Multifunctional charger shell tapping equipment

A multifunctional charger and processing equipment technology, applied in the field of mechanical processing, can solve the problems of unguaranteed drilling position accuracy and low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

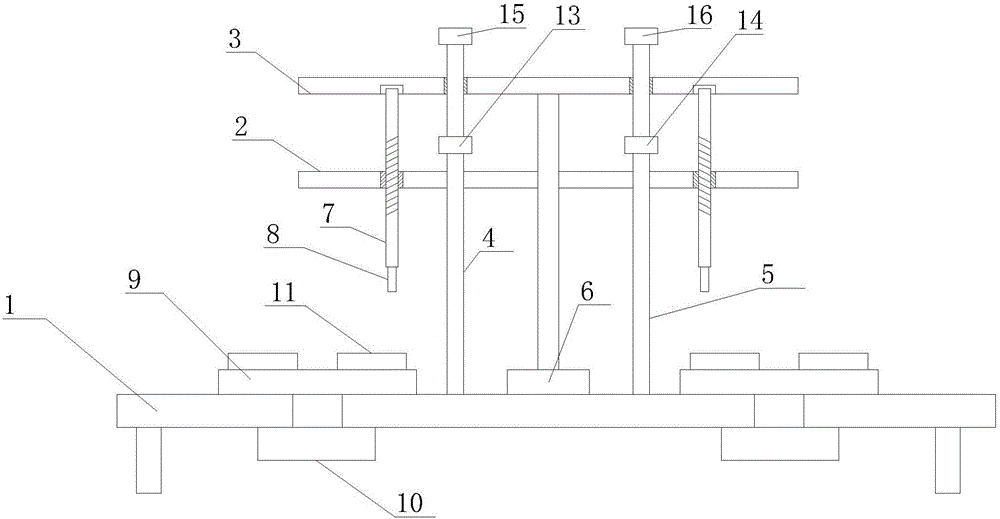

[0018] refer to figure 1 , figure 2 , the present invention proposes a multifunctional charger housing tapping processing equipment, including a workbench 1, a fixed plate 2, a moving plate 3, a first guide column 4, a second guide column 5, a first drive mechanism 6, a plurality of Rotating rod 7 and a plurality of fixed mechanisms, wherein:

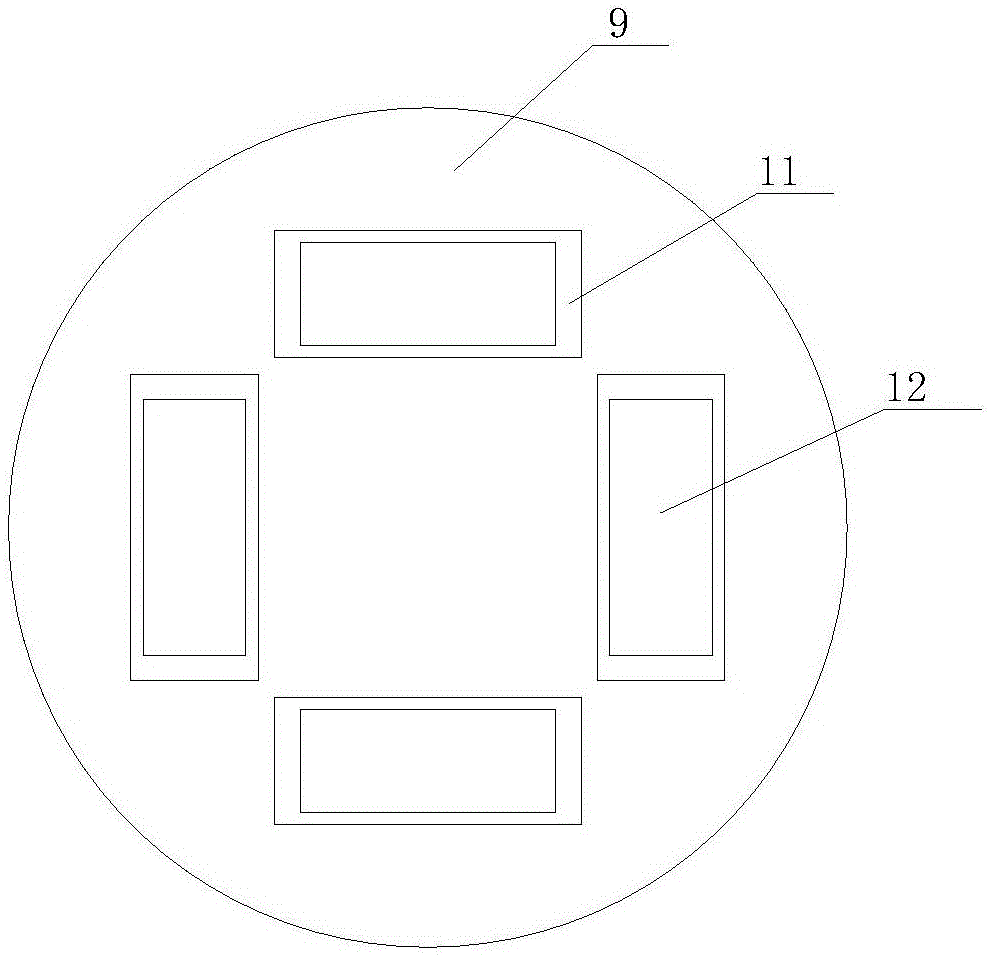

[0019] The workbench 1 is arranged horizontally, the fixed plate 2 is located above the workbench 1, the movable plate 3 is located above the fixed plate 2, and the workbench 1, the fixed plate 2, and the movable plate 3 are arranged parallel to each other; the fixed plate 2 is provided with a plurality of internal screws Holes, multiple internal screw holes are distributed in a circle.

[0020] The first guide column 4 and the second guide column 5 are vertically arranged, and the first ends of the first guide column 4 and the second guide column 5 are connected with the workbench 1 respectively, and the second ends of the first gui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com