Highway curbstone automatic laying robot system

A robot system and automatic laying technology, applied in the direction of roads, roads, road repair, etc., can solve the problems of high cost and low efficiency of artificial laying of curbs, and achieve the effect of unique structure, high laying efficiency and reliable working principle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

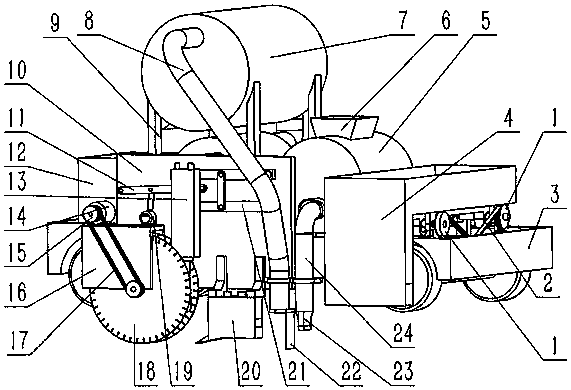

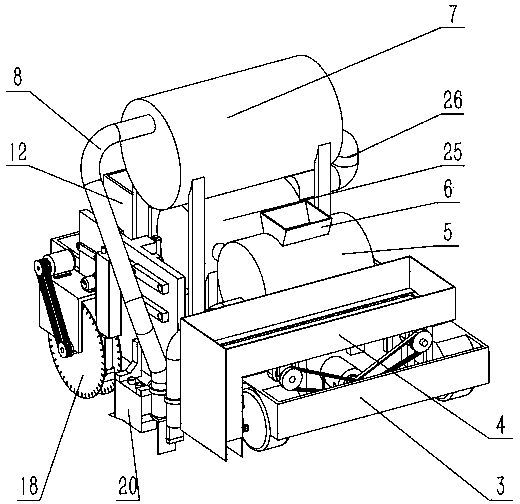

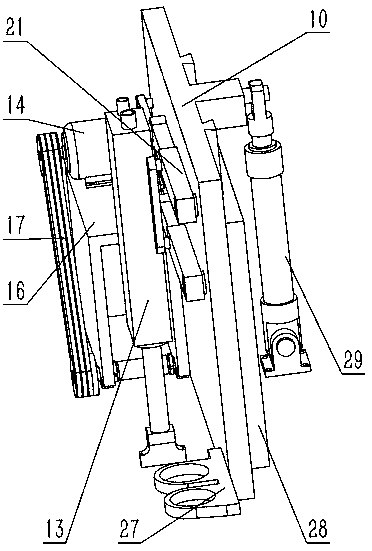

[0025] Example: such as Figure 1 to Figure 9 Shown is a robot system for automatically laying road curbs. The technical solution adopted by the present invention is: a robot system for automatically laying road curbs, including a stone feeding part, a groove cutting part, and a foundation material recovery part.

[0026] The stone-feeding part includes an L-shaped stone-feeding support 4, a conveying motor 36, two supporting rods 30 and two eccentric disk shafts 31, the L-shaped stone-feeding support 4 is fixedly installed at the rear of the car body 3, and the bottom surface of the L-shaped stone-feeding support 4 Two rectangular through slots are arranged perpendicular to the length direction of the car body 3, and two sets of mounting seats 401 are arranged on the outside of the bottom surface of the L-shaped stone feeding bracket 4. 31 are respectively rotated and installed on the mounting base 401, two eccentric disks are arranged eccentrically on the circumference of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com