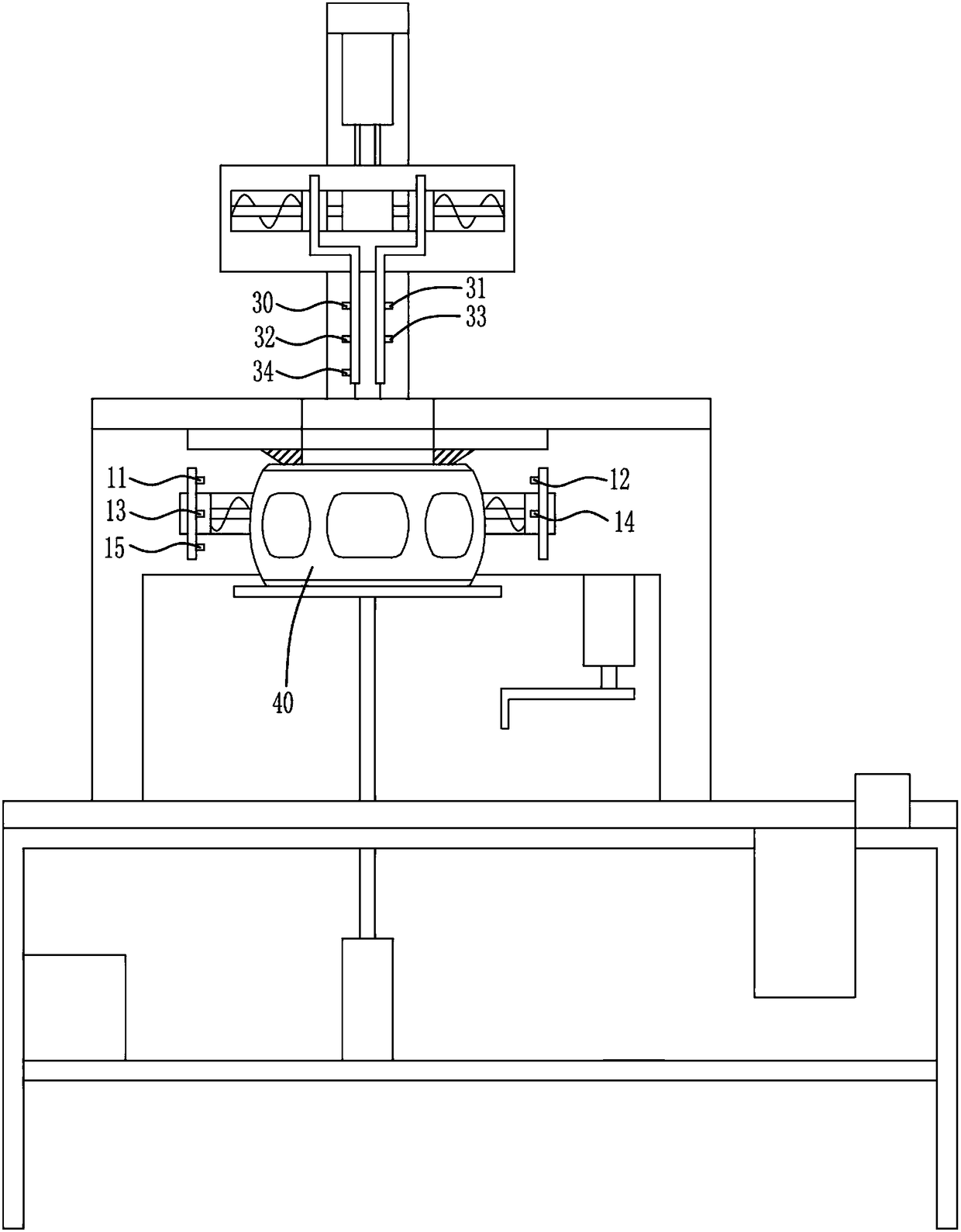

[0032] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the technical solutions in the specific embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings, so as to further illustrate the present invention. Obviously, the The specific implementations described are only some of the implementations of the present invention, but not all of them.

[0033] This embodiment is an automatic measuring device for the cage cage with six equally divided windows, such as Figure 1-Figure 6 as shown, figure 1 It is the front view of this embodiment, figure 2 It is a top view of the specific embodiment, image 3 It is the process state diagram of this embodiment, Figure 4 It is a schematic diagram of the structure of the cage with six equally divided windows, Figure 5 The parameter position diagram of the measured dimensions required f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com