Conveniently-clamped punching clamp for processing automobile heat insulation plates

A technology for heat shields and automobiles, which is applied to vehicle parts, transportation and packaging, etc., and can solve problems such as inability to turn over materials, heat and breakage during processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

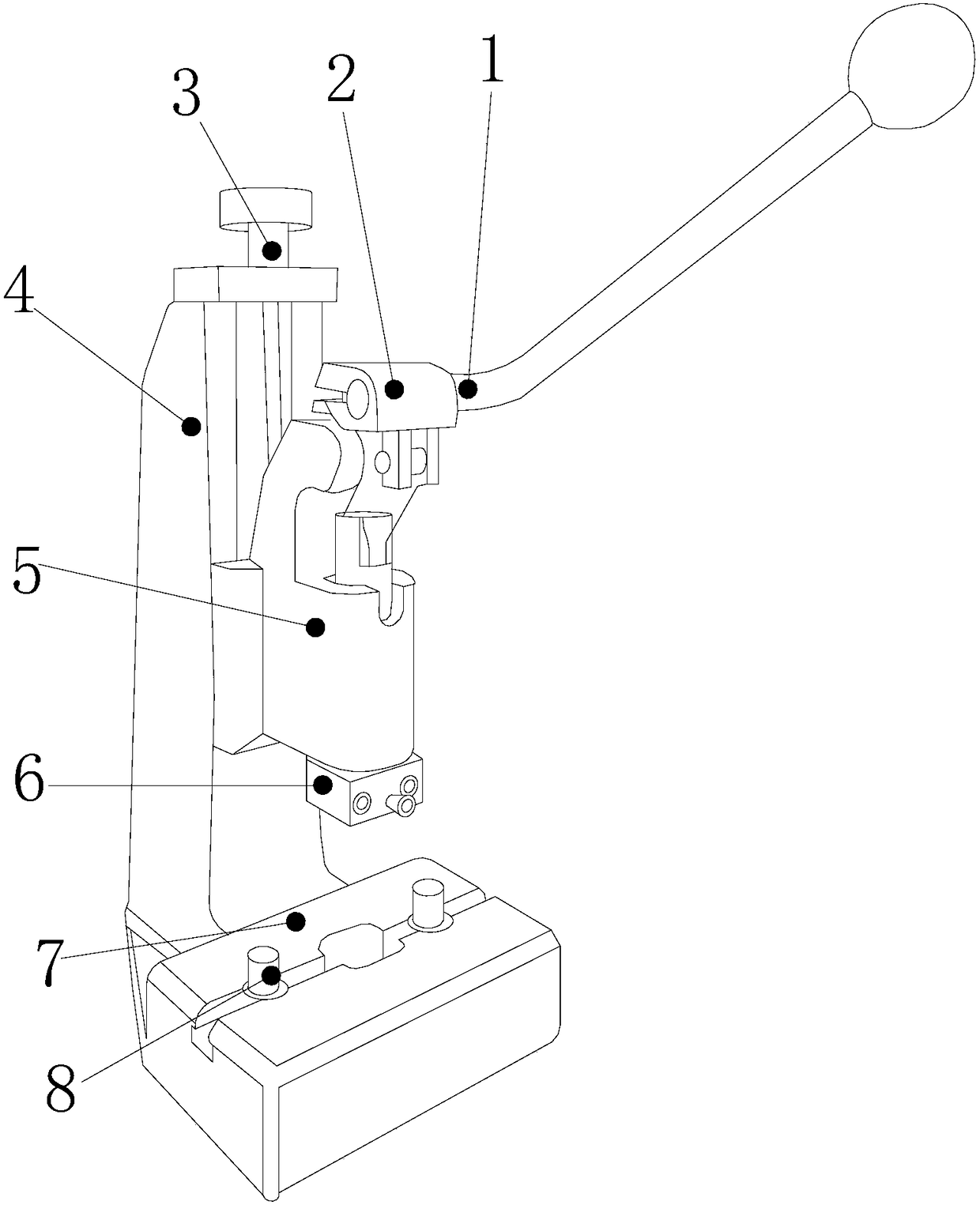

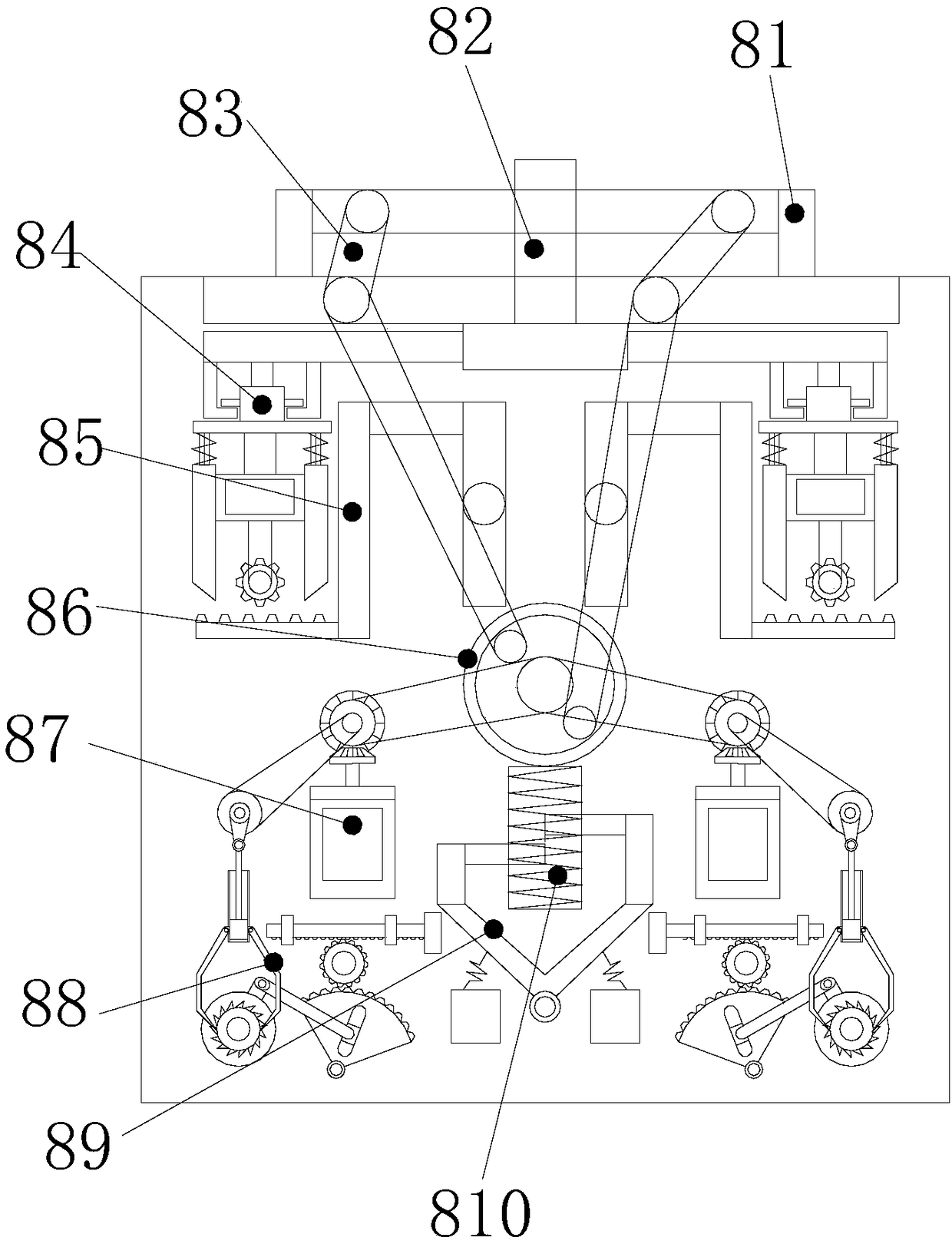

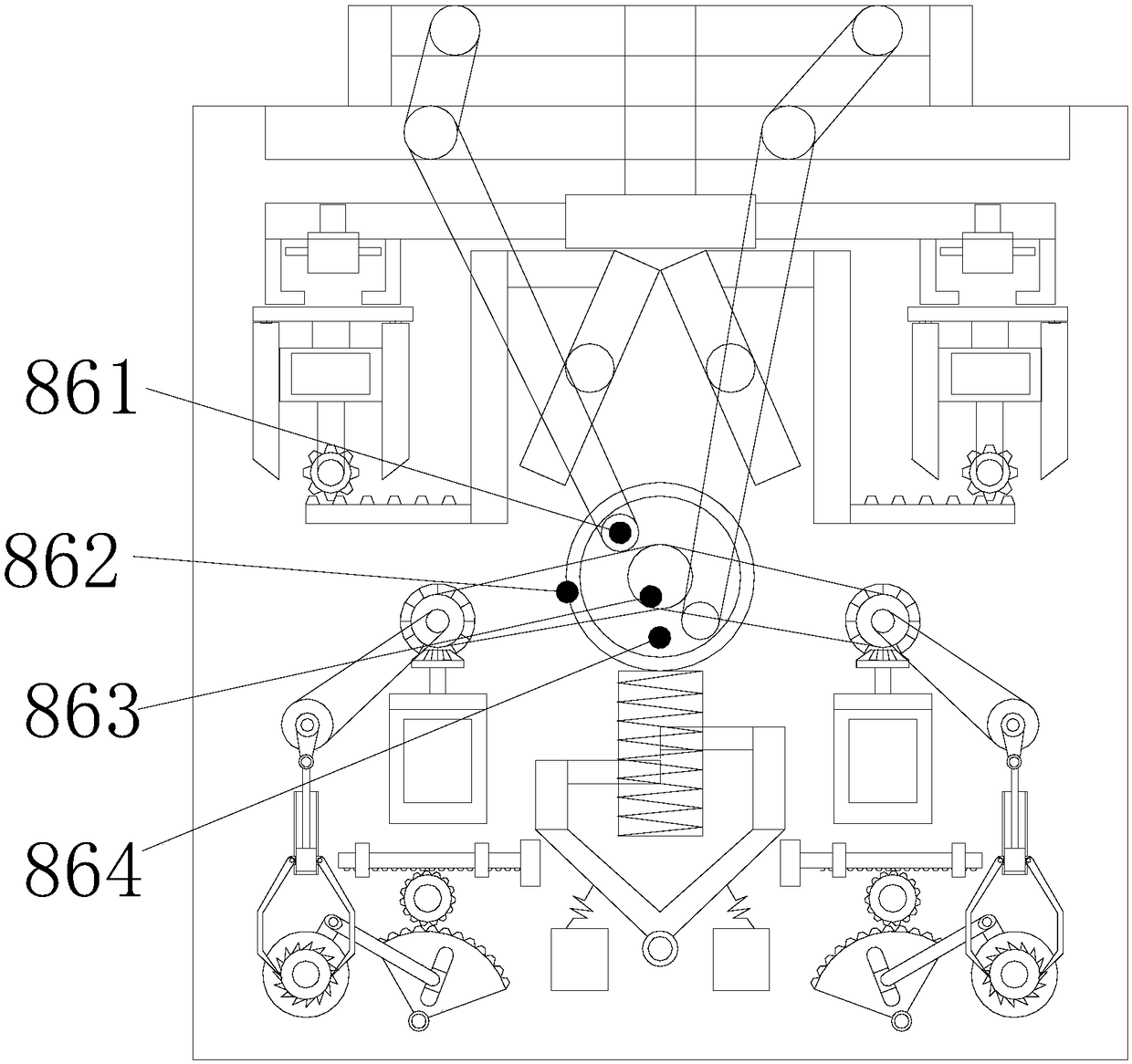

[0025] see Figure 1-Figure 5 , the present invention provides a technical solution for punching fixtures for processing automobile heat shields that is easy to clamp: its structure includes a hydraulic rod 1, a hydraulic head 2, a poppet 3, a body 4, a hydraulic tank 5, a processing punch 6, The base 7 is fixed, the turning mechanism 8 is fixed, the hydraulic rod 1 is arranged on the right side of the hydraulic head 2, and the hydraulic head 2 and the hydraulic rod 1 adopt clearance fit;

[0026] The bottom of the hydraulic head 2 is provided with a hydraulic tank 5, the hydraulic tank 5 and the hydraulic head 2 are an integrated structure, the bottom of the hydraulic tank 5 is provided with a processing punch 6, and the processing punch 6 and T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com