Linear motion bearing

A linear motion bearing and bearing outer ring technology, applied in the direction of linear motion bearings, bearings, shafts and bearings, can solve the problems of increased installation cost, no positioning structure, time-consuming and labor-intensive, etc., to reduce occupied space and installation. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

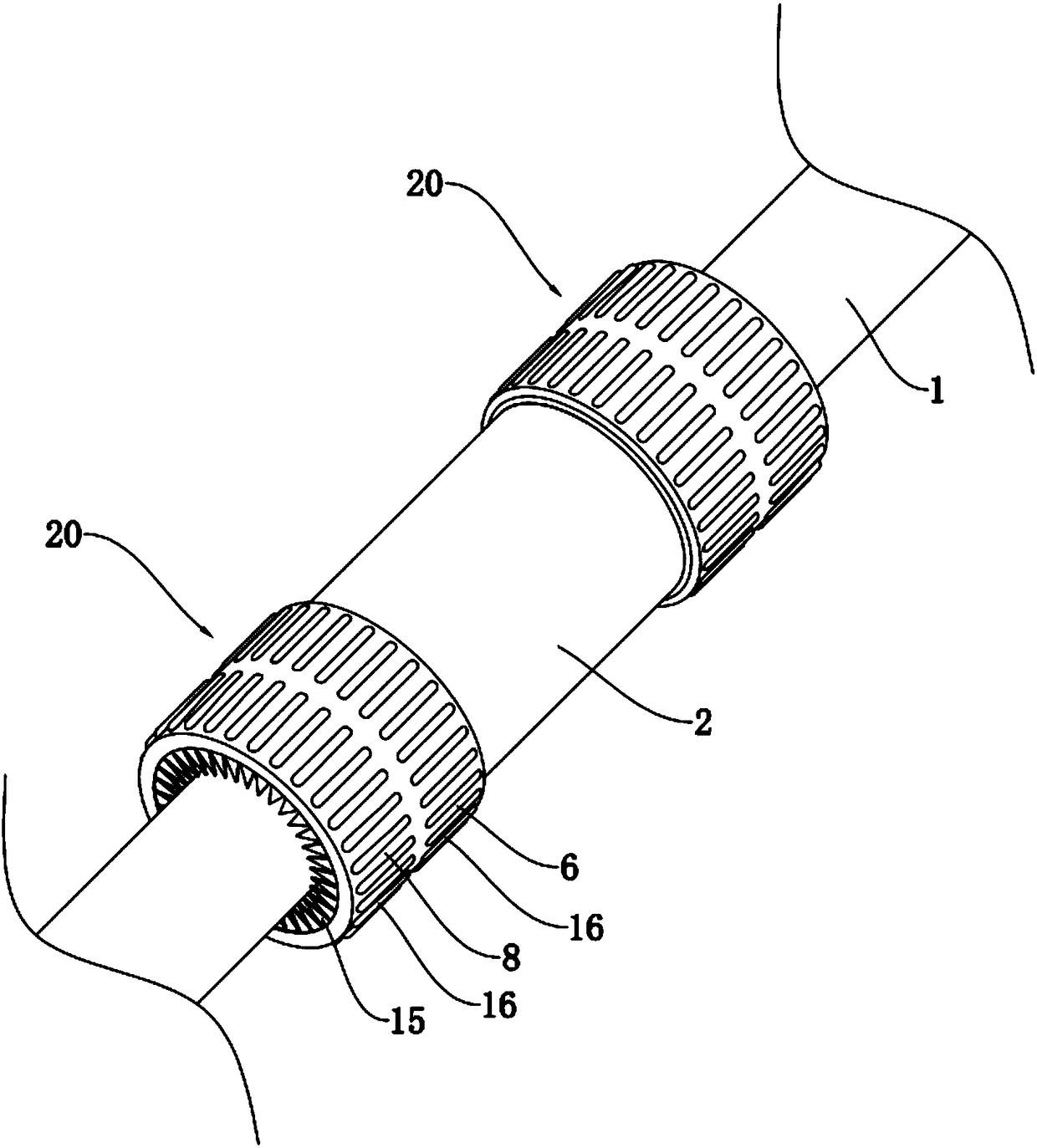

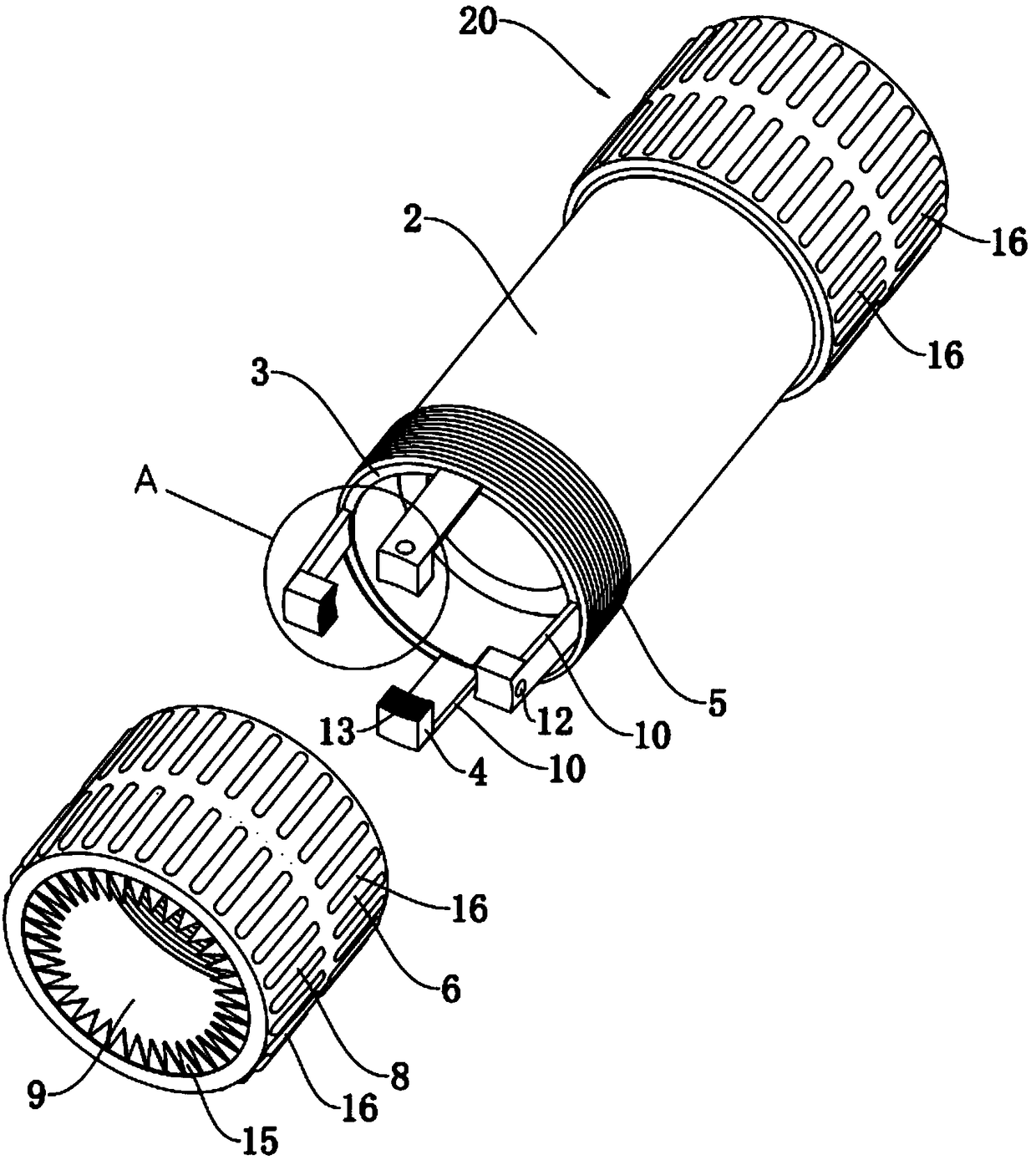

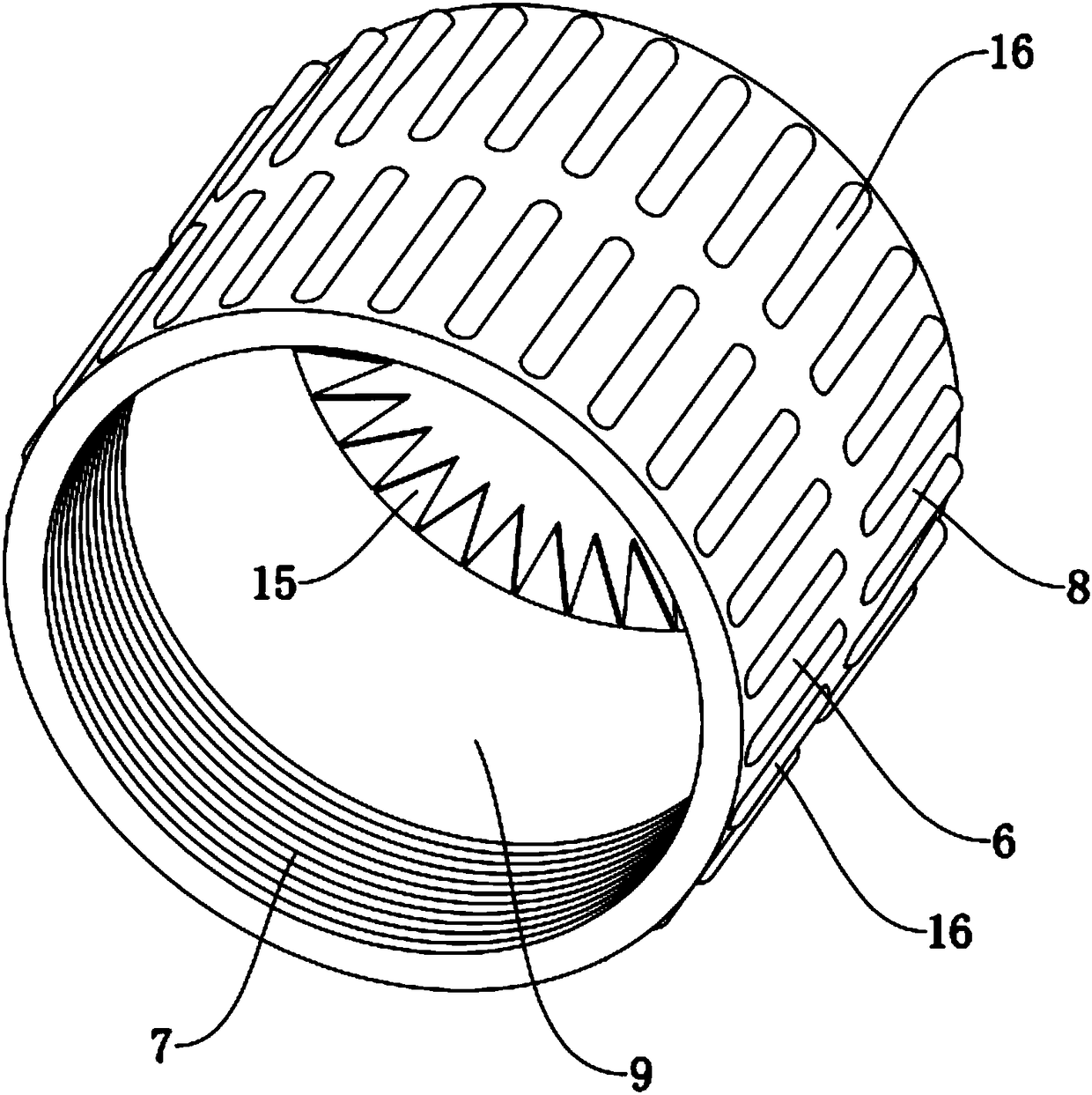

[0034] A linear motion bearing disclosed in this embodiment, such as figure 1 As shown, it includes a bearing outer ring 2 for the guide shaft 1 to slide and pass through. A retainer 17 is installed in the bearing outer ring 2 for the guide shaft 1 to pass through. The retainer 17 is equipped with a plurality of steel balls 18, and is used as Infinite circular movement enables the guide shaft 1 to slide smoothly in the cage 17 , so that the bearing outer ring 2 can slide along the guide shaft 1 .

[0035] Such as figure 1 with figure 2 As shown, the end of the bearing outer ring 2 is provided with a positioning mechanism 20, and the positioning mechanism 20 is provided with two groups, which are symmetrically arranged at both ends of the bearing outer ring 2 respectively. Each set of positioning mechanisms 20 includes an engaging sleeve 3, several positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com