A rice processing and conveying equipment that improves the stability of collecting tanks

A technology for rice processing and conveying equipment, applied in solid separation, chemical instruments and methods, grids, etc., can solve the problems of incomplete collection, low collection efficiency, poor stability of the collection tank, etc., and achieve easy popularization and use and improve stability. , the effect of preventing clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

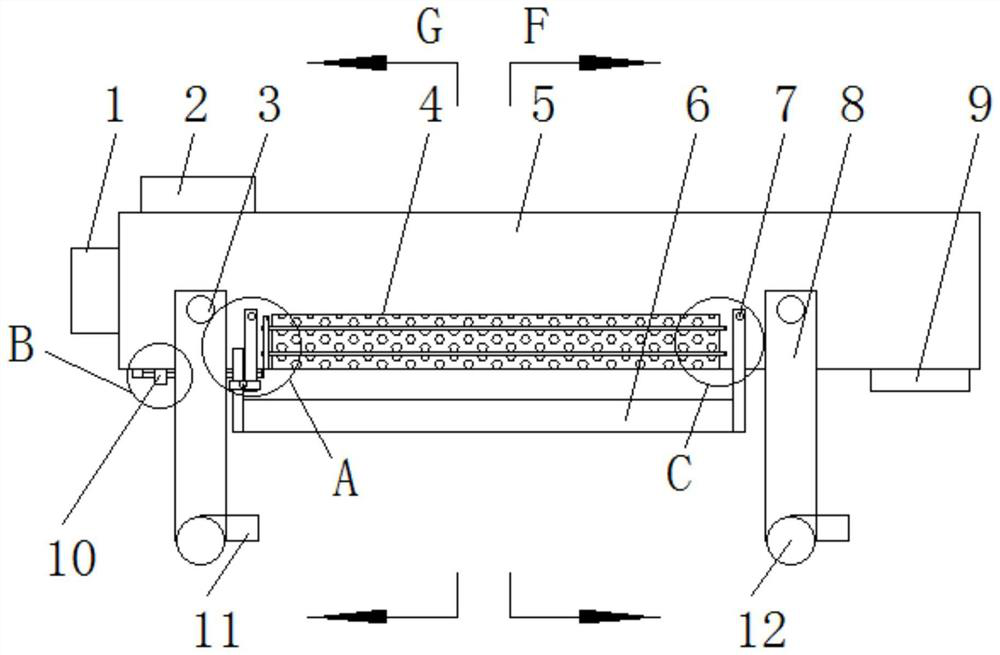

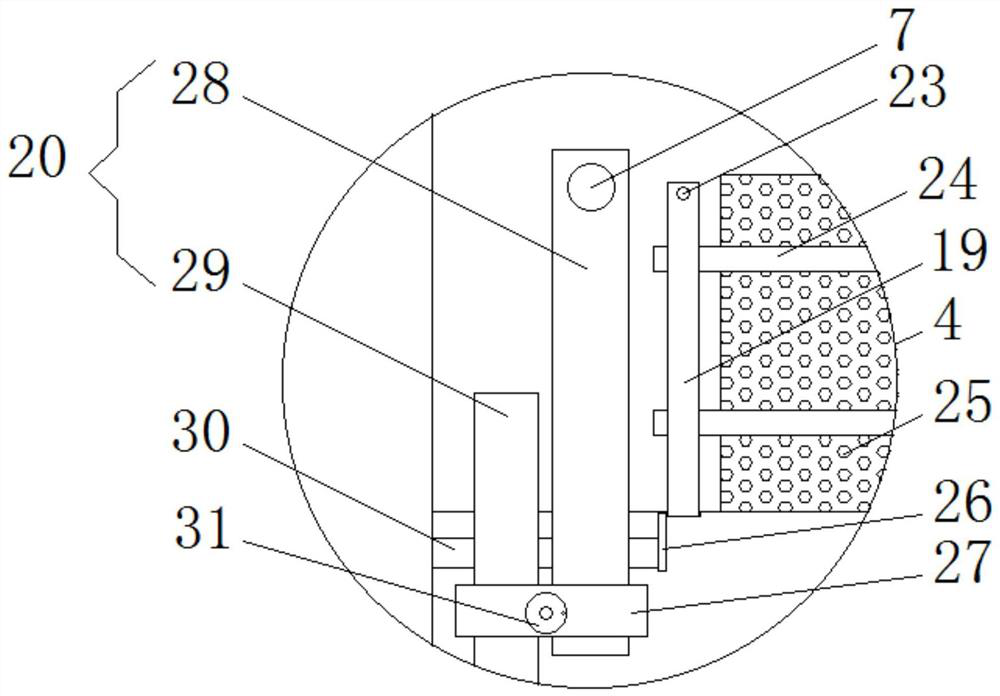

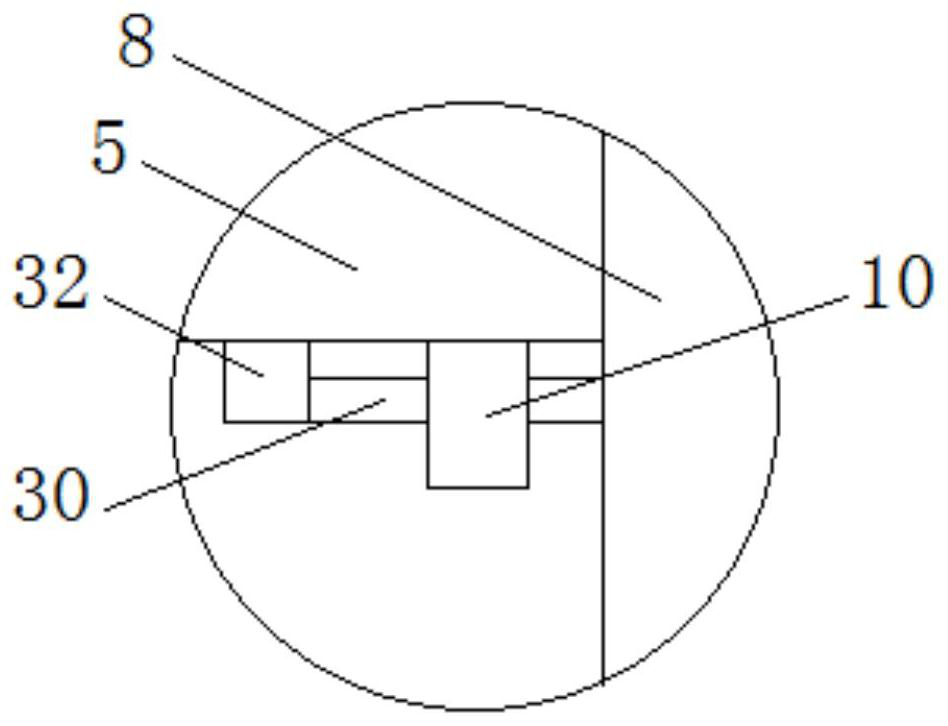

[0025] Embodiment 1, a kind of rice processing and conveying equipment that improves the collection stability of the collection tank, includes a device main body 5, the upper end of one side of the device main body 5 is provided with a feed inlet 2, and the bottom of the other side of the device main body 5 is provided with an outlet The feed opening 9, and the inside of the device main body 5 is provided with a rotating shaft 39, the rotating shaft 39 is provided with some evenly distributed auger blades 38, the two ends of the device main body 5 are provided with symmetrically distributed fixed mounts 8, and the device main body 5 The middle part is provided with a separation sieve 4, and the separation sieve 4 is provided with a number of evenly distributed sieve holes 25, and the two ends of the separation sieve 4 are respectively provided with a symmetrically distributed first fixed rod 15 and a second fixed rod 20. The bottoms of the first fixing rod 15 and the second fix...

Embodiment 2

[0030] Embodiment 2, a kind of rice processing and conveying equipment that improves the collection stability of the collection tank, includes a device main body 5, the upper end of one side of the device main body 5 is provided with a feed inlet 2, and the bottom of the other side of the device main body 5 is provided with an outlet. The feed port 9, and the inside of the device main body 5 is provided with a rotating shaft 39, the rotating shaft 39 is provided with some evenly distributed auger blades 38, the two ends of the device main body 5 are provided with symmetrically distributed fixed mounts 8, and the device main body 5 The middle part is provided with a separation screen 4, and the separation screen 4 is provided with a number of uniformly distributed screen holes 25, and the two ends of the separation screen 4 are respectively provided with a symmetrically distributed first fixed rod 15 and a second fixed rod 20. The bottoms of the first fixing rod 15 and the secon...

Embodiment 3

[0036] Embodiment 3, a kind of rice processing and conveying equipment that improves the collection stability of the collection tank, includes a device main body 5, the upper end of one side of the device main body 5 is provided with a feed inlet 2, and the bottom of the other side of the device main body 5 is provided with an outlet. The feed opening 9, and the inside of the device main body 5 is provided with a rotating shaft 39, the rotating shaft 39 is provided with some evenly distributed auger blades 38, the two ends of the device main body 5 are provided with symmetrically distributed fixed mounts 8, and the device main body 5 The middle part is provided with a separation sieve 4, and the separation sieve 4 is provided with a number of evenly distributed sieve holes 25, and the two ends of the separation sieve 4 are respectively provided with a symmetrically distributed first fixed rod 15 and a second fixed rod 20. The bottoms of the first fixing rod 15 and the second fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com