Crack damage monitoring and strain field measuring method based on FBG (Fiber Bragg Grating) sensor array spectrum

A sensor array, damage monitoring technology, applied in measuring devices, using stable tension/pressure to test the strength of materials, instruments, etc., can solve the problems of not being able to obtain damage information and not involving the measurement of the stress field at the crack tip.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

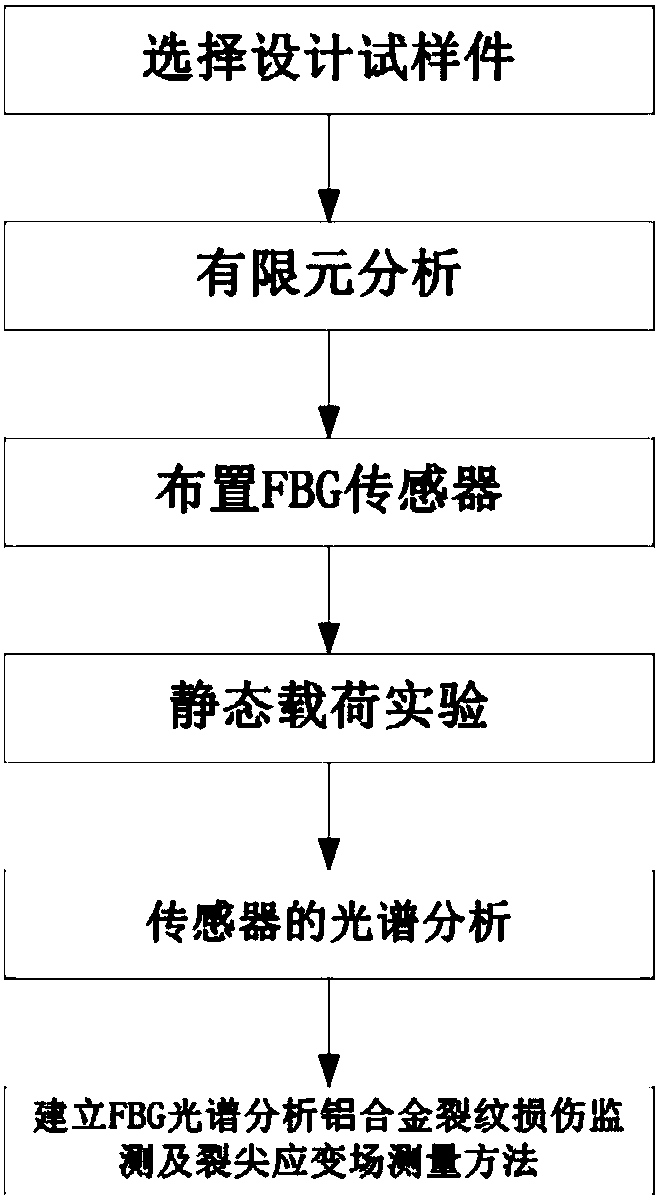

[0029] A preferred embodiment of a crack damage monitoring and strain field measurement method based on the FBG sensor array spectrum of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0030] The crack damage monitoring and strain field measurement method based on the FBG sensor array spectrum of the present invention can be tested in the laboratory now, and the specific steps are as follows:

[0031] Step 1: Select the sample and design the sample, select the non-destructive sample and the damaged sample, and the damaged sample is a crack with a certain length in the central area of one side of the test piece;

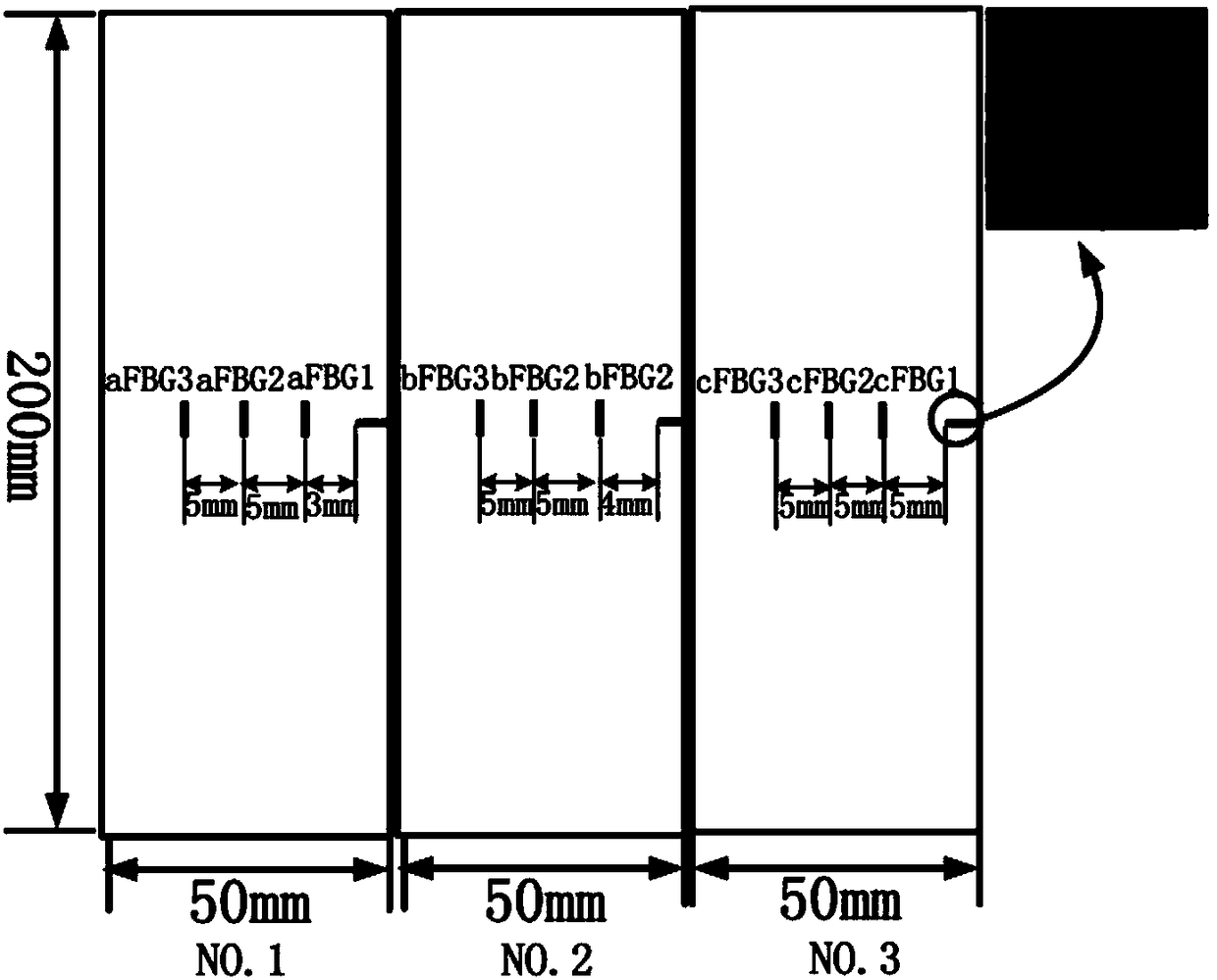

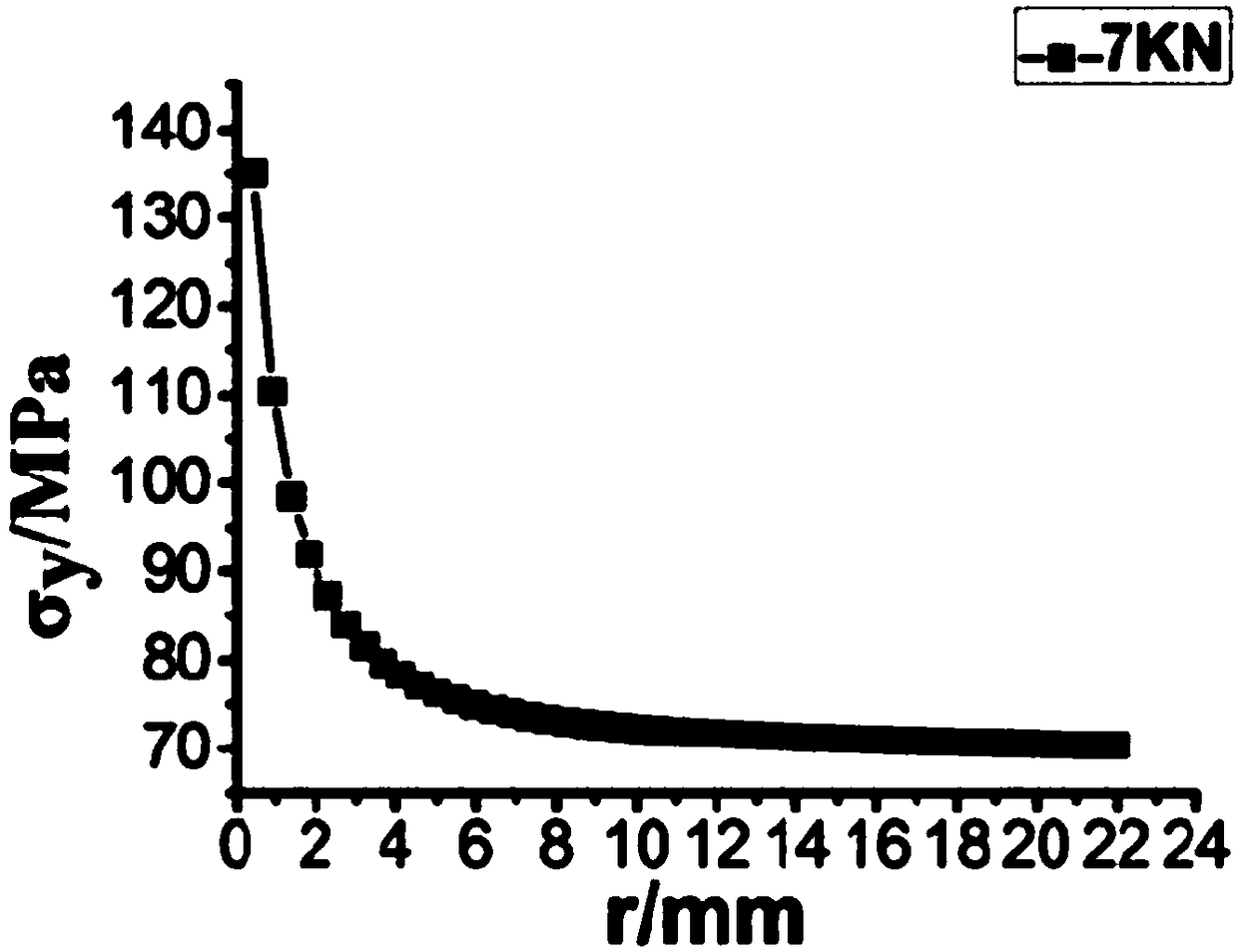

[0032] Step 2: Carry out structural mechanics analysis on the specimen. Perform finite element simulation analysis on the damaged test piece to determine the stress and strain distribution at the crack tip: before the finite element analysis, it is necessary to determine the external loading conditions, test p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com