Storage medium and intelligent goods elevator control method and system

A control method and control system technology, applied in the field of storage media, can solve problems such as scheduling errors and affecting logistics and transportation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

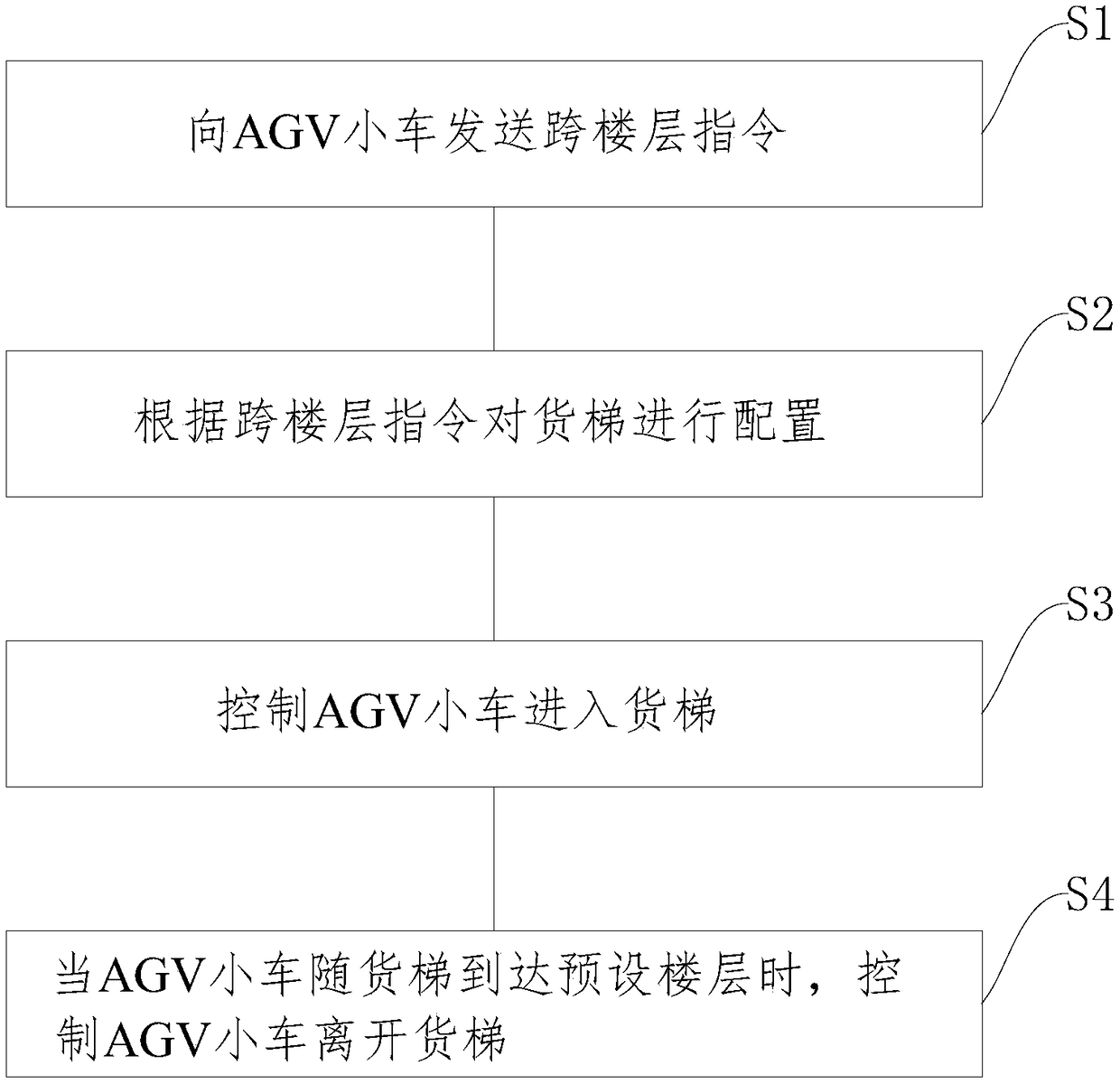

[0043] see figure 1 and figure 2 , this embodiment provides a control method for an intelligent freight elevator 200, which can reasonably dispatch the freight elevator 200 and reduce the errors of the AGV trolley 100 during transportation, so that the AGV trolley 100 can efficiently and smoothly complete the cross-floor operation task.

[0044] It should be noted that the intelligent freight elevator 200 control method provided in this embodiment is used to reasonably schedule the freight elevator 200 and the AGV trolley 100 when the AGV trolley 100 performs cross-floor operation tasks through the freight elevator 200, so as to realize the cross-floor operation task of the AGV trolley 100 And improve the transportation efficiency of AGV trolley 100.

[0045] The control method of the intelligent freight elevator 200 provided in this embodiment includes: S1: sending a cross-floor instruction to the AGV car 100; S2: configuring the freight elevator 200 according to the cross-...

no. 2 example

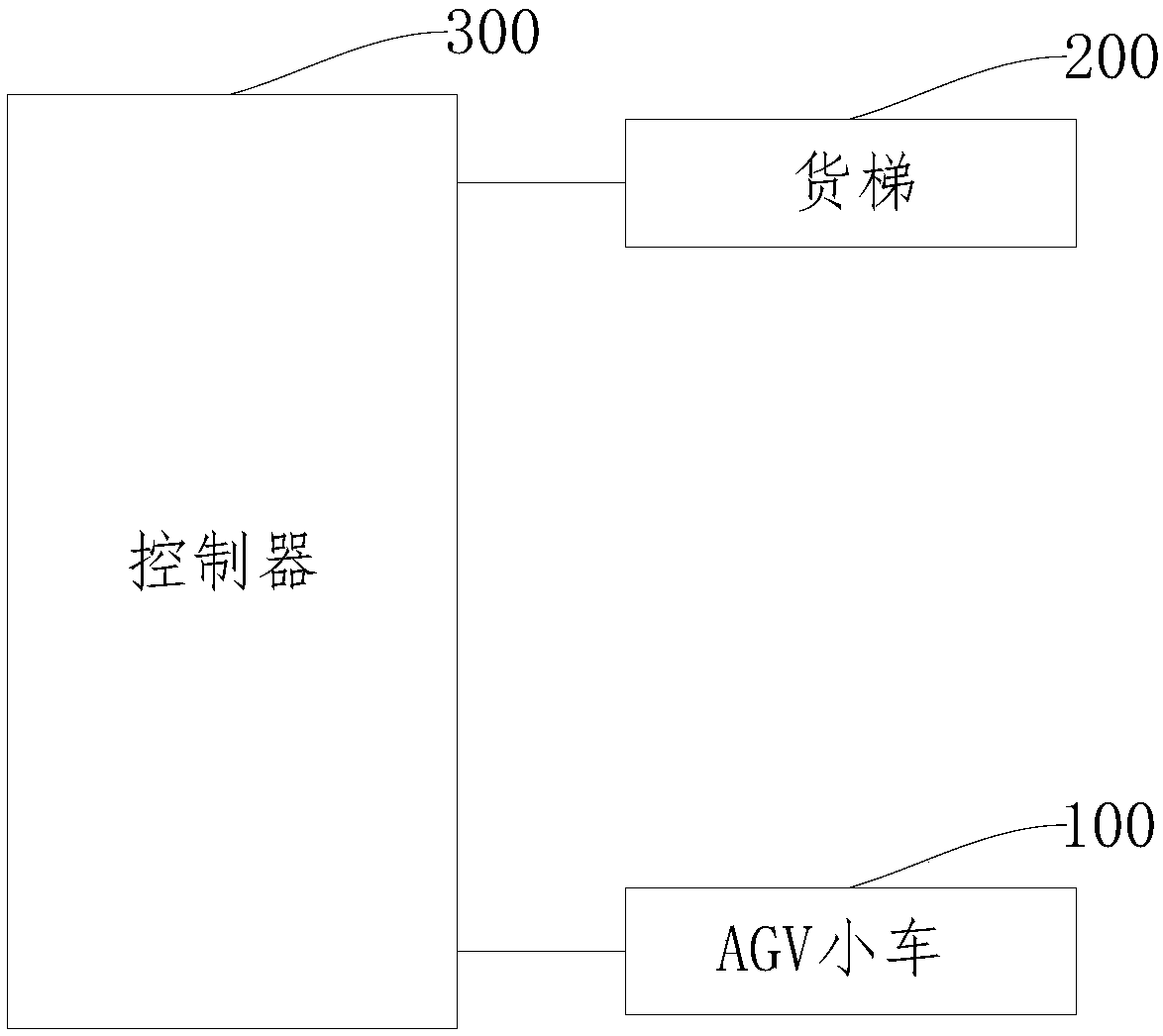

[0058] see figure 1 and figure 2 , this embodiment provides an intelligent freight elevator 200 control system, which can reasonably dispatch the freight elevator 200 and reduce the errors of the AGV trolley 100 in the transportation process, so that the AGV trolley 100 can efficiently and smoothly complete the cross-floor operation task.

[0059] The intelligent freight elevator 200 control system provided in this embodiment is used to implement the intelligent freight elevator 200 control method provided in the first embodiment. The smart freight elevator 200 control method includes: sending a cross-floor instruction to the AGV car 100; configuring the freight elevator 200 according to the cross-floor instruction, wherein the configured content of the freight elevator 200 includes the identity information of the AGV car 100 and the preset corresponding to the AGV car 100 floor; control the AGV car 100 to enter the freight elevator 200; when the AGV car 100 arrives at the p...

no. 3 example

[0067] see figure 1 and figure 2 , this embodiment provides a storage medium, the program of which can reasonably schedule the freight elevator 200 during operation, and reduce the errors of the AGV trolley 100 in the transportation process, so that the AGV trolley 100 can efficiently and smoothly complete the cross-floor operation task .

[0068] The storage medium provided in this embodiment includes a stored program, wherein, when the program is running, the device where the storage medium is located is controlled to execute the control method of the intelligent freight elevator 200 . The control method of the intelligent freight elevator 200 includes: sending a cross-floor instruction to the AGV car 100; configuring the freight elevator 200 according to the cross-floor instruction, wherein the configured content of the freight elevator 200 includes the identity information of the AGV car 100 and the preset floor corresponding to the AGV car 100 ; Control the AGV car 100...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com