A Pre-tensioned Prefabricated Beam-Slab Tension Pedestal Structure

A technology of tensioning pedestals and prefabricated beams, which is applied to manufacturing tools, ceramic molding machines, etc., and can solve problems such as large size, high foundation requirements, and large floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

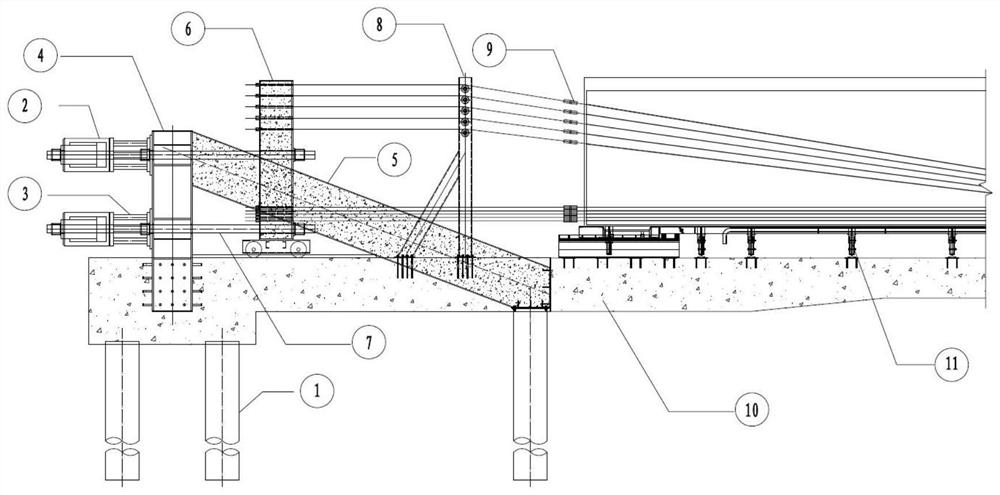

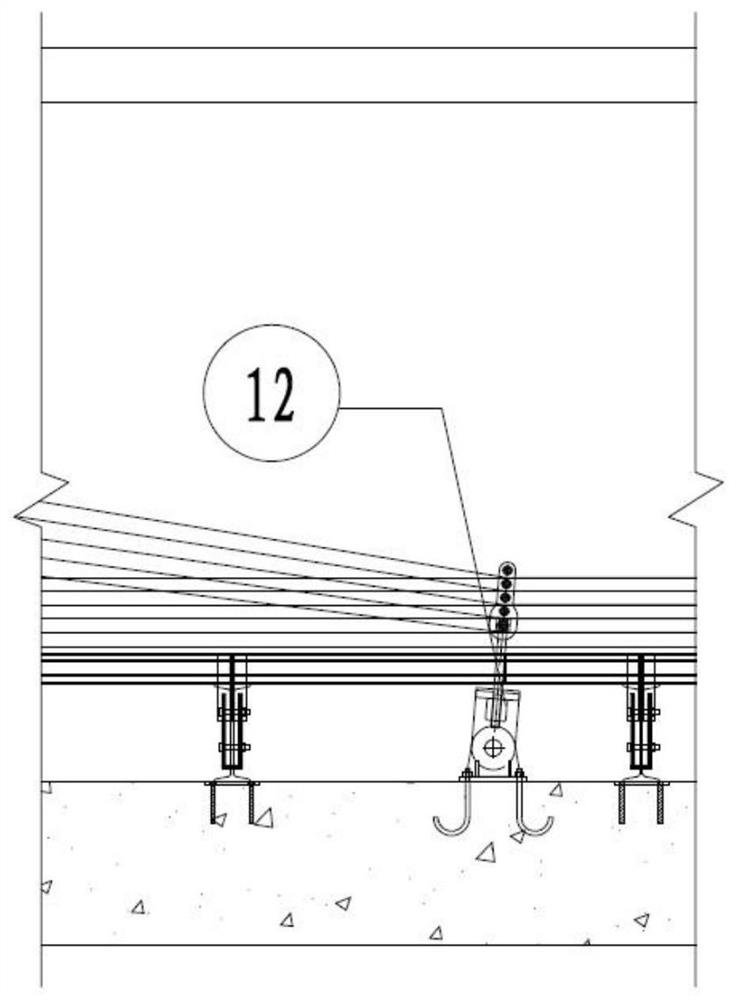

[0032] see Figure 1-7 As shown, this embodiment is a pre-tensioned prefabricated beam slab tensioning platform structure, including a first tensioning anchor end, an enlarged foundation 10, a bottom form frame 11, a bender 12, a second bogie 13 and a second Tension anchor ends, the first tension anchor ends are installed on both ends of the top of the enlarged foundation 10, and several groups of second tension anchors are installed between the two first tension anchor ends on the top of the enlarged foundation 10 There are two second tension anchor ends in each group, and the two second tension anchor ends of each group are arranged symmetrically. The enlarged foundation 10 is adjacent to the first tension anchor end, the second tension anchor end A second bogie 13 is installed between the anchor ends and between each group of second tension anchor ends, and the top of the enlarged foundation 10 is between the first tension anchor ends, the second bogie 13 and the 13 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com