Tapping machine for threaded hole

A technology of tapping machine and threaded hole, which is applied in the direction of thread trimmer, metal processing mechanical parts, driving device, etc., can solve the problems of high scrap rate, low production efficiency, broken taps, etc. The effect of tolerance balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

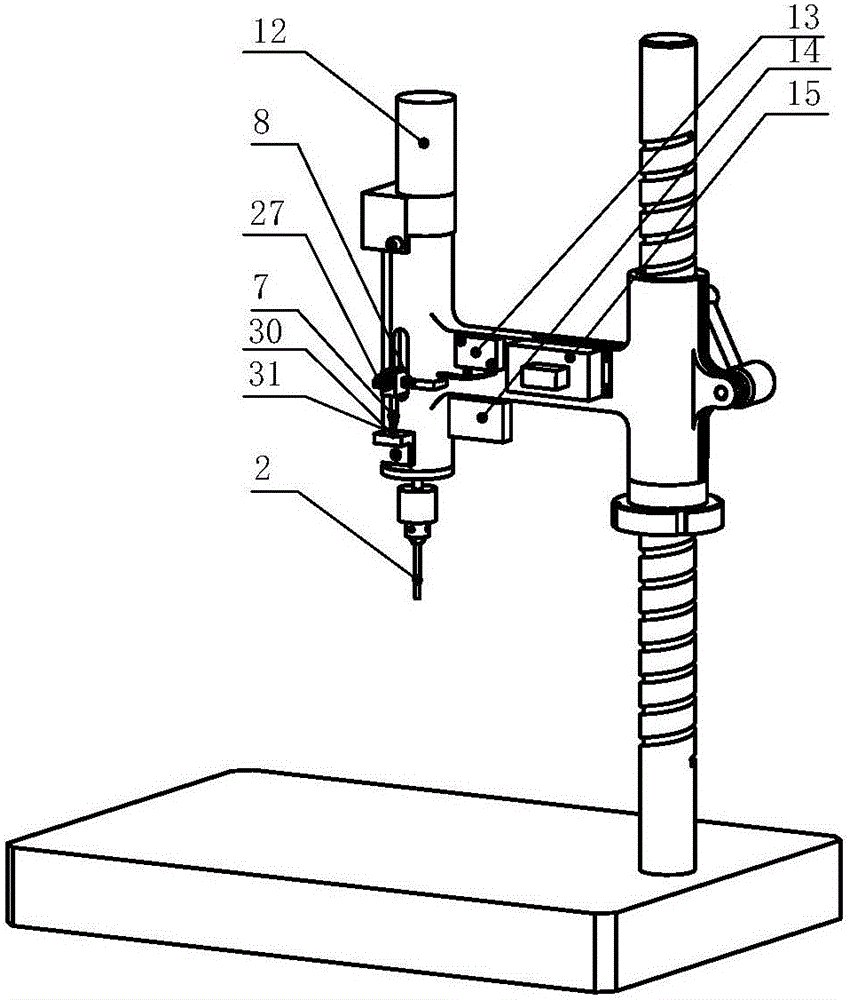

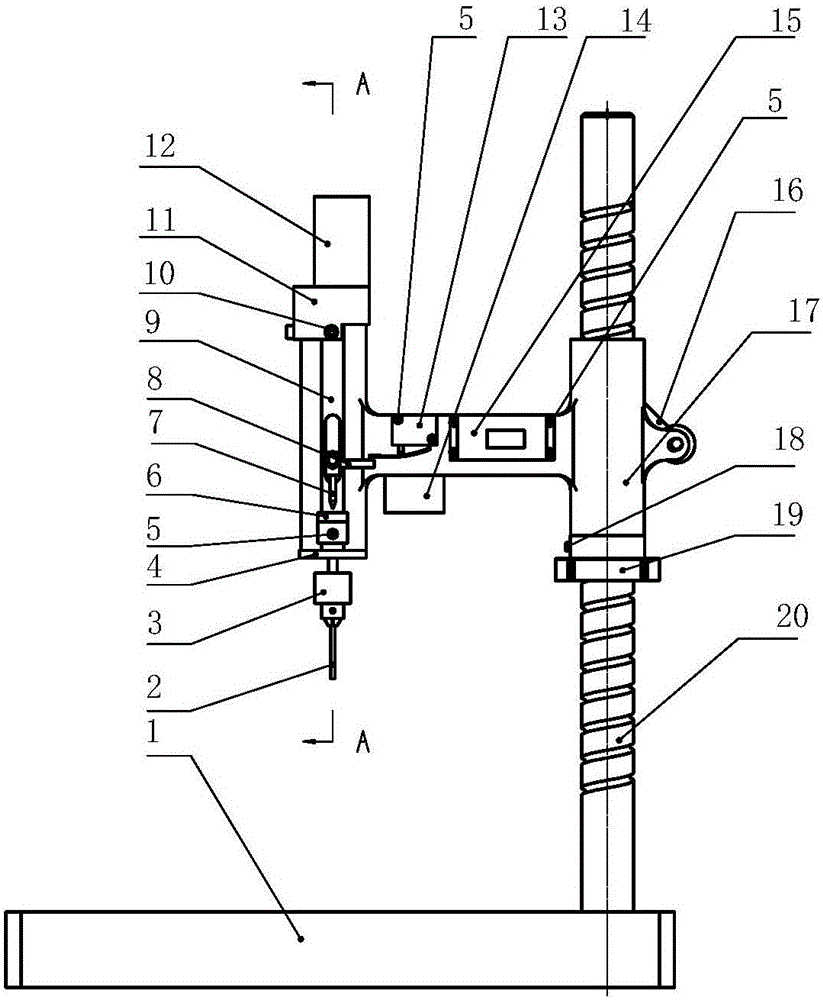

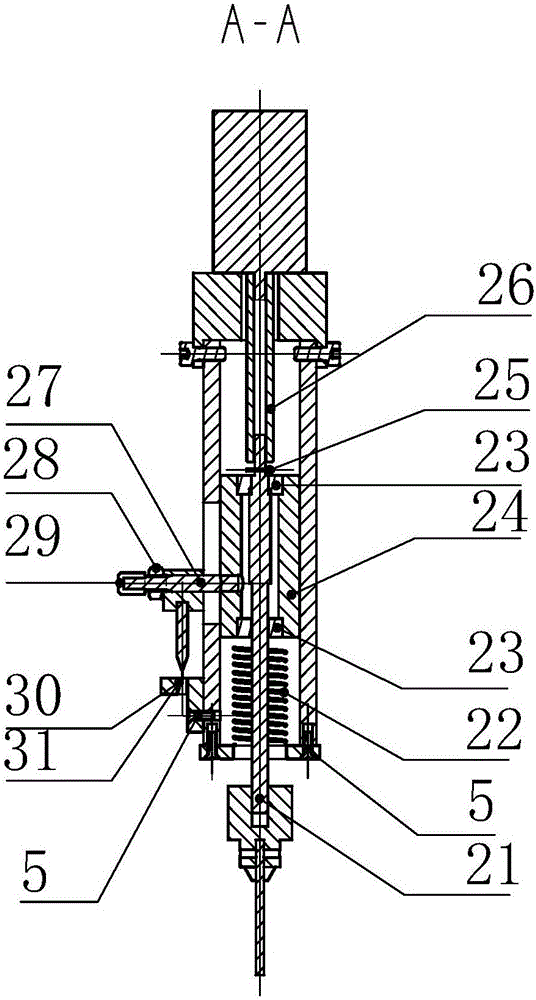

[0016] refer to Figure 1-3 . In the embodiment described below, a threaded hole tapping machine includes: a screw rod 20 vertically fixed on one side of the base workbench 1 and a cantilever bushing 17 fitted on the screw rod 20 , a vertical fixed connection In the electric mechanism and stroke control system of the cantilever bushing 17, the motor 12 is fixed on the mounting frame 9 through the motor mounting seat 11 of the electric mechanism, and the motor mounting seat 11 is connected with the mounting frame 9 through a hexagon socket head cap screw 10 In one body, the main shaft of the motor 12 is connected to the transmission shaft 26, the transmission shaft 26 is connected to the mandrel 21 through the bearing 23 matched with the sleeve, the transmission shaft 26 and the mandrel 21 are locked by the locking pin 25, and the mandrel 21 is connected The tapping chuck 3 with thread tap 2 is housed; the motor 12 is electrically connected to the intermediate relay 15 through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com