Slidable rail lower plate for automatic transmission of continuously welded rails

A technology of seamless lines and under-rail pads, applied in the directions of roads, tracks, fixed rails, etc., can solve the problems affecting the stability of high-speed trains such as track structure safety, track bottom voids, and line irregularities. The effect of reducing the beam-rail interaction of the seamless line, reducing the maintenance and repair workload, and avoiding the expansion of the track

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

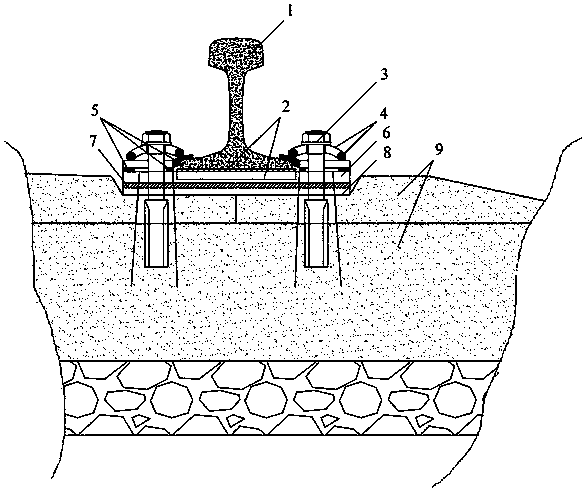

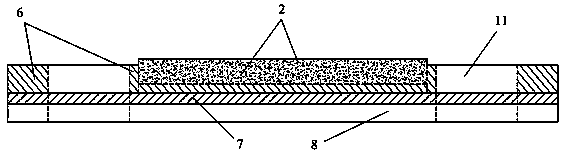

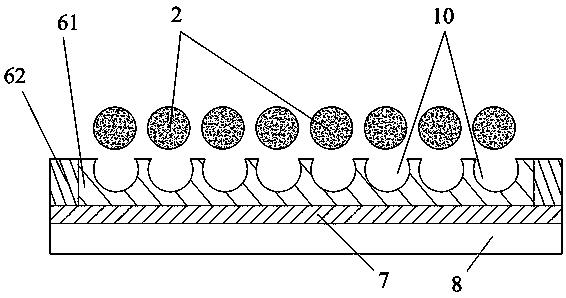

[0014] A slidable backing plate under the rail that can realize the automatic stress relief of the seamless line, including a sliding backing plate 6, a rubber backing plate 7 and a height-adjusting backing plate 8 arranged in sequence from top to bottom, and the three-layer backing plate passes through Fastener bolts 3, fastener elastic strips 4, and fastener gaskets 5 are installed on the concrete sleeper 9, and it is characterized in that the sliding backing plate 6 is composed of an inner sliding backing plate 61 and an outer sliding backing plate 62 , the inner sliding backing plate 61 is embedded in the outer sliding backing plate 62, the inner sliding backing plate 61 can be taken out from the outer sliding backing plate 62, and the inner sliding backing plate 61 is provided with Several transparent roller grooves 10 are arranged in parallel between the roller grooves 10. The radial section of the roller grooves 10 is an arc, and its diameter is the same as that of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com