Slide-belt track pad

A technology of sliding belts and sliding plates, which is applied in the direction of tracks, roads, fixed rails, etc., can solve problems such as lack of real-time performance, reduced support elasticity, and empty rail bottom, so as to reduce maintenance and repair workload, longitudinal The effect of reducing resistance and avoiding the expansion of the track

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

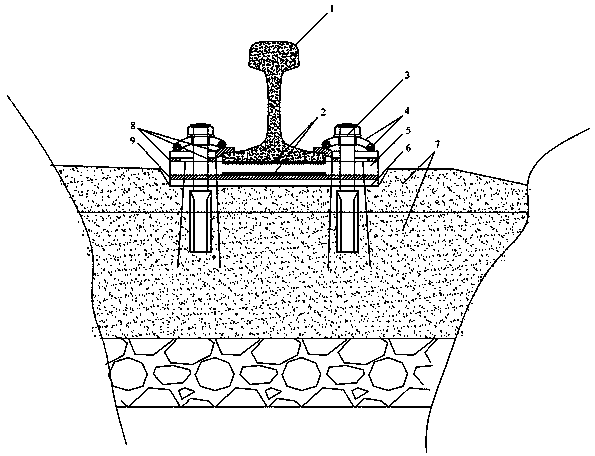

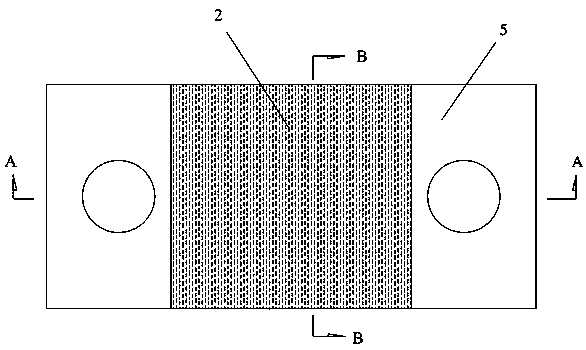

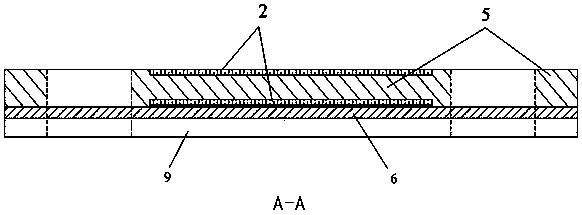

[0014] A kind of sliding belt type track backing plate, comprising sliding belt 2, sliding plate 5, rubber backing plate 9, height-adjusting backing plate 6, it is characterized in that, the front and rear end surfaces of the middle part of the sliding plate 5 are semicircular structures, and the middle part There are sliding grooves on the upper and lower end surfaces, and the annular sliding belt 2 is wrapped in the central sliding groove of the sliding plate 5, keeping close contact with the central sliding groove. The inner side of the annular sliding belt is smooth, and the outer side is rough surface; the sliding plate 5, the rubber backing plate 9, and the height-adjusting backing plate 6 are fixed on the concrete sleeper 7 through the fastener bolts 3 in turn, and the rail 1 is installed on the annular sliding belt 2 and passed through the fastener elastic strip 4, the fastener Bolt 3 is fixed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com