Electric wire bundling device

A power line and surface fixing technology, applied to electrical components, etc., can solve problems such as poor flexibility, mixed wires, and large usage, and achieve the effects of improving efficiency, reducing labor intensity, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

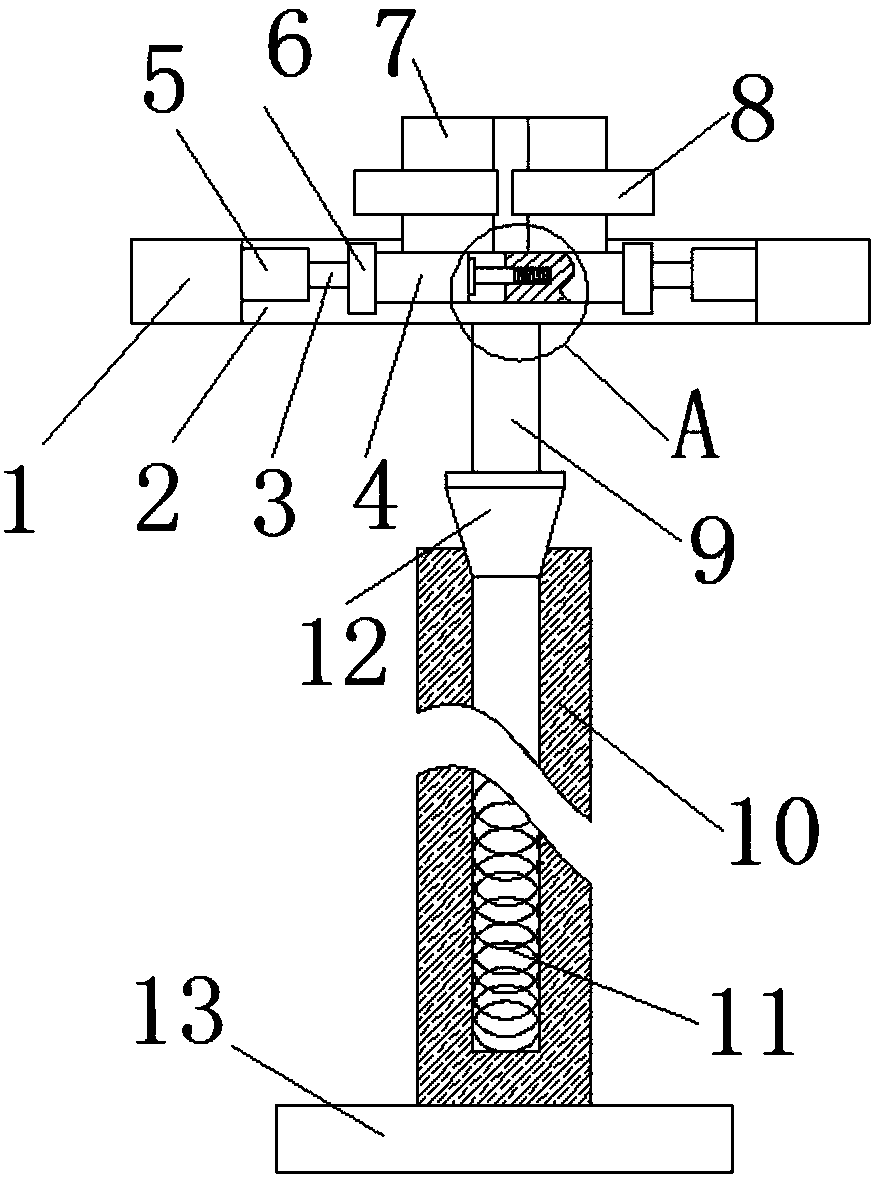

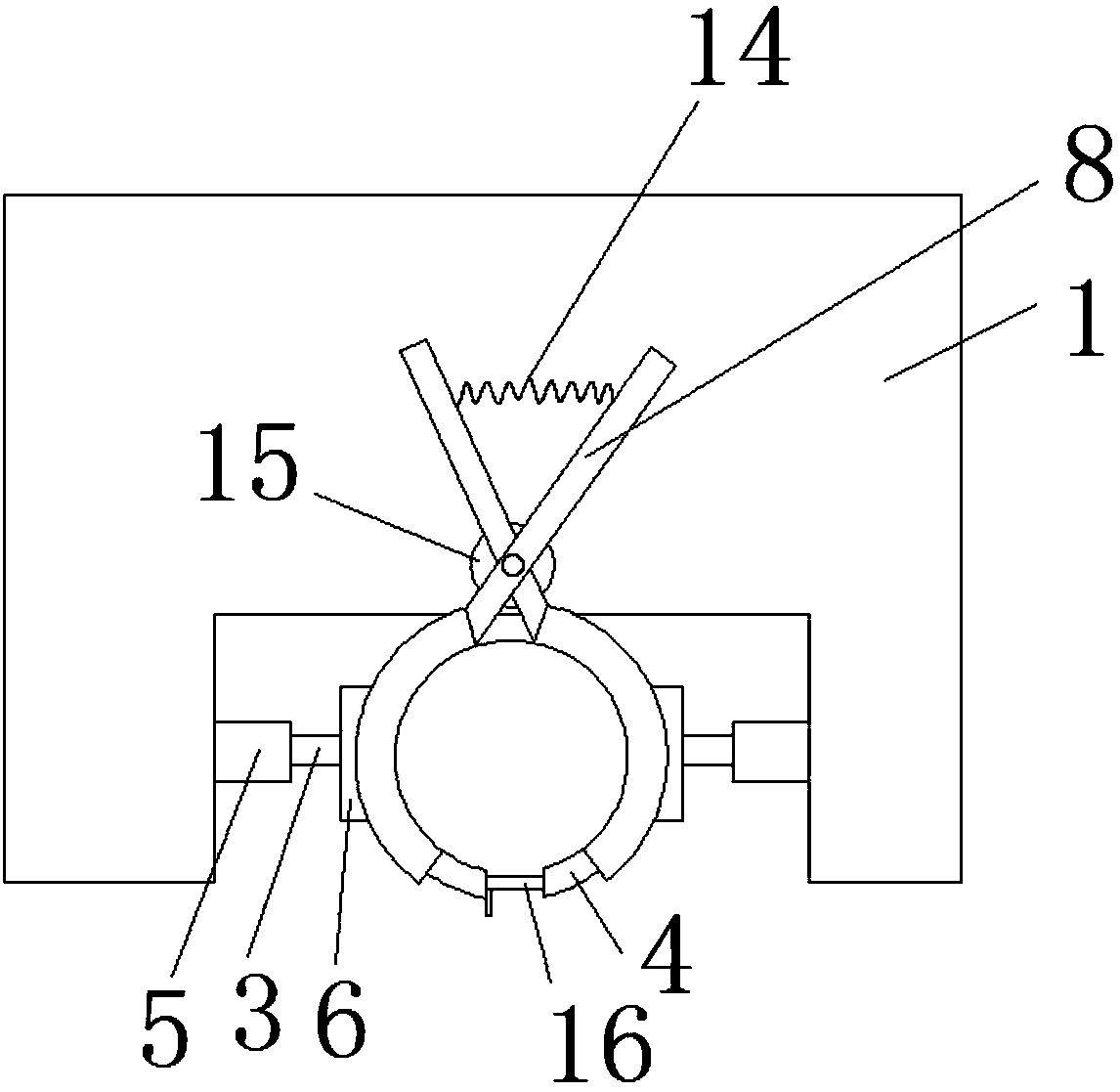

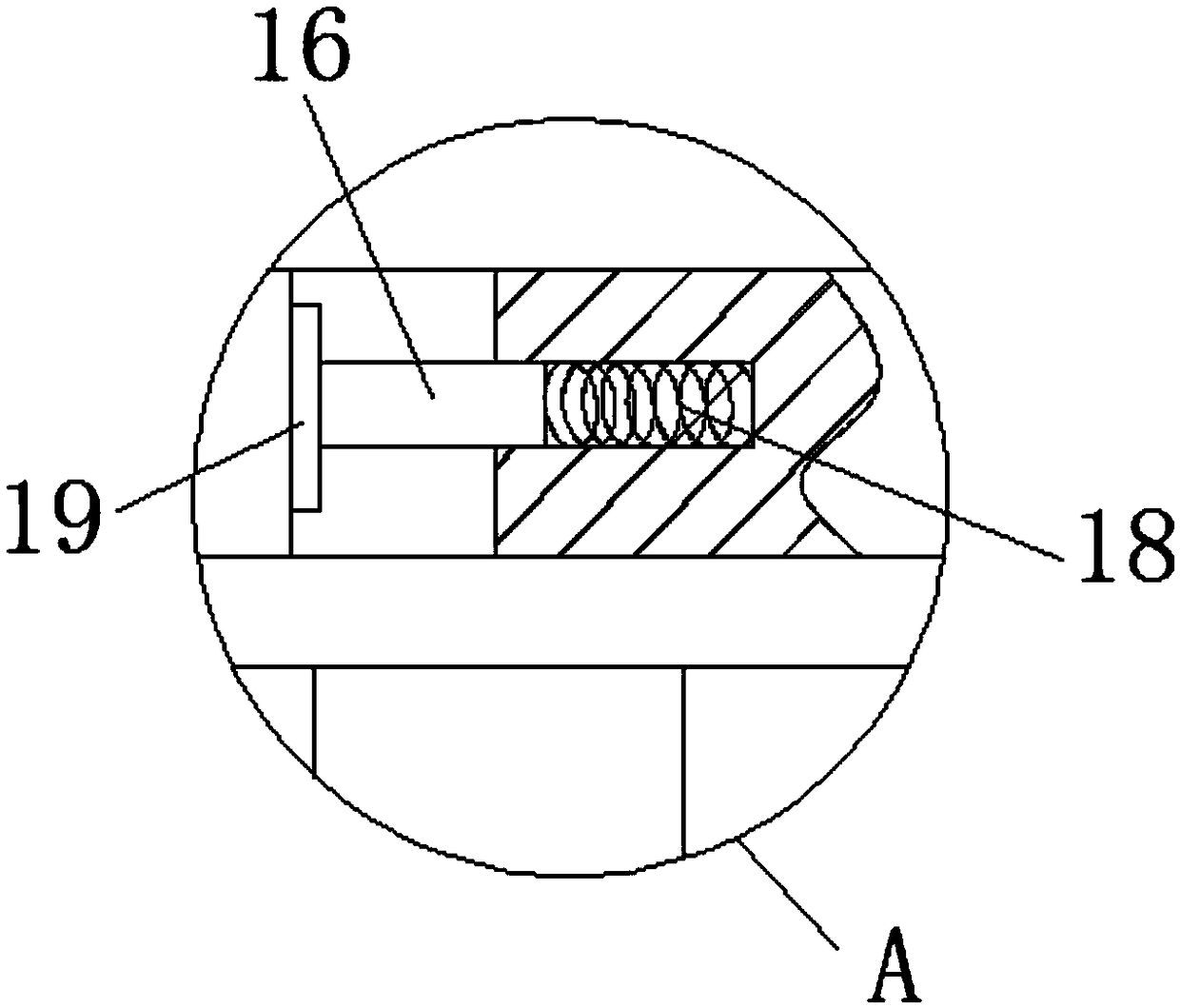

[0026] Such as Figure 1-4 As shown, in the embodiment of the present invention, a power line harness device includes a support plate 1, a rectangular opening is opened on the upper surface of the support plate 1, and elastic rods 2 are fixedly connected to the inner walls of the left and right sides of the rectangular opening, elastically stretchable Rod 2 comprises outer rod 5, is provided with second cavity in outer rod 5, and is provided with fourth spring 17 and inner rod 3 in the second cavity, and the two ends of fourth spring 17 are connected with the inner wall of cavity and the inner rod respectively. One end of the rod 3 is fixedly connected, the other end of the inner rod 3 passes through the second cavity and extends outwards, the opposite sides of the two elastic telescopic rods 2 are fixedly connected with a fixed block 6, and the opposite side of the two fixed blocks 6 Both sides are provided with arc-shaped grooves, and the surface of the arc-shaped grooves is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com