Bucket lever metering device

A metering device and lever-type technology, which is applied in the field of bucket lever-type metering devices, can solve the problems of uneven falling impact, low production efficiency, high moisture content, etc., and achieve high reliability and stability, convenient operation and maintenance, cost-effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

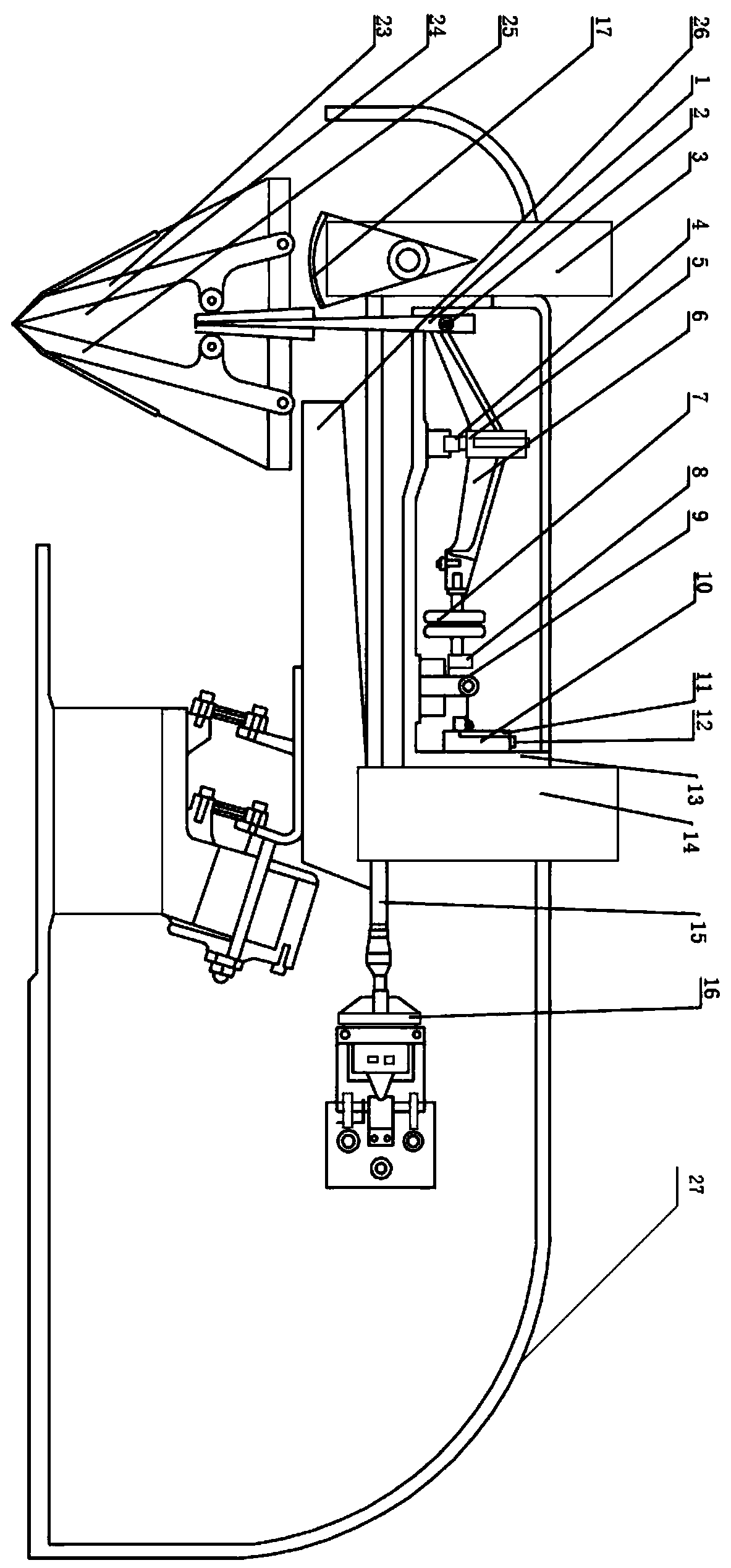

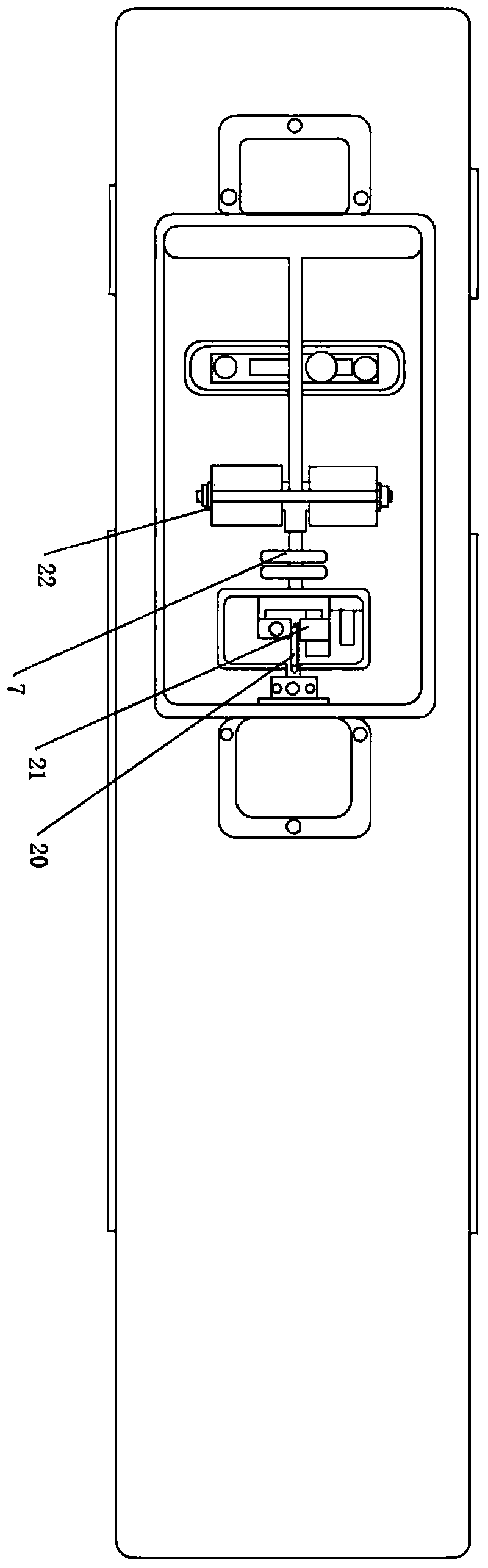

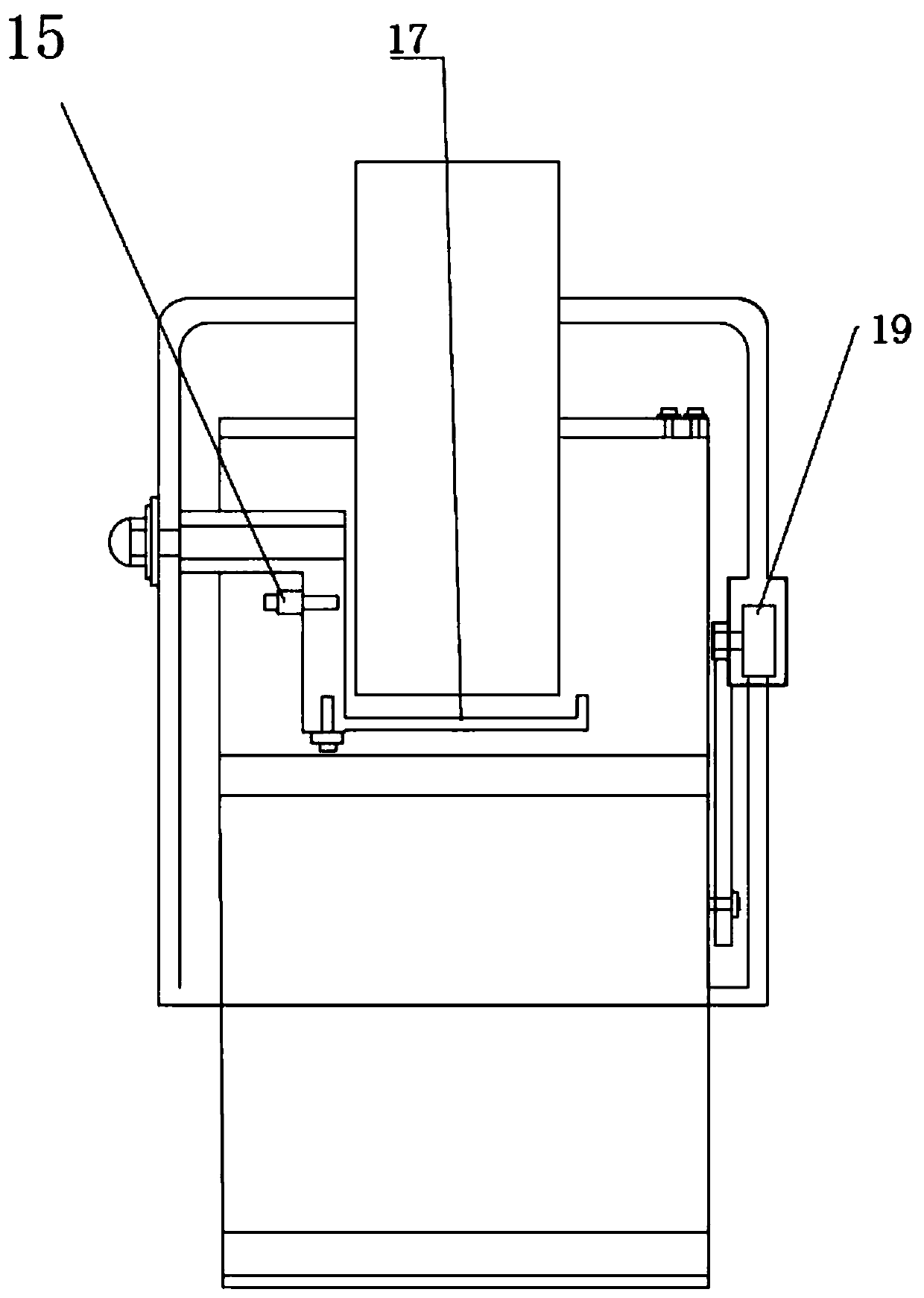

[0033] Such as Figure 1-3 As shown, a bucket lever type metering device, said device includes a cover body 27 and a bucket lever type metering device body located in the cover body 27,

[0034] The cover body 27 is provided with a first assembly area and a second assembly area, the first and second assembly areas are separated by a spacer 13, and the main body of the bucket lever type metering device body is arranged in the first assembly area; The main body of the bucket lever type metering device includes the following components:

[0035] The hanging bucket 24 is located below the first assembly area and is composed of a left hanging bucket 23 and a right hanging bucket 25. The left and right hanging buckets can be relatively opened and closed, and the top of the hanging bucket 24 is fixed with a connecting structure;

[0036] The metering mechanism is located in the first assembly area, which includes a crossbeam 6, the middle part of the crossbeam 6 is horizontally fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com