A rice processing conveying device with good mobile flexibility

A technology for rice processing and conveying devices, which is applied in solid separation, chemical instruments and methods, grids, etc., can solve the problems of utilization of conveying devices, time-consuming and laborious, troublesome handling and moving, etc., to prevent clogging, improve flexibility, and improve handling. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

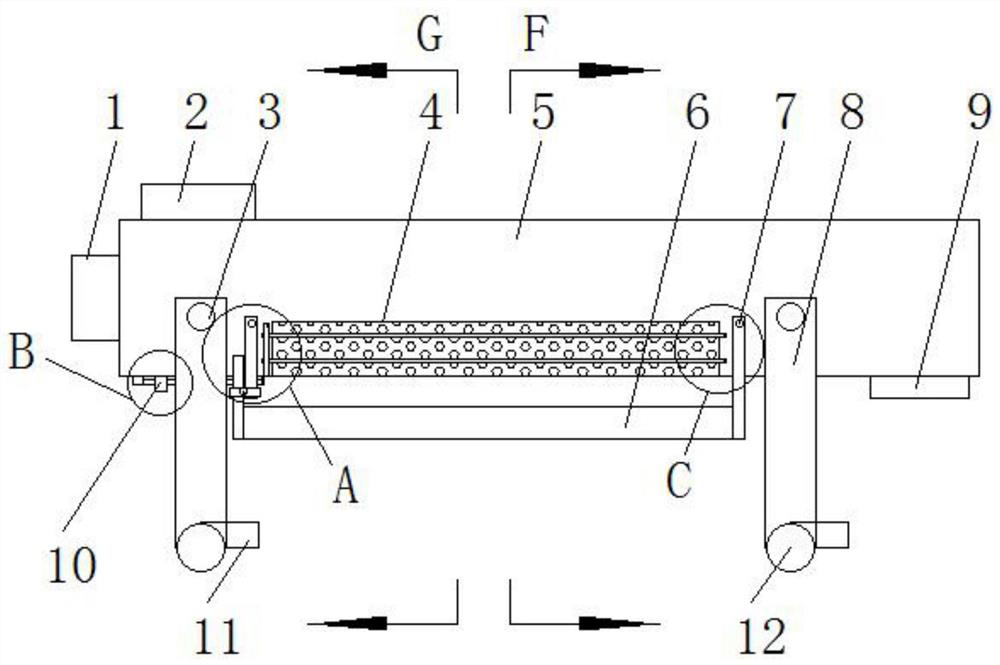

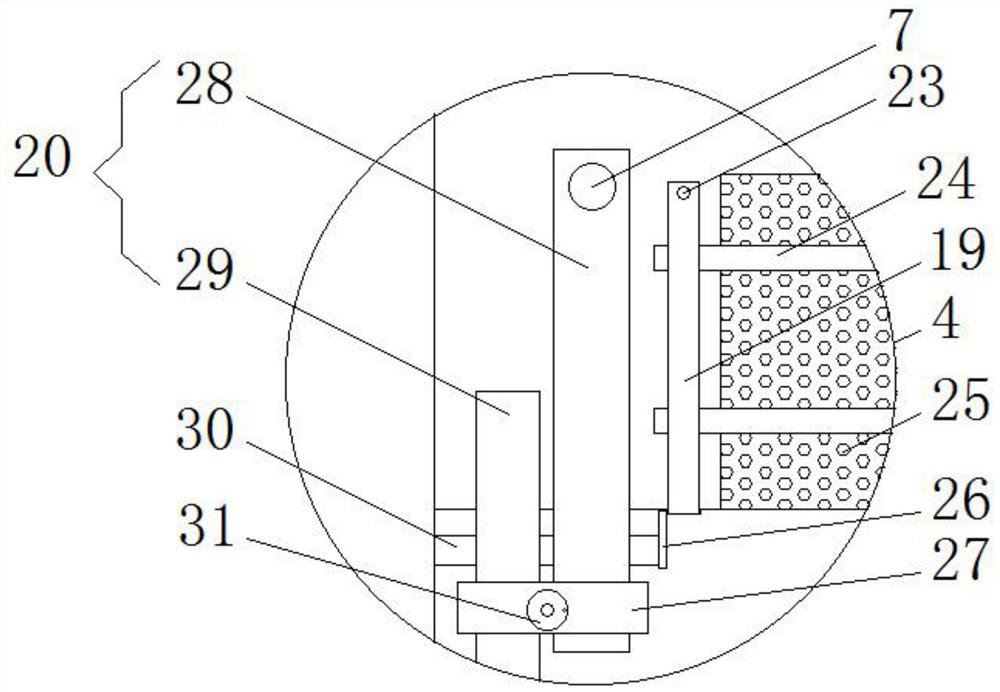

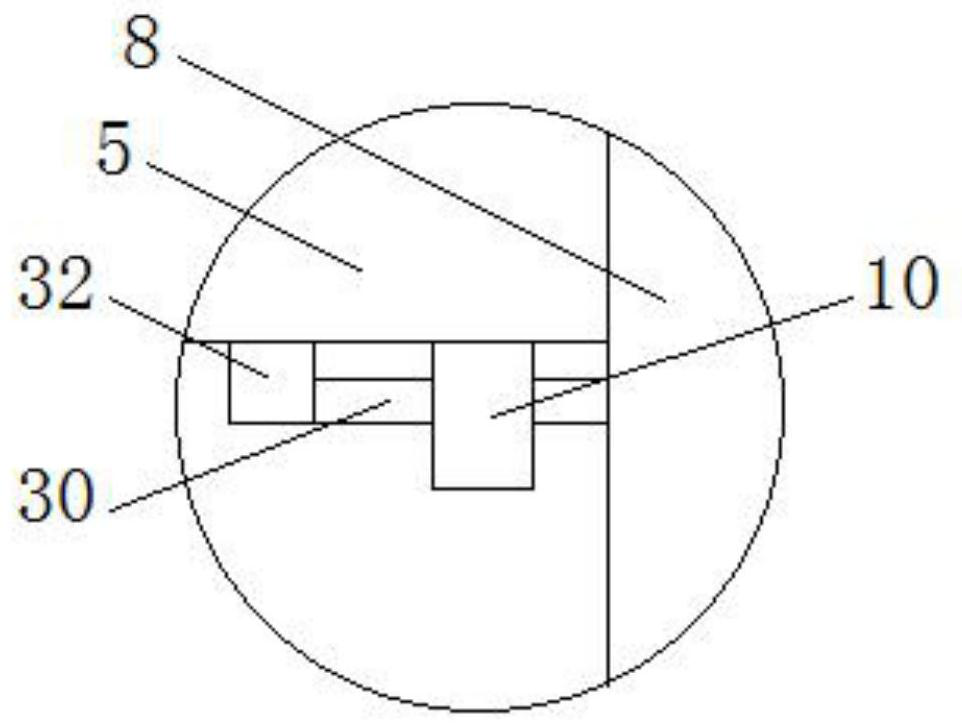

[0027] Embodiment 1, a rice processing and conveying device with good mobile flexibility, including a device main body 5, the upper end of one side of the device main body 5 is provided with a material inlet 2, and the bottom of the other side of the device main body 5 is provided with a discharge mouth 9, and the interior of the main body 5 of the device is provided with a rotating shaft 39, on which a number of uniformly distributed auger blades 38 are arranged, the two ends of the main body 5 of the device are provided with fixed mounts 8 symmetrically distributed, and the middle part of the main body 5 of the device A separation sieve 4 is provided, and the separation sieve 4 is provided with a number of evenly distributed sieve holes 25, and the two ends of the separation sieve 4 are respectively provided with a symmetrically distributed first fixed rod 15 and a second fixed rod 20, and the first fixed rod 20 is provided with a symmetrical distribution. The bottoms of the ...

Embodiment 2

[0032] Embodiment 2, a rice processing and conveying device with good mobile flexibility, including a device main body 5, the upper end of one side of the device main body 5 is provided with a material inlet 2, and the bottom of the other side of the device main body 5 is provided with a discharge mouth 9, and the interior of the main body 5 of the device is provided with a rotating shaft 39, on which a number of uniformly distributed auger blades 38 are arranged, the two ends of the main body 5 of the device are provided with fixed mounts 8 symmetrically distributed, and the middle part of the main body 5 of the device A separation sieve 4 is provided, and the separation sieve 4 is provided with a number of evenly distributed sieve holes 25, and the two ends of the separation sieve 4 are respectively provided with a symmetrically distributed first fixed rod 15 and a second fixed rod 20, and the first fixed rod 20 is provided with a symmetrical distribution. The bottoms of the ...

Embodiment 3

[0038] Embodiment 3, a rice processing and conveying device with good mobile flexibility, including a device main body 5, the upper end of one side of the device main body 5 is provided with a feed inlet 2, and the bottom of the other side of the device main body 5 is provided with a discharge mouth 9, and the interior of the main body 5 of the device is provided with a rotating shaft 39, on which a number of uniformly distributed auger blades 38 are arranged, the two ends of the main body 5 of the device are provided with fixed mounts 8 symmetrically distributed, and the middle part of the main body 5 of the device A separation sieve 4 is provided, and the separation sieve 4 is provided with a number of evenly distributed sieve holes 25, and the two ends of the separation sieve 4 are respectively provided with a symmetrically distributed first fixed rod 15 and a second fixed rod 20, and the first fixed rod 20 is provided with a symmetrical distribution. The bottoms of the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com