Humidifying method for convenient tail sealing without glue in household roll paper

A technology for household paper and paper rolls, which is applied in the directions of winding strips, thin material handling, transportation and packaging, etc. It can solve the problems of insufficient paper binding force, loose paper tails, and weak roll seals, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

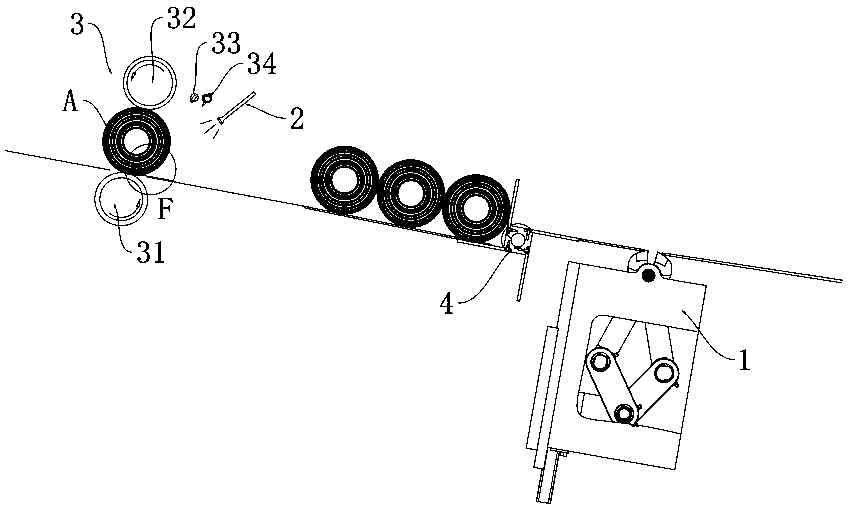

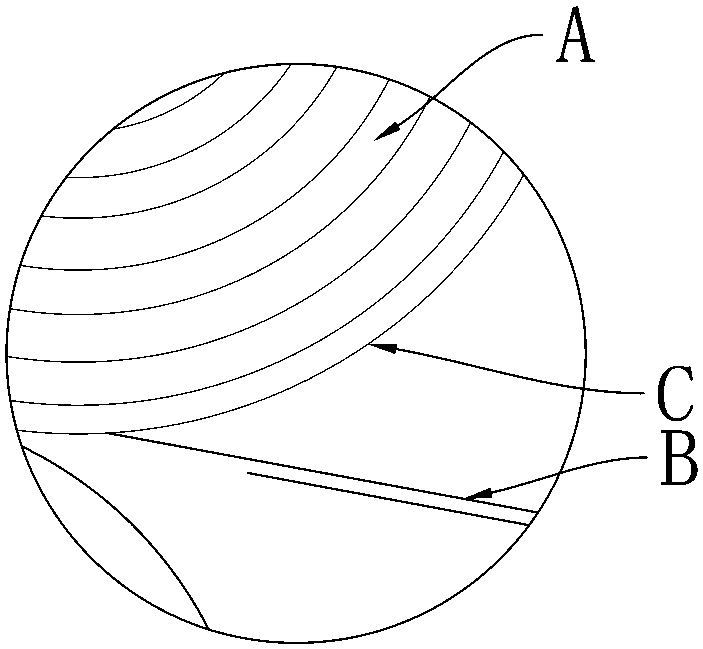

[0026] See attached figure 1 And attached figure 2 As shown, in this embodiment, a humidification method for conveniently sealing household paper rolls without glue, including a sealing mechanism 1 for pressing the outer peripheral surface of the roll A to form a pressing part, and a sealing mechanism 1 located in the sealing mechanism. 1 upstream and used for spraying water mist humidification mechanism 2, located upstream of the humidification mechanism 2 and used for positioning and deploying the tail-seeking expansion mechanism 3 of the tail. The tail-seeking unfolding mechanism 3 includes an upper orienting roller 31 and a lower orienting roller 32 arranged up and down oppositely, a detection electric eye 33 and an air blowing pipe 34, wherein, there is formed between the upper orienting roller 31 and the lower orienting roller 32 for the coil 10 to pass through. gap, so as to form a reel rotation station that makes the reel A rotate in place. Specifically, the upper or...

Embodiment 2

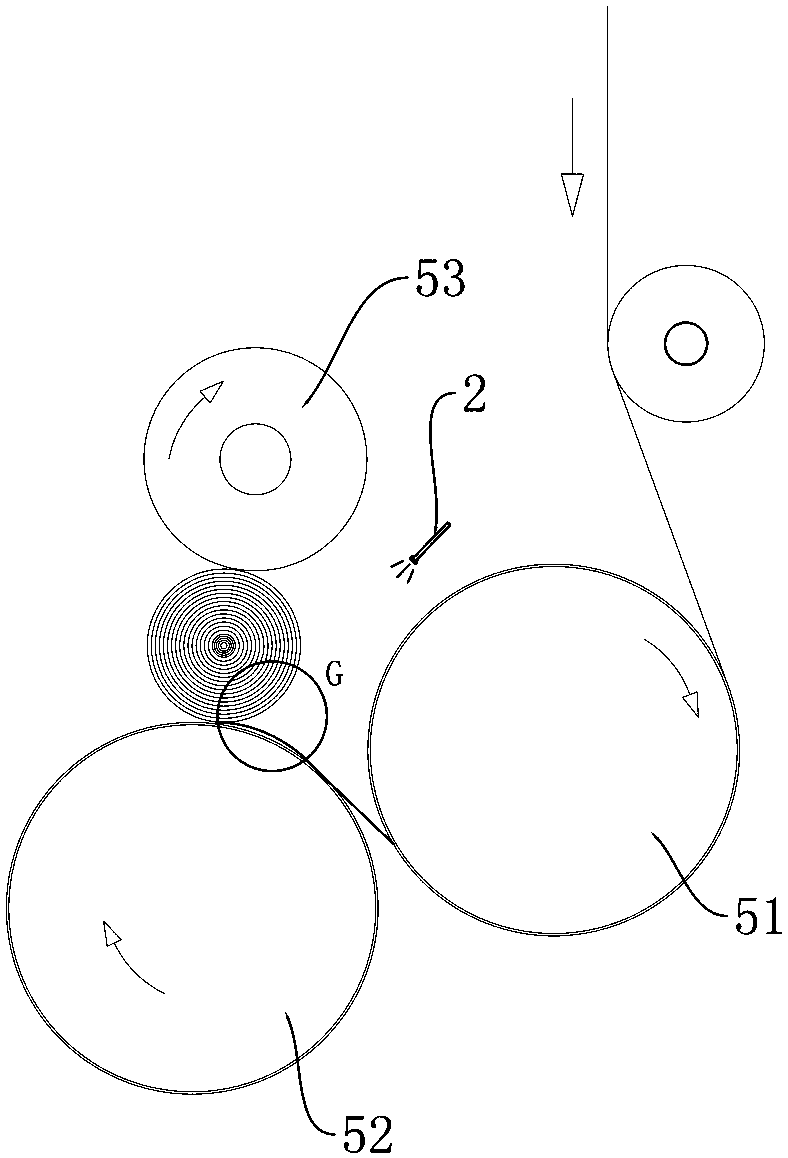

[0035] See attached image 3 to attach Image 6 As shown, compared with the first embodiment, this embodiment can spray the reel A during the rewinding process, so that the rewinded reel A can be directly transported to the sealing mechanism 1 for final sealing. For this reason, in this embodiment, it includes a sealing mechanism 1 for pressing the outer peripheral surface of the reel A to form a pressing portion, a rewinding mechanism located upstream of the sealing mechanism 1, and a humidifying mechanism located at the rewinding mechanism. 2. Wherein, the sealing mechanism 1 of this embodiment can adopt the sealing mechanism 1 as described in the first embodiment, which will not be repeated in this embodiment.

[0036] In this embodiment, the rewinding mechanism includes an upper rewinding roller 51, a lower rewinding roller 52 and a pressure roller 53, wherein the area surrounded by the upper rewinding roller 51, the lower rewinding roller 52 and the pressure roller 53 serv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com