Patents

Literature

34results about How to "Improve tapping accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

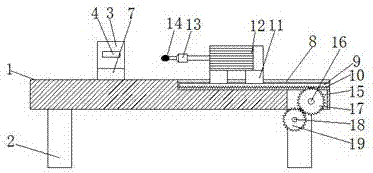

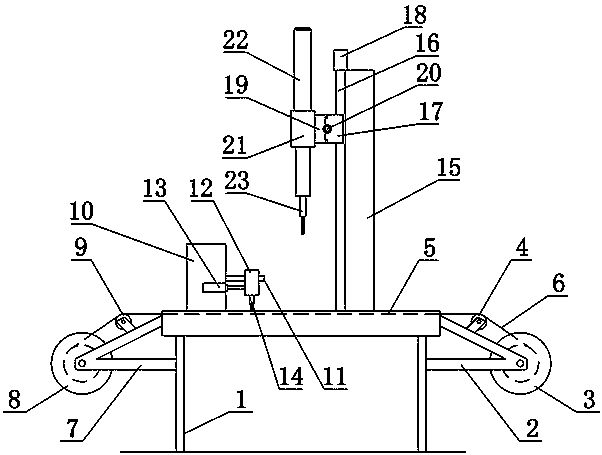

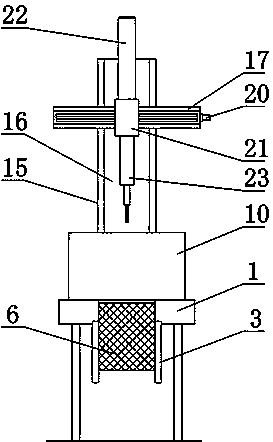

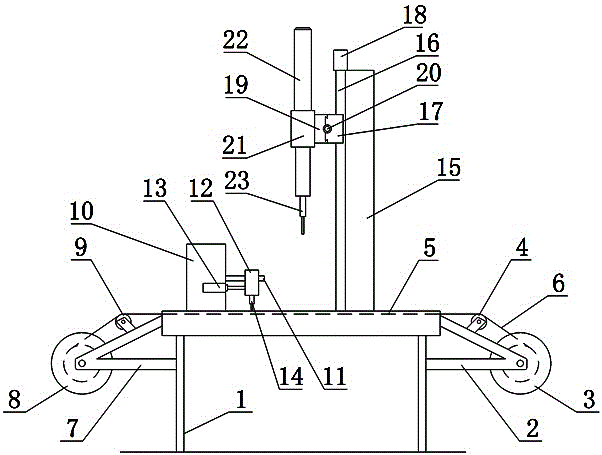

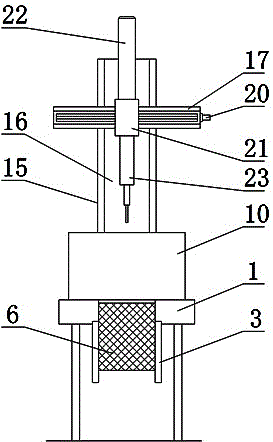

Machine tool for easy tapping of tube body

InactiveCN107350579AHigh precisionImprove tapping efficiencyThread cutting machinesDrive motorMachine tool

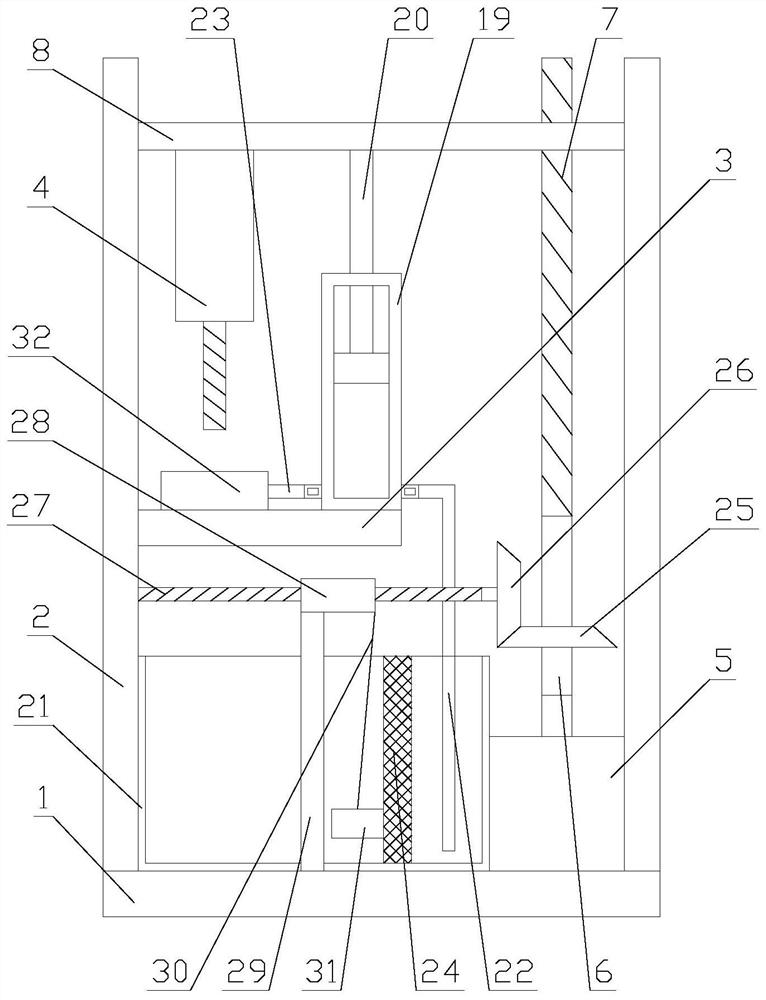

The invention provides a machine tool for pipe body tapping, which relates to the electromechanical field. The machine tool for pipe body tapping includes a bed body, the bottom of the bed body is fixedly connected with support legs, the top of the bed body is fixedly connected with two fixed blocks, and the sides of the two fixed blocks are provided with push screws The threaded ends of the two push screw rods both pass through the fixed block and extend between the two fixed blocks. Two clamping blocks are arranged between the two fixing blocks, and the sides of the two clamping blocks that are far away from each other are fixed The first bearing is connected, and the threaded ends of the two push screw rods are located between the two fixing blocks and are fixedly sleeved with the first bearing. This machine tool is convenient for pipe body tapping. The transmission motor drives the rotation of the main gear and the transmission gear, so that the slider can move horizontally to the left inside the chute. Carry out positioning tapping, effectively improve the accuracy of tapping and improve the tapping efficiency.

Owner:王之韵

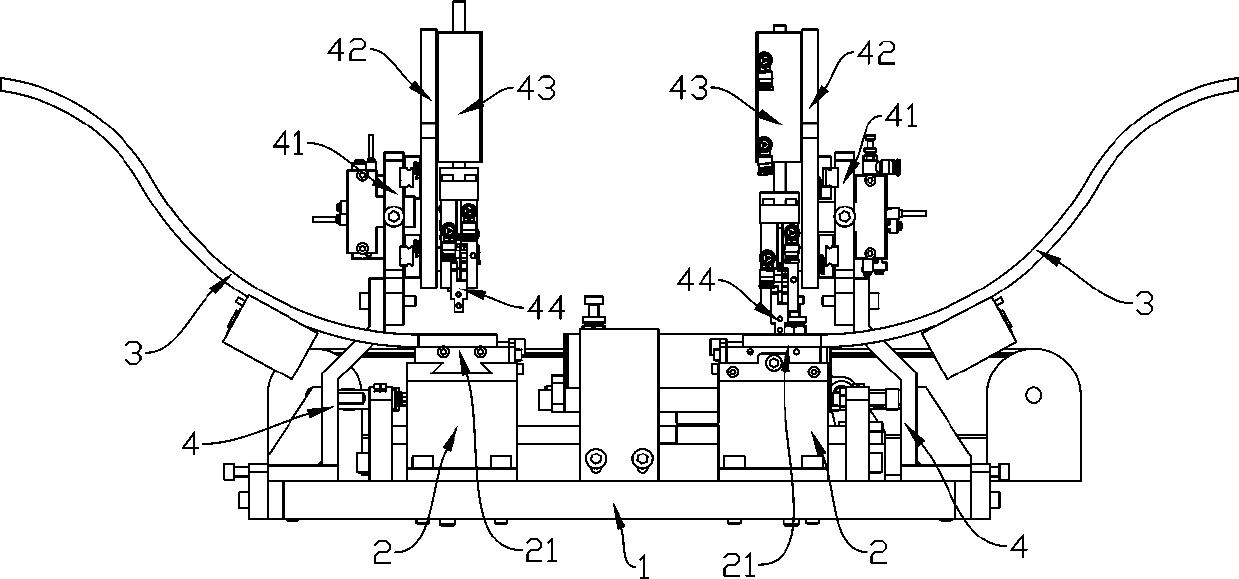

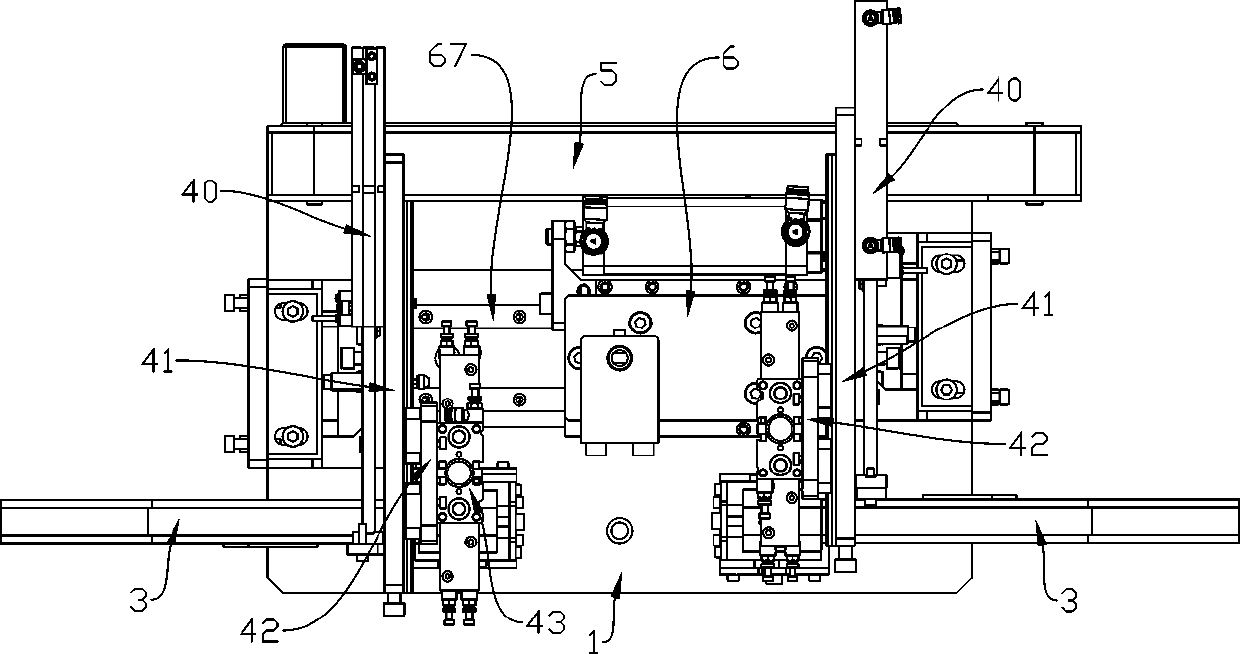

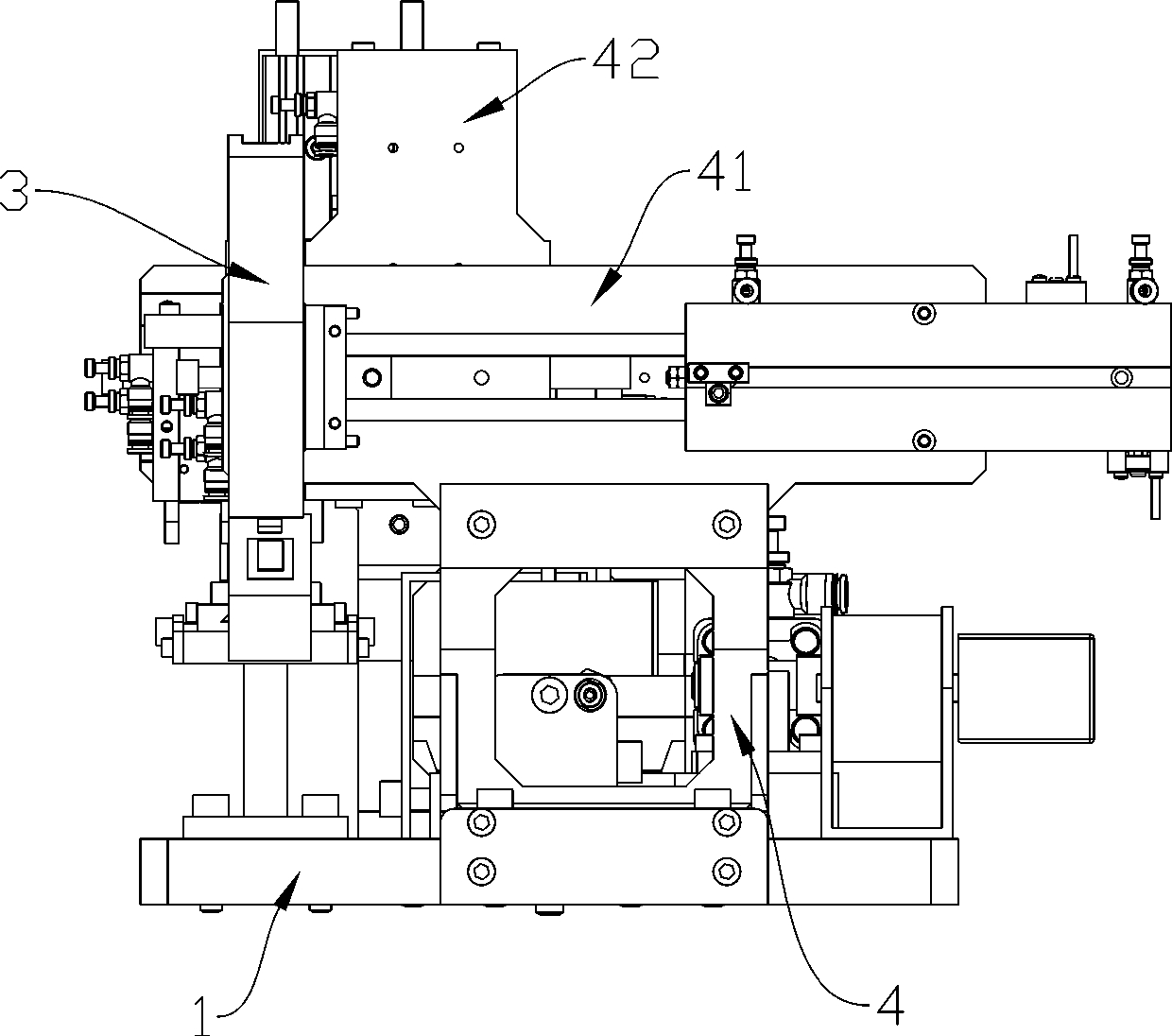

Automatic nut tapping equipment

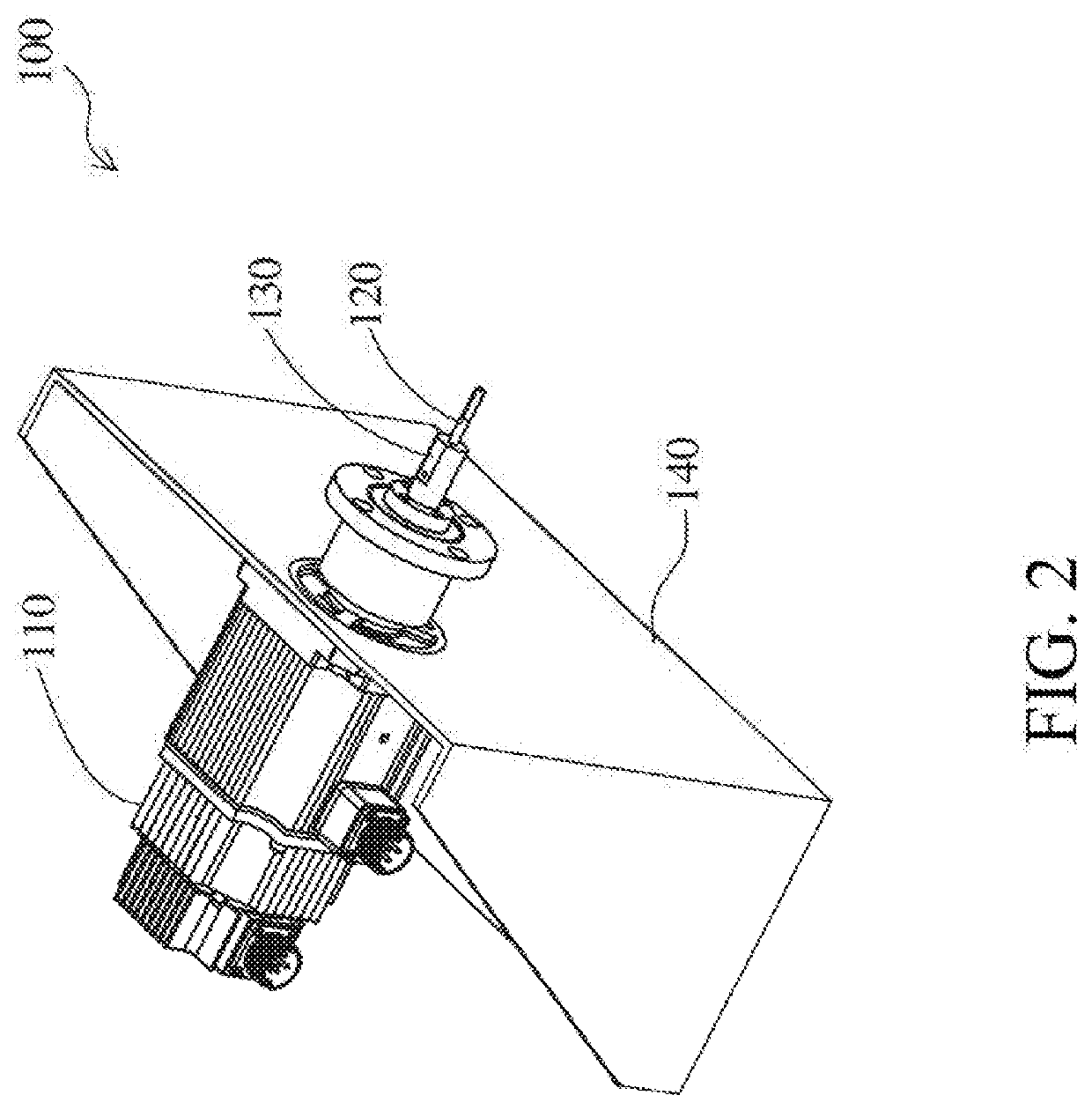

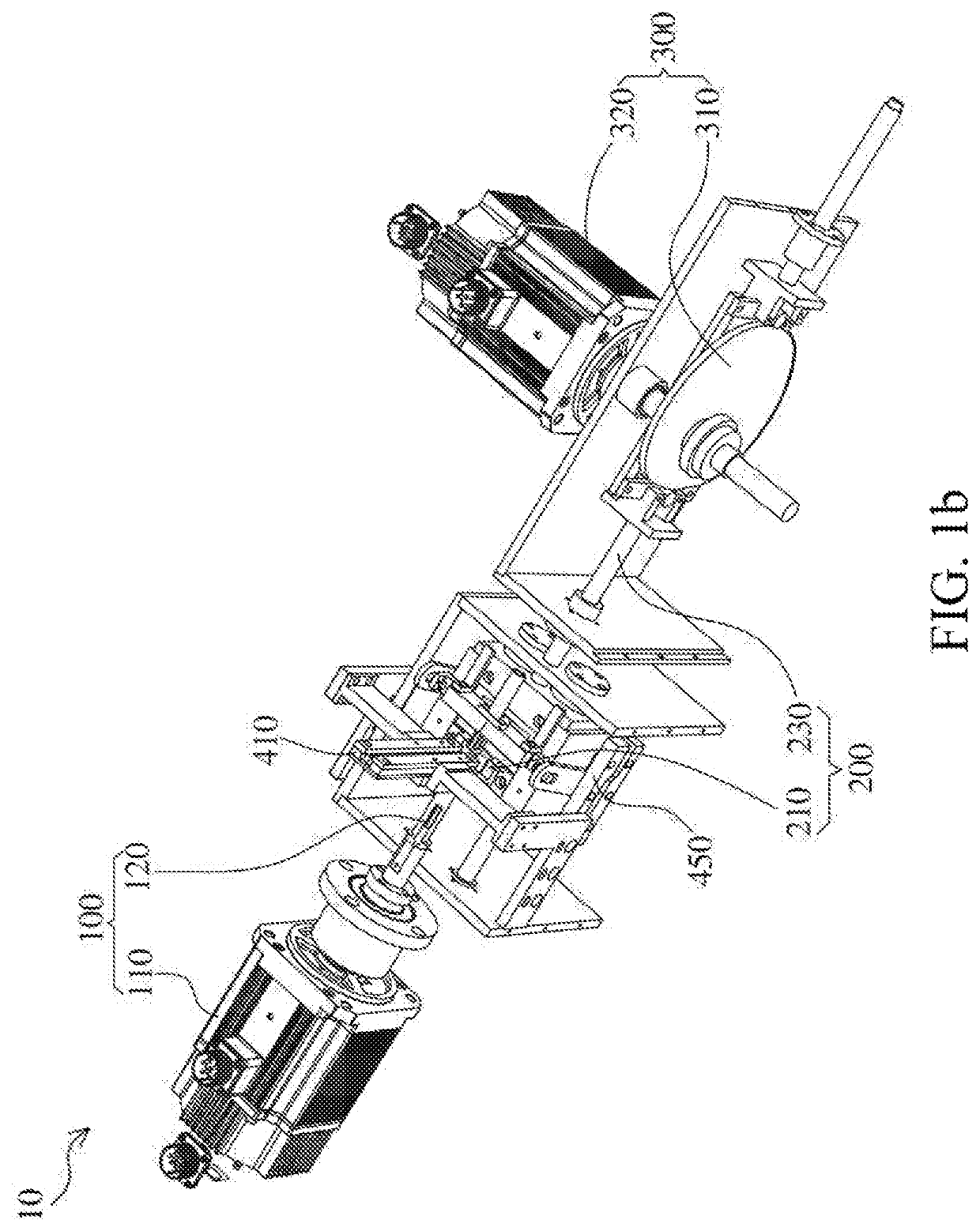

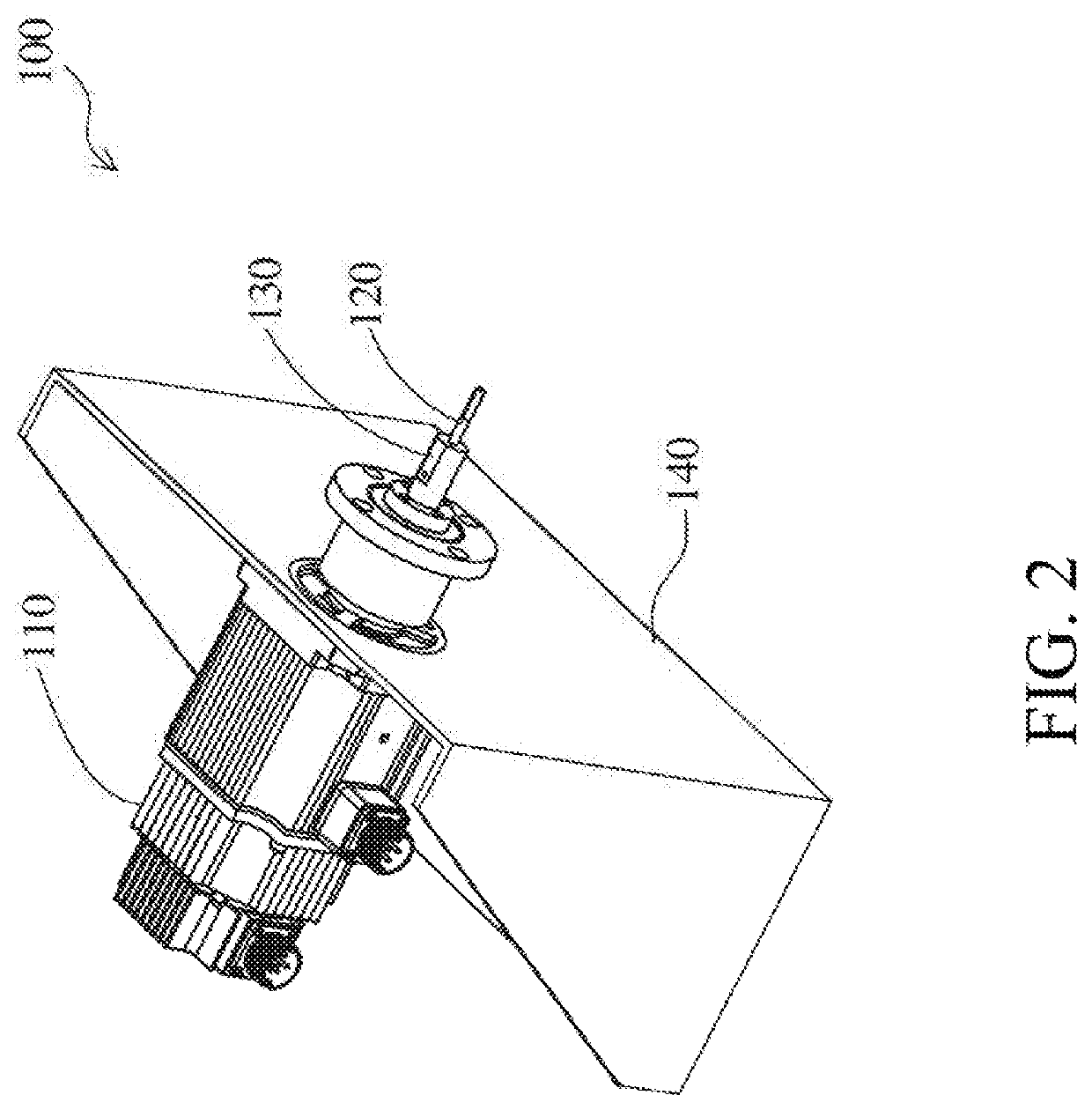

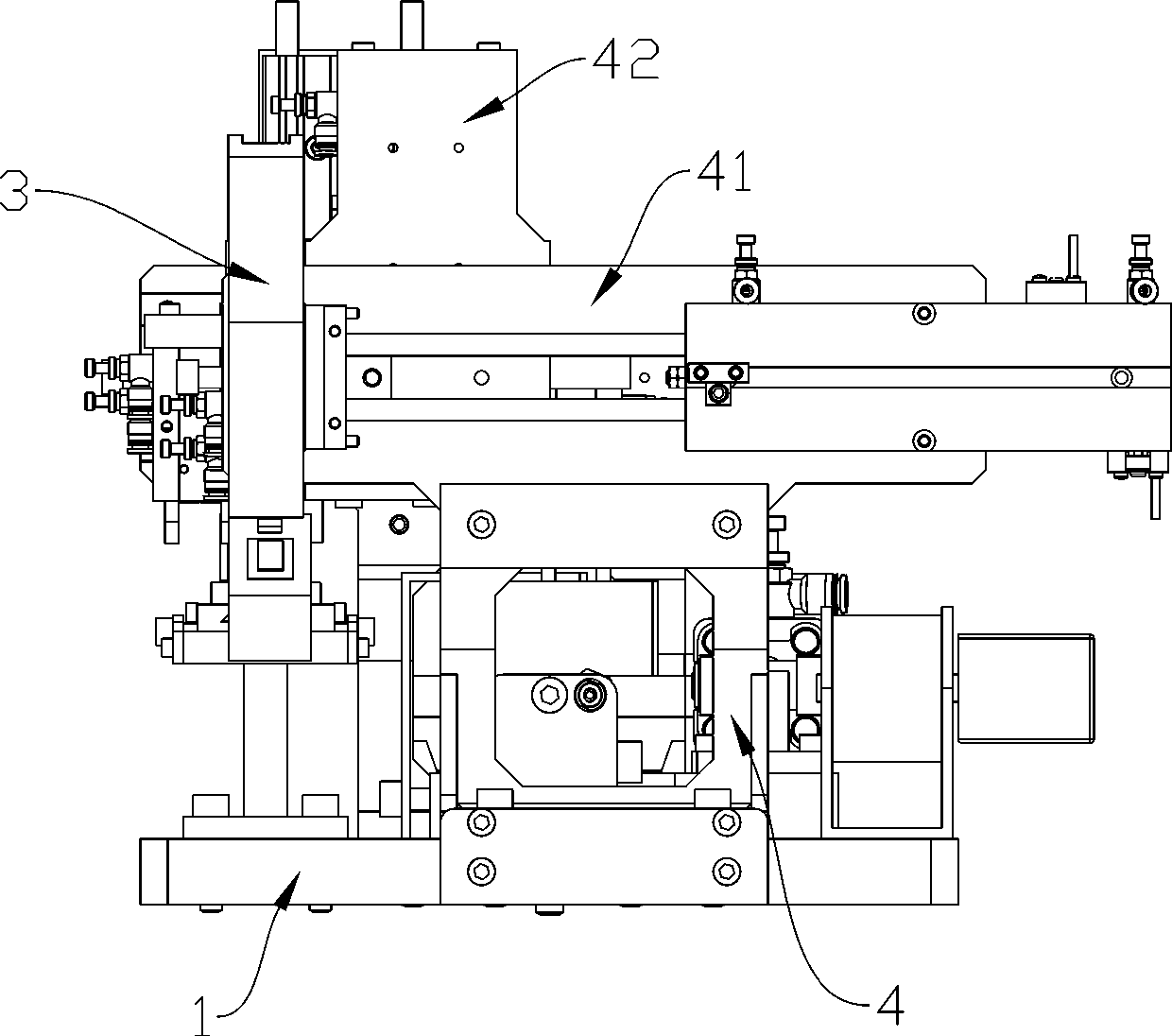

ActiveUS20210237182A1Increased torsional stiffnessImprove rigidityThread cutting machinesFeeding apparatusElectric machineryControl theory

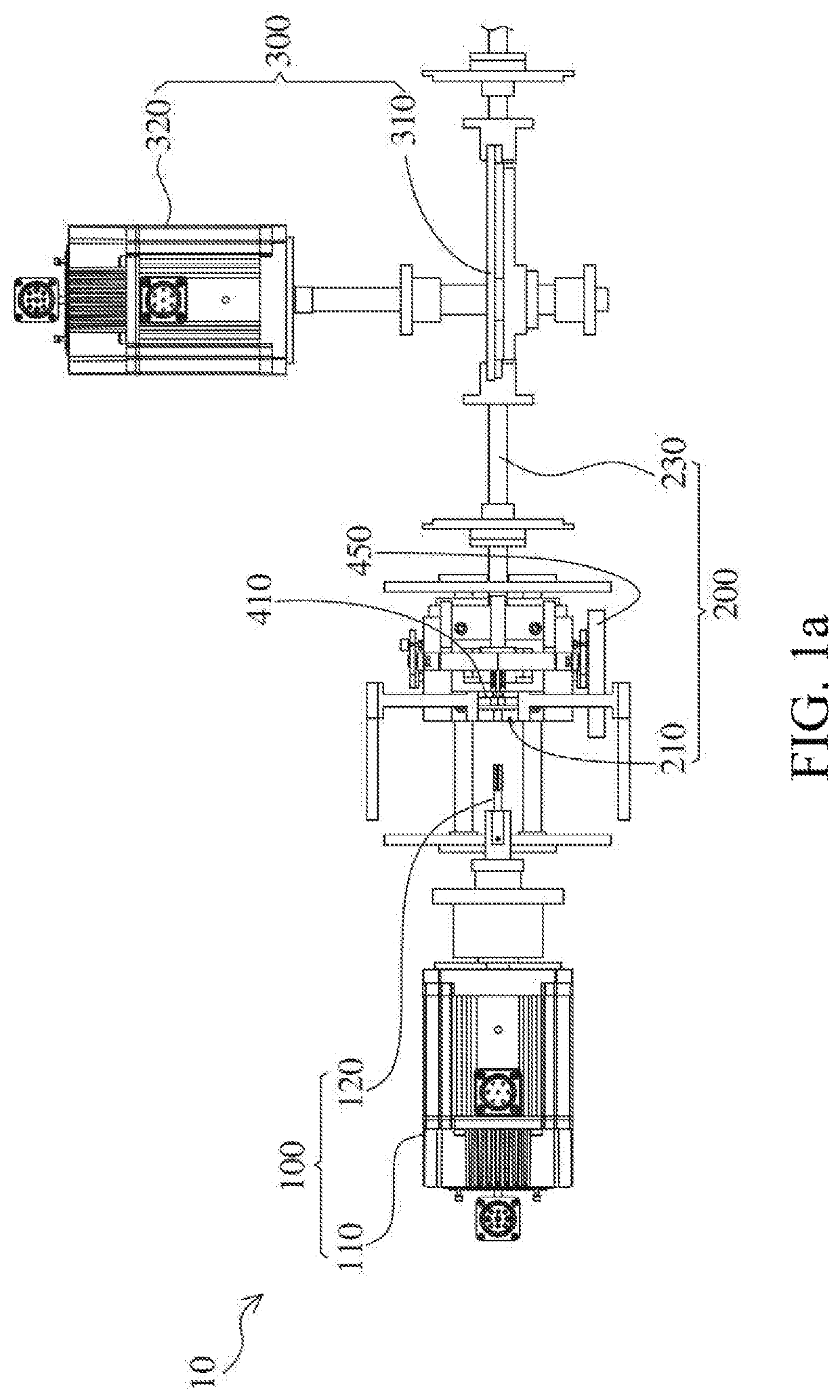

An automatic nut tapping equipment is provided. The automatic nut tapping equipment includes a tap rotating mechanism, a nut clamping mechanism, an axial transmission mechanism, and a nut placing slot. The tap rotating mechanism includes a tap rotary motor and a tap, wherein the tap is driven by the tap rotary motor. The nut clamping mechanism includes a clamping assembly and a sliding rail, wherein the clamping assembly is disposed on the sliding rail and is configured for clamping a to-be-tapped nut to restrict the to-be-tapped nut from rotating. The axial transmission mechanism controls the clamping assembly to axially translate one pitch in response to the tap rotating one revolution, such that a forward nut-tapping motion and a backward nut-retracting motion are performed by the nut clamping mechanism. The nut placing slot is configured to arrange and control the dropping of another to-be-tapped nut.

Owner:NAT SUN YAT SEN UNIV

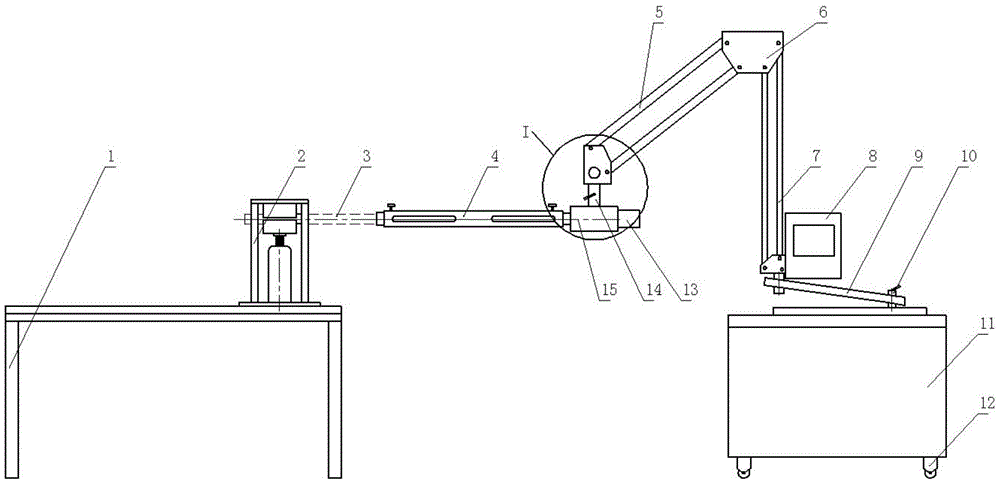

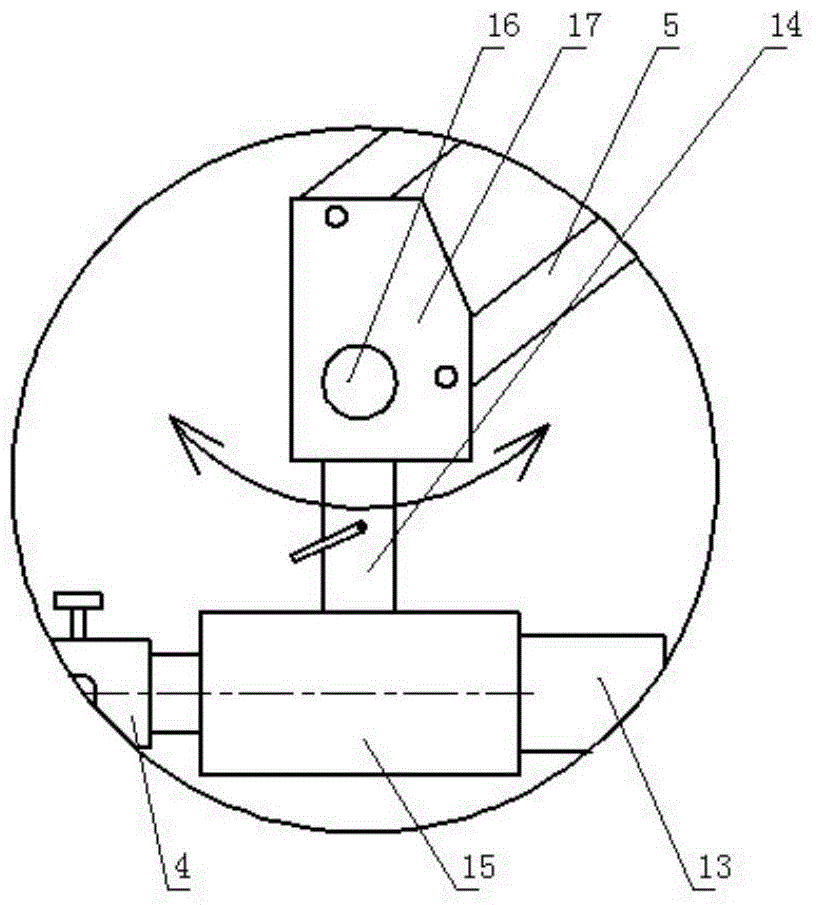

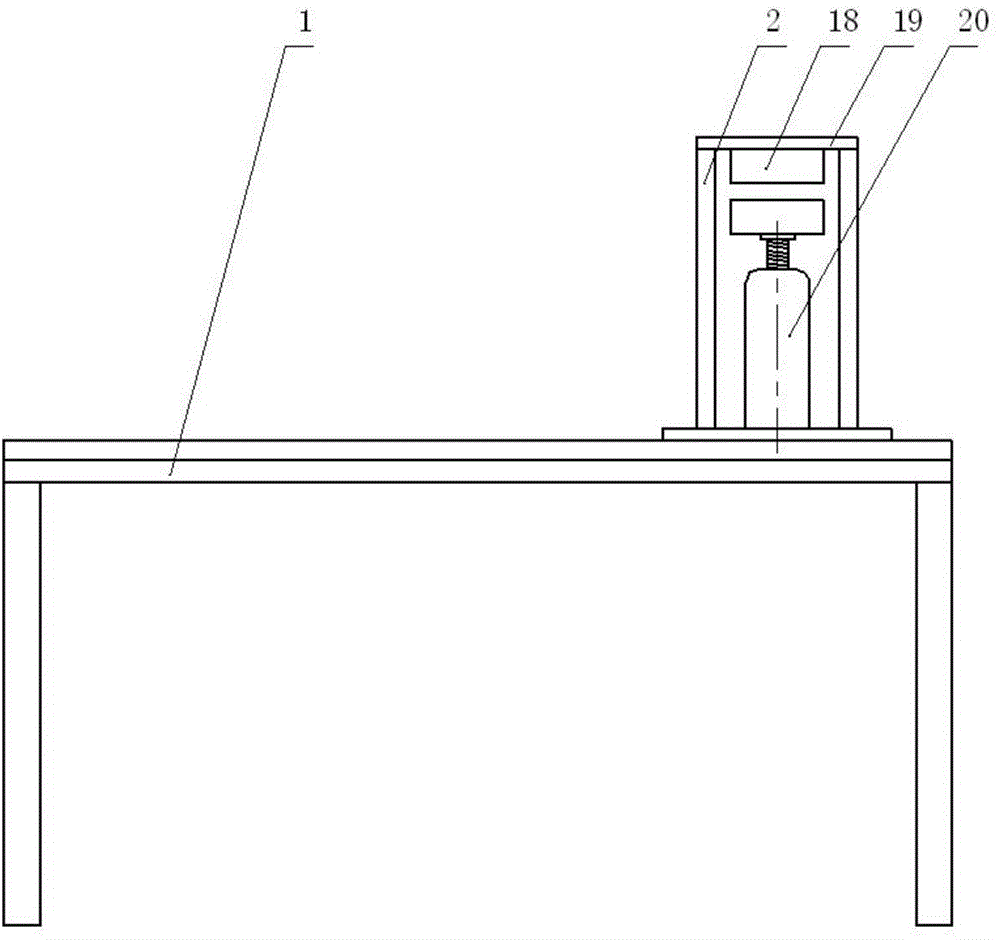

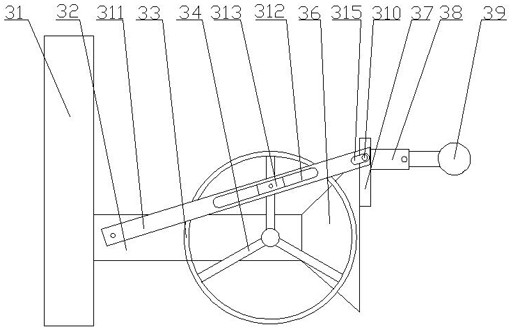

Tapping device capable of machining internal threads and external threads

InactiveCN105562842AImprove tapping accuracySave human effortThread cutting machinesPositioning apparatusHydraulic cylinderEngineering

The invention relates to a tapping device capable of machining internal threads and external threads. The tapping device comprises a tapping machine and a workpiece clamping assembly. After a workpiece is clamped through the workpiece clamping assembly, thread machining is performed through the tapping machine. The tapping machine comprises a platform. A vertical shaft is installed on the platform. One end of a lower supporting arm is rotationally installed on the vertical shaft. The other end of the lower supporting arm is hinged to the lower end of a longitudinal supporting arm. The upper end of the longitudinal supporting arm is hinged to one end of an upper supporting arm through a connector. A vertically-arranged connecting shaft is installed at the other end of the upper supporting arm. A chuck is installed at the lower end of the connecting shaft. The workpiece clamping assembly comprises a support. A supporting frame is installed on one side of the support. A top board is fixedly arranged at the upper end of the supporting frame. A hydraulic cylinder is vertically installed upwards at the portion, corresponding to the top board, of the support. A pair of clamping pieces are symmetrically installed at the piston rod end of the hydraulic cylinder and the lower end face of the top board. The tapping device is simple in structure, scientific and reasonable in design, flexible in operation, convenient to operate, high in tapping accuracy and capable of effectively improving the work efficiency.

Owner:TIANJIN XIANFEI TECH

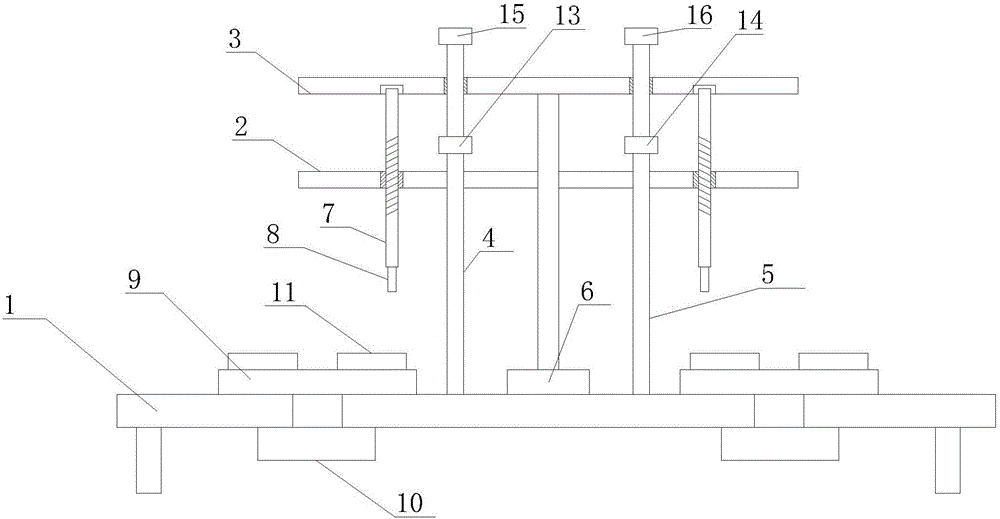

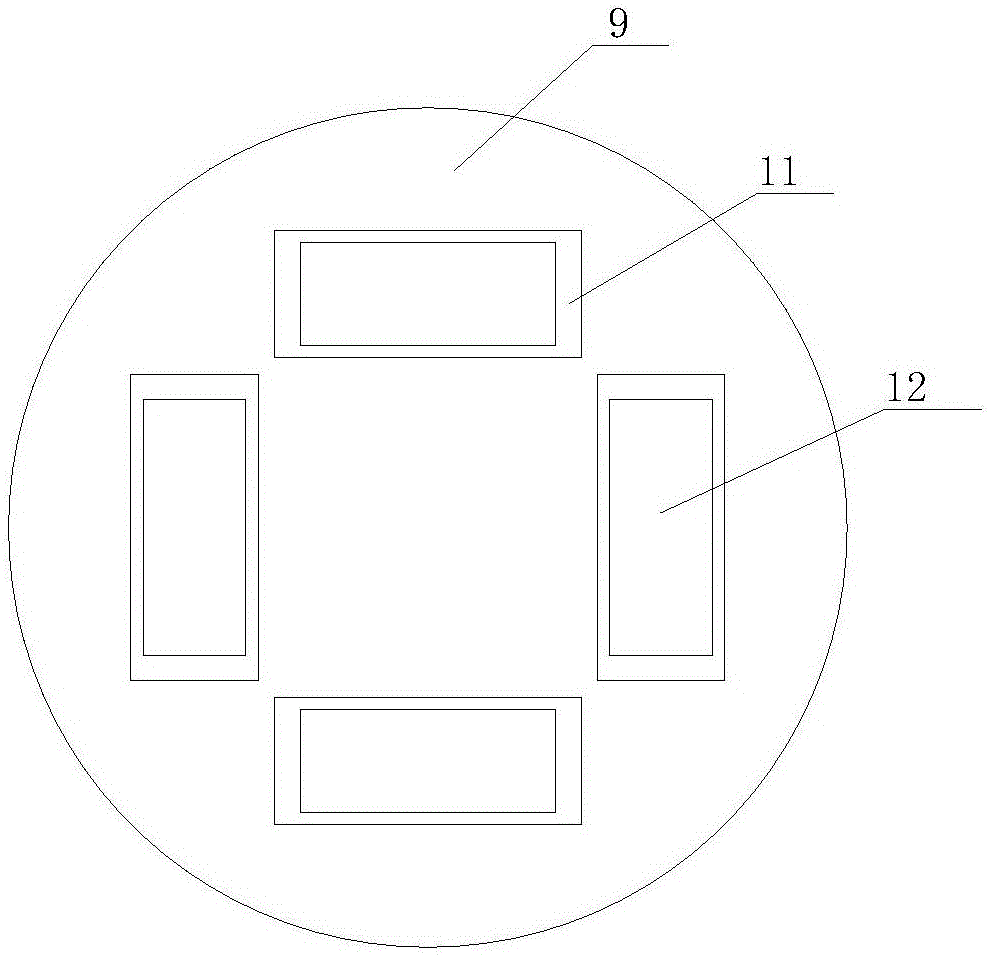

Multifunctional charger shell tapping equipment

The invention provides multifunctional charger shell tapping equipment which comprises a workbench, a fixed plate, a movable plate, a first guiding column, a second guiding column, a first driving mechanism, a plurality of rotating rods and a plurality of fixing mechanisms. The second end of the first guiding column and the second end of the second guiding column sequentially penetrate through the fixed plate and the movable plate correspondingly, and the first guiding column and the second guiding column are fixedly connected with the fixed plate and slidably connected with the movable plate. The first driving mechanism is connected with the movable plate and drives the movable plate to move up and down along the first guiding column and the second guiding column in the vertical direction. The first ends of the rotating rods penetrate through inner screw holes to be rotatably connected with the movable plate, the rotating rods are provided with external threads matched with the inner screw holes, and tapping screw taps are arranged at the second ends of the rotating rods. Each fixing mechanism comprises a fixing circular table and a second driving mechanism, wherein the second driving mechanism is connected with the fixing circular table and drives the fixing circular table to rotate. The multifunctional charger shell tapping equipment can conduct tapping on a plurality of charger shells at a time, and work efficiency is high.

Owner:天长市优信电器设备有限公司

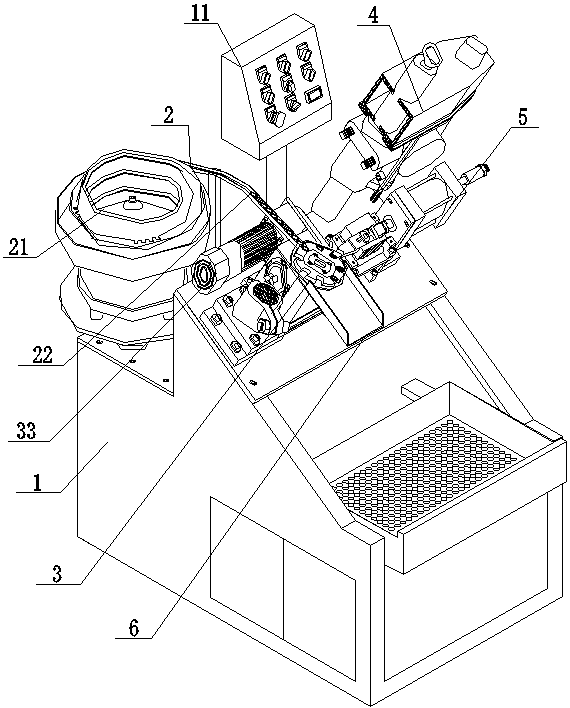

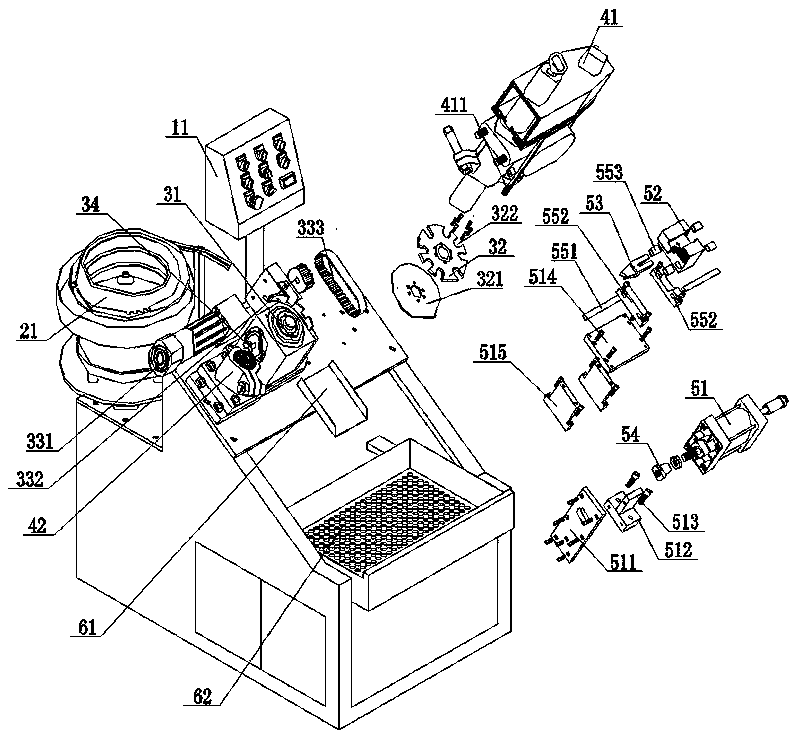

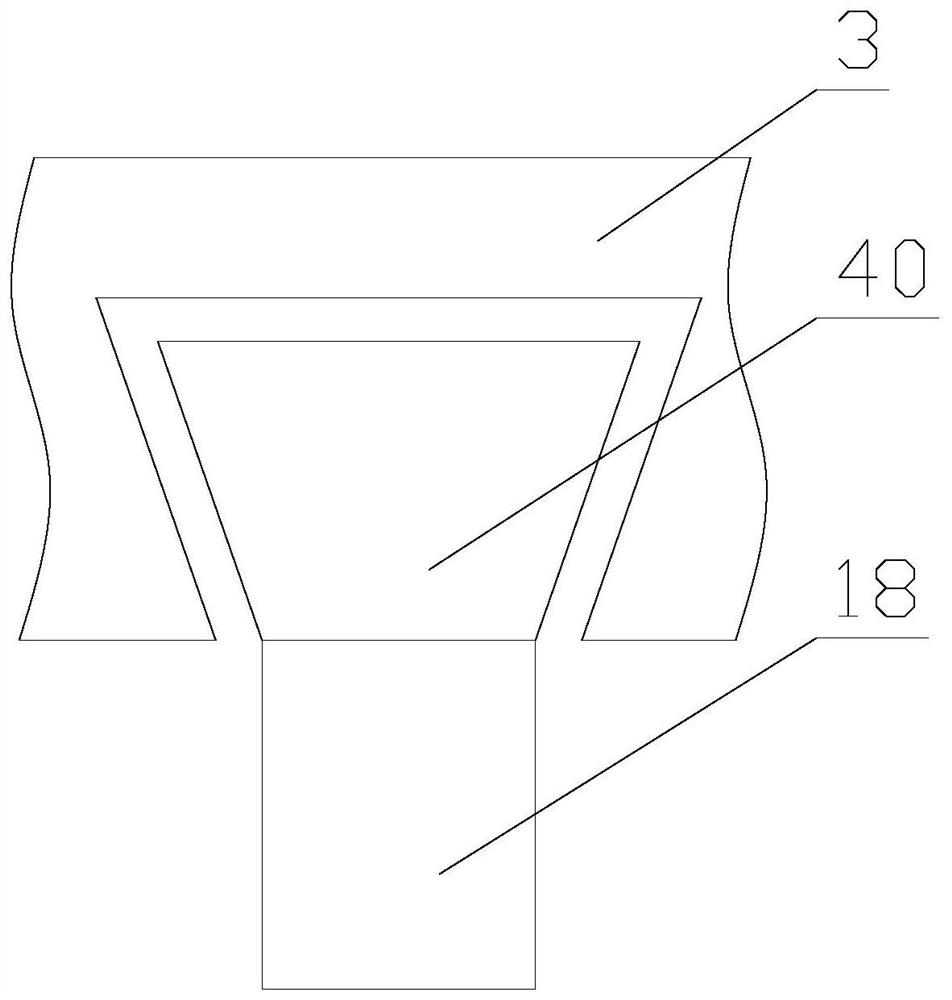

Full-automatic cap tapping machine

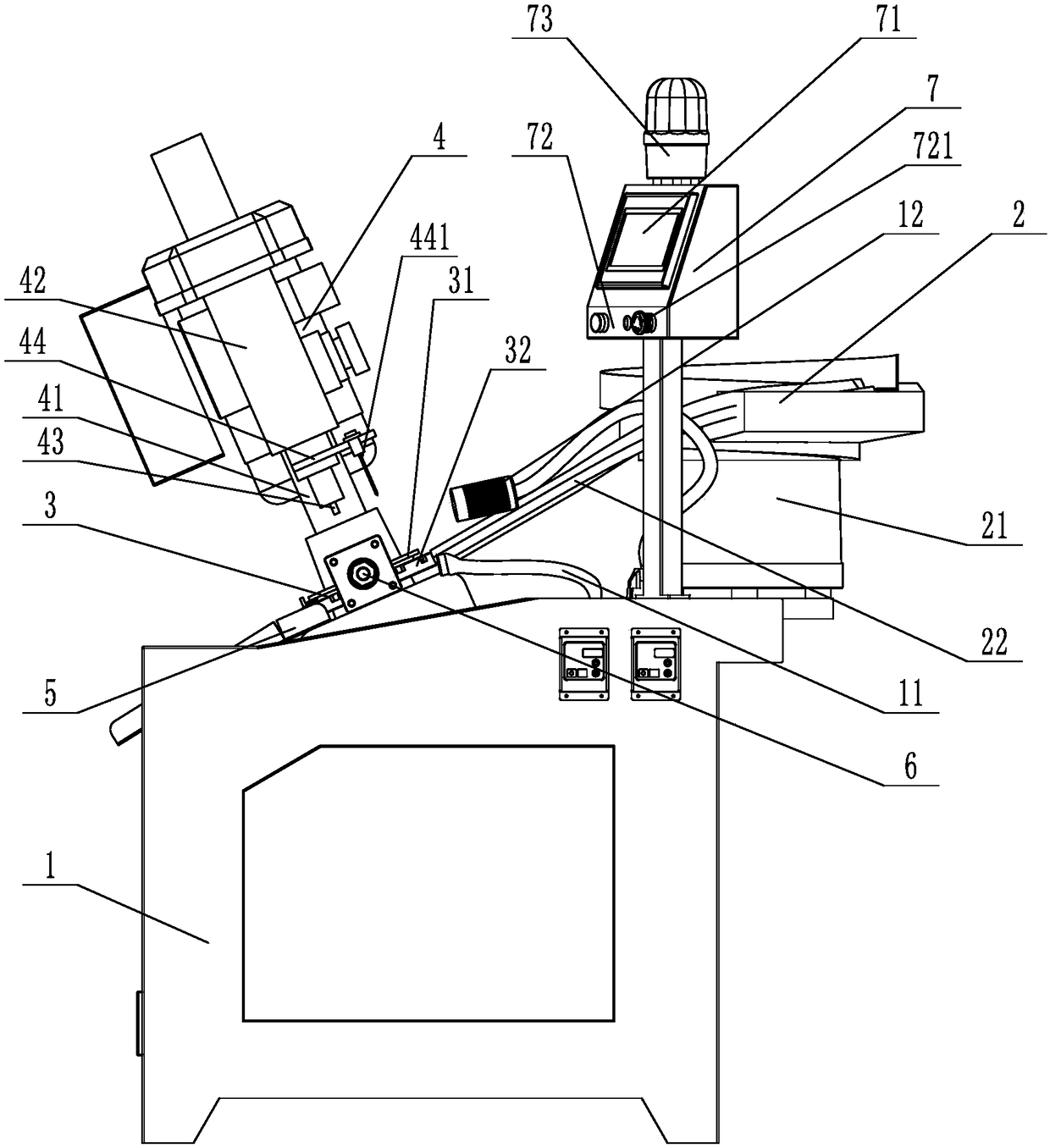

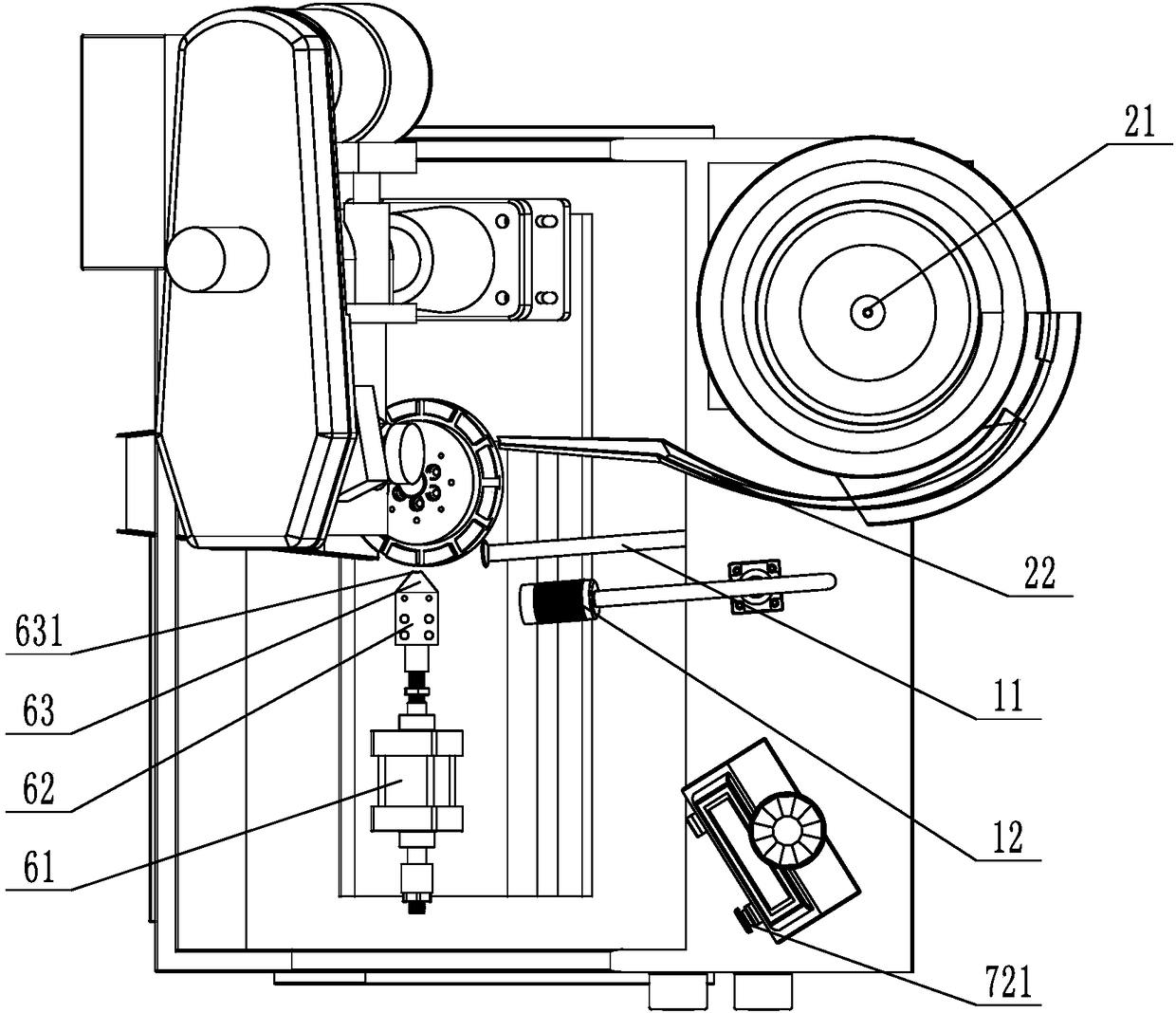

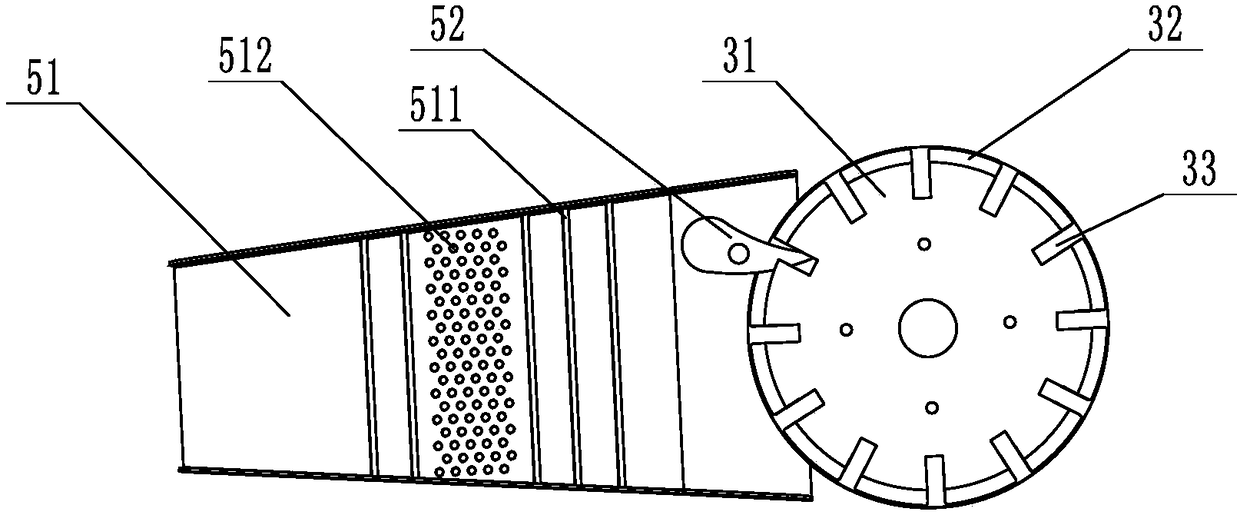

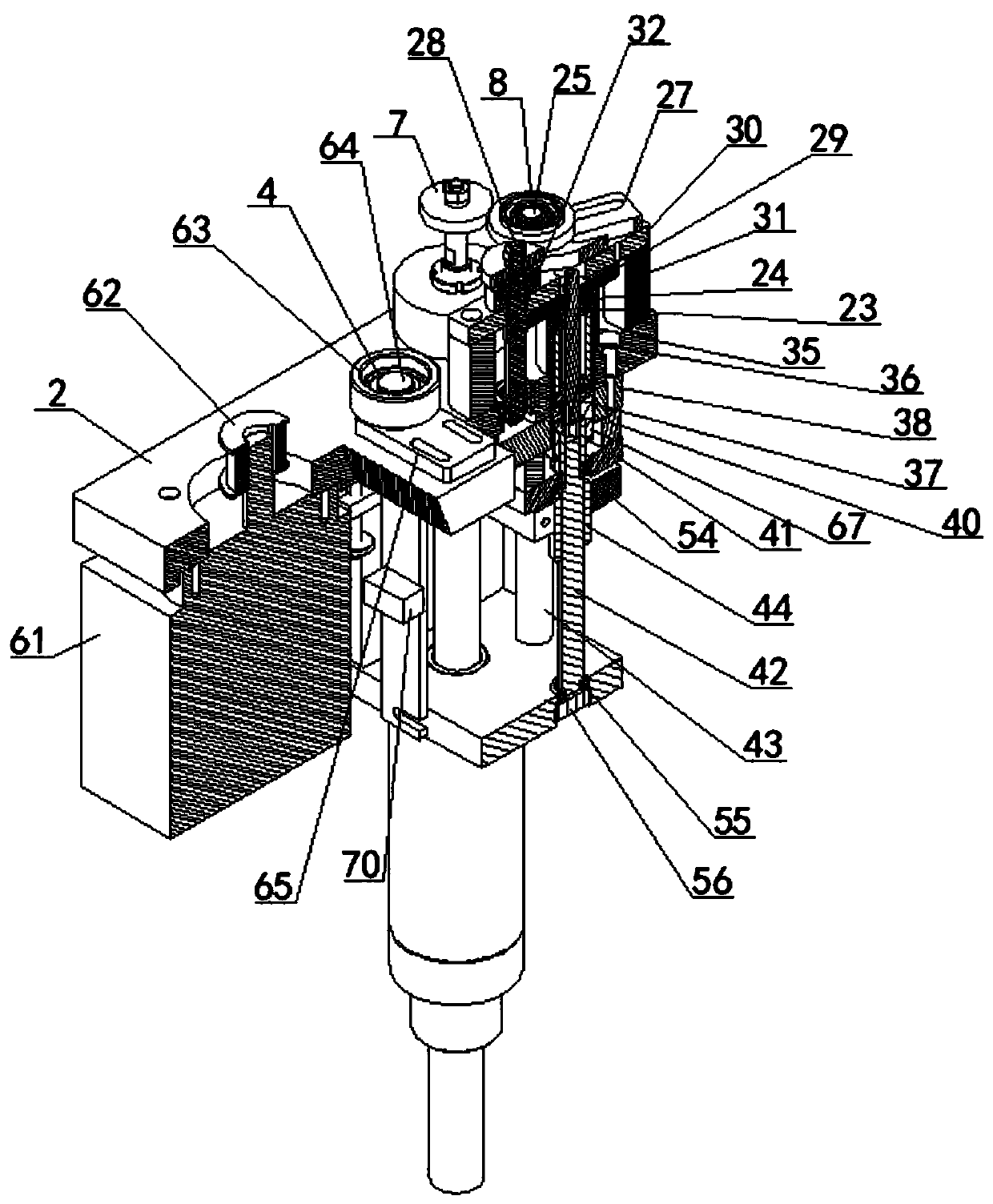

PendingCN110802284APrecise positioningImprove tapping accuracyThread cutting feeding devicesThread cutting machinesStructural engineeringElectrical and Electronics engineering

The invention provides a full-automatic cap tapping machine. The full-automatic cap tapping machine comprises a machine box, a feeding device, a driving device, a tapping device and a discharging device, wherein the feeding device is arranged on the machine box and comprises a vibration disc and a sliding rail; the tapping device comprises a tapping bench drill; the driving device comprises a divider and a cap positioning rotary disc; the divider is connected with the cap positioning rotary disc and drives the cap positioning rotary disc to rotate; the vibration disc is connected with one endof the sliding rail, and the other end of the sliding rail is positioned on the divider; a plurality of positioning grooves are formed in the cap positioning rotary disc; the tapping bench drill is arranged above the cap positioning rotary disc; the discharging device is arranged on the lower side of the divider and comprises a sliding way and a water filtering and feeding frame; the sliding way is positioned on the lower side of the divider; and the water filtering and feeding frame is arranged below the sliding way. The full-automatic cap tapping machine is simple in structure, good in machining precision, high in machining efficiency and high in finished product percent of pass.

Owner:浙江百润厨房用品有限公司

Small hole automatic tapping equipment

ActiveCN106141333BImprove automationImprove tapping efficiencyThread cutting feeding devicesThread cutting machinesEngineeringIn degree

Owner:CHENGDU HOMIN TECH

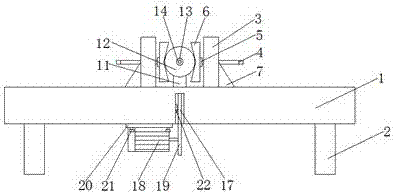

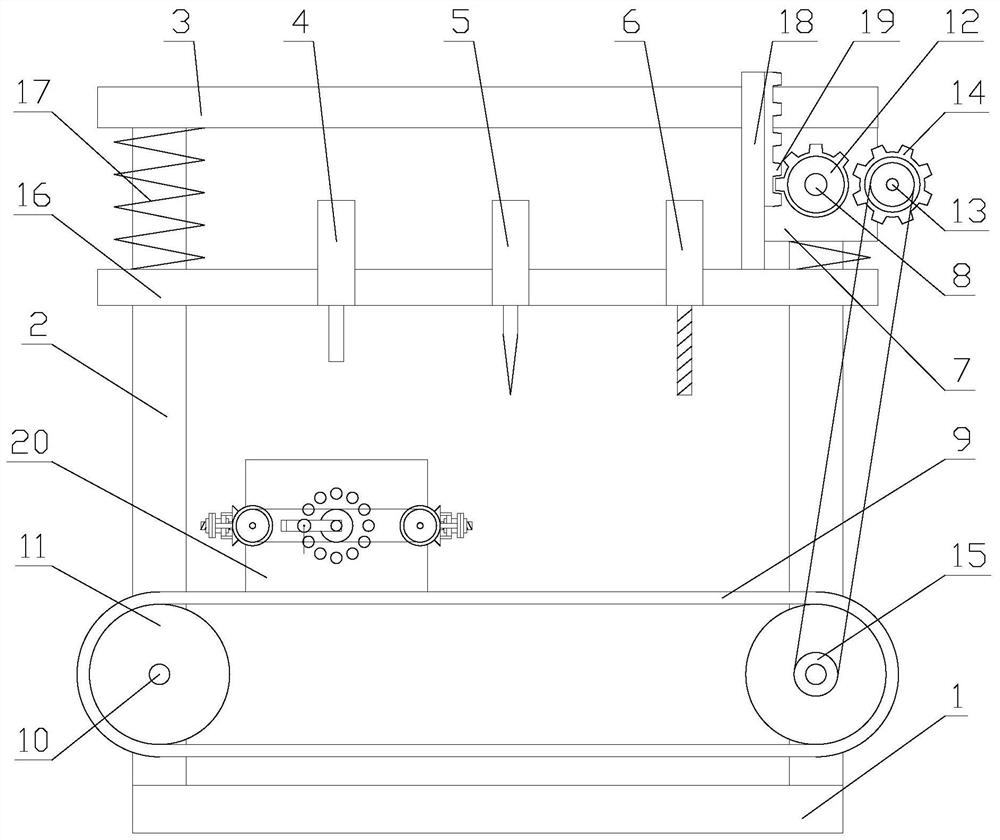

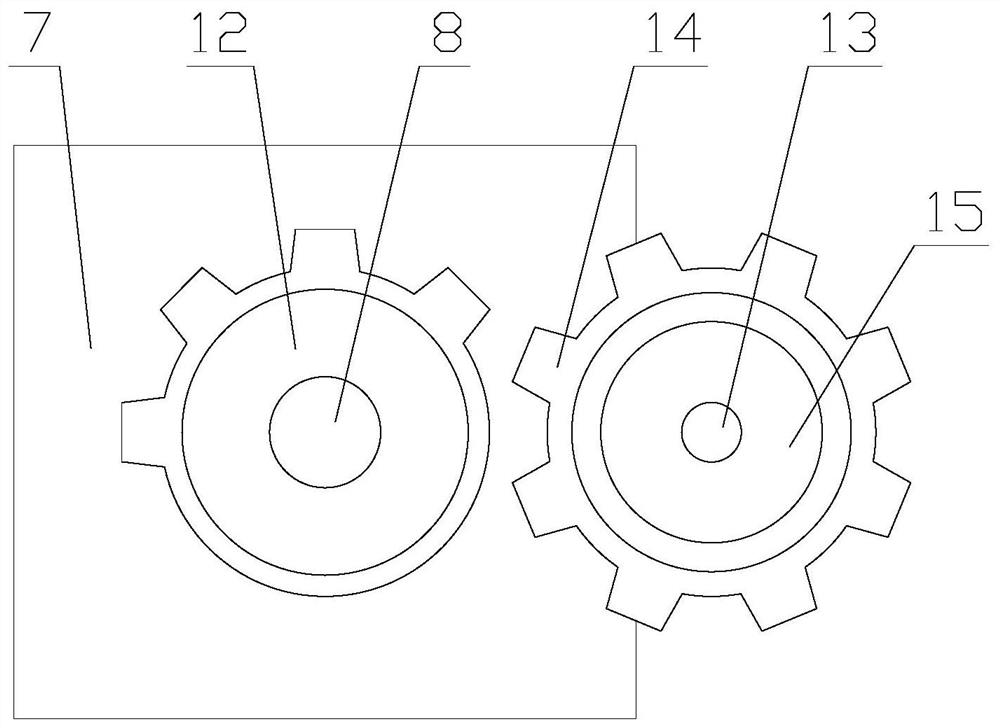

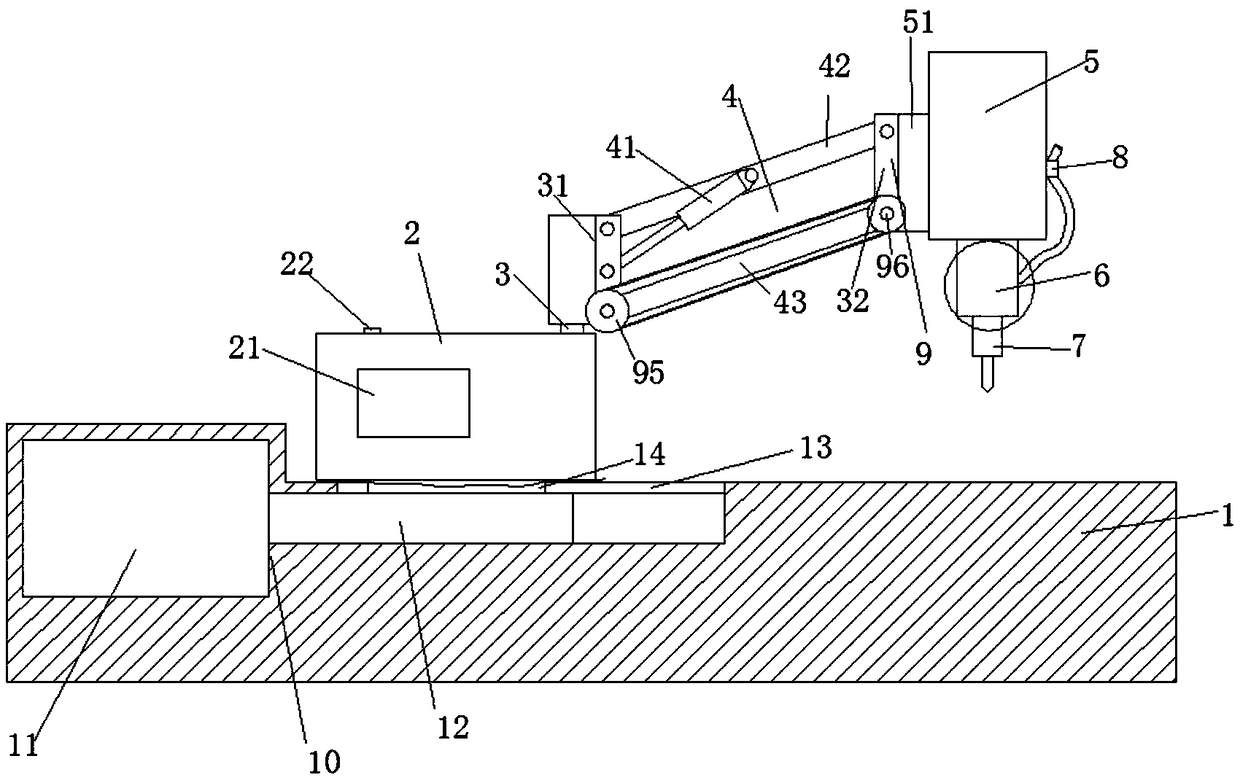

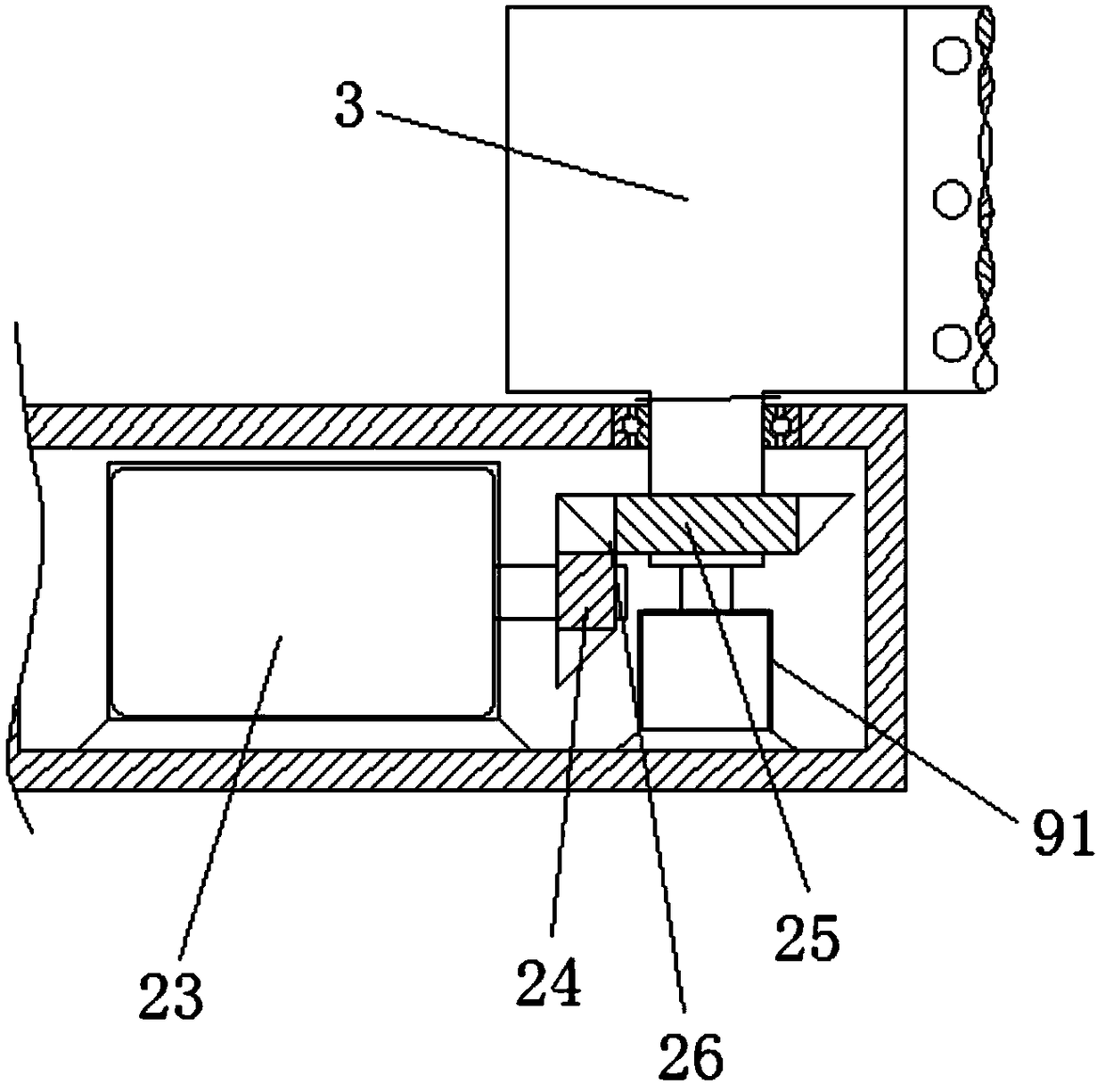

Automatic tapping equipment for small holes

ActiveCN106141333AImprove automationImprove tapping efficiencyThread cutting feeding devicesThread cutting machinesEngineeringSmall hole

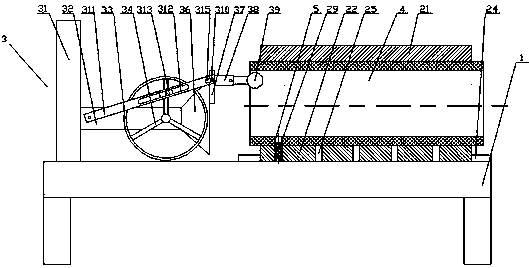

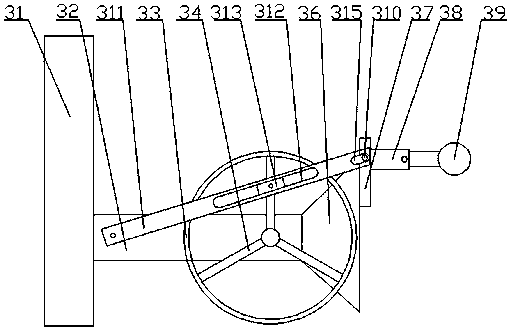

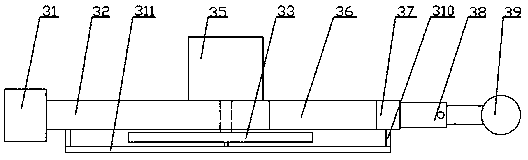

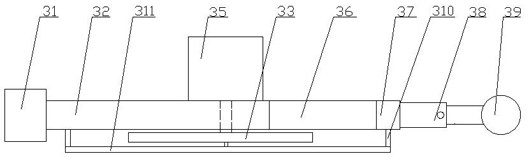

The invention relates to automatic tapping equipment for small holes. The automatic tapping equipment comprises a workbench, a feeding mechanism, a tapping mechanism, a dragging mechanism and a receiving mechanism. The feeding mechanism and the receiving mechanism are symmetrically arranged at the two ends of the workbench. A belt material groove is formed in the workbench. The tapping mechanism and the dragging mechanism are sequentially arranged above the workbench in the movement direction of a belt material. The tapping mechanism comprises a back plate, a vertical guide rail, a horizontal guide rail, a horizontal moving sliding block, a spindle and a screw tap. The lower end of the back plate is fixed to the workbench. The vertical guide rail is arranged on the side wall of the back plate. The horizontal guide rail is mounted on the vertical guide rail in a sliding fit manner. A vertical movement motor is mounted on the top of the back plate. The horizontal movement sliding block is mounted on the horizontal guide rail in a sliding fit manner. A horizontal movement motor is mounted at the end of the horizontal guide rail. A spindle seat is fixedly arranged on the horizontal movement sliding block. The spindle is fixed to the position above the spindle seat. The screw tap is fixed to the lower end of the spindle. The automatic tapping equipment has the beneficial effects of being high in degree of automation, low in labor intensity and good in small hole tapping quality.

Owner:CHENGDU HOMIN TECH

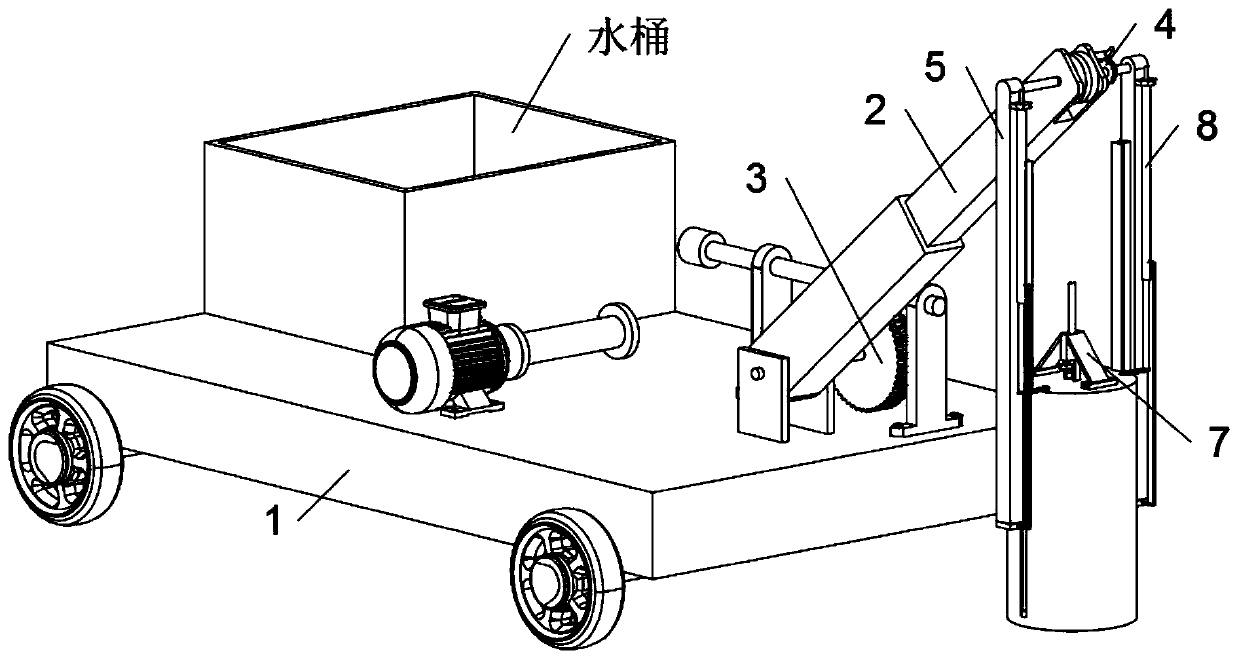

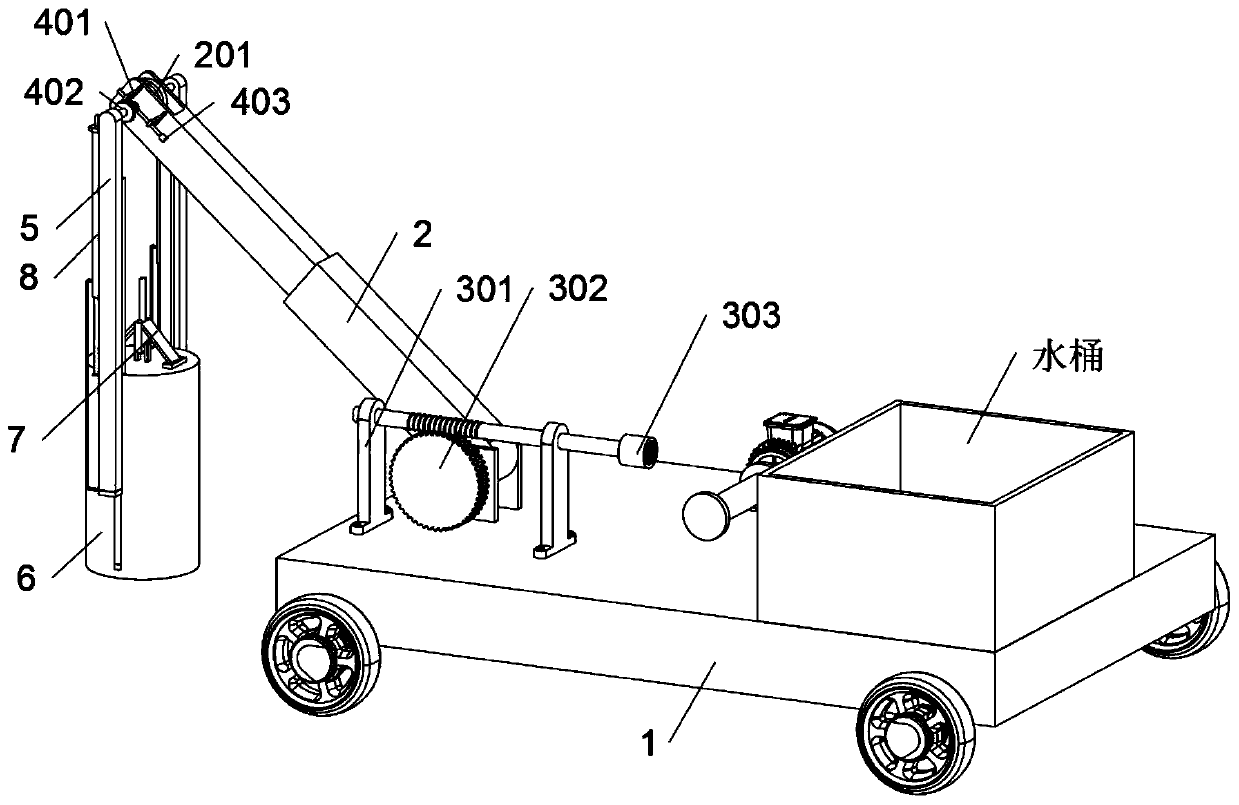

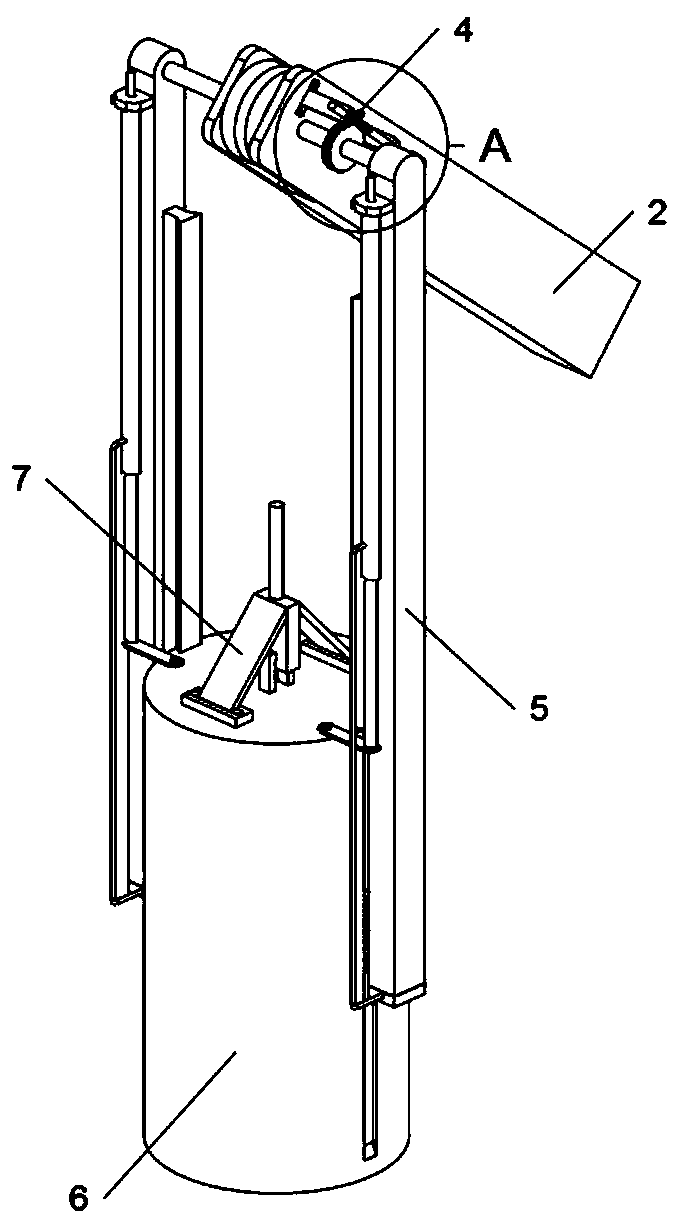

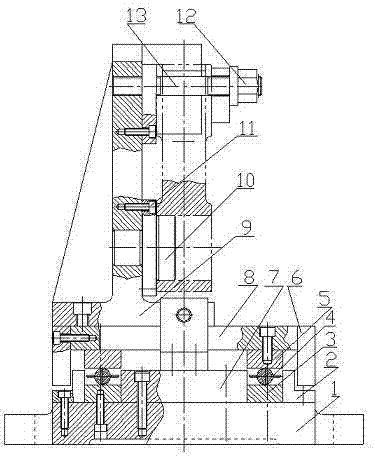

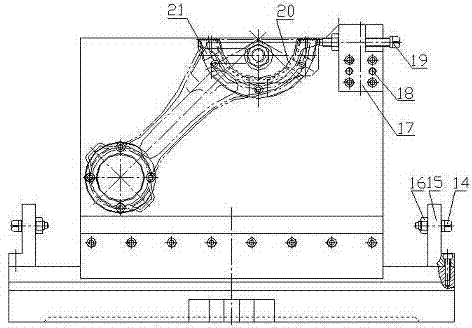

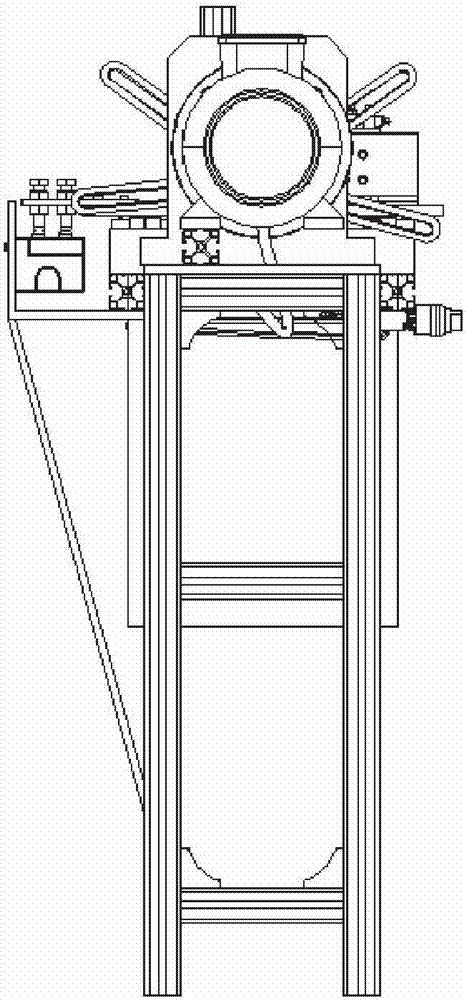

Punching pile machine convenient for folding and moving

InactiveCN111485815AEliminate the effects ofImprove tapping accuracyEarth drilling toolsDrill bitsSuspension (vehicle)Impact

The invention provides a punching pile machine convenient for folding and moving, and relates to the field of road and bridge construction equipment. The problems that a falling position of an impacthead is prone to shifting under the influence of wind force in windy weather; when the impact head is fixed, fixing is usually conducted by a clamp, the disassembly is cumbersome, and diversified fixed structures cannot be adopted simultaneously to synchronously fix are solved. The punching pile machine convenient for folding and moving comprises a vehicle body, a telescopic arm is rotatably connected to the vehicle body. Because an elastic clamp pin is installed on a suspension head, the head end of the elastic clamp pin is of an inclined structure, the convenience of clamping installation between a suspension heat and the suspension head can be improved; and secondly, when a clamping arm and a clamping seat are clamped, the suspension head is in contact with the bottom end surface of theinner wall of the suspension seat, thus on the one hand, the clamping seat and the clamping arm can be used as second fixing and limiting structures for use, and on the other hand, the two clamping structures can be clamped or inserted for fixation at the same time.

Owner:贵阳品创科技有限公司

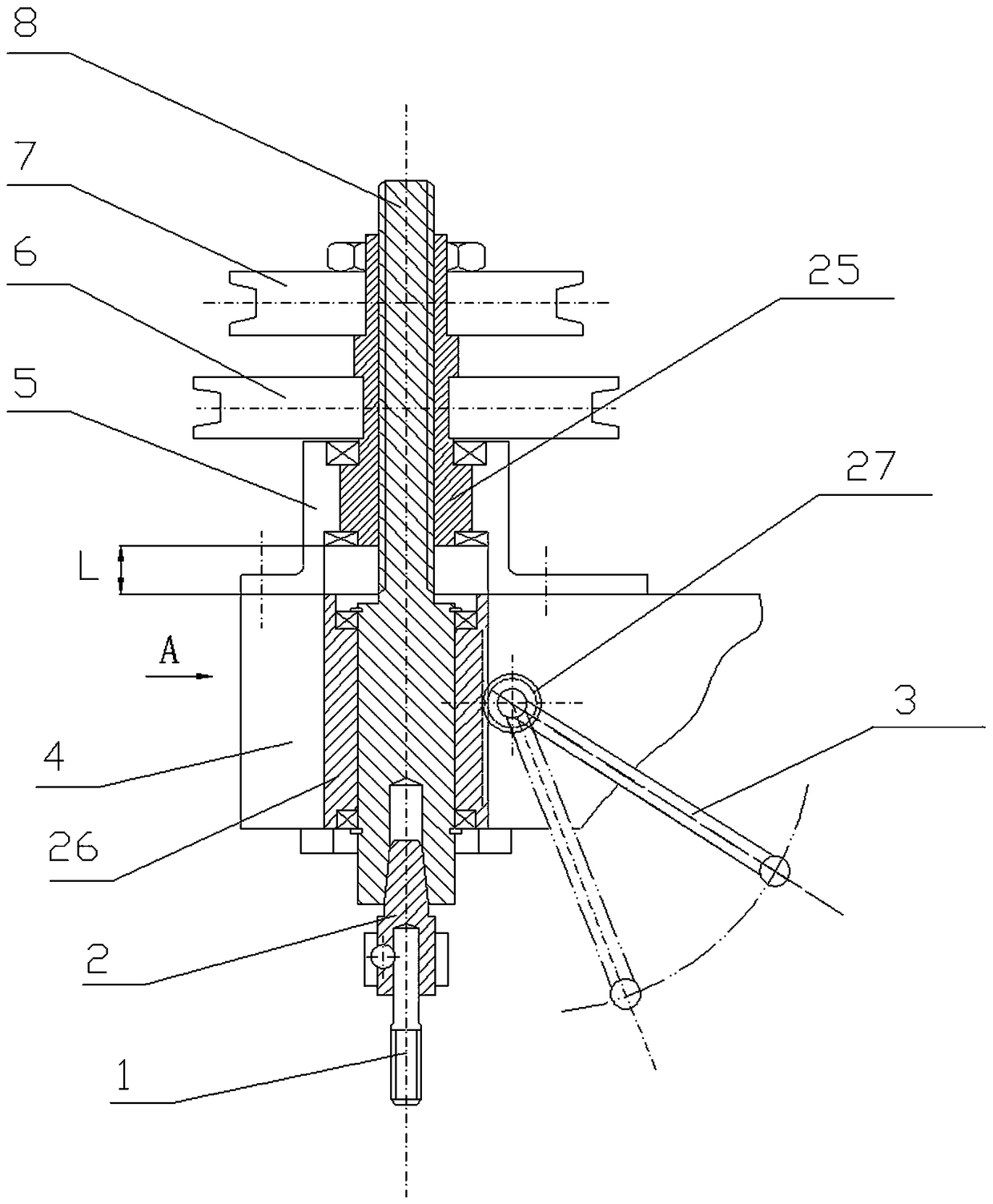

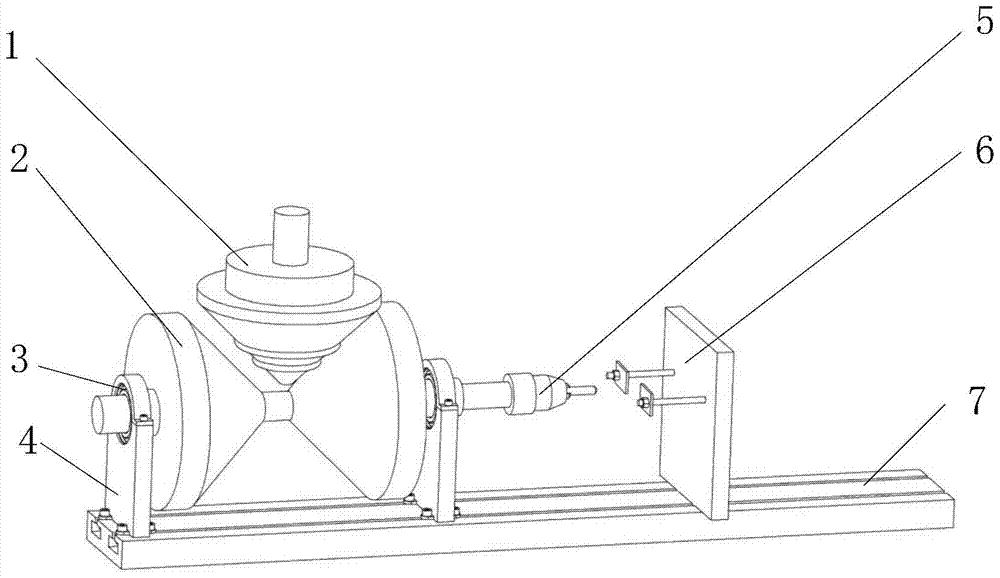

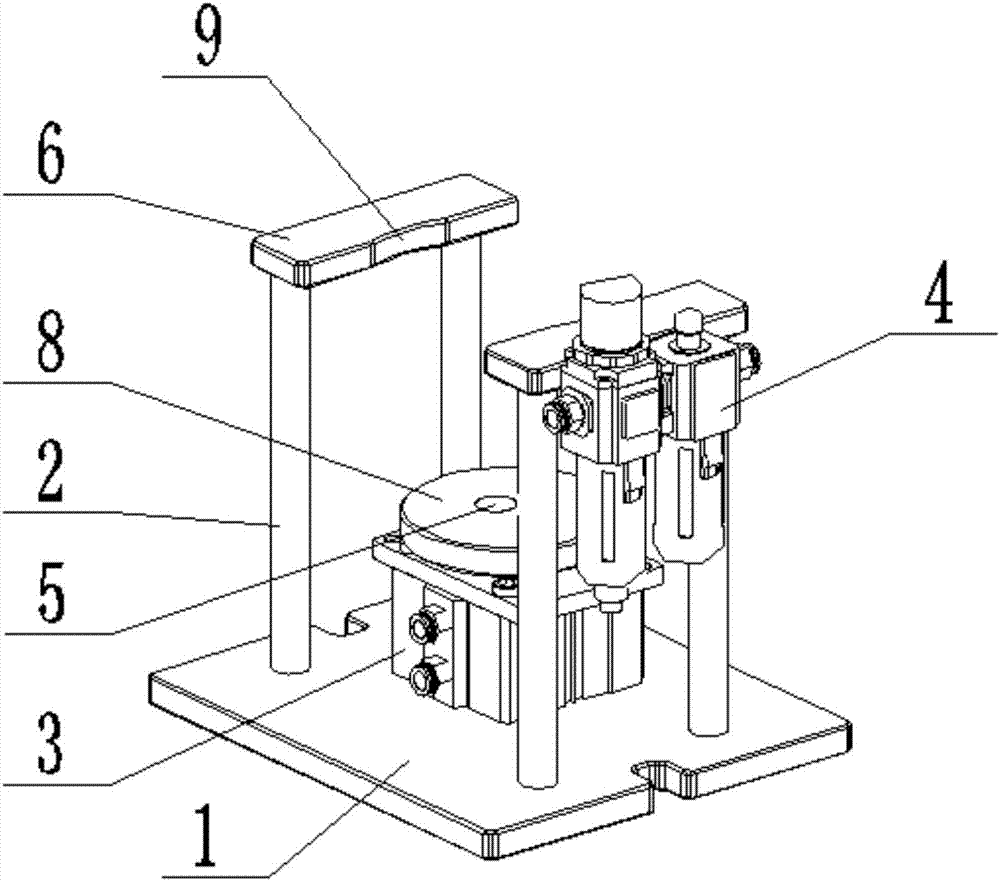

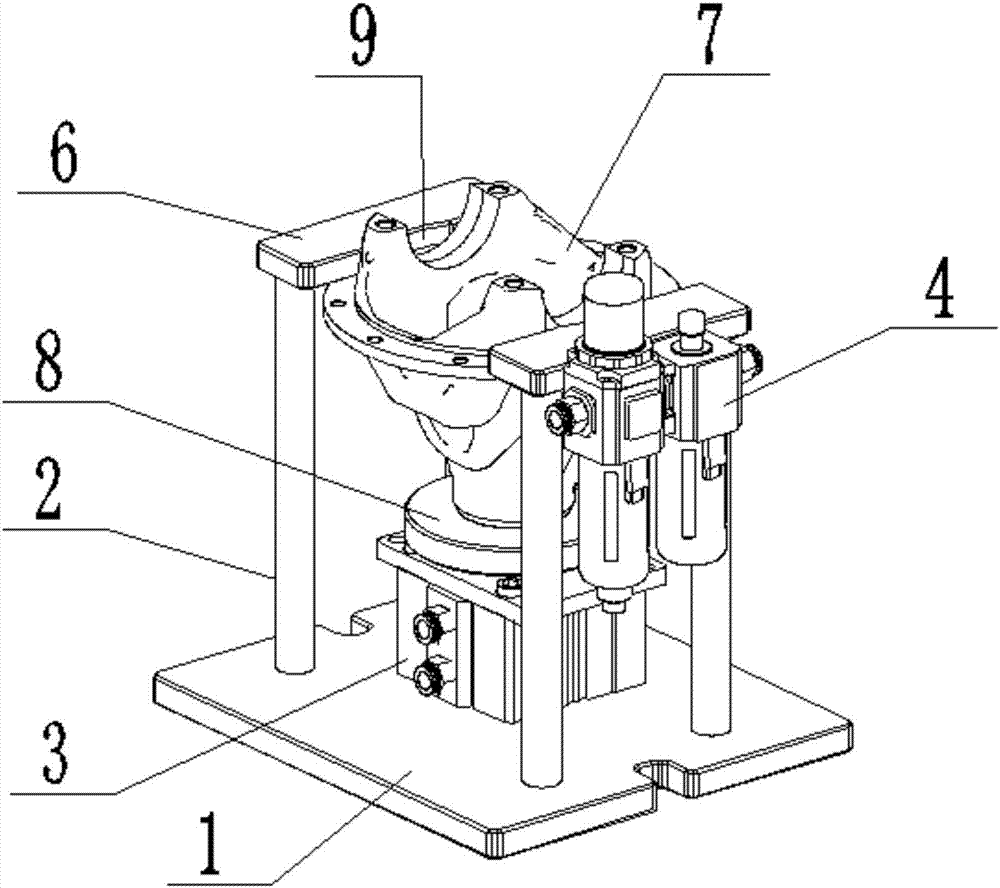

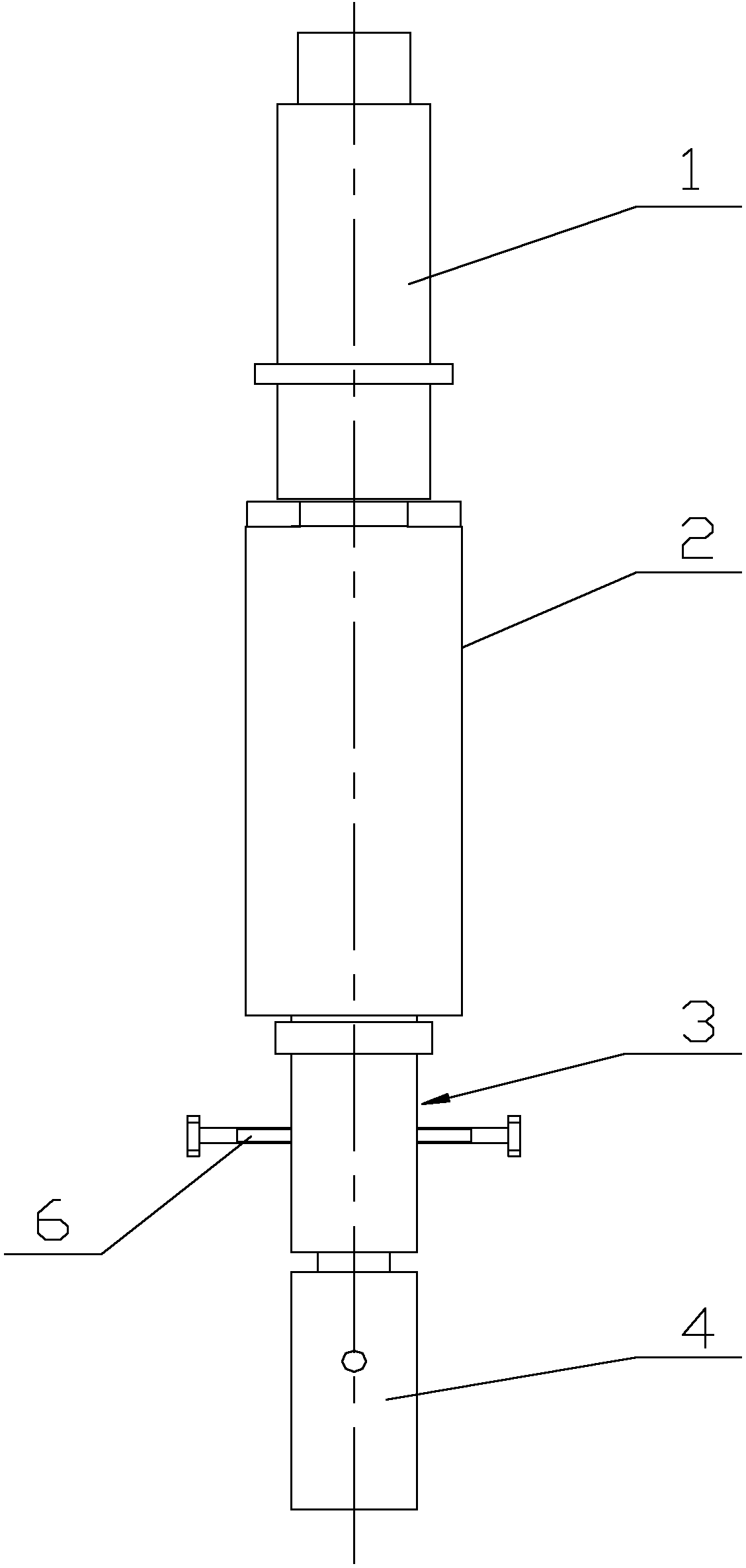

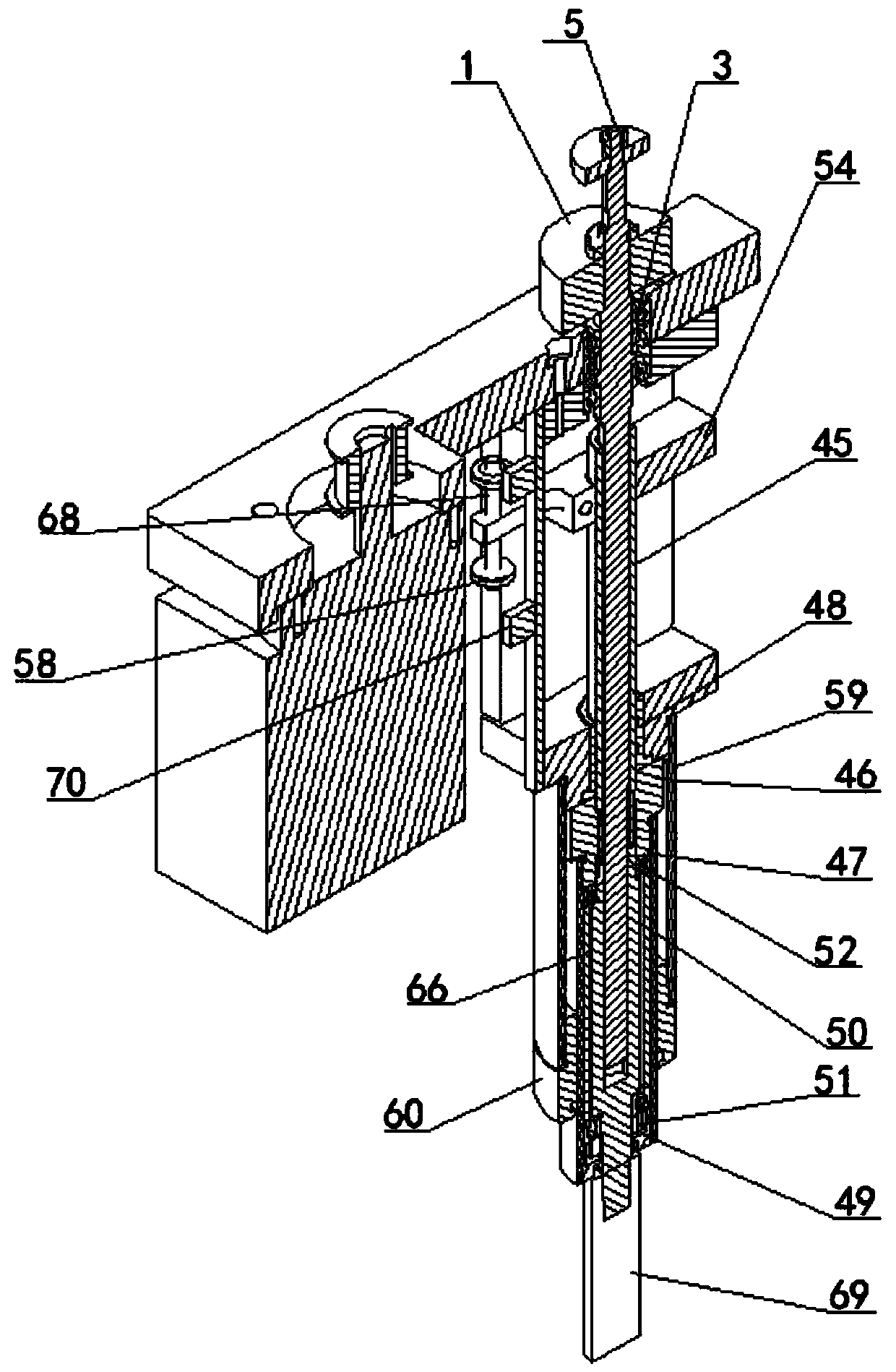

Floating tapping clamp for automotive connecting rods

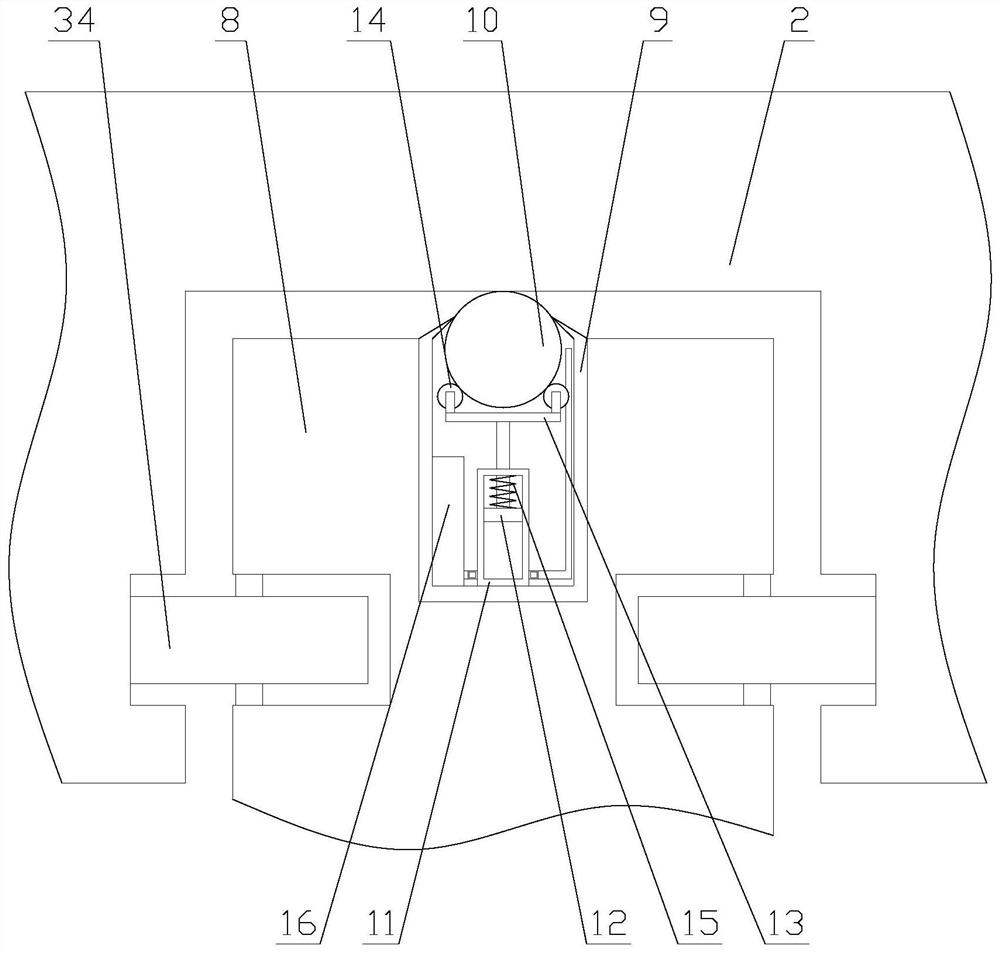

InactiveCN102000891BFast Floating TappingImprove tapping accuracyThread cutting machinesPositioning apparatusEngineeringSteel ball

The invention relates to a floating tapping clamp for automotive connecting rods, which is capable of carrying out floating tapping on automotive connecting rods and has high tapping precision. A base cushion block is arranged on a base, a lower steel ball support plate is sleeved on the base and forms a boss with the base cushion block, steel balls and spring jaws are arranged on the boss, an upper support plate is arranged on an upper steel ball support plate and is formed by stack, an angle iron clamp is fixed on the upper support plate, a gauge pile head is connected with the angle iron clamp, a double end stud is connected with the angle iron clamp, two fixing backers are fixed on the base, a jack bolt is fixed at the upper end of each fixing backer, a fixing block is fixed at the upper part of the angle iron clamp through a taper pin, a hexagonal bolt goes across each fixing block, a semicircular support block is fixed on the angle iron clamp, and an opening pressing plate is arranged on the semicircular support blocks and is positioned through the jack bolts.

Owner:HANGZHOU JIULONG MACHINERY MFG

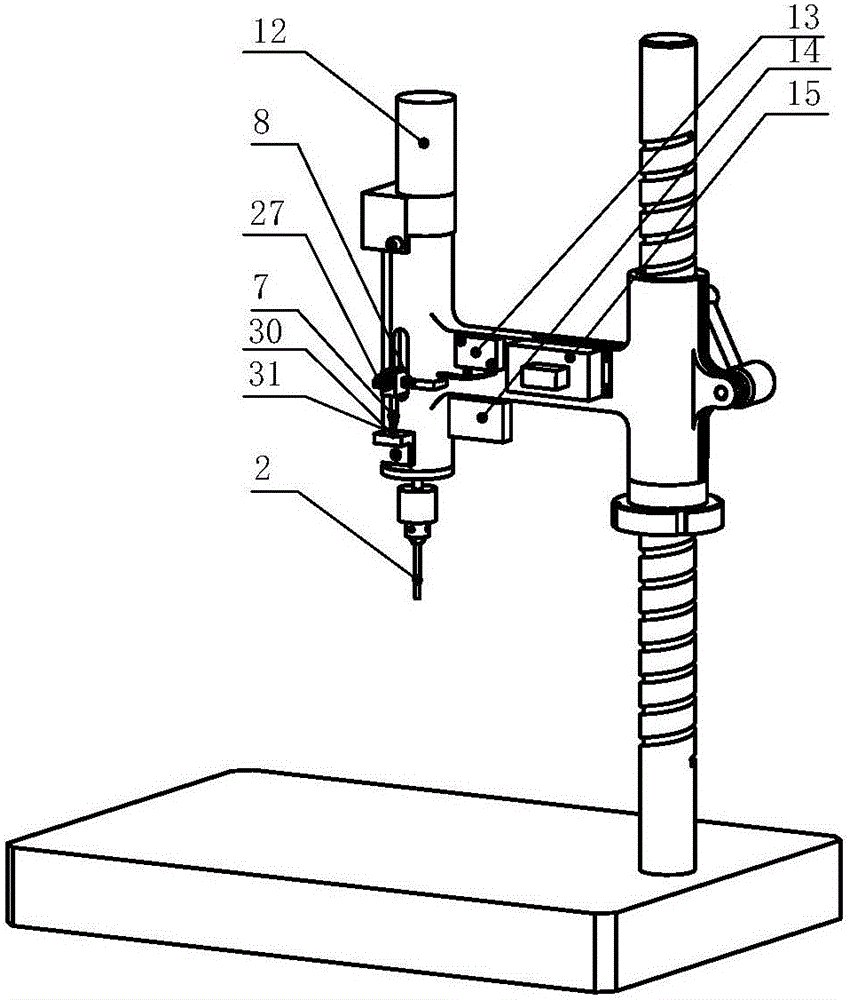

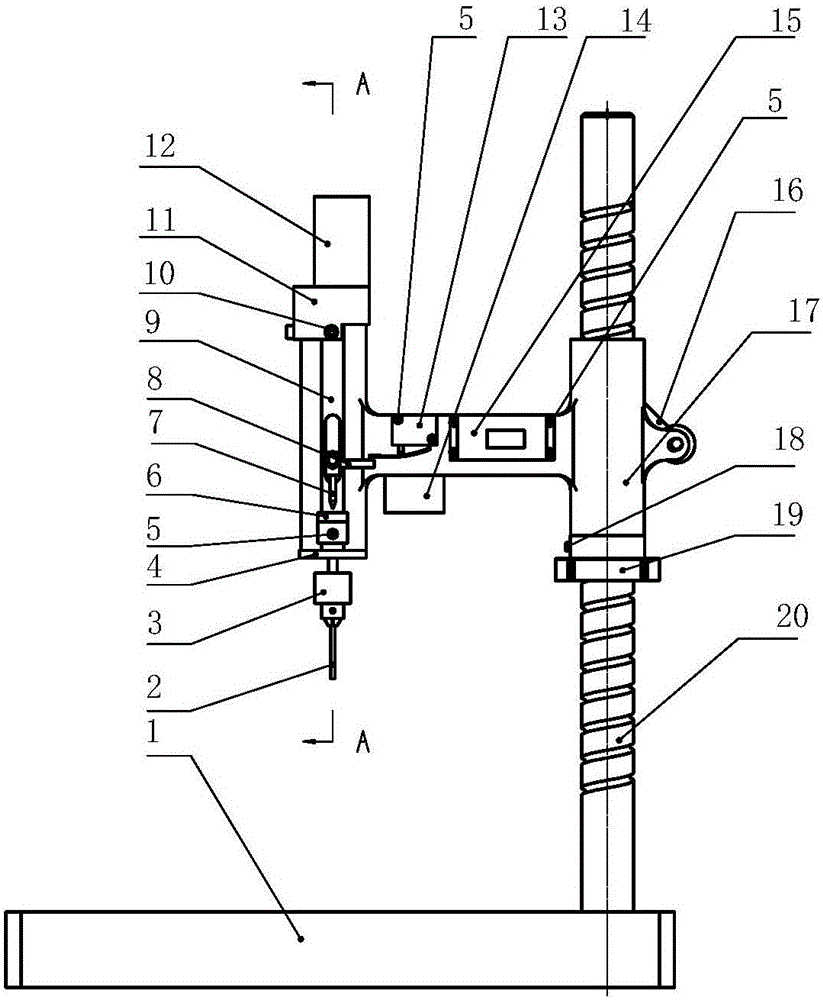

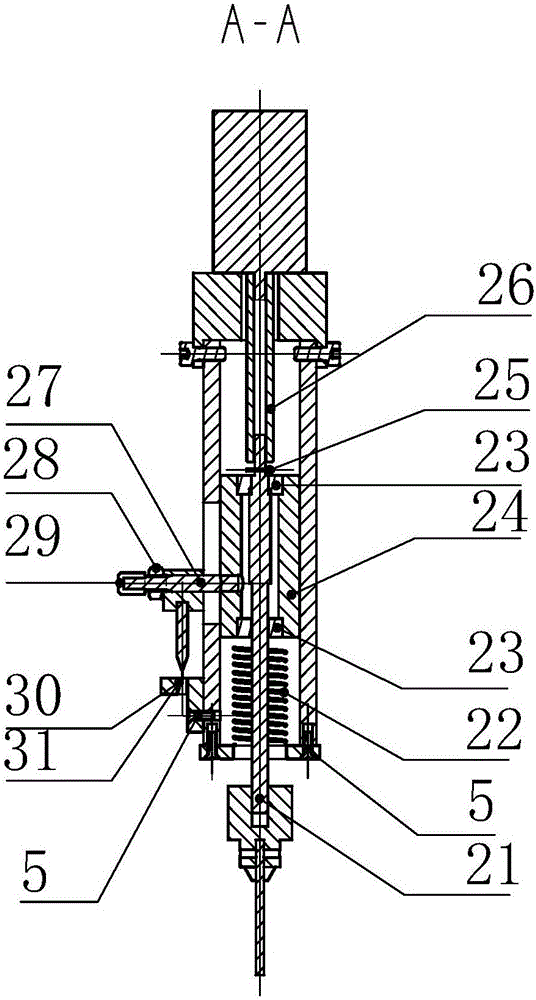

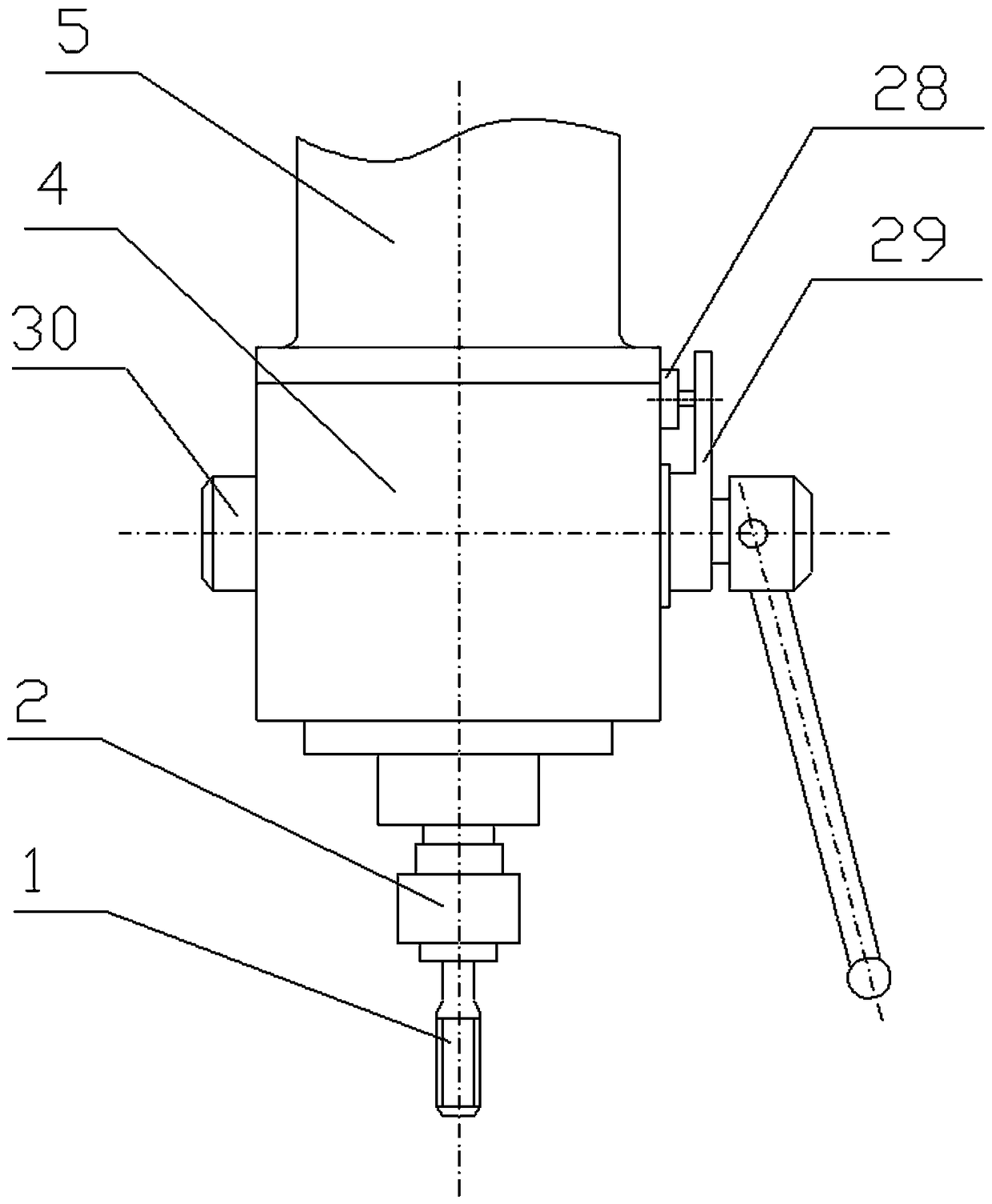

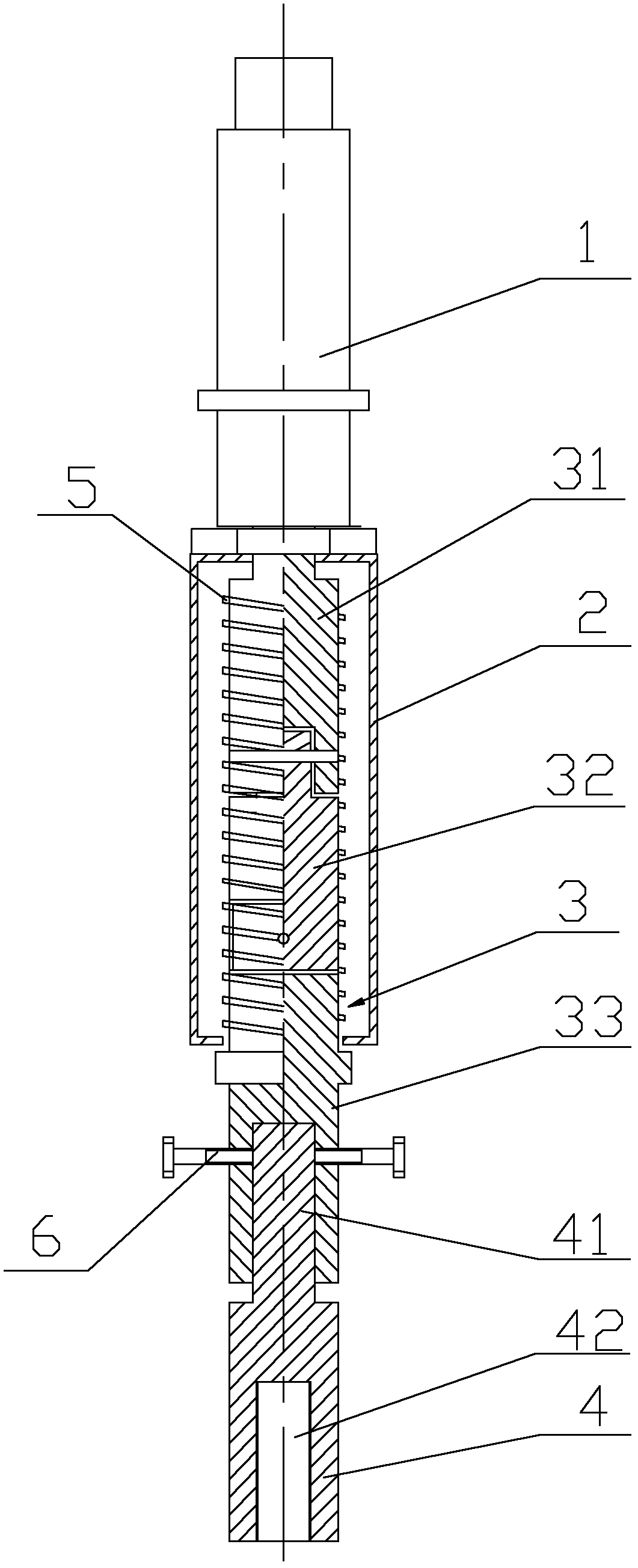

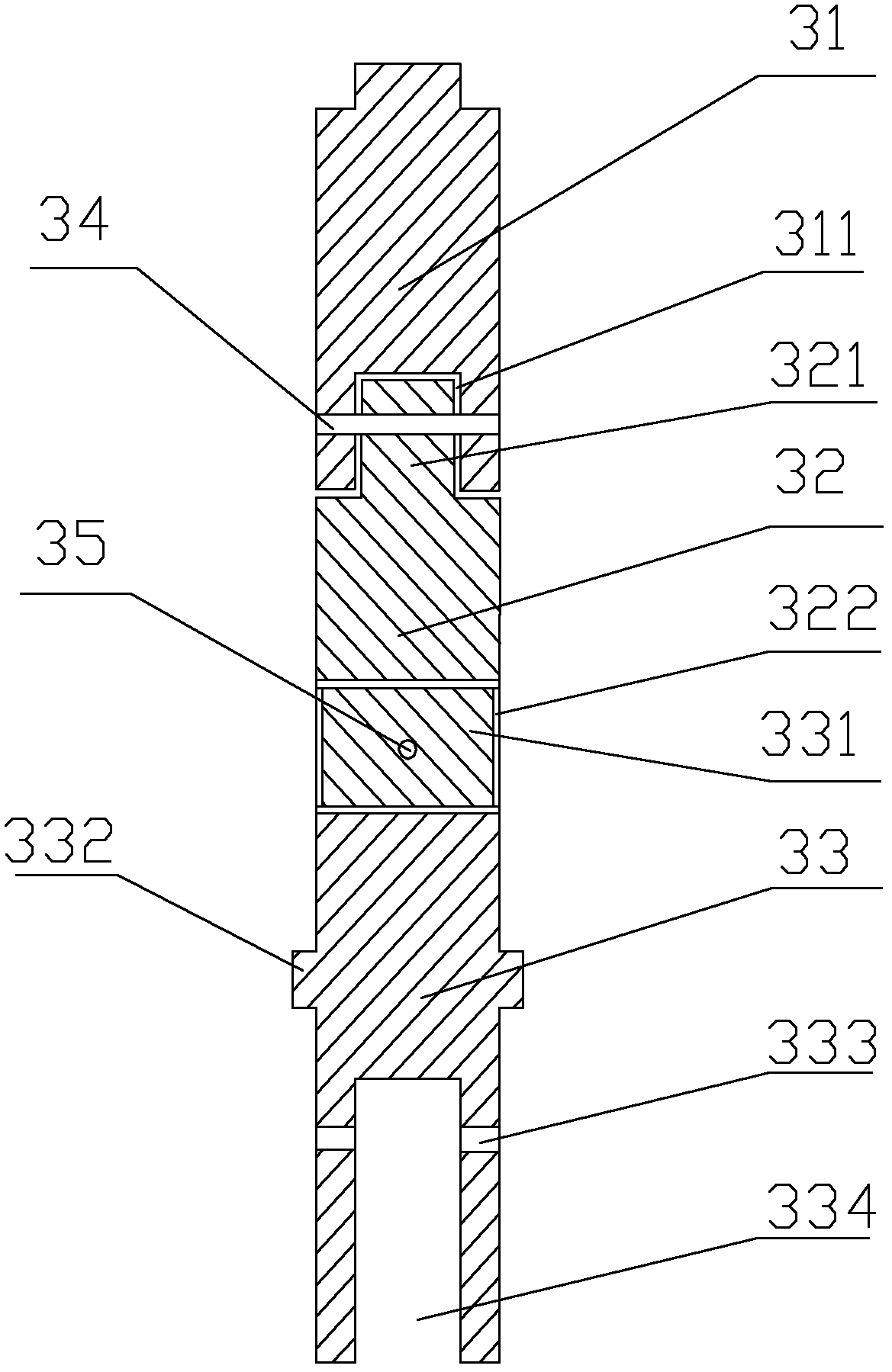

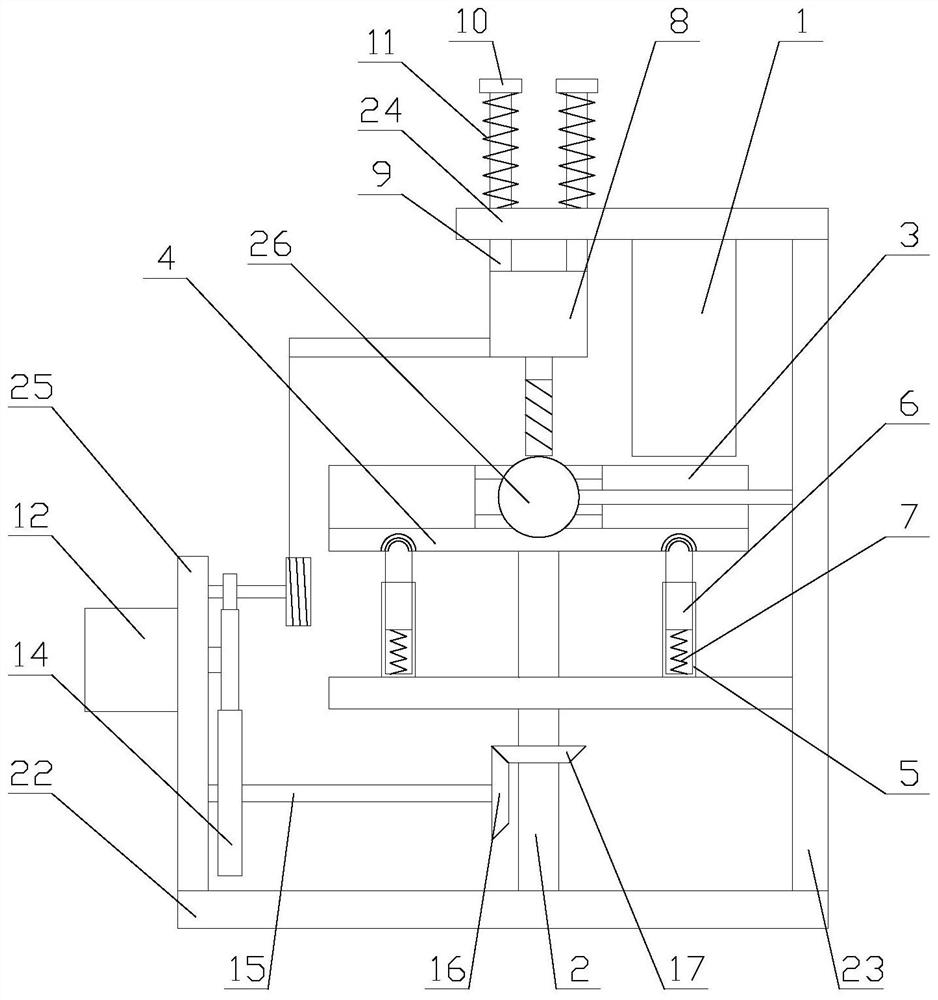

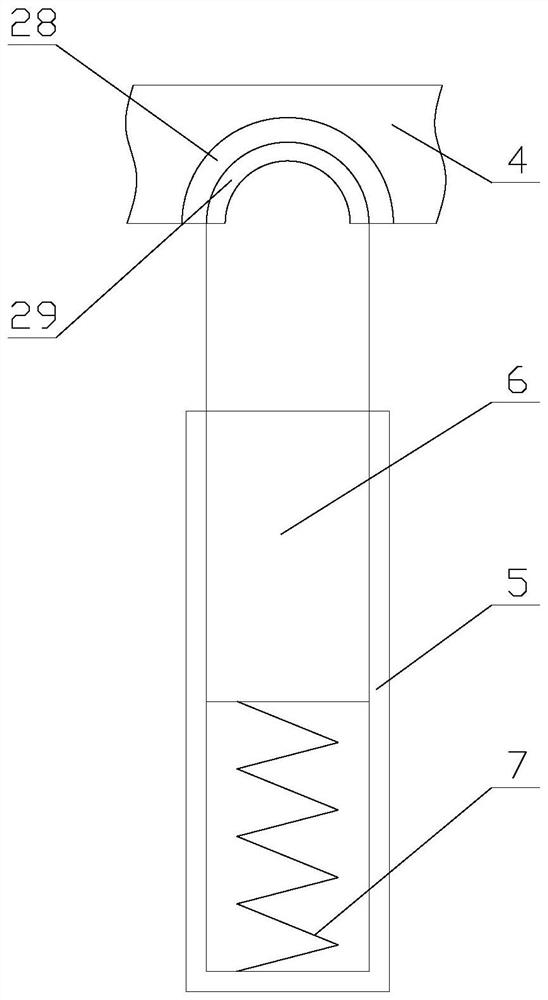

Tapping machine for threaded hole

InactiveCN106077844AImprove machining accuracySimple structureThread cutting feeding devicesThread cutting machinesControl systemDrive shaft

The invention discloses a tapping machine for a treaded hole and aims at providing a thread tapping tool with easiness in control, high efficiency, low working intensity, stable torque and controllable tapping depth. The tapping machine comprises a screw rod, a cantilever shaft sleeve, an electrically operated mechanism and a stroke control system, wherein the screw rod is vertically fixed at one side of a base worktable; the cantilever shaft sleeve is matched onto the screw rod; the electrically operated mechanism is vertically and fixedly connected onto the cantilever shaft sleeve; and an electric motor and a shaft end screw are connected into a whole by a fixed sleeve of the electrically operated mechanism. The tapping machine is characterized in that a spindle of the electric motor (12) is connected with a driving shaft (26); the driving shaft (26) is connected with a mandrel (21) through a bearing (23) matched with a shaft sleeve; a tapping chuck (3) provided with a thread tap (2) is connected with the mandrel (21); and the electric motor is electrically with an intermediate relay through a stroke switch (13) and a total switch (14) which are arranged on a cantilever, and electrically controls the tapping chuck (3) to rotate and tap in a semiautomatic manner.

Owner:CHENGDU KAITIAN ELECTRONICS

Secondary machining process for oil hole of hydraulic cylinder of horizontal jack

The invention relates to a secondary machining process for an oil hole of a hydraulic cylinder of a horizontal jack. The process includes the specific steps that S1, an oil hole knocking device is positioned; S2, the length of the oil hole of the hydraulic cylinder is measured, wherein the length d between the end face of the hydraulic cylinder and the center of the oil hole is measured by a vernier caliper; S3, the hydraulic cylinder is installed and the oil hole is positioned; S4, the length of a fixing rod is positioned and then adjusted to be consistent with d; S5, the oil hole is perpendicularly knocked by a steel ball in a reciprocating mode for 8 s to 10 s; and S6, the oil hole is polished by rubber, wherein a clamping table is moved and the hydraulic cylinder is dismounted, and theoil hole is polished by the rubber dipped with diamond micro-powder. The secondary machining process has the following advantages that the oil hole is knocked so as to be smoother and flatter, scraping damage of a sealing part is avoided, and clamping of the sealing part and normal operation of a pushing piston are guaranteed.

Owner:江苏海力达机电制造有限公司

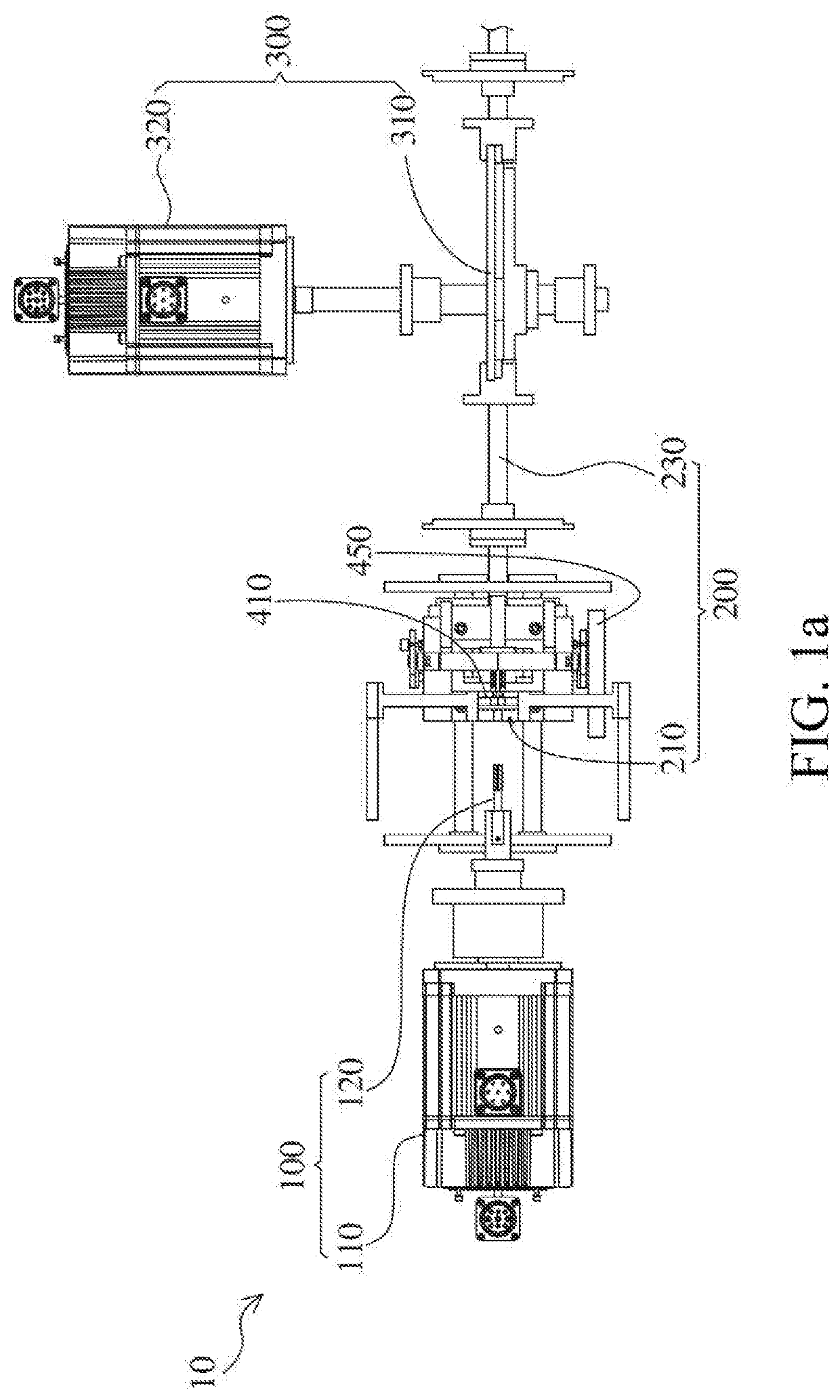

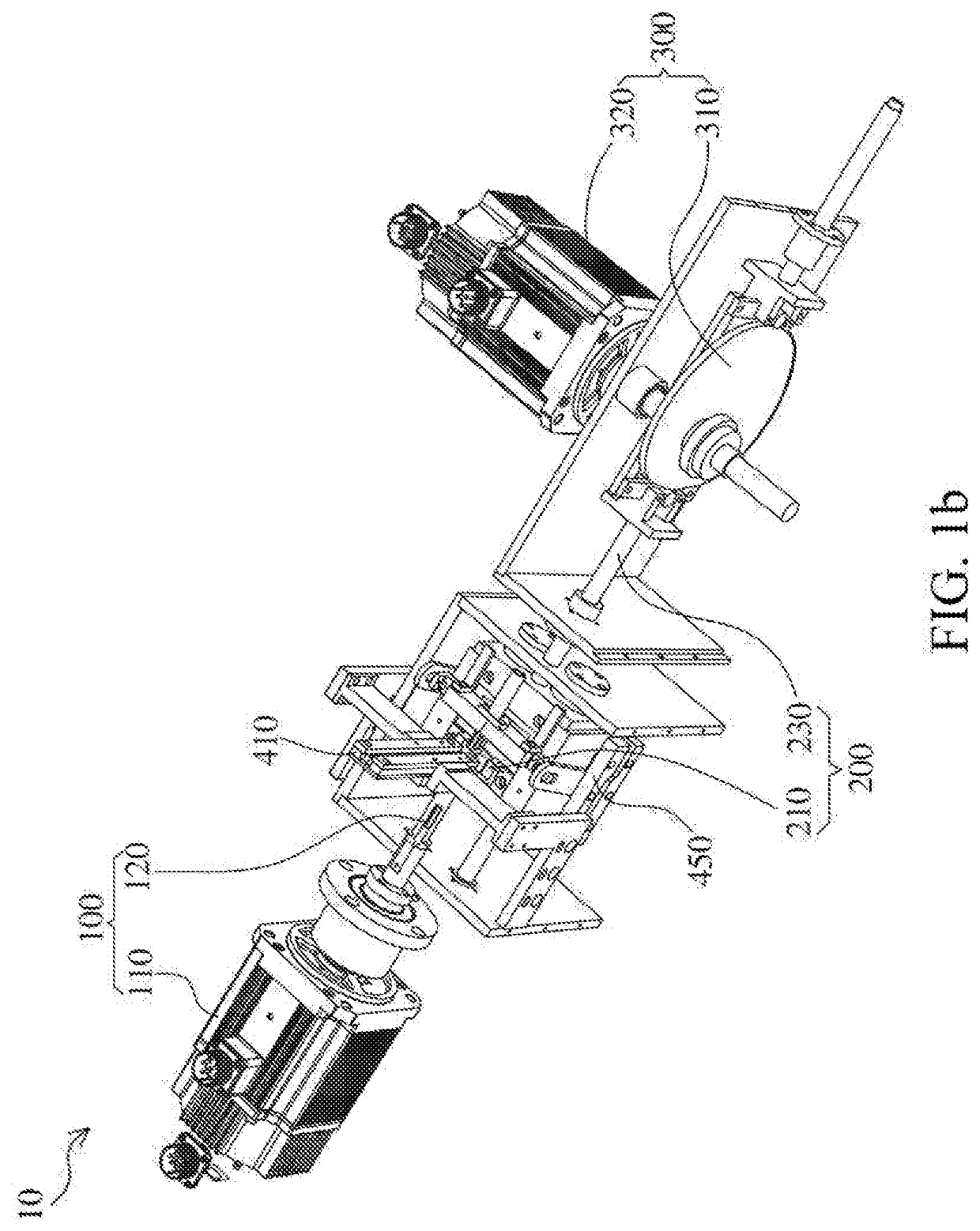

Automatic nut tapping equipment

ActiveUS11141806B2Increased torsional stiffnessImprove rigidityThread cutting machinesFeeding apparatusElectric machineryEngineering

An automatic nut tapping equipment is provided. The automatic nut tapping equipment includes a tap rotating mechanism, a nut clamping mechanism, an axial transmission mechanism, and a nut placing slot. The tap rotating mechanism includes a tap rotary motor and a tap, wherein the tap is driven by the tap rotary motor. The nut clamping mechanism includes a clamping assembly and a sliding rail, wherein the clamping assembly is disposed on the sliding rail and is configured for clamping a to-be-tapped nut to restrict the to-be-tapped nut from rotating. The axial transmission mechanism controls the clamping assembly to axially translate one pitch in response to the tap rotating one revolution, such that a forward nut-tapping motion and a backward nut-retracting motion are performed by the nut clamping mechanism. The nut placing slot is configured to arrange and control the dropping of another to-be-tapped nut.

Owner:NAT SUN YAT SEN UNIV

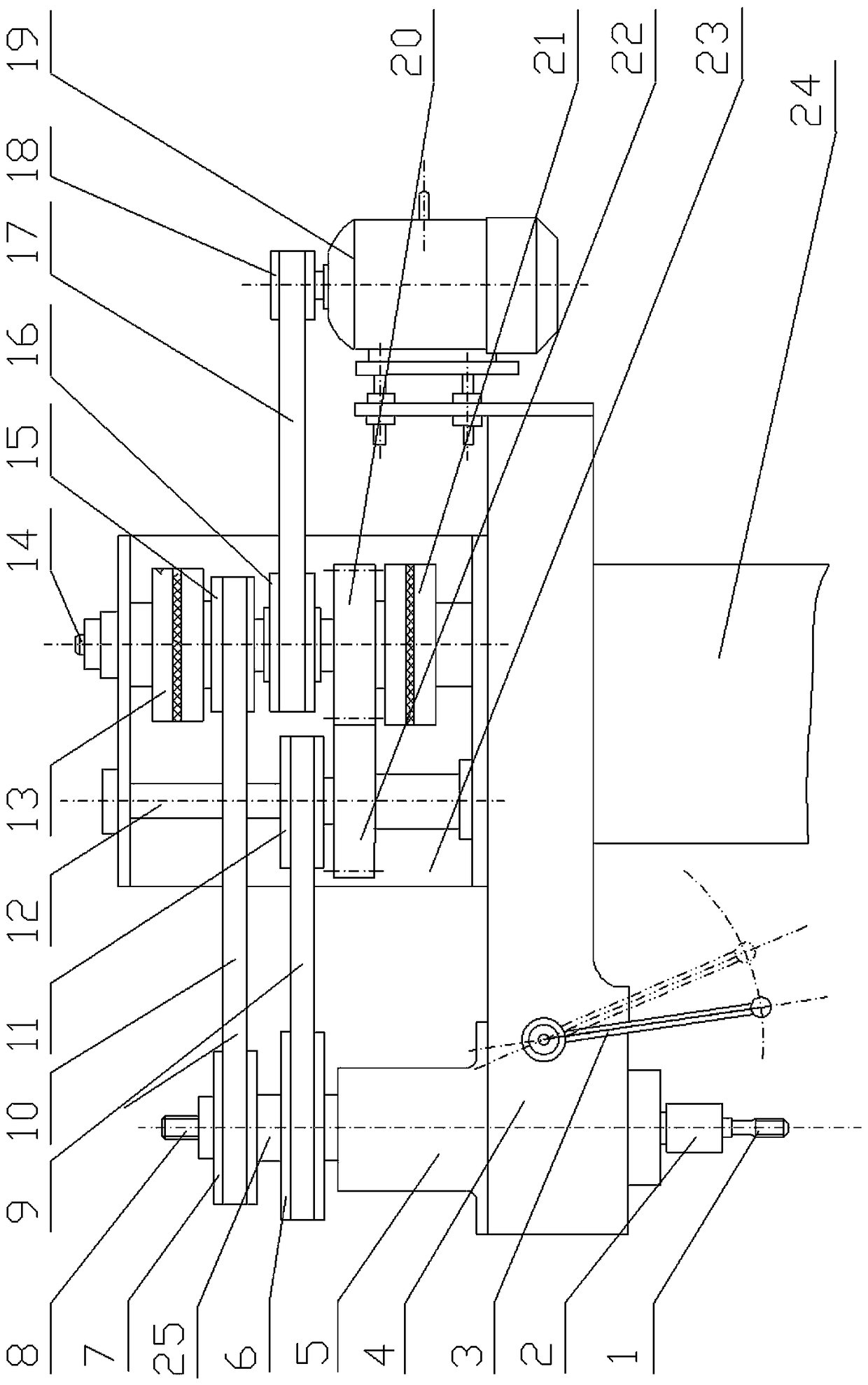

A workpiece automatic tapping device

ActiveCN106180916BHigh degree of automationImprove tapping accuracyThread cutting feeding devicesThread cutting machinesEconomic benefitsEngineering

The invention discloses an automatic tapping device for workpieces. The automatic tapping device comprises a box body, a pushing rod component, a tapping head component, a guiding component and a motor, wherein the pushing rod component is connected to one end of the box body; the other end of the box body is connected with a tensioning device; the pushing rod component is connected with the tapping head component through a bearing and a sealing ring; the pushing rod component comprises a pushing rod, a copper sleeve which is nested on the outer surface of the pushing rod and a lubrication system which is arranged at the connection part of the pushing rod component and the box body; the lubrication system comprises a buffer pad, an embedded component and a lubrication head; the guiding component is arranged on the pushing rod component; the tensioning device is connected with a driving device; the tensioning device drives a stoke switch component; the motor is arranged on the box body; and a controller which controls the tensioning device and the driving device is also arranged on the box body. According to the automatic tapping device, the action of the driving device and the action of the tensioning device are controlled through the controller in a whole process; the automation degree is high; the working efficiency is greatly improved; the tapping precision is high; the rejection rate is low; production cost is greatly lowered; and the economic benefit is good.

Owner:深圳市格仕乐科技有限公司

Tapping machine with tapping oil recycling function

InactiveCN113020723AWith recycling functionRealize online sprayingThread cutting machinesProcess engineeringIndustrial engineering

The invention relates to a tapping machine with a tapping oil recycling function. The tapping machine comprises a base, a main body, a moving mechanism and an oil spraying mechanism. According to the tapping machine with the tapping oil recycling function, the main body moves through the moving mechanism; a workpiece is tapped through the main body; and tapping oil is sprayed through the oil spraying mechanism. Compared with an existing tapping machine, the movement of the main body and the spraying of the tapping oil are achieved through one output end, and energy is saved. Moreover, the moving mechanism and the oil praying mechanism are linked to achieve online spraying of the tapping oil. The linkage uses a pure mechanical structure, the stability of the device is improved, and the service life of the device is prolonged. Compared with an existing moving mechanism, the moving rod can more stably move through a lubricating assembly, accordingly, the tapping precision is improved, and a better tapping effect is achieved. Compared with an existing oil spraying mechanism, recycling of scrap iron and dredging of a filter screen are achieved through the movement of a magnet, the tapping oil is better reused, and the practicability is improved.

Owner:包宇峰

A Secondary Processing Technology of Oil Hole of Horizontal Jack Hydraulic Cylinder

The invention relates to a secondary processing technology for the oil hole of a hydraulic cylinder of a horizontal jack. The specific steps include: S1, positioning the oil hole knocking device; S2, measuring the length of the oil hole of the hydraulic cylinder, and measuring the distance between the end surface of the hydraulic cylinder with a vernier caliper The length d at the center of the oil hole; S3, install the hydraulic cylinder and position the oil hole; S4, locate the length of the fixed rod, adjust the length of the fixed rod to make it consistent with d; S5, strike the oil hole vertically with a steel ball, The knocking time is 8s‑10s; S6, rubber polishing oil hole, move the clamping table and disassemble the hydraulic cylinder, and polish the oil hole with diamond powder on the rubber. The invention has the following advantages: the oil hole is smoother and smoother by knocking the oil hole; The locking of the parts and the normal operation of the push piston.

Owner:江苏海力达机电制造有限公司

Large stroke high speed electric tapping machine

ActiveCN106238833BIncrease speedOptimize layoutThread cutting auxillary apparatusElectromagnetic clutchEngineering

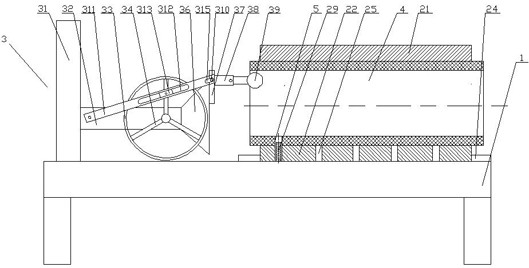

The invention provides a large-stroke and high-speed electric tapper. A clutch transmission case is arranged between a feed machine head of a machine head base and an electric motor. A clutch rotating shaft and a transmission shaft are vertically arranged in the case side by side. The clutch rotating shaft is connected with the electric motor through belt wheel transmission. Two electromagnetic clutches are arranged at the upper end and the lower end of the clutch rotating shaft correspondingly. A first transfer belt wheel and a reversing driving gear which are in sliding fit with the clutch rotating shaft are connected with armatures of the two electromagnetic clutches correspondingly. A second transfer belt wheel and a reversing driven gear engaged with the reversing driving gear are fixed to the transmission shaft. An inner spline sleeve is supported in the head end of the machine head base. Two driven belt wheels on the inner spline sleeve are connected with the first transfer belt wheel and the second transfer belt wheel through conveyor belts correspondingly. The upper section of a main shaft of the feed machine head is a spline section and matched with a spline of the inner spline sleeve. The lower section of the main shaft of the feed machine head is a cylindrical section which is positioned together with a stroke sleeve through a shaft, and the lower section is in sliding fit with the stroke sleeve. A rack is arranged on the outer wall of the stroke sleeve and engaged with a gear shaft. A switch thumbing fork installed on the gear shaft corresponds to a stroke switch.

Owner:邻水县川邻机械制造有限公司

Tapping device for cylindrical metal workpiece

InactiveCN113102999AImprove tapping accuracyGood tapping effectThread cutting feeding devicesThread cutting machinesPhysicsEngineering

The invention relates to a tapping device for a cylindrical metal workpiece. The tapping device for the cylindrical metal workpiece comprises a base, supporting rods, a cross rod, a hole dotting machine, a drilling machine, a tapping machine, a driving mechanism, a conveying mechanism, a moving mechanism and a clamping mechanism. According to the tapping device for the cylindrical metal workpiece, workpiece clamping is achieved through the clamping mechanism, and the moving mechanism and the conveying mechanism are driven by the driving mechanism to operate intermittently, so that tapping of the workpiece is achieved; compared with an existing clamping mechanism, the tapping precision is improved by centering the workpiece, and the better tapping effect is achieved; and compared with an existing tapping device, operation of the moving mechanism and the conveying mechanism is achieved through one output end, energy is saved, meanwhile, the moving mechanism and the conveying mechanism are in linkage, online tapping of workpieces is achieved, the linkage is of a pure mechanical structure, the stability of the device is improved, the service life of the device is prolonged, and practicability is improved.

Owner:南京安特鲁新能源技术开发有限公司

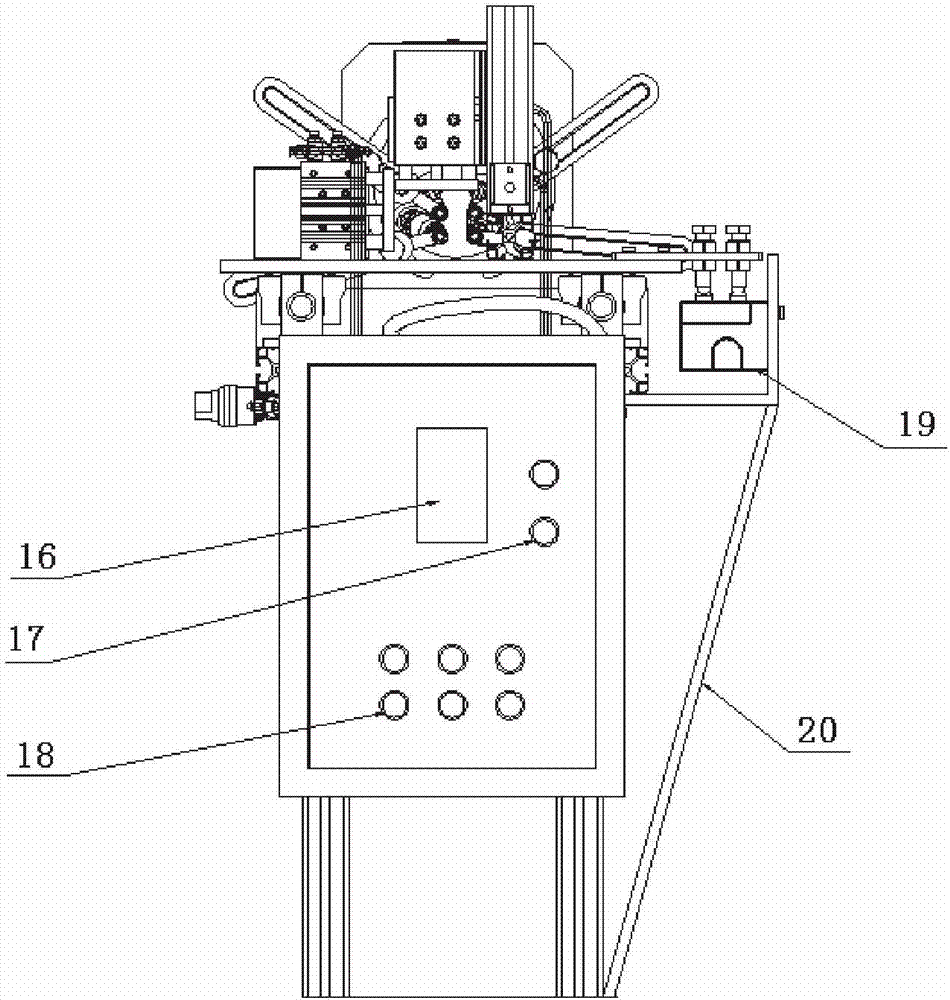

Nut tapping mechanism for knock sensor

PendingCN110788417AEfficient tapping operationPrecise positioningThread cutting feeding devicesThread cutting machinesStructural engineeringMechanical engineering

The invention provides a nut tapping mechanism for a knock sensor. The nut tapping mechanism comprises a discharging assembly, a clamping assembly, a moving assembly, a tapping platform, a tapping assembly and a material receiving assembly, wherein the discharging assembly comprises a discharging groove, a discharging table is arranged at the tail end of the discharging groove, and a discharging station used for positioning nuts is arranged on the discharging table; and the clamping assembly is arranged on the moving assembly and comprises a first clamping head and a second clamping head; themoving assembly comprises a transverse air cylinder and a vertical air cylinder, the transverse air cylinder drives the transverse movement of the vertical air cylinder, and the vertical air cylinderdrives the vertical movement of the clamping assembly. According to the tapping mechanism, efficient automatic nut tapping operation can be achieved, and meanwhile clamping, placing, tapping operations are accurate in positioning and high in precision. In the preferred scheme, by means of left and right feeding assemblies, the clamping assembly, the moving assembly and the tapping assembly, tapping can be achieved while feeding is conducted, feeding and tapping can be conducted simultaneously, and the efficiency is greatly improved.

Owner:YUYAO CITY ZHENXING IND TRADE DEV

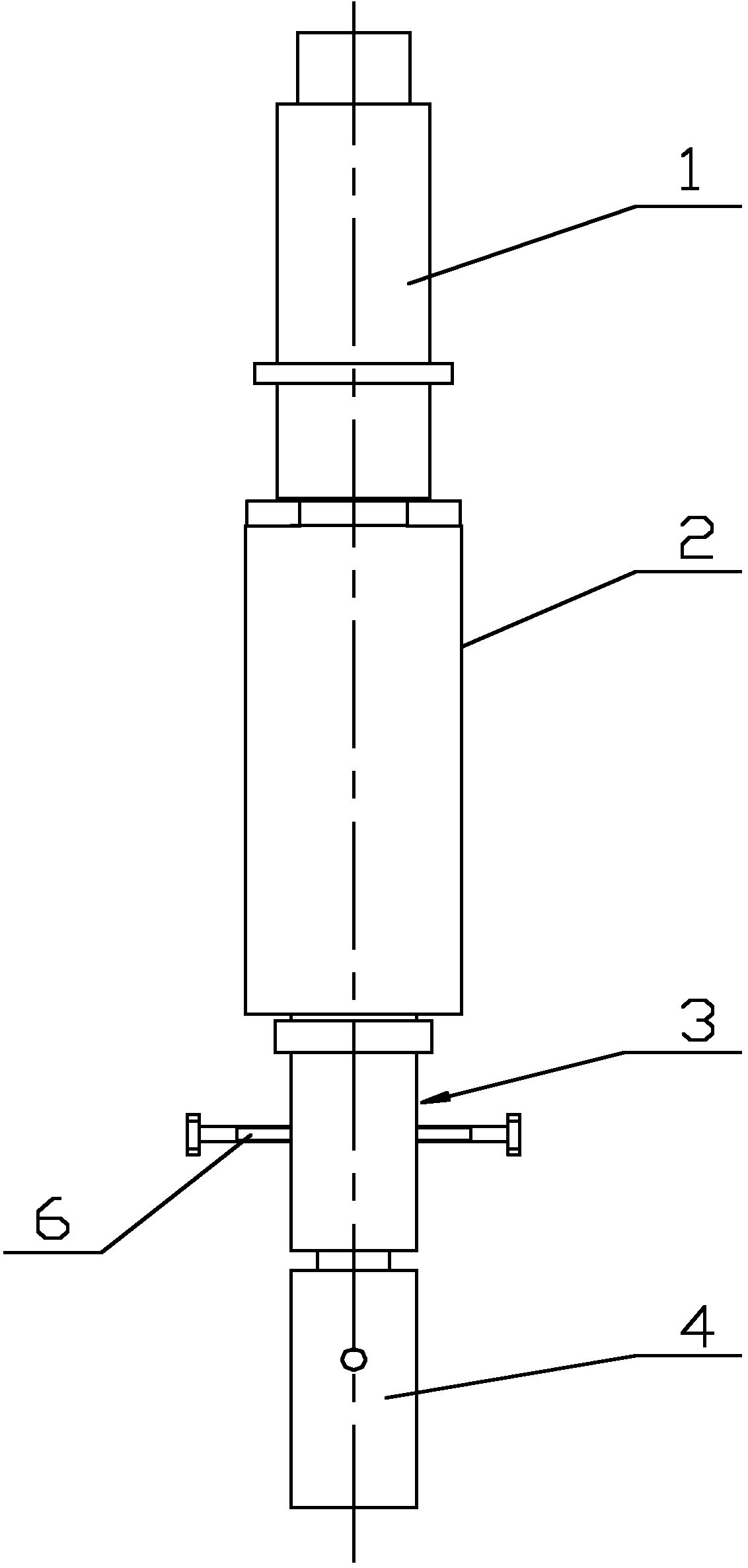

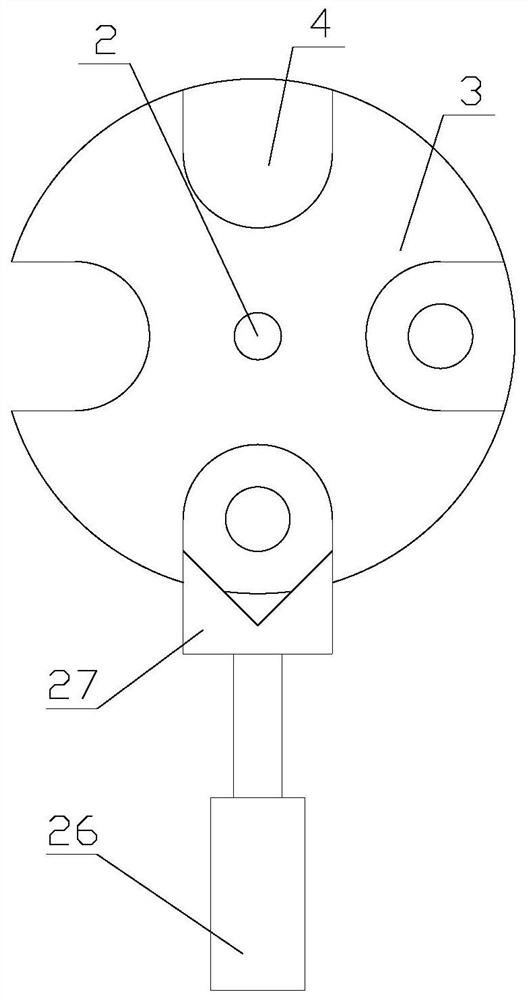

A simple tapping mechanism for drilling machine

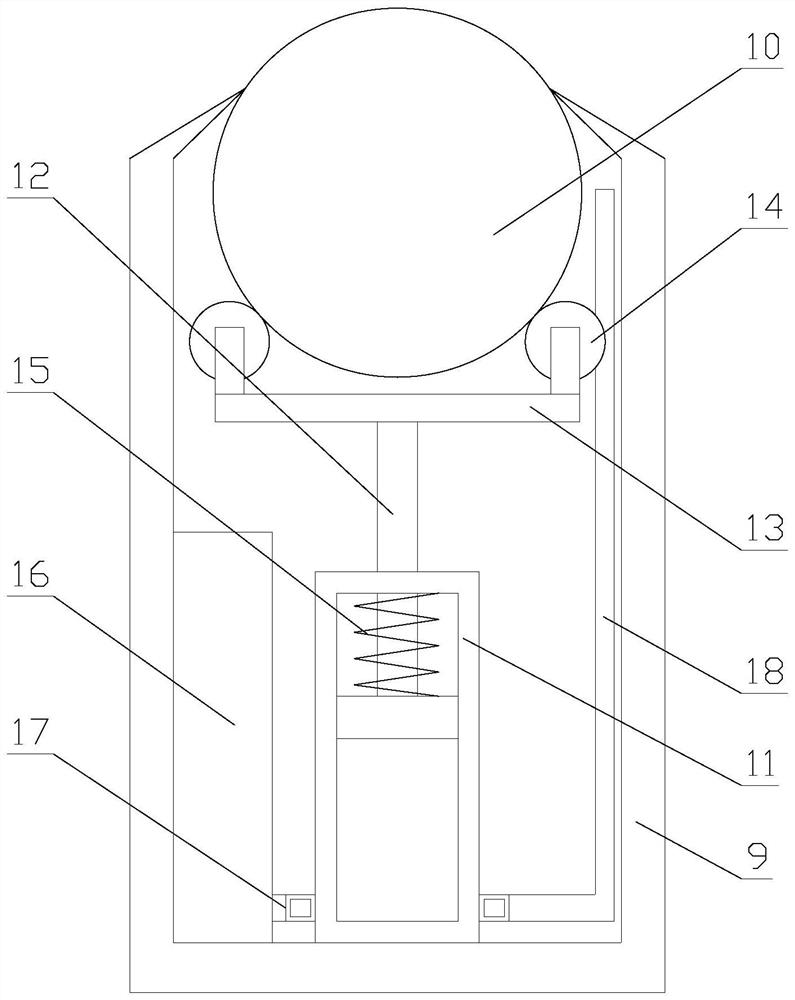

InactiveCN104625253BSimple structureThe tapping process is simple and convenientThread cutting auxillary apparatusPositioning apparatusEngineeringMechanical engineering

The invention provides a simple tapping mechanism for a drilling machine. The simple tapping mechanism comprises a friction wheel with a sealing ring, a double-disc type friction wheel, a bearing, supports, a drill bit clamp, a workpiece clamp and a guide rail. The simple tapping mechanism is characterized in that the friction wheel with the sealing ring is connected with a drilling machine main shaft, the double-disc type friction wheel is arranged between the two supports through the bearing, one end of the double-disc type friction wheel is fixedly connected with the drill bit clamp, the workpiece clamp is arranged on the guide rail in a sliding mode, the two supports are fixedly connected to the guide rail through bolts and nuts, and a left wheel body and a right wheel body of the double-disc friction wheel are driven by left-right sliding of the double-disc type friction wheel between the two supports to make contact with the friction wheel with the sealing ring respectively so as to achieve forward and reverse rotating of the drill bit clamp; the drill bit clamp is used for clamping screw taps. By means of the simple tapping mechanism for the drilling machine, the tapping process is made to be easier and more convenient to operate, the reversing process is the tapping process and conducted along with the tapping strength, no active reversing mechanism is needed, the tapping accuracy is improved due to guidance of the guide rail, and meanwhile, the simple tapping mechanism is simple in structure, convenient to maintain and low in cost.

Owner:BEIJING POLYTECHNIC

Aluminum profile tapping machine

InactiveCN106984874AImprove work efficiencyGuaranteed accuracyThread cutting machinesDrive shaftPulley

The invention discloses an aluminum profile tapping machine which comprises a power part and a transmission part, wherein the power part comprises a motor, a guide pulley and a guide pulley sliding block; the transmission part comprises a gearbox, at least one universal swing arm and a swing arm bracket; the gearbox is arranged on the main shaft side of the motor; a gear connected with a main shaft is arranged inside the gearbox; at least one driving shaft connected with the gear is arranged on the gearbox; the universal swing arm is arranged on the driving shaft; one end of the universal swing arm is connected with the driving shaft; a tapping screw is arranged at the other end of the universal swing arm and fixed on the swing arm bracket; the position of the tapping screw can be adjusted on the swing arm bracket; and after the tapping screw of the universal swing arm is aligned with a workpiece, the tapping operation is performed. The aluminum profile tapping machine has the advantages that the tapping quantity can be flexibly set; the tapping position can be adjusted through the universal swing arm; the tapping operation can be performed on a plurality of hole sites simultaneously; and accordingly, the working efficiency and the tapping accuracy can be improved.

Owner:ROLED OPTO ELECTRONICS SHANGHAI

Efficient tapping clamping device

InactiveCN106903381AAchieve stabilityRealize tappingThread cutting machinesPositioning apparatusPneumatic valveEngineering

The invention relates to an efficient tapping clamping device. The efficient tapping clamping device comprises a base, two supporting frames, a pneumatic cylinder, a pneumatic valve and a pressure relay, wherein the two supporting frames are fixedly arranged on the two sides of the upper end of the base respectively, and stop blocks are fixedly arranged at the upper ends of the two supporting frames; the pneumatic cylinder is fixedly arranged at the upper end of the base and is located between the two supporting frames; an output shaft of the pneumatic cylinder is located at the upper end of the pneumatic cylinder, an upper push block for placing a work-piece is arranged at the upper end of the output shaft of the pneumatic cylinder, and the output shaft of the pneumatic cylinder stretches out and retracts to drive the upper push block and the work-piece to vertically move; the pneumatic valve is fixedly arranged on one supporting frame, communicates with the pneumatic cylinder through an air pipe and further communicates with an external air source through an air pipe; and the pressure relay is embedded at the upper end of the push block, and the control end of the pneumatic valve is connected with the pressure relay through a line. Compared with the prior art, the efficient tapping clamping device has the advantages that the irregular work-piece is stabilized and tapped, and the tapping precision and efficiency are high.

Owner:LIUZHOU CITY LONGCHEN AXLE PARTS MFG

Flexible tapping fixture

ActiveCN102974901AExtended service lifeImprove tapping accuracyThread cutting machinesEngineeringMachine tool

The invention discloses a flexible tapping fixture. The flexible tapping fixture comprises a fixed handle, a sleeve, a cardan joint and a screw tap clamping handle, wherein the lower end of the fixed handle is connected with the upper end of the sleeve, the cardan joint is installed inside the sleeve, the upper end of the cardan joint is connected with the top wall of the sleeve, and the lower end of the cardan joint exceeds the open end of the sleeve and is connected with the screw tap clamping handle. Due to the fact that the sleeve and the cardan joint are installed between the fixed handle and the screw tap clamping handle, and the cardan joint is installed inside the sleeve, during the operation of tapping, under the condition of the center of the screw tap is deviated, the screw tap manufacturing is defect or the feed of a machine tool is insufficient, the precision between the fixed handle and the screw tap clamping handle can be adjusted by the cardan joint, the precision of the tapping can be improved and the service life of the screw tap can be prolonged.

Owner:BEIJING NANKOU RAILWAY TRANSIT MACHINERY

Tapping machine

PendingCN109047954AImprove tapping accuracyReduce heatThread cutting feeding devicesThread cutting machinesAgricultural engineeringTurbine

The invention discloses a tapping machine, and relates to the field of mechanical processing devices. A hydraulic device is arranged in a working table, the hydraulic device is connected with a main body, the main body is connected with a connecting rod mechanism, a connecting sleeve is fixedly connected with a rotating shaft, the connecting rod mechanism is connected with a motor protection coverthrough a connecting block and a connecting body, the connecting block and the connecting body are in shaft connection, the motor protection cover is internally provided with a servo motor, and the servo motor is connected with a tapping mechanism; and a rotating motor is arranged below the rotating shaft, a rotating motor output shaft passes through the center of the rotating shaft to be connected with a first worm, the first worm is meshed with a first turbine, the first turbine is meshed with a first gear, the first gear is connected to a drive pulley rotating shaft, a drive pulley and a driven pulley are in belt connection, the drive pulley and the driven pulley are connected to a lower connecting rod, a driven pulley rotating shaft is provided with a second worm, the second worm is meshed with a second turbine, the second turbine is meshed with a second gear, and a gear shaft of the second gear is connected with the connecting body. The tapping machine can realize multi-directional rotation tapping, is convenient to use, does not need multiple positioning, and is high precision.

Owner:芜湖龙鳞汽车部件有限公司

Chipping removal, tapping and clamping device

InactiveCN106736758AAchieve stabilityEasy to cleanWork clamping meansPositioning apparatusPneumatic valveEngineering

The invention relates to a chipping removal, tapping and clamping device. The chipping removal, tapping and clamping device comprises a base, two support frames, a pneumatic cylinder, a pneumatic valve and a pedal switch. The two support frames are correspondingly fixed to the two sides of the upper end of the base. Check blocks are correspondingly and fixedly arranged at the upper ends of the two support frames. The pneumatic cylinder is fixedly arranged at the upper end of the base. An output shaft of the pneumatic cylinder is located at the upper end of the pneumatic cylinder. An upper push block for containing a machining piece is arranged at the upper end of the output shaft of the pneumatic cylinder. The output shaft of the pneumatic cylinder extends and contracts to drive the upper push block and the machining piece to move vertically. The pneumatic valve is fixedly arranged on one of the support frames and communicates with the pneumatic cylinder through a gas pipe. The pneumatic valve communicates with an external gas source through the gas pipe. The pedal switch is arranged on one side of the base. The control end of the pneumatic valve is connected with the pedal switch through a circuit. An electroproduction magnetic device is arranged at the upper end of the base and connected with the pedal switch through a circuit. Compared with the prior art, by the adoption of the chipping removal, tapping and clamping device, stabilizing and tapping of irregular workpieces are achieved, the tapping accuracy is high, the efficiency is high, and waste chippings are removed conveniently.

Owner:LIUZHOU CITY LONGCHEN AXLE PARTS MFG

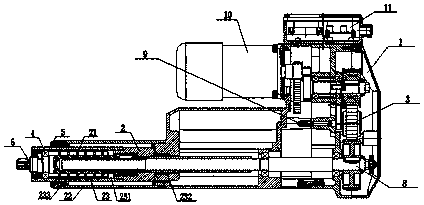

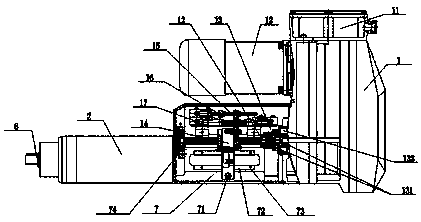

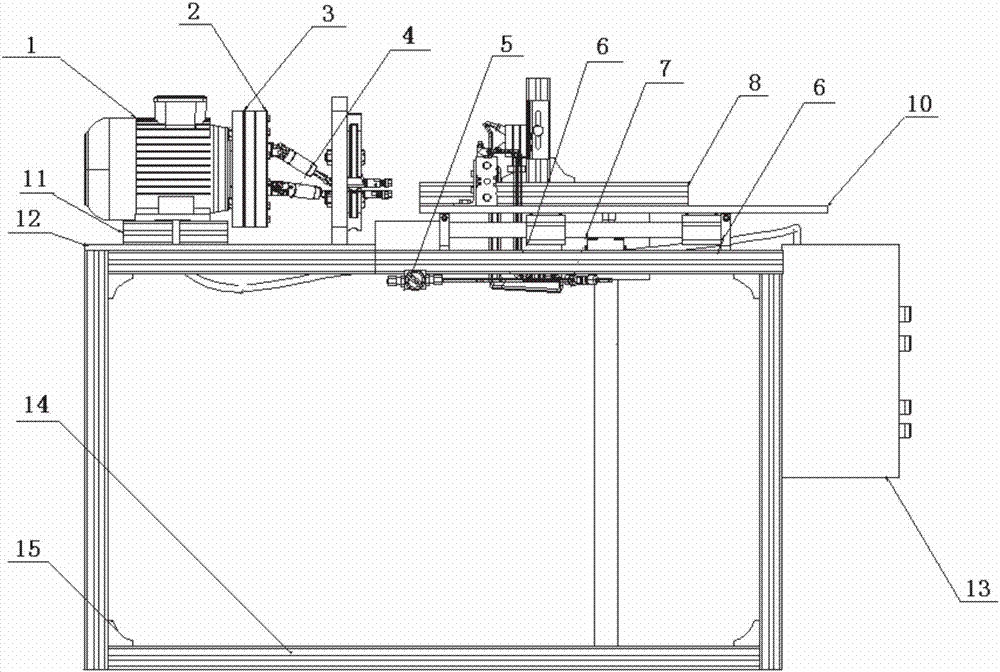

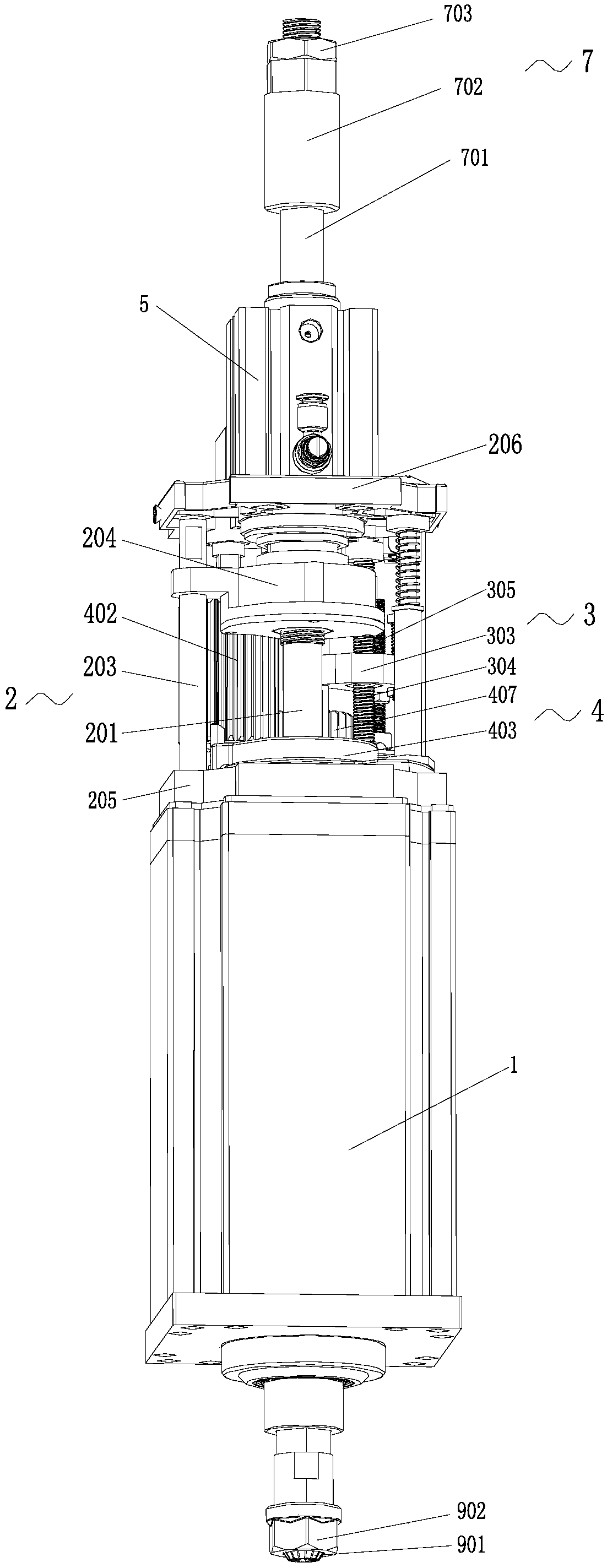

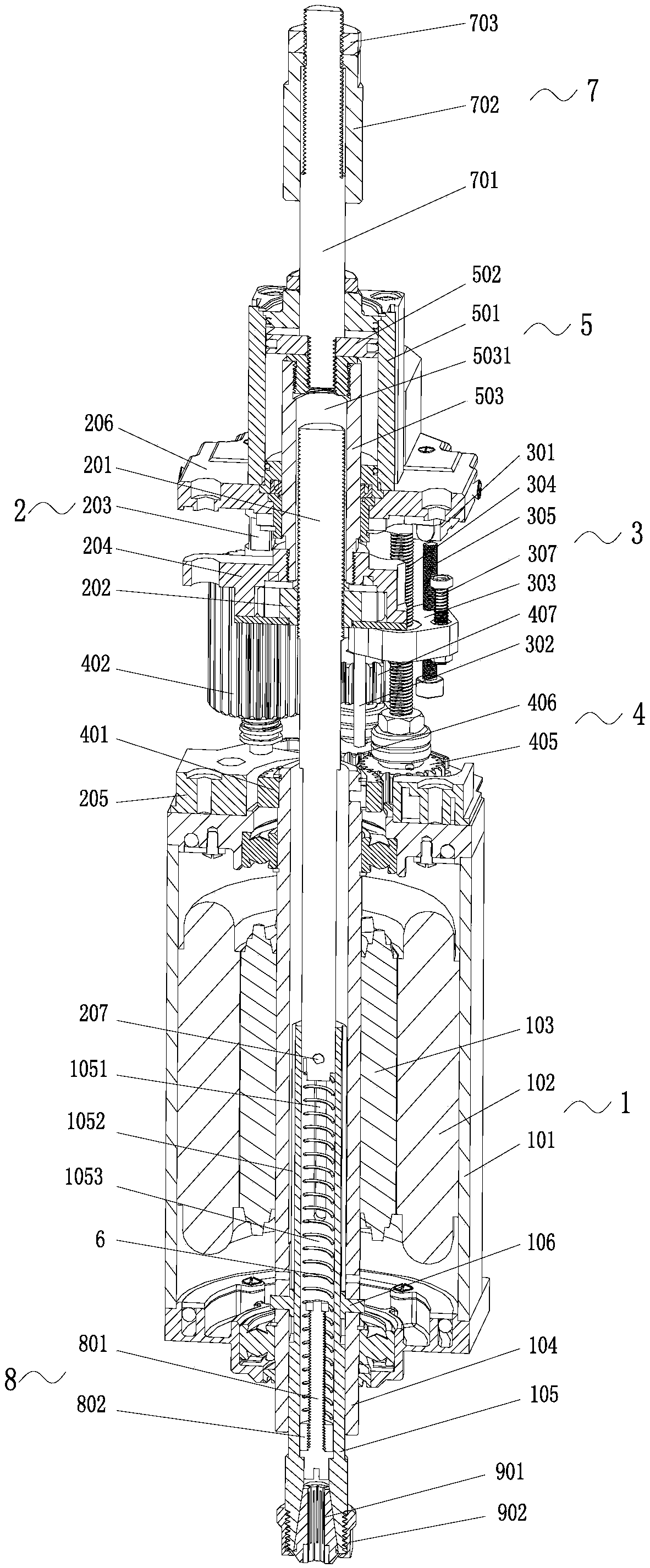

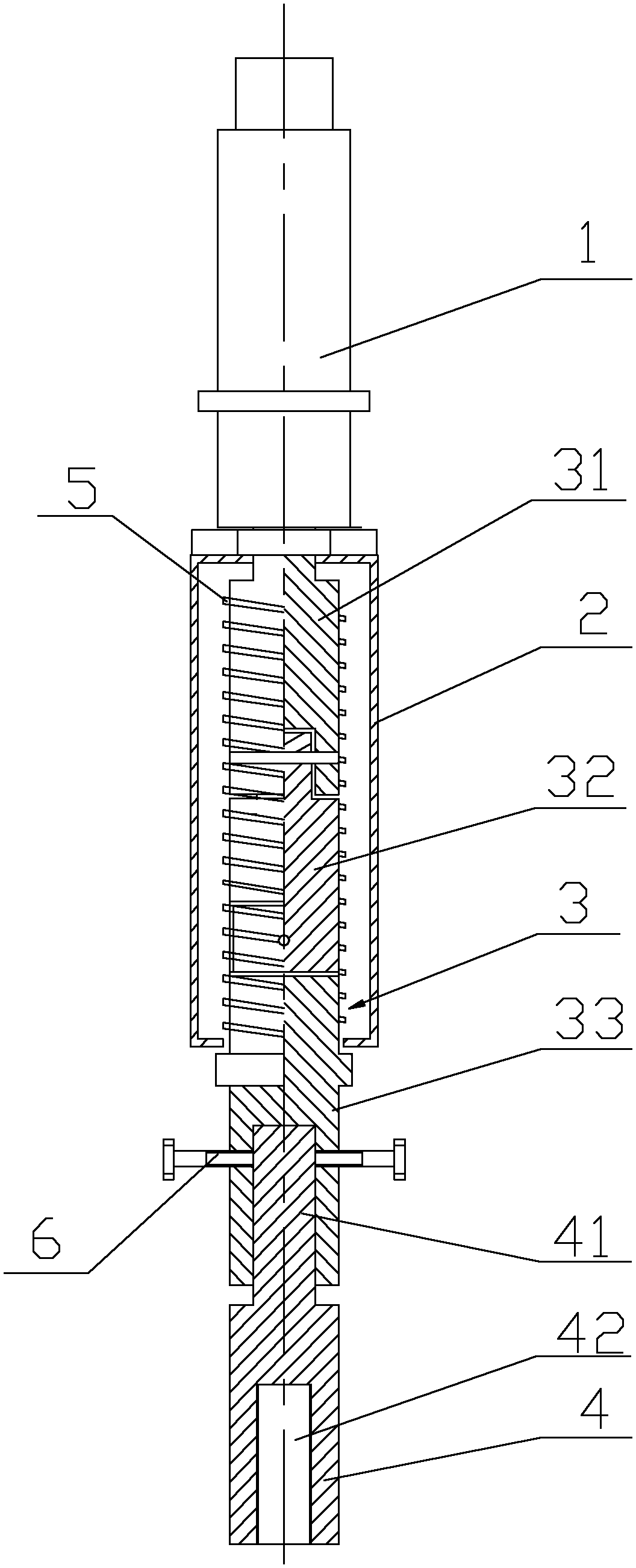

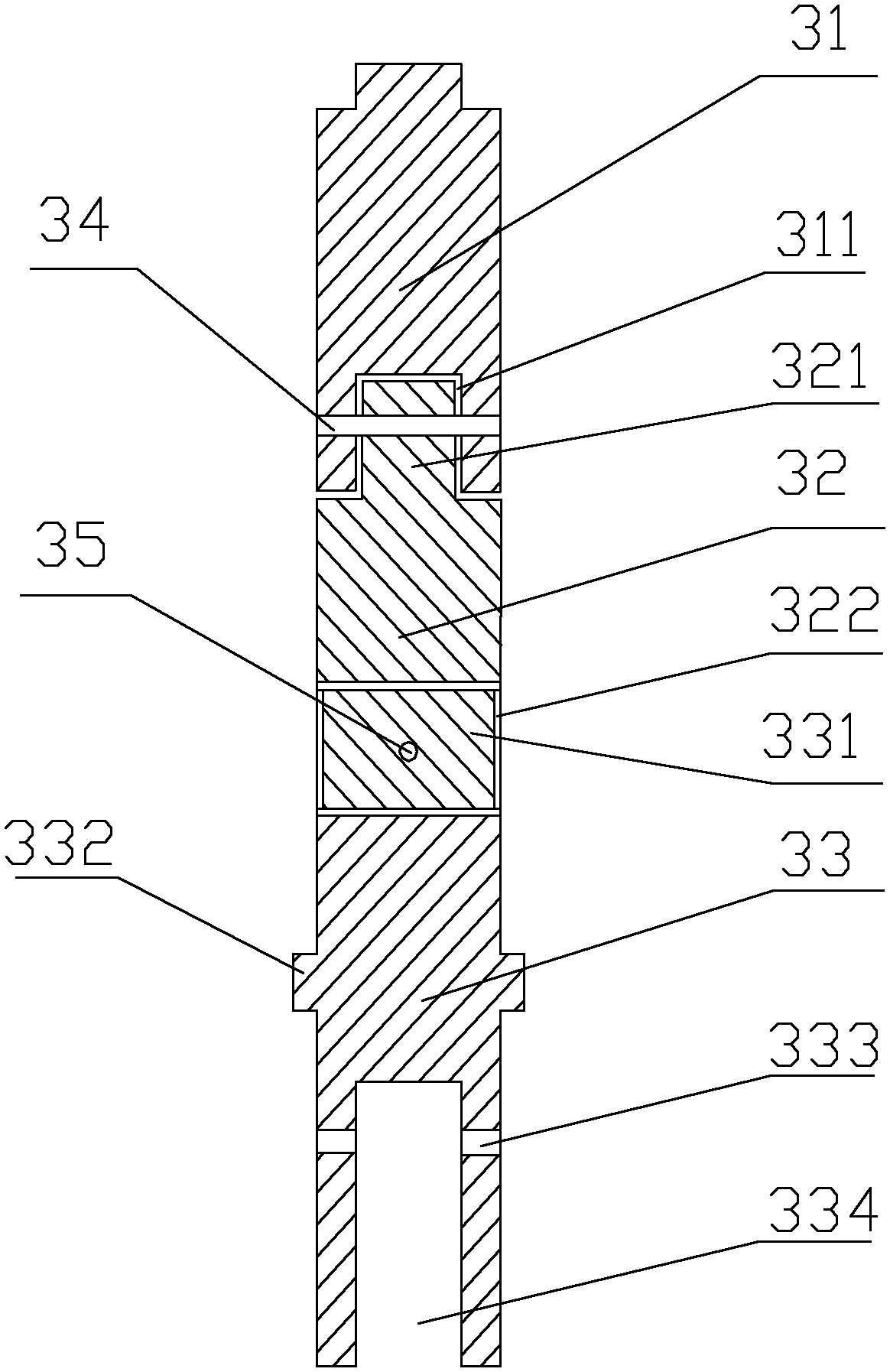

Automatic tapping machine having both self-adaptive tapping function and synchronous tapping function

ActiveCN109014448AAvoid problems such as breakingImprove tapping accuracyThread cutting feeding devicesThread cutting machinesManufacturing cost reductionSelf adaptive

The invention relates to the field of machining equipment, in particular to an automatic tapping machine having both a self-adaptive tapping function and a synchronous tapping function. The automatictapping machine comprises a motor assembly, a screw-nut transmission mechanism, a travel switch assembly, a screw pitch adaption spring, a switching device and an air cylinder device; the motor assembly comprises a shell, a stator, a rotor iron core and a motor spindle; the motor spindle is composed of a shaft sleeve body and an inner shaft, and the lower end of the inner shaft is provided with aconnection part for installing a screw tap or a screw die; the screw-nut transmission mechanism comprises a main screw, a main nut, a guide rod, a main nut installation seat, a lower fixing plate andan upper fixing plate; and the switching device comprises an output gear, an input gap bridge spool gear, a reduction gear set and an adjustable gear supporting seat and further comprises a position fixing device and a limiting device. The automatic tapping machine can be suitable for tapping of different screw pitches and is wide in application range, the tapping precision can be improved, the tapping failure, screw tap breaking and other problems can be solved, and the manufacturing cost is reduced.

Owner:福鼎市金雄机车部件有限公司

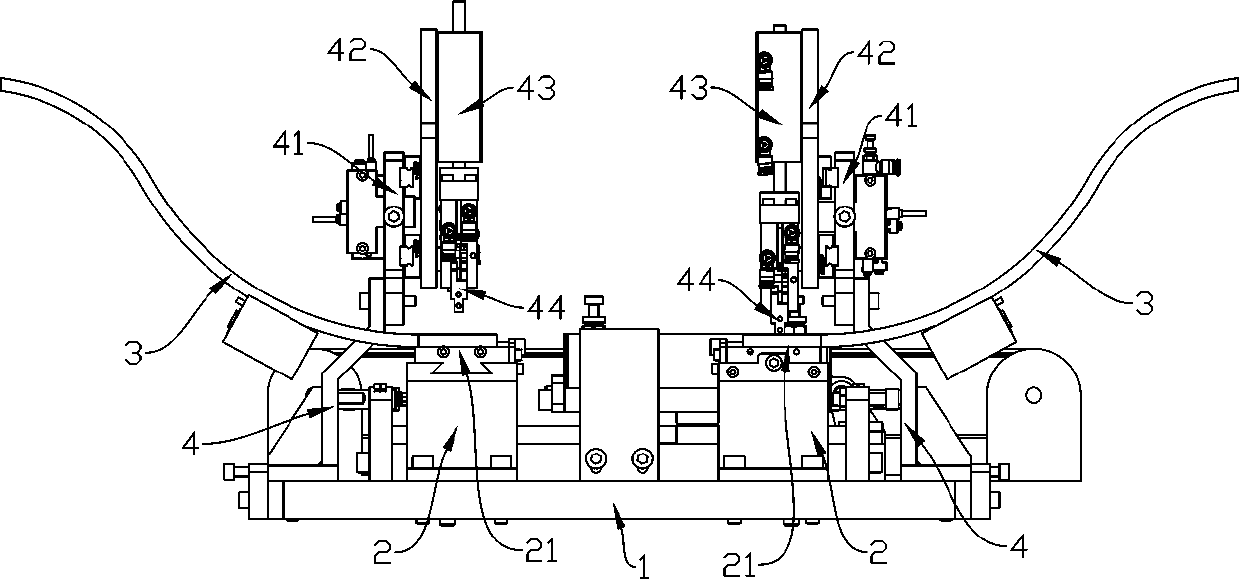

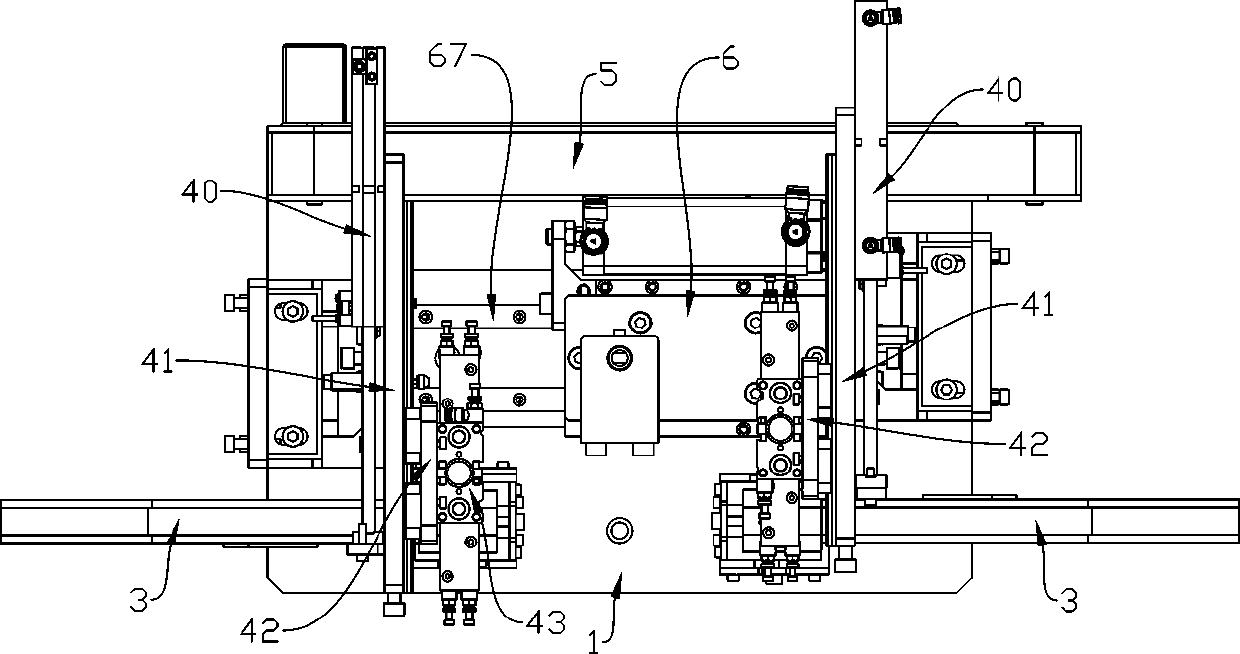

Automatic nut tapping machine for knocking sensor

PendingCN110814443AEfficient tapping operationPrecise positioningThread cutting feeding devicesThread cutting machinesControl engineeringMachine

The invention provides an automatic nut tapping machine for a knocking sensor. The automatic nut tapping machine comprises a table, a feeding assembly, a clamping assembly, a moving assembly, a tapping platform, a tapping assembly and a receiving assembly, wherein the feeding assembly comprises a feeding groove, the tail end of the feeding groove is provided with a placement table, and the placement table is provided with a placement site used for positioning a nut; the clamping assembly is arranged on the moving assembly, and the clamping assembly comprises a first clamp head and a second clamp head; the moving assembly comprises a transverse air cylinder and a vertical air cylinder, the transverse air cylinder drives the clamping assembly to transversely move, and the vertical air cylinder drives the clamping assembly to vertically move. By means of the tapping machine, the efficient automatic nut tapping operation can be achieved, positioning is accurate during clamping, placement and tapping operation, and the precision is high; in a preferred embodiment, feeding is conducted while tapping is conducted by means of left and right feed assemblies, the clamping assembly, the moving assembly and the tapping assembly, feeding and tapping are conducted at the same time, and the efficiency is greatly improved.

Owner:YUYAO CITY ZHENXING IND TRADE DEV

Flexible tapping fixture

ActiveCN102974901BExtended service lifeImprove tapping accuracyThread cutting machinesEngineeringMachine tool

The invention discloses a flexible tapping fixture. The flexible tapping fixture comprises a fixed handle, a sleeve, a cardan joint and a screw tap clamping handle, wherein the lower end of the fixed handle is connected with the upper end of the sleeve, the cardan joint is installed inside the sleeve, the upper end of the cardan joint is connected with the top wall of the sleeve, and the lower end of the cardan joint exceeds the open end of the sleeve and is connected with the screw tap clamping handle. Due to the fact that the sleeve and the cardan joint are installed between the fixed handle and the screw tap clamping handle, and the cardan joint is installed inside the sleeve, during the operation of tapping, under the condition of the center of the screw tap is deviated, the screw tap manufacturing is defect or the feed of a machine tool is insufficient, the precision between the fixed handle and the screw tap clamping handle can be adjusted by the cardan joint, the precision of the tapping can be improved and the service life of the screw tap can be prolonged.

Owner:BEIJING NANKOU RAILWAY TRANSIT MACHINERY

Automatic tapping machine for hoop nut

PendingCN108098082ASimple structureReduce labor costsThread cutting feeding devicesThread cutting machinesCouplingEngineering

The invention provides an automatic tapping machine for a hoop nut. The automatic tapping machine for the hoop nut comprises a frame, a feeding device, a material clamping device, a tapping device anda discharging device. The feeding device comprises a vibration disk and a feeding track, wherein the vibration disk is arranged on the frame, and the feeding track is connected with the vibration disk. The material clamping device comprises a first fixing plate and a second fixing plate, wherein the first fixing plate and the second fixing plate are arranged in a up and down mode. A plurality ofopenings which are matched with the hoop nut are evenly distributed on the outer edge of the first fixing plate and the second fixing plate. The discharging outlet of the feeding track corresponds toone of the openings. The tapping device comprises a movable frame, a coupling and a tapping knife, wherein the movable frame is arranged on the frame and placed at one side of the material clamping device, the coupling is arranged on the movable frame, and the tapping knife is arranged at the end part of the coupling. The coupling is sleeved with a snap ring. The snap ring is provided with a thimble for detecting the hoop nut. The tapping knife and the thimble are placed directly on the upper portion of the different openings.

Owner:项炳林

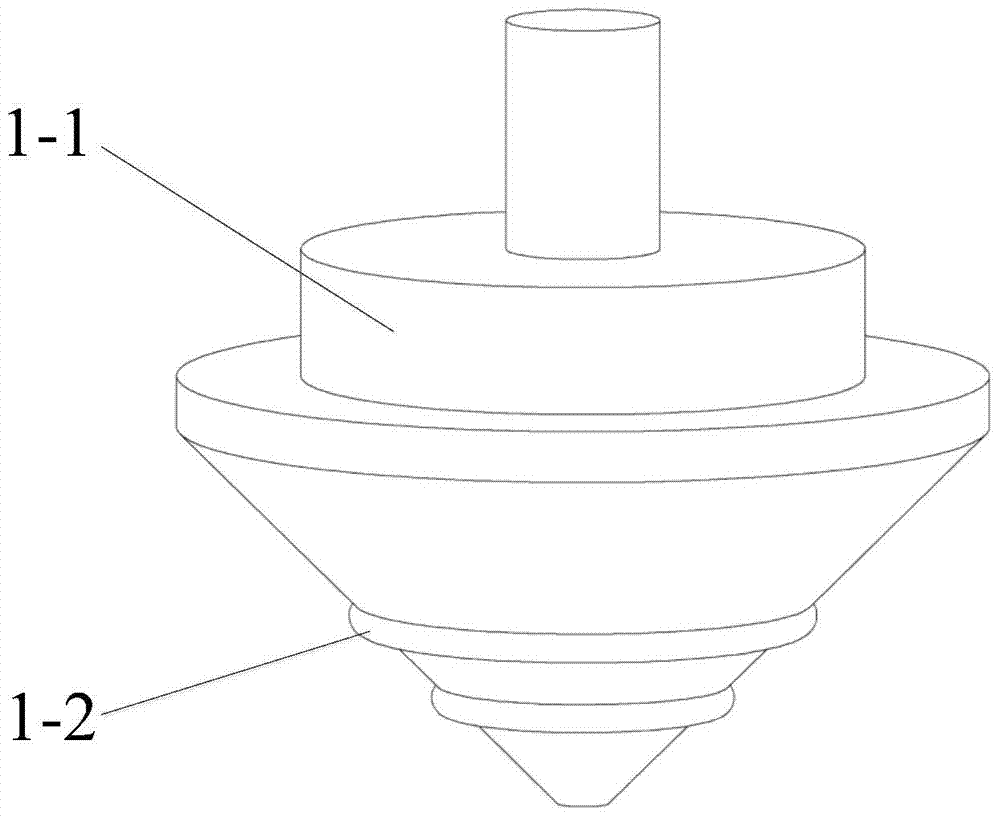

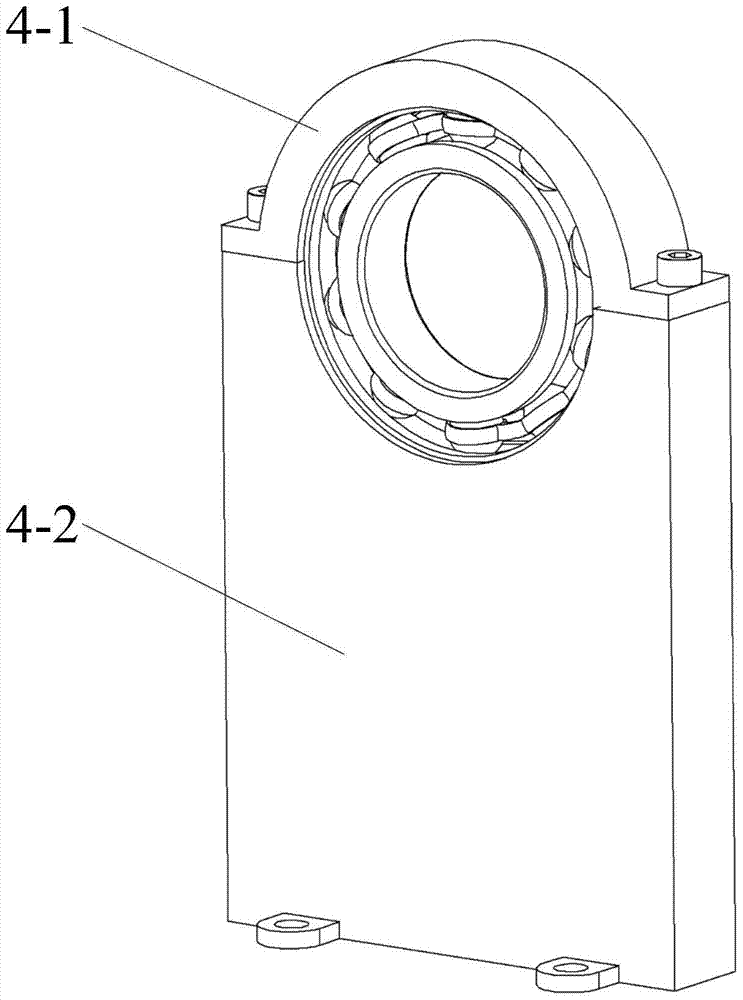

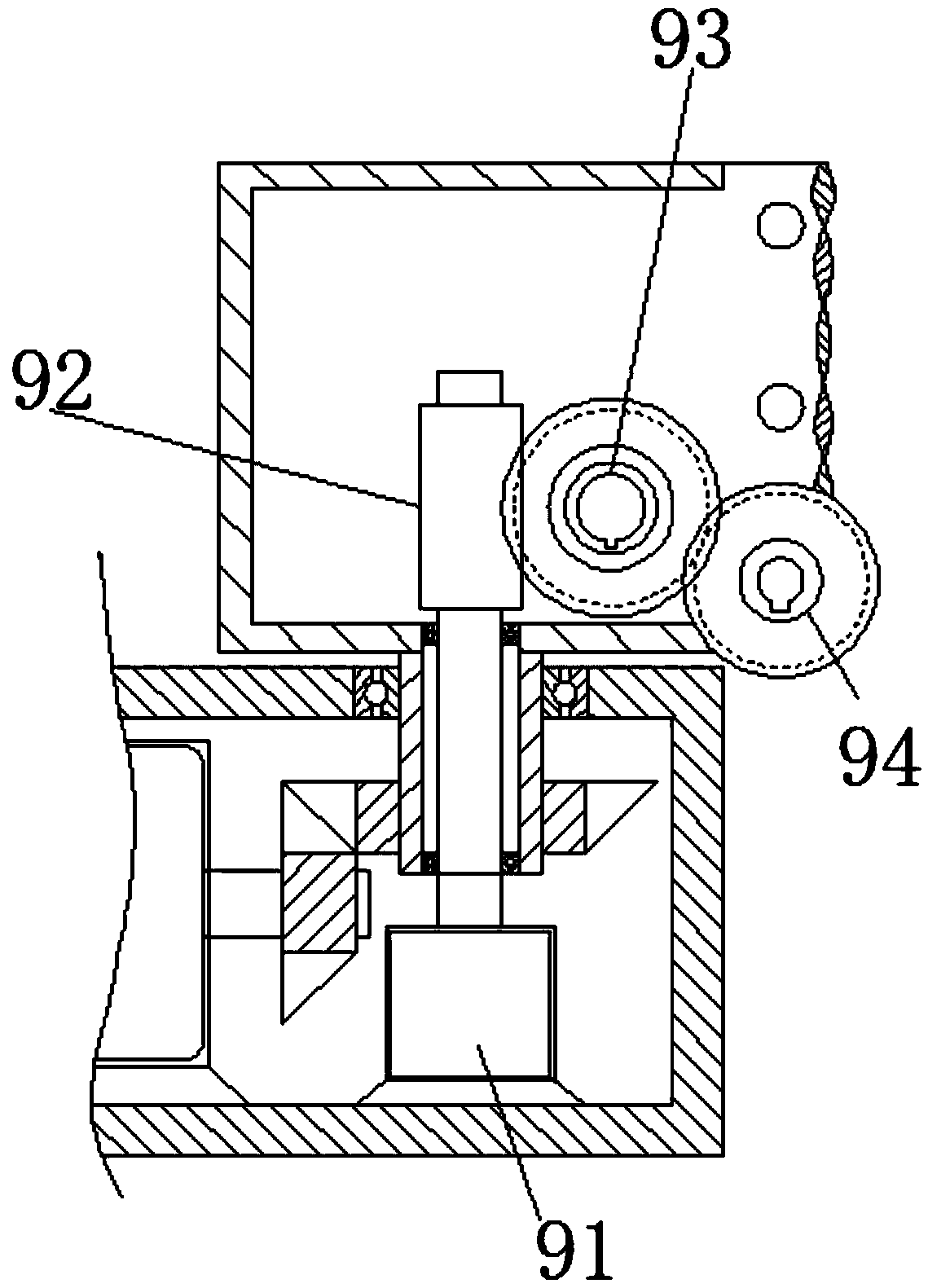

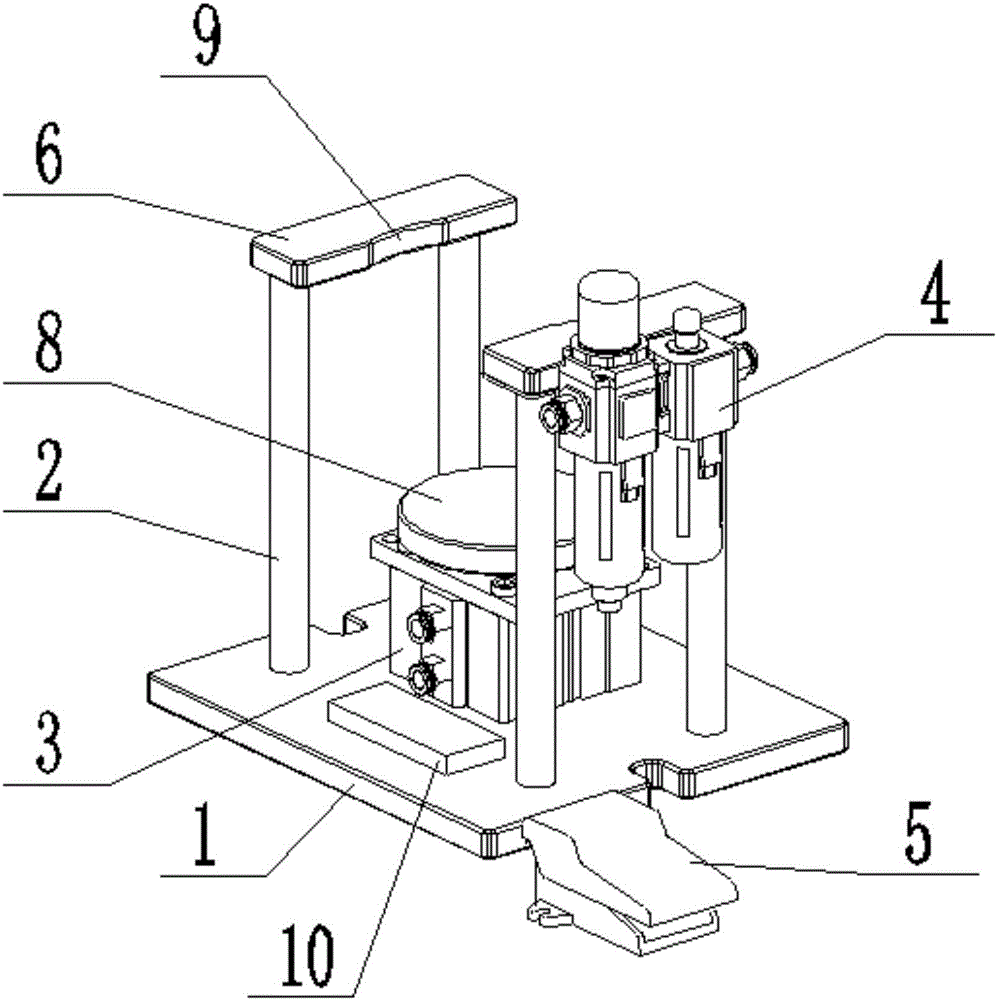

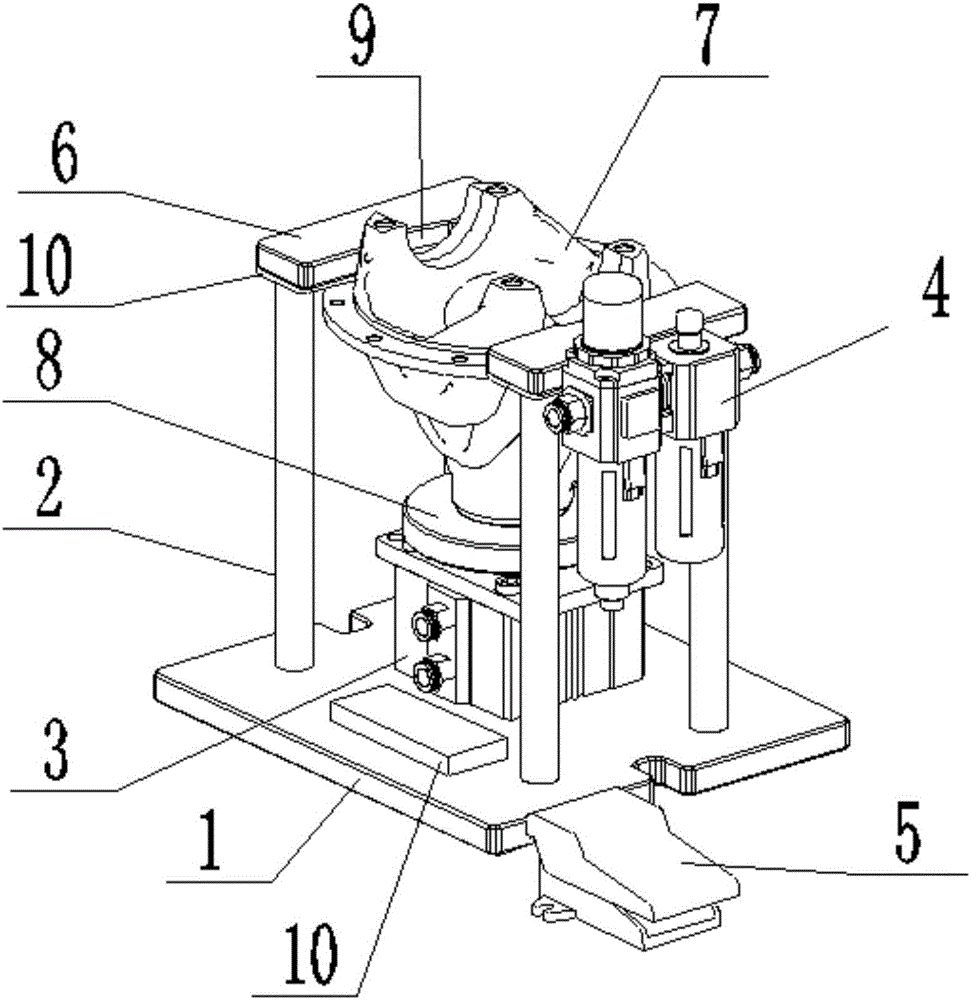

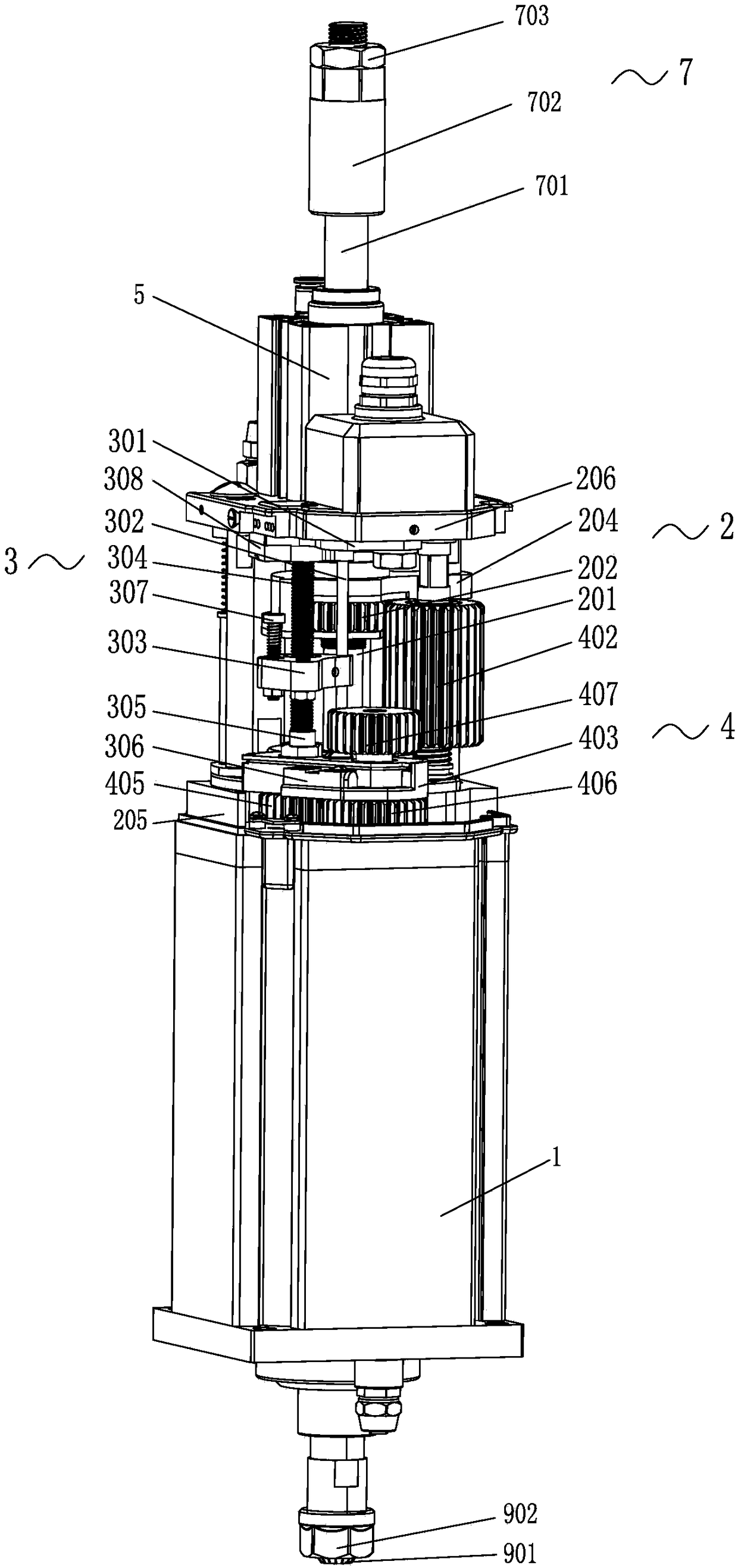

Power head structure for gear type tapping machine

PendingCN110773822ARealize rigid tappingRealize fully automatic tappingThread cutting machinesGear wheelElectric machinery

The invention discloses a power head structure for a gear type tapping machine. The power head structure includes a mounting bracket and a motor, the motor is fixedly connected to the bottom of the mounting bracket, a mounting block is provided with a mounting port corresponding to the motor, the output end of the motor is fixedly sleeved with a motor belt pulley, the top of the end, close to themotor, of the mounting bracket is fixedly connected with a tensioning wheel mounting plate, the top of the tensioning wheel mounting plate is rotationally connected to a tensioning wheel through a tensioning wheel shaft, a lifting shaft is rotatably inserted into the top of the end, away from the motor, of the mounting bracket, a driving gear is fixedly connected to the top of the lifting shaft ina sleeving manner, and a synchronous pulley is arranged below the driving gear. According to the power head structure, through the compact mechanism arrangement, the manufacturing cost is reduced, the tapping accuracy is also improved, rigid tapping can be realized, the application scope of the device is improved, the power head structure can serve as a novel tapping machine to be singly used, and automatic tapping can be realized in cooperation with automation.

Owner:无锡恒莫斯智能科技有限公司

Automatic nut tapping device for automobile manufacturing

InactiveCN113714573ARealize intermittent tappingRealize online tappingThread cutting feeding devicesThread cutting machinesMechanical engineeringAutomotive manufacturing

The invention relates to an automatic nut tapping device for automobile manufacturing. The automatic nut tapping device comprises a support, a driving mechanism, a tapping mechanism and a feeding mechanism; the driving mechanism and the feeding mechanism are both arranged on the support; the tapping mechanism is arranged above the feeding mechanism; the feeding mechanism comprises a feeding box, a rotating assembly and a locking assembly; the tapping mechanism comprises a body and a limiting assembly; the driving mechanism comprises a driving assembly and a linkage assembly; and a clamping unit is arranged on one side of a rotary disc. According to the automatic nut tapping device for automobile manufacturing, the driving mechanism drives the tapping mechanism and the feeding mechanism to operate intermittently, and thus intermittent tapping of workpieces is achieved; feeding and main pushing movement of the workpieces are achieved through one output end, and energy is saved; linkage is adopted, online tapping of the workpieces is achieved, and efficiency is improved; meanwhile, a pure mechanical structure is adopted for linkage, the stability of the device is improved, and the service life of the device is prolonged; and precise rotation of the workpieces is achieved through the feeding mechanism, and thus the tapping precision is improved.

Owner:广州市荔湾区呐特网络科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com