Small hole automatic tapping equipment

A technology of automatic tapping and equipment, applied in the field of tapping, can solve the problems of scrapped electronic components, low efficiency, high labor intensity of operators, and achieve the effect of easy guarantee of position accuracy, improved product quality, and high tapping accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

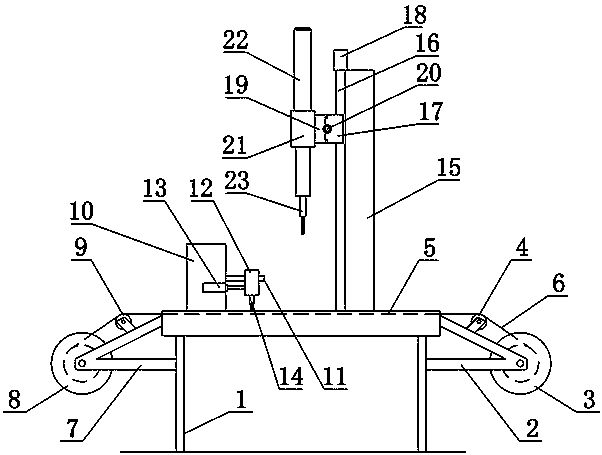

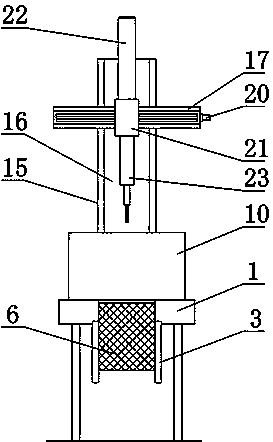

[0019] Such as figure 1 As shown, the small hole automatic tapping equipment includes a workbench 1, a feeding mechanism, a tapping mechanism, a dragging mechanism and a receiving mechanism, and the feeding mechanism and the receiving mechanism are symmetrically installed at both ends of the workbench 1, There is a tape trough 5 on the workbench 1, and the tape 6 wound on the feeding mechanism is introduced into the tape trough 5 and wound on the receiving mechanism. The tapping mechanism and the dragging mechanism are along the belt The moving direction of the material 6 is installed on the top of the workbench 1 in turn, and the dragging mechanism can intermittently drag the strip material 6 in the strip chute 5 forward, and the tapping mechanism includes a back plate 15, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com