Aluminum profile tapping machine

A technology of tapping machine and aluminum profile, applied in the direction of thread cutting machine, metal processing equipment, thread cutting device, etc., can solve the problems of poor compatibility, fixed structure, and single function, so as to improve tapping quality, ensure accuracy, and increase flexibility sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0027] In this embodiment, a four-head tapping machine is taken as an example for illustration.

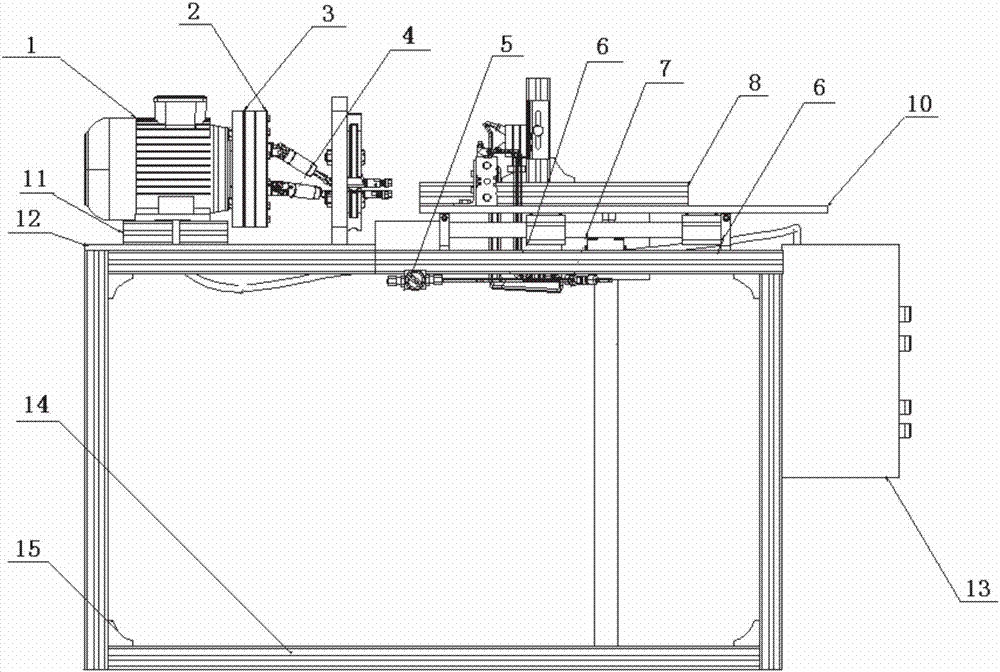

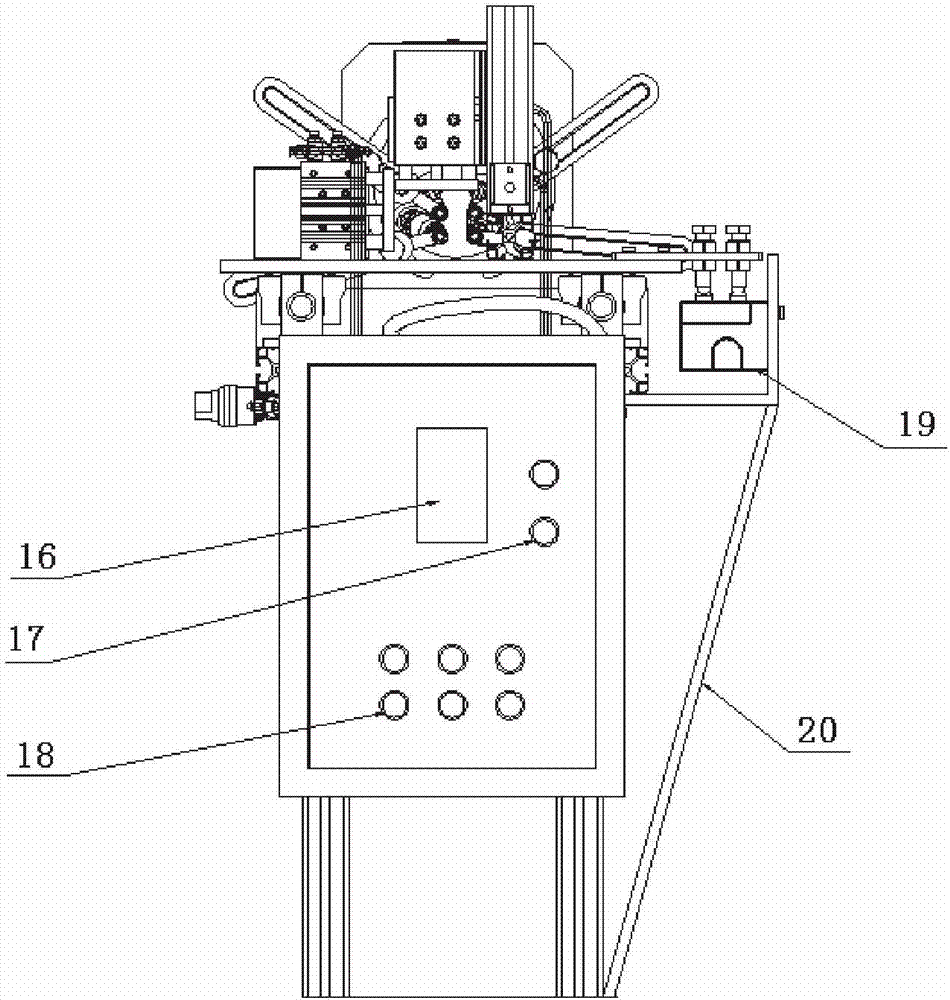

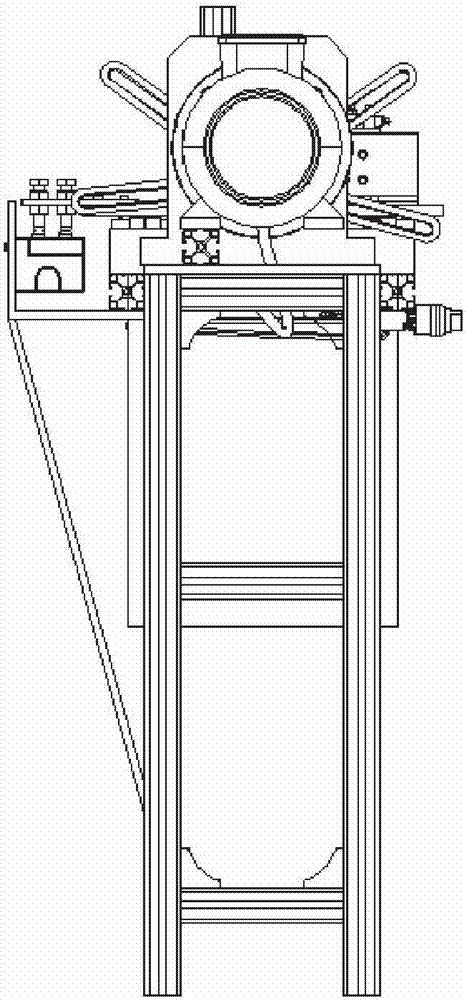

[0028] Such as Figure 1 to Figure 5 As shown, an aluminum profile tapping machine includes four parts, namely a power part, a transmission part, an electrical part, and a workbench part; wherein, the power part is divided into a power end and a pneumatic end, and the power end includes a motor 1. This embodiment The motor 1 is a horizontal and vertical motor, and the pneumatic end includes a cylinder, a pneumatic switch, a polished rod guide rail 7, and a guide rail slider 6; the transmission part includes a gear box, a universal swing arm, and a swing arm bracket. The main shaft side of the motor 1 is provided with a gear box. The inside of the gearbox has a gear connected to the main shaft, and the outside of the gearbox includes a gearbox base 3 and a gearbox cover 2. The gearbox base 3 is close to one end of the motor, and the gearbox cover 2 is provided with at least one dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com