Energy-saving lean control method for air tobacco supply

A control method and wind wire feeding technology, applied in the manufacture of cigarettes, applications, tobacco, etc., can solve the problems of energy waste, increased material crushing and moisture loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, thereby making a clearer definition of the protection scope of the present invention;

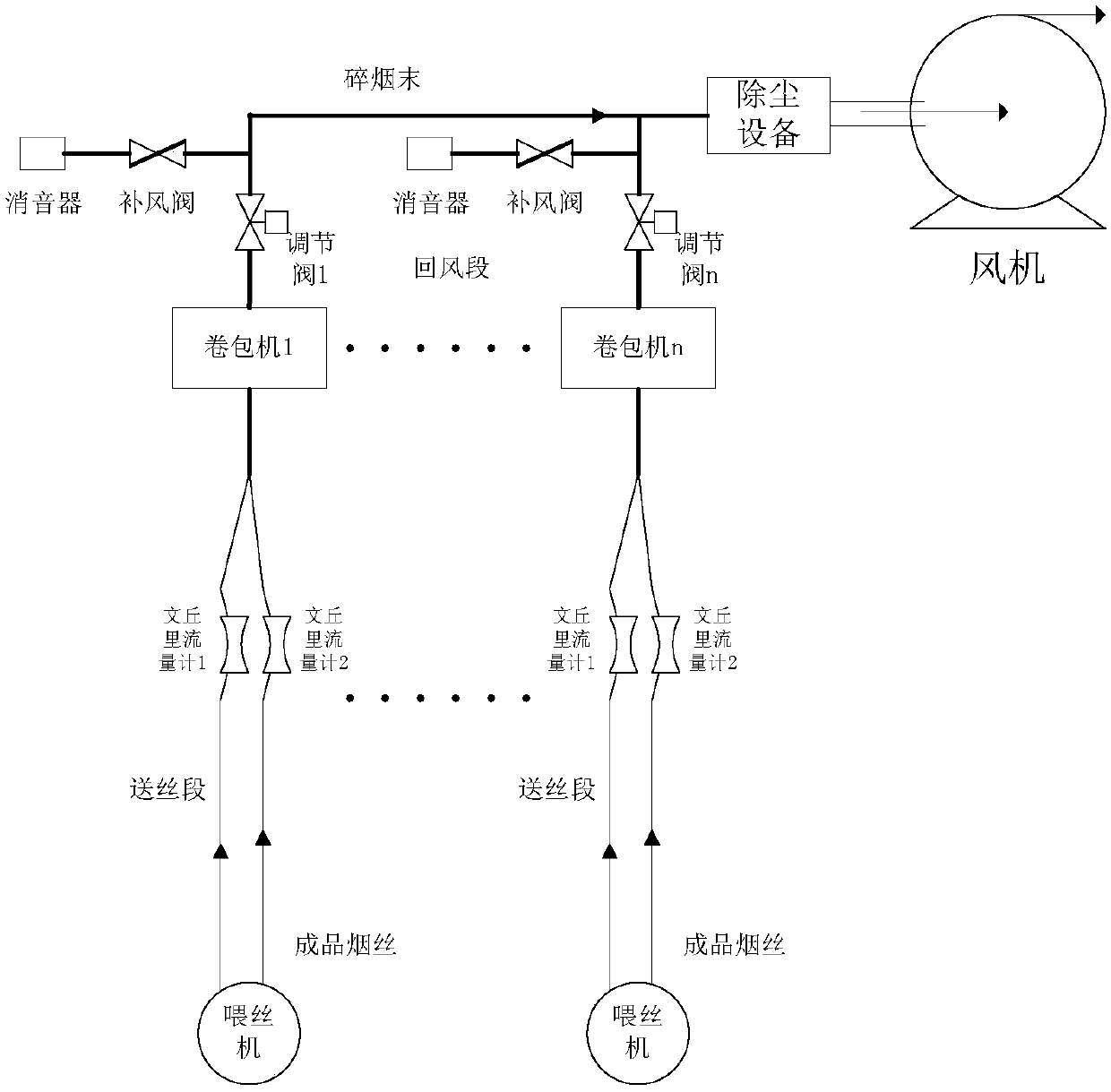

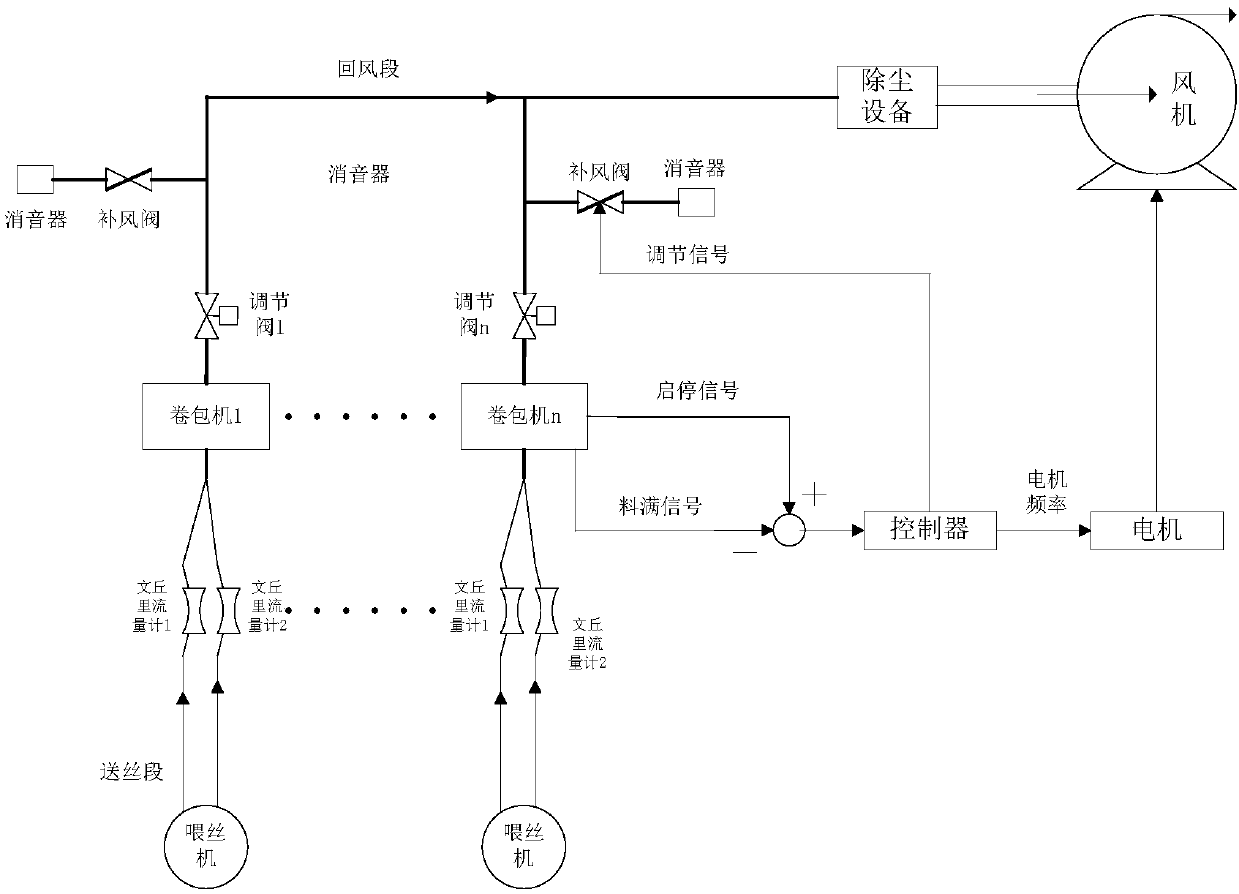

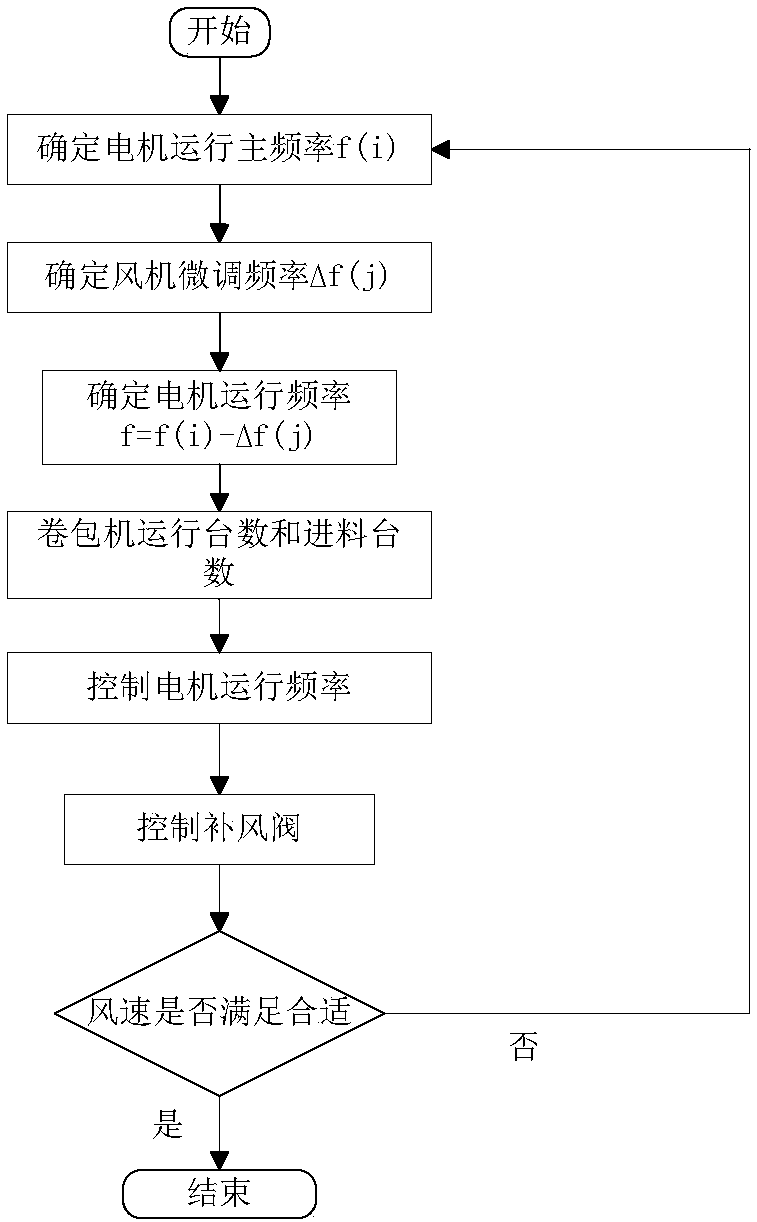

[0035] Such as Figure 2-3 As shown, the present embodiment is as follows to the method for lean control of fan wind power in tobacco enterprises:

[0036] The invention relates to an energy-saving and lean control method for wind-forced wire-feeding. Through in-depth analysis of the operating characteristics and process requirements of the wind-forced wire-feeding system, the changing law of the wind-forced wire-feeding working condition is found out. Determine the main frequency of motor operation according to the number of wrapping units in operation, and then determine the fine-tuning motor frequency according to the different mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com