Fiber residual length dynamic measuring system for steel pipe production line

A technology for optical fiber excess length and dynamic measurement, applied to measurement devices, instruments, etc., can solve the problems of time-consuming, wasteful optical fiber, grease, and accidental factors that cannot be eliminated, and achieve the effect of accurate measurement and calculation, and stable system control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] A dynamic measurement system for the excess length of an optical fiber used in a steel pipe production line according to the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

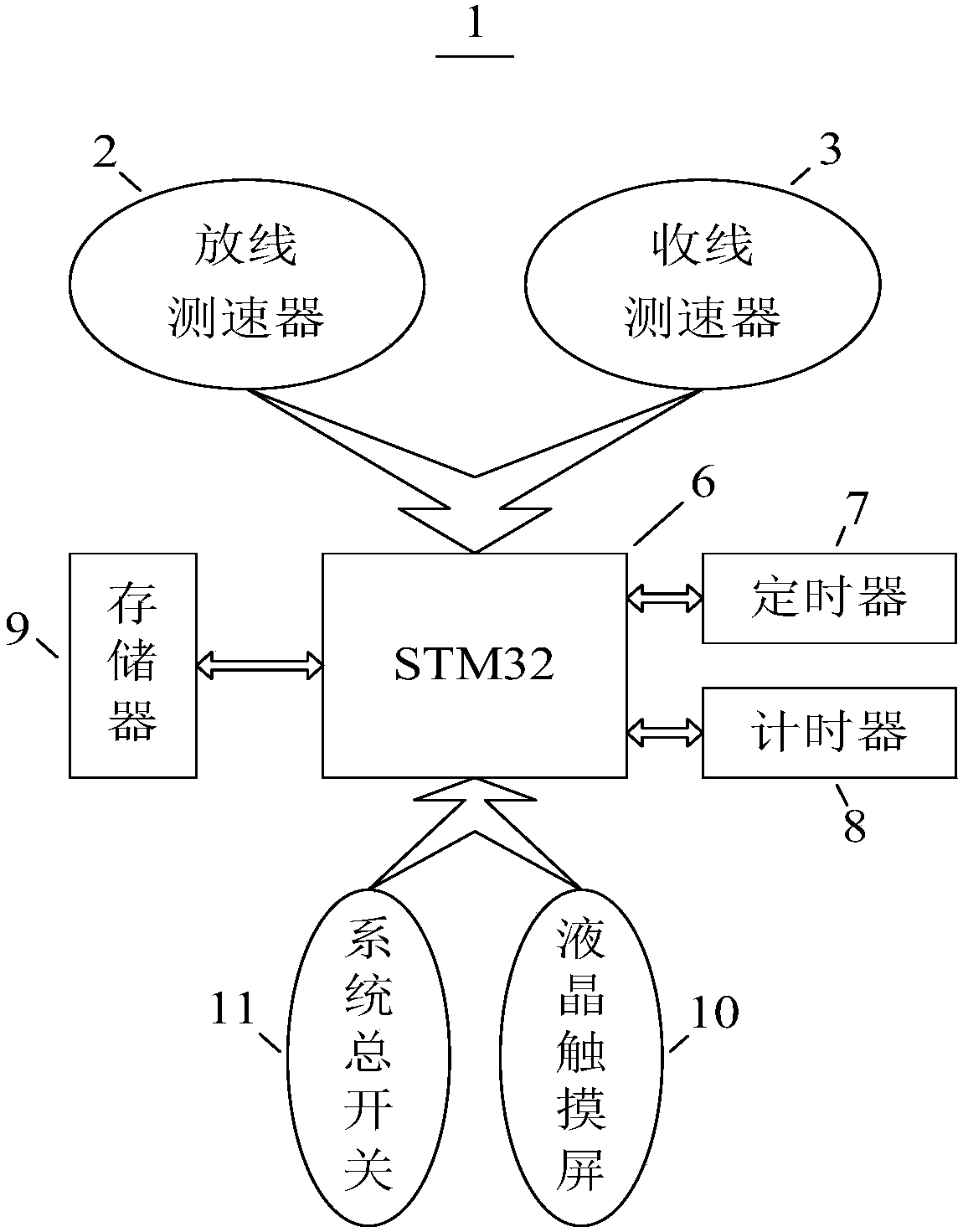

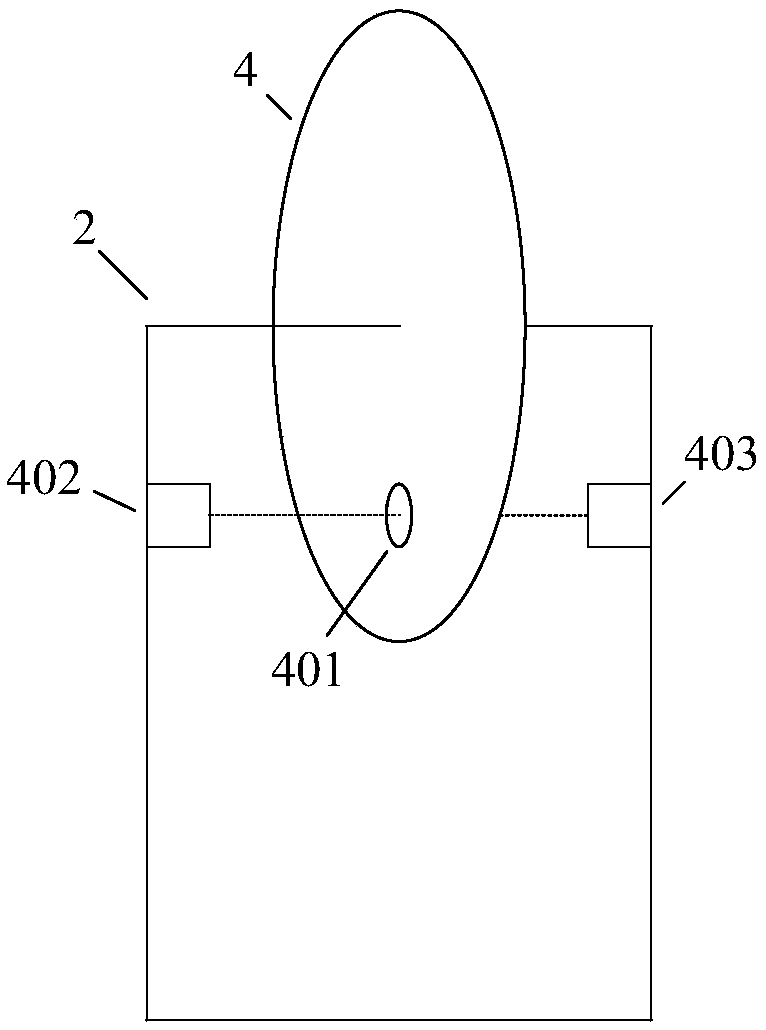

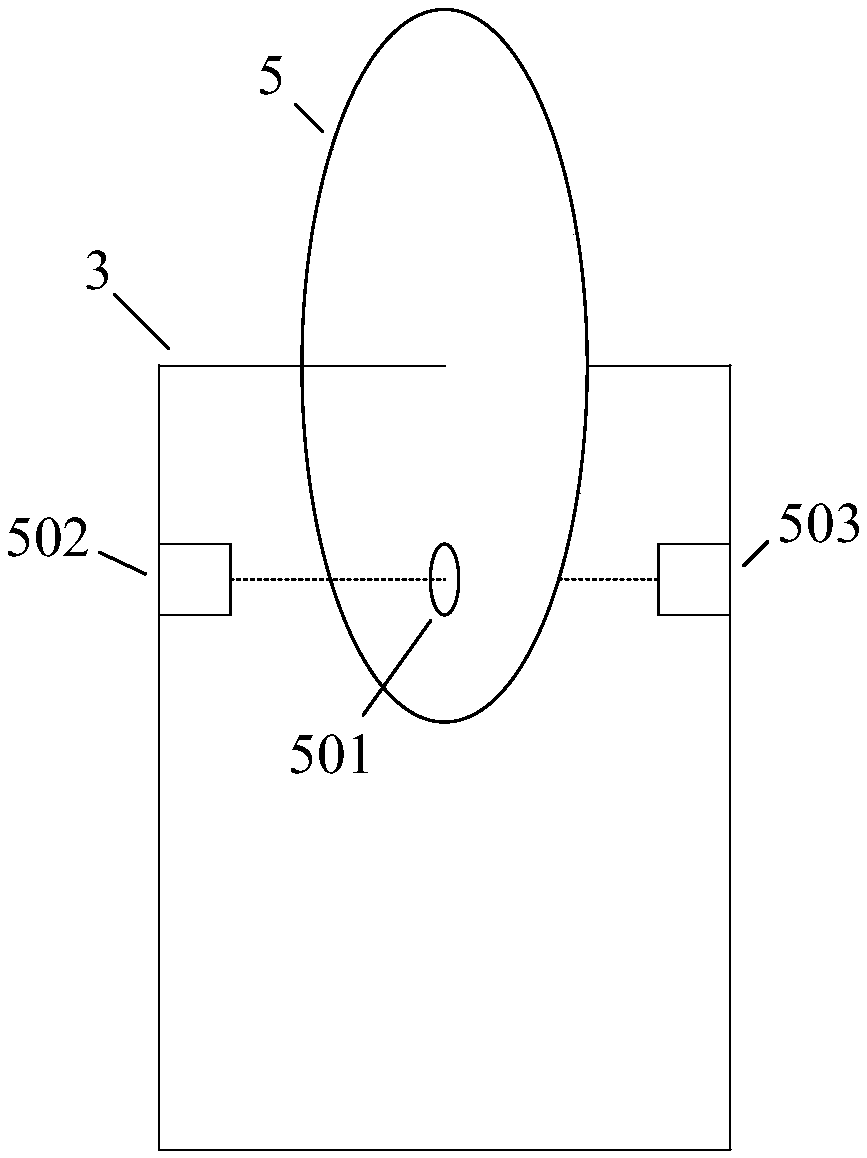

[0018] Such as figure 1 As shown, a dynamic measurement system for optical fiber excess length for a steel pipe production line of the present invention includes a system main body 1 and an STM32 main control chip 6 installed in the system main body 1 , a pay-off speed detector 2 and a wire take-up speed detector 3 . The STM32 main control chip 6 is electrically connected with a liquid crystal touch screen 10 and a system master switch 11, and the peripheral circuit of the STM32 main control chip 6 is provided with a timer 7, a timer 8 and a memory 9, and the timer 7, the timer 8 and the memory 9 are all It is electrically connected with the STM32 main control chip 6 . The main body of the system 1 is attached to the steel p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com