Automatic tapping machine having both self-adaptive tapping function and synchronous tapping function

A tapping machine, self-adaptive technology, applied in the direction of thread cutting machine, driving device, manufacturing tools, etc., can solve the problems of increased manufacturing cost, low tapping precision, enterprise loss, etc., to improve work efficiency, improve tapping precision, simplify structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments of the description:

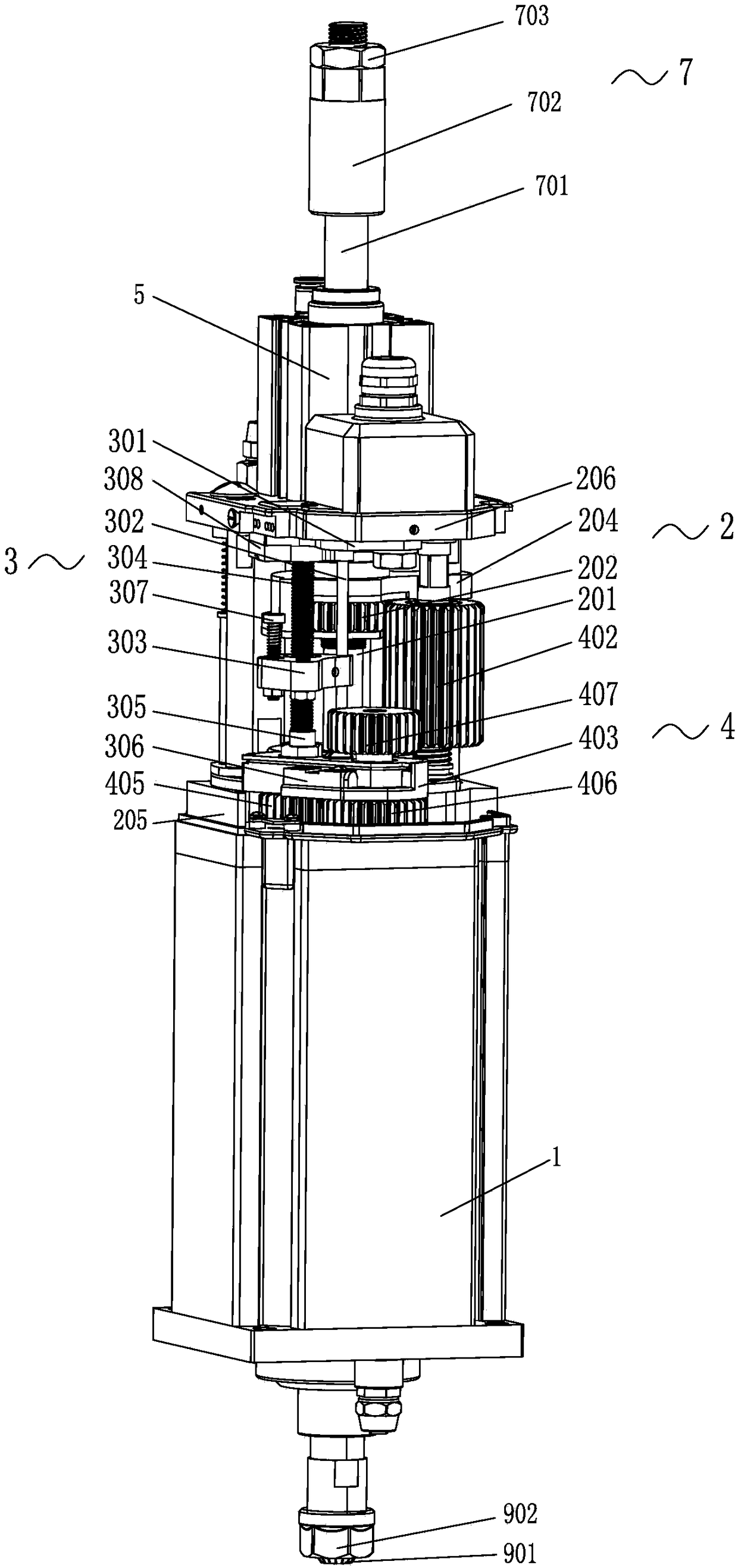

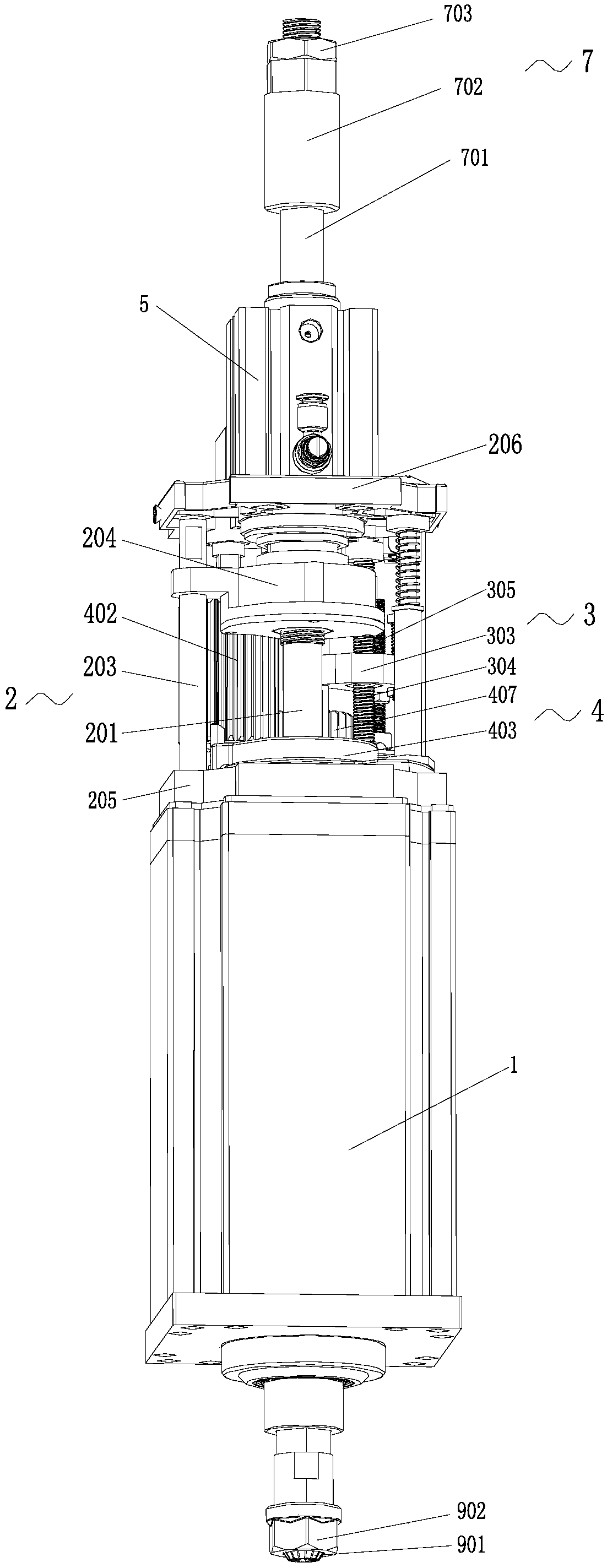

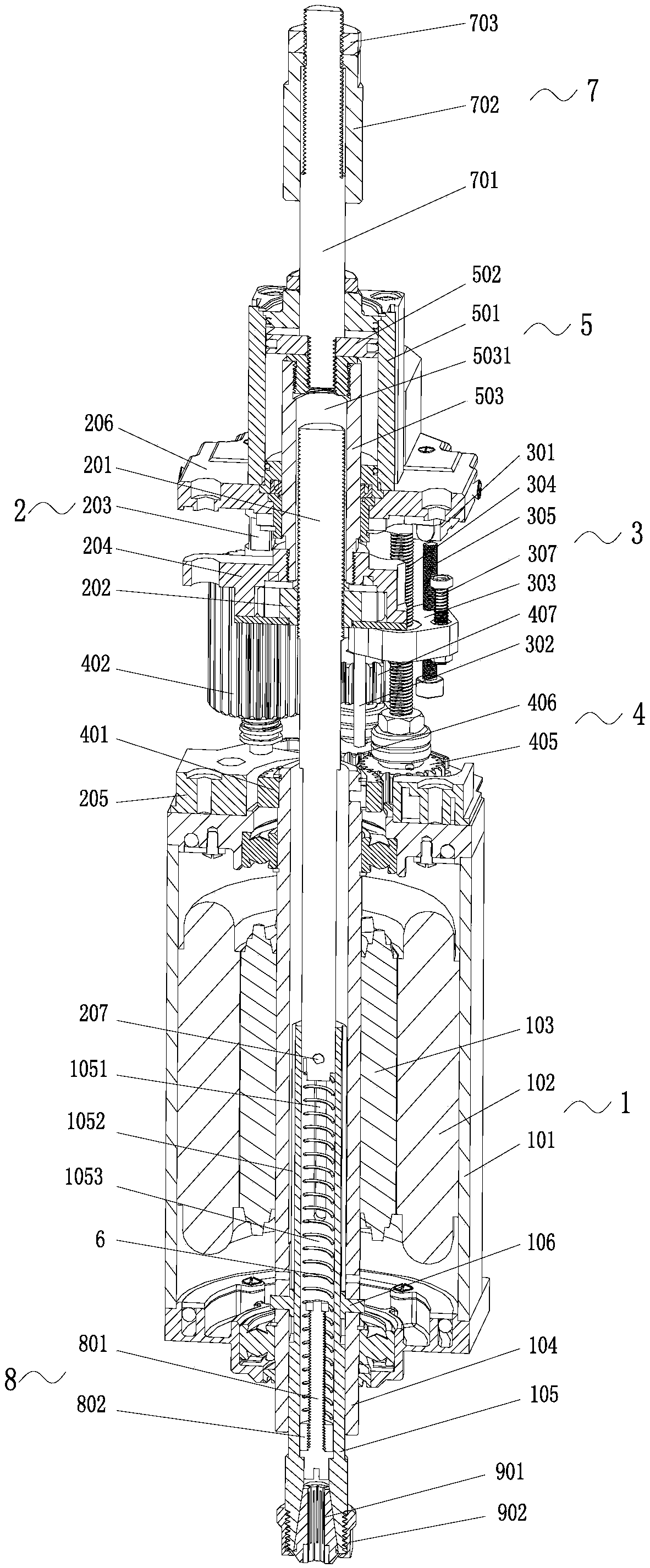

[0035] Such as Figure 1-7 As shown, an automatic tapping machine with adaptive tapping and synchronous tapping provided by the present invention is characterized in that it includes a motor assembly 1, and the motor assembly 1 includes a The casing 101, the stator 102 fixed in the casing 101, the rotor core 103 movably arranged in the middle of the stator 102, and the motor spindle arranged in the middle of the rotor core 103; the motor spindle is coaxially fixed on the rotor iron The shaft sleeve body 104 in the central hole of the core 103 is composed of the inner shaft 105 coaxially movably sleeved in the shaft sleeve body 104 body. It cannot rotate relative to the sleeve body 104 but can move axially relative to the sleeve body 104, and the lower end of the inner shaft 105 is provided with a connecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com