Anchor cable secondary tension anchorage device and anchor cable secondary tension device

A tensioning device and anchor cable technology, applied in sheet pile wall, excavation, building structure, etc., can solve the problems of lower anchor cable tensile force, difficulty in re-tensioning the anchor cable, and inability to hold the anchor cable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

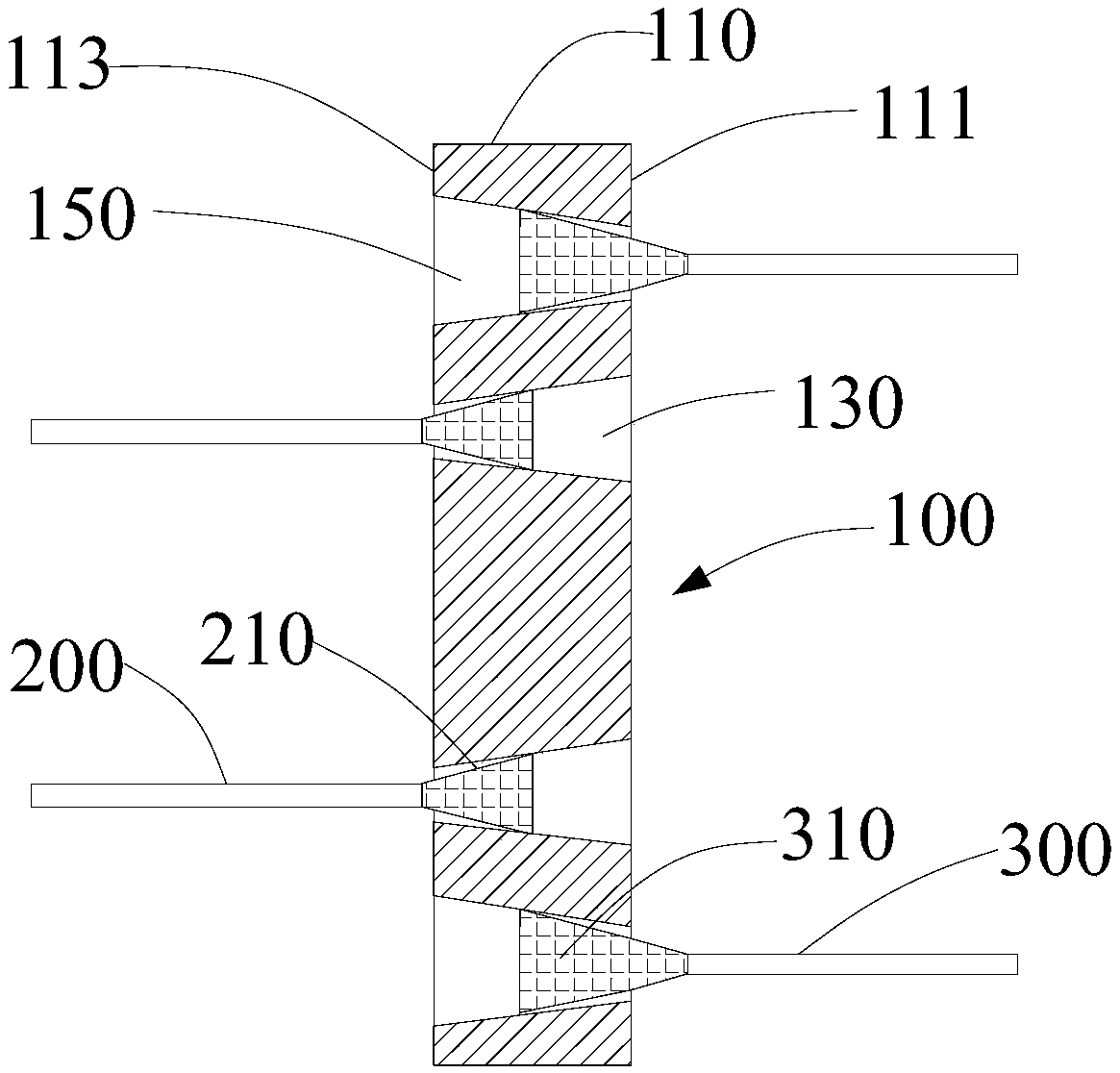

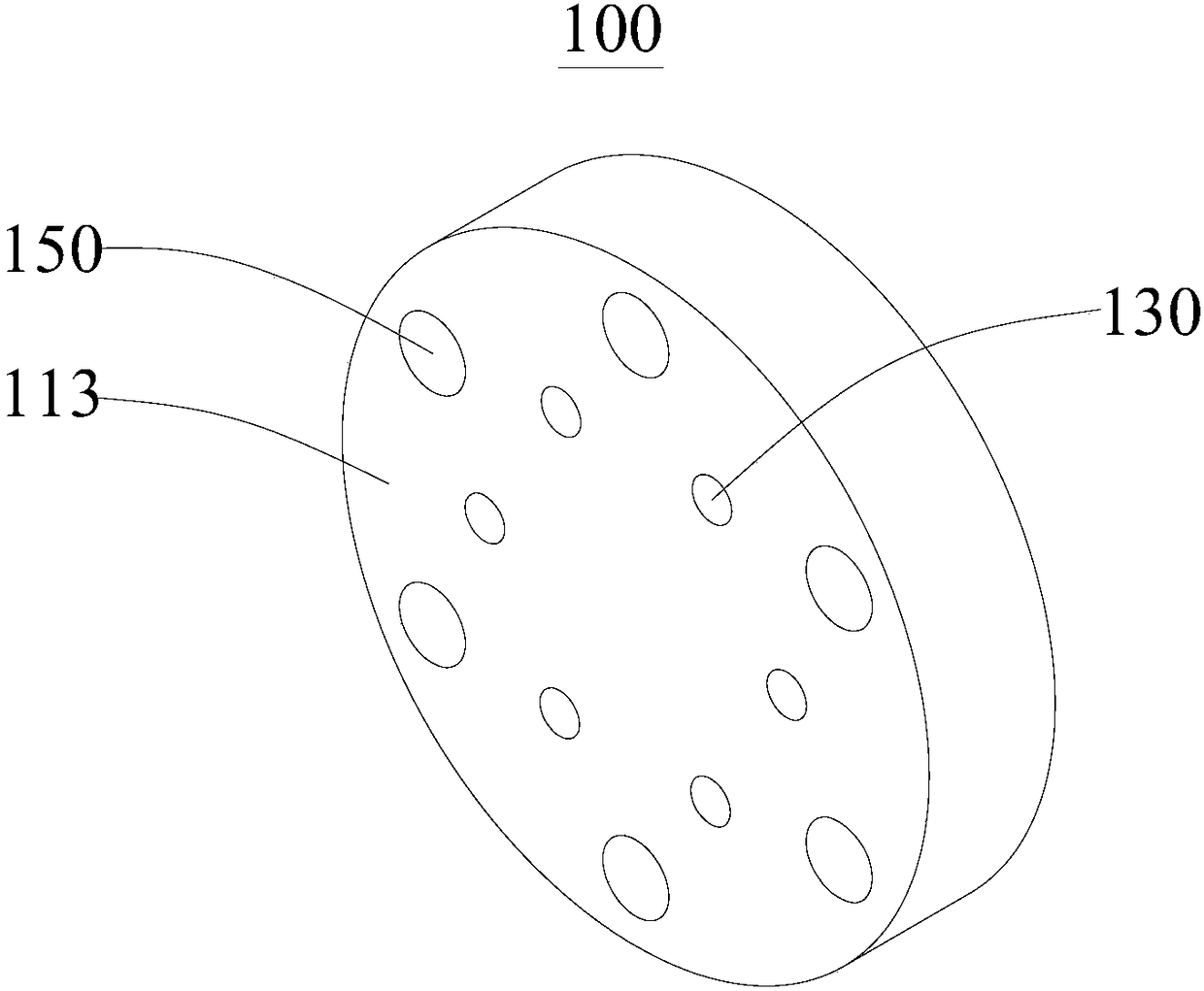

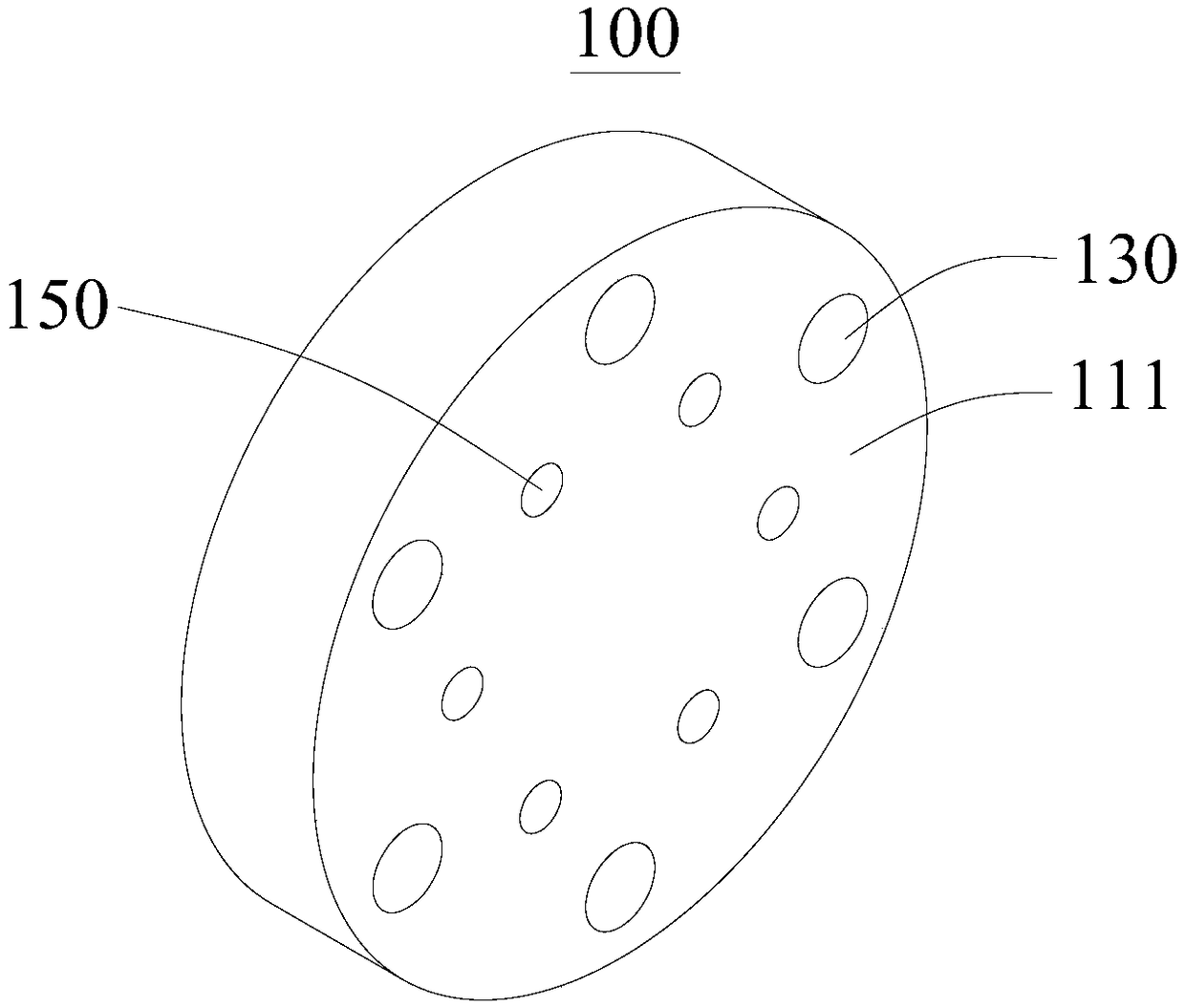

[0035] see in conjunction Figure 1 to Figure 3, the present embodiment provides a secondary tensioning anchor 100 for the anchor cable, which is used to clamp the anchor cable 200 and the cable 300. The anchor cable secondary tensioning anchor 100 includes a tensioning disc body 110, The body 110 has a first force-bearing surface 111 and a second force-bearing surface 113 that are oppositely arranged. The first force-bearing surface 111 is provided with a plurality of first snap joints penetrating through the first force-bearing surface 111 and the second force-bearing surface 113. holes 130, and the area of each first fastening hole 130 close to the first bearing surface 111 is greater than the area of the through hole close to the second bearing surface 113, so that the anchor cable 200 is clamped in the first fastening hole 130 Inner and protruding toward the outside of the second force-bearing surface 113; the second force-bearing surface 113 is provided with a plural...

no. 2 example

[0046] Please continue to see figure 1 , the present embodiment provides an anchor cable secondary tensioning device (not labeled in the figure), including anchor cable 200, multiple stay cables 300 and anchor cable secondary tension anchorage 100, wherein the anchor cable secondary tension The basic structure, principle and technical effect of the anchorage 100 are the same as those of the first embodiment. For a brief description, for parts not mentioned in this embodiment, reference may be made to the corresponding content in the first embodiment.

[0047] The anchor cables 200 are passed through a plurality of first clamping holes 130 respectively, and one end of the anchor cables 200 is clamped in the corresponding first clamping holes 130, so that the anchor cables 200 and the stretching disc body 110 remain relatively fixed, The other end of the anchor cable 200 extends away from the second bearing surface 113 . A plurality of pull cables 300 are passed through a plura...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com