Rail tracked vehicle carrier for automatic three-dimensional garage

A car carrier and automatic parking technology, which is applied in the direction of parking buildings, transportation and packaging, building types, etc., can solve the problems of broken gears, few applications, and high construction costs of garages, so as to avoid twisting of transmission shafts or gears Breaking, ingenious and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

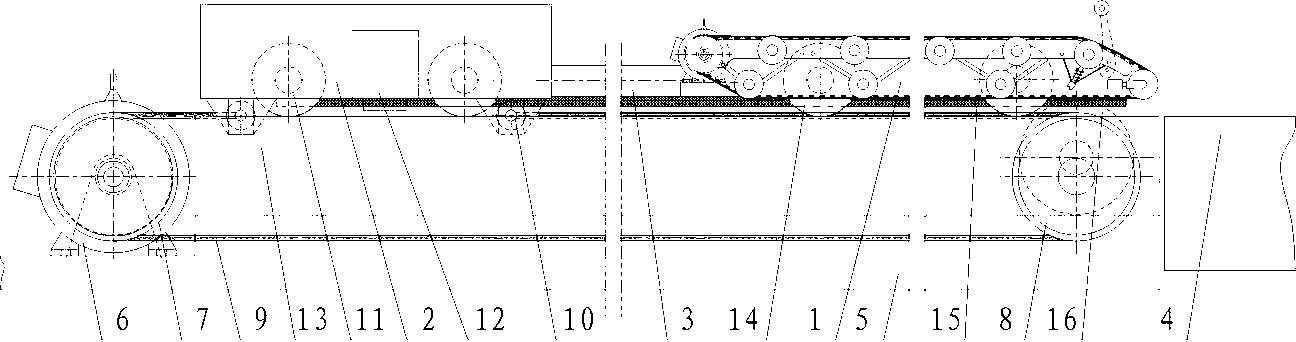

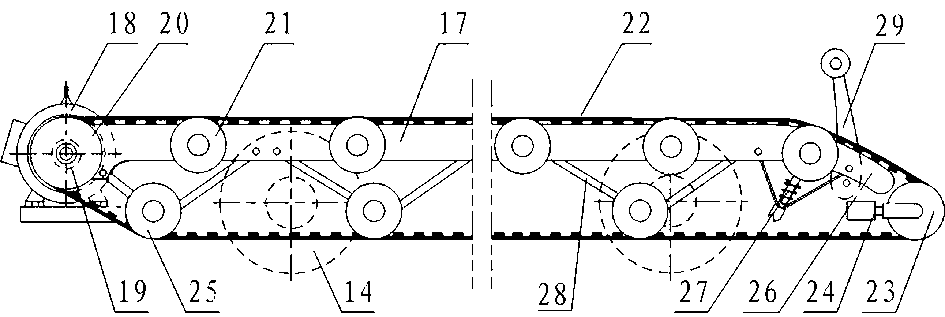

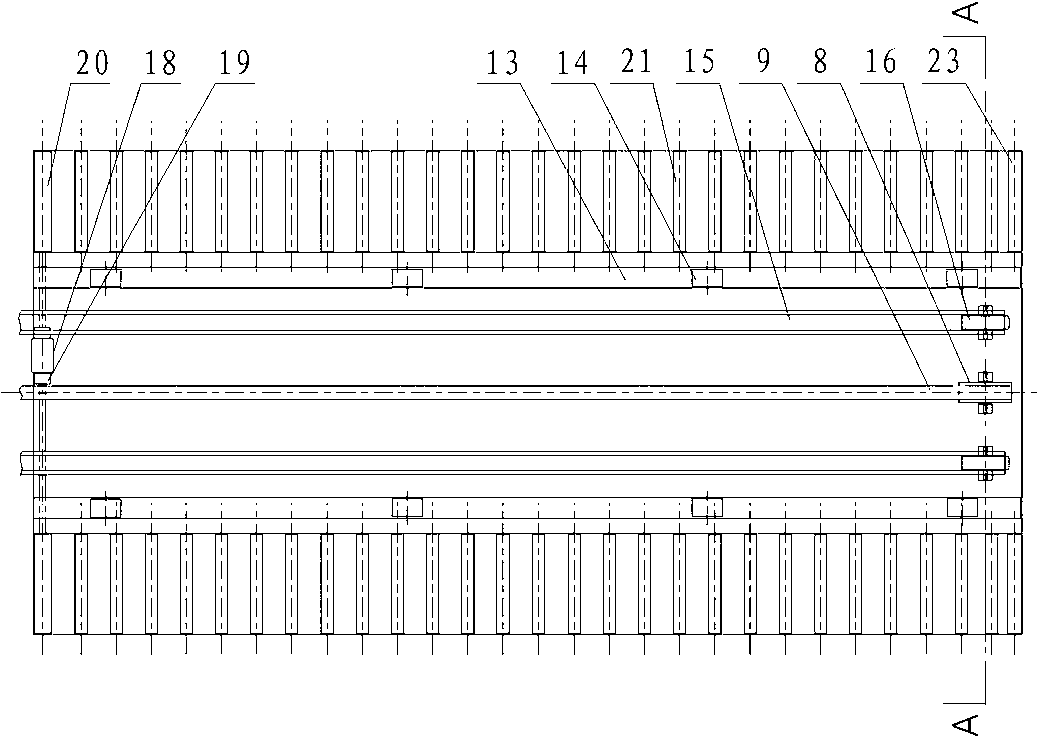

[0015] The specific implementation of the technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0016] The rail crawler vehicle carrier of the present invention is mainly used in a three-dimensional automatic parking garage. From figure 1 It can be clearly seen that the railed tracked vehicle carrier is composed of a crawler vehicle 1 and a tractor 2 tightly connected to the tracked vehicle 1. The traveling mechanism is composed of a tracked stacker chassis 5 with friction wheels 8 and positioning wheels 16. constitute. The tracked vehicle 1 and the tractor 2 are fastened together through a connecting shaft 3 . The crawler vehicle 1 of the running mechanism is used to carry the vehicles entering and leaving the warehouse, and the tractor 2 of the running mechanism is used to drive the crawler vehicle 1 to move back and forth in the horizontal direction.

[0017] From figure 1 , 2 , 3, 4 can clearly see...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com